what is a mechanical seal in stock

Mechanical Seals Market size was valued at USD 3.6 Billion in 2022 and is projected to reach USD 5.2 Billion by 2030, growing at a CAGR of 4.4% from 2023 to 2030.

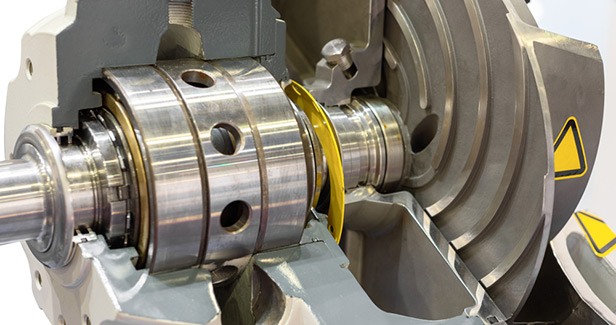

Mechanical seals are devices that provide a seal at the entrance or exit point of a drive shaft. It is generally used to avoid the leakage of a high-pressure fluid into a lower-pressure fluid. Rising applications in the food and beverage industry, as well as in food tanks, are anticipated to drive the growth in the Global Mechanical Seals Market in the forecast period. The Global Mechanical Seals Market report provides a holistic evaluation of the market. The report offers a comprehensive analysis of key segments, trends, drivers, restraints, competitive landscape, and factors that are playing a substantial role in the market.

Mechanical seals are leakage control devices found on rotating equipment including pumps and mixers. Such seals prevent liquids and gases from exiting to the outside. A robotic seal is comprised of two components, one of which is static and the other of which rotates against it to form a seal. Seals of various types are available to satisfy a wide range of applications. These seals are used in a wide range of industries, such as oil and gas, water, beverages, chemical, and others. Seal rings can endure the mechanical force from springs or bellows, as well as the hydraulic force from procedure fluid pressure.

Mechanical seals are typically found in the automotive sector, ships, rockets, manufacturing pumps, compressors, residential pools, dishwashers, etc. The products in the market are comprised of two faces that are divided by carbon rings. Products in the market are manufactured using a range of materials, such as polyurethane or PU, fluorosilicone, polytetrafluoroethylene or PTFE, and industrial rubber, among others. Cartridge seals, balanced and unbalanced seals, pusher and non-pusher seals, and traditional seals are some of the key types of goods developed by manufacturers operating in the Global Mechanical Seals Market.

Mechanical seals are extensively used in end industries to avoid leaks, propelling the market. Mechanical seals are mainly used in the oil and gas industry. The continued growth of oil and natural gas has influenced the Mechanical Seals Market. Moreover, the rising use of such seals in other industries like mining, chemical, and food and beverage drives demand mechanical seals. The increasing efforts of infrastructure development across the globe as a result of constant technological advances as well as the increasing worldwide population is also expected to positively impact sales in the market during the forecast period.

Moreover, increasing applications in the food and beverage industry, including in food tanks, are expected to positively impact expansion in the market throughout the forecast period. Furthermore, Progressive economic plans, initiatives, and schemes such as Make in India promote the mechanical seal industry to create advanced solutions, boosting the market growth during the projected period. The existence of other alternatives, including mechanical packaging, and the rising use of electronic seals in automated production, are anticipated to hamper the growth of the Mechanical Seals Market.

The use of substitute packaging materials including such glad packaging is mostly used in water treatment facilities. Therefore, The use of electronic seals in automated manufacturing units may also inhibit growth throughout the forecast period. The innovation of mechanical seals in circulation pumps, cooling towers, cold or hot water, boiler feed, fire pumping systems, and booster pumps in the HVAC industry leads to an increase in the growth of the market.

Based on Design, The market is segmented into Pusher Type Mechanical Seals and Non-Pusher Type Mechanical Seals. The Pusher Type Mechanical Seals are the largest growing segment of the market because of the growing use of small and large diameter ring shafts in light end services to manage high temperatures over the projected period.

Based on End User Industry, The market is segmented into Oil and Gas, Chemical, Mining, Water and Wastewater Treatment, Food and Beverage, and Others. Oil and Gas have the highest growing segment of the market attributing to the increasing use of mechanical seals in the oil and gas industry to decrease fluid losses, leisure time, seals, and general maintenance as compared to other End User Industries.

On the basis of Geography, The Global Mechanical Seals Market is classified into North America, Europe, Asia Pacific, and the Rest of the world. The Asia Pacific has the highest growing segment of the market attributed to increased industrial applications in the region’s emerging economies, including India Moreover, rapid expansion in the regional manufacturing sector is anticipated to fuel the Asia Pacific Mechanical Seals Market throughout the forecast period.

The “Global Mechanical Seals Market” study report will provide a valuable insight with an emphasis on the global market including some of the major players such as EnPro Industries Inc., A.W. Chesterton Company, Flowserve Corporation, YALAN Seals Ltd, AESSEAL plc., Trelleborg Sealing Solutions, Freudenberg Sealing Technologies GmBH, and Flex-A-Seal Inc.

Our market analysis also entails a section solely dedicated to such major players wherein our analysts provide an insight into the financial statements of all the major players, along with its product benchmarking and SWOT analysis. The competitive landscape section also includes key development strategies, market share, and market ranking analysis of the above-mentioned players globally.

• In December 2019, Freudenberg Sealing Technologies expanded its Low Emission Seal Solutions (LESS) Solutions with the addition of new features in it, the next type of company with low friction. The product is designed to collect and push lubrication under the washer, thus facilitating improved performance and higher critical speed.

• In March 2019, Chicago-based circulation specialist, John Crane, unveils the T4111 Single Use Elastomer Bellows Cartridge Seal, designed to close mid-rotary pumps. The product is designed for normal use and at low cost and has a simple cartridge seal structure.

• In May 2017, Flowserve Corporation announced the termination of an agreement involving the sale of a Gestra AG unit to Spirax Sarco Engineering plc. This sale was part of Flowserve’s strategic decision to improve its product range, making it more focused on its core business activities and allowing it to be more competitive.

• In April 2019, Dover announces the latest Air Mizer solutions for AM Conveyor devices. Manufacturers Association shaft seal, clearly designed for CEMA equipment and screw conveyors.

• In March 2018, Hallite Seals continued its third-party certification with the Milwaukee School of Engineering (MSOD for the integrity and integrity of its design and sealing designs.

KEY COMPANIES PROFILEDEnPro Industries Inc., A.W. Chesterton Company, Flowserve Corporation, YALAN Seals Ltd, AESSEAL plc., Trelleborg Sealing Solutions.

CUSTOMIZATION SCOPEFree report customization (equivalent to up to 4 analysts’ working days) with purchase. Addition or alteration to country, regional & segment scope.

To know more about the Research Methodology and other aspects of the research study, kindly get in touch with our Sales Team at Verified Market Research.

• Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

• Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

• The current as well as the future market outlook of the industry with respect to recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Mechanical Seals Market was valued at USD 3.6 Billion in 2022 and is projected to reach USD 5.2 Billion by 2030, growing at a CAGR of 4.4% from 2023 to 2030.

Rising applications in the food and beverage industry, as well as in food tanks, are anticipated to drive the growth in the Global Mechanical Seals Market in the forecast period.

The major players are EnPro Industries Inc., A.W. Chesterton Company, Flowserve Corporation, YALAN Seals Ltd, AESSEAL plc., Trelleborg Sealing Solutions, Freudenberg Sealing Technologies GmBH.

The sample report for the Mechanical Seals Market can be obtained on demand from the website. Also, the 24*7 chat support & direct call services are provided to procure the sample report.

We specialize in hard-to-find seals and demanding applications. Our extensive network of resources enables us to locate the right manufacturer and part, every time.

At All Seals we know down time is not an option. We specialize in hard-to-find seals and demanding applications. With over 40 years of experience in supplying quality replacement mechanical seals, we can help you identify the seal you need and solve your sealing problem. Our technical staff is available to help you – just give us a call. Our comprehensive stock of components ensures that we can build almost any seal combination for same day shipment. Whether you need a new seal or you have a seal to be repaired, we welcome the opportunity to help you with your rotary sealing needs.

We carry a comprehensive inventory of mechanical seal components, which allows us to build the right seal for your application. We’ll even design custom seals for one-of-a-kind applications.

Our goal is to make your repair easy without compromising on quality. Repair kits greatly reduce costly downtime, saving costs while sustaining production. Our pump rebuild kits are supplied with the same components you’ll find in an OEM kit; however, we offer them at a fraction of the price.

Need hard faces or specialty elastomers? Give us a call. We can quickly build a repair kit to withstand any medium being pumped. You’ll find All Seals’ pump repair kits an invaluable part of your operation.

Mechanical seals are composed of many unique parts formed from various materials. Steel, various rubbers, silicon, carbon, PTFE – these are just a few examples of the types of materials that may be present in just one mechanical seal. Due to the diverse material properties and the precise, delicate nature of these devices, it’s important to understand how long a seal can be stored safely without compromising function.

If the mechanical seal is stored in a clean, temperature/humidity controlled environment, you can effectively keep these seals safely for five years if the proper procedures are followed.

To prevent face lock and loss of face flatness, rotate the seal faces against each other (by rotating the sleeve or shaft) two turns every three months if the seal is not used in operation during that time.

Storing a seal for less than two years: Store in a clean, cool environment and rotate the faces against each other approximately two rotations every three months.

Disassemble the seal and store all parts as individual components. Ensure ‘O’-rings are in a relaxed state and meet the environmental conditions outlined above.

This is an outline of a few of the basic recommendations for storage and reintroduction to service for a mechanical seal. For more detail, see international standards such as DIN 7716 and ISO 2230, which detail fundamental instructions on the storage and maintenance of elastomeric seal elements.

Mechanical seals are critical components in centrifugal pump systems. These devices preserve the integrity of the pump systems by preventing fluid leaks and keeping contaminants out. Mechanical seal systems are used on various seal designs to detect leakage, control the seal environment and lubricate secondary seals.

Depending on the pump type and the process variables, there are various mechanical seal types to choose from. Each seal variant has its unique design and characteristics which make it suitable for a specific application. MES has years of experience with industrial mechanical seals and support systems, making us an authority in this area.

Mechanical seal types vary in design, arrangement, and how they disperse the hydraulic forces acting at their faces. The most common seal types include the following:

Balanced mechanical seal arrangements refer to a system where the forces acting at the seal faces are balanced. As a result of the lower face loading, there is more even lubrication of the seal faces and longer seal life. Learn about our mechanical seal lubrication systems today.

Balanced mechanical seals are particularly suited to higher operating pressures, typically above 200 PSIG. They are also a good choice when handling liquids with low lubricity and higher volatility.

Unbalanced mechanical seal types are commonly employed as a more economical option to the more complex balance seal. Unbalanced seals may also exhibit less product leakage due to tighter control of the face film, but as a result can exhibit much lower mean time between failure. Unbalanced seals are not recommended for high pressure or most hydrocarbon applications.

Pusher seals utilize one or multiple springs to maintain seal closing forces. The springs can be in the rotating or stationary element of the mechanical seal. Pusher type seals can provide sealing at very high pressures but have a drawback due to the elastomer under the primary seal face that can be subjected to wear as the face moves along the shaft/sleeve during operation.

Non-pusher seals utilize a metal or elastomeric bellows to maintain seal closing forces. These seals are ideally suited to dirty and high temperature applications. Bellows seals are limited to medium/lower pressure applications.

Conventional seals are typically lower cost and often installed on general service equipment. These seals require higher operator skill to service as they installed as individual components.

Cartridge type mechanical seals incorporate all of the seal elements into a single assembly. This dramatically reduces the potential for assembly error and the time require for seal replacements. Learn more about the difference between cartridge and non-cartridge mechanical seals today.

When deciding on the type of seal system for a centrifugal pump, operators must choose according to their unique application. Failure to select the proper seal type can lead to loss of pump integrity, breakdowns and costly repairs. To avoid these undesirable results, all operators must consider the following factors before deciding.

The amount of pressure exerted at a mechanical seal’s faces has a significant effect on its performance. If a pump is to be operated at low pressures, an unbalanced mechanical seal will be suitable. However, in conditions where higher pressures are anticipated, balanced seals will prove a more reliable solution.

Balanced mechanical seals perform better than their unbalanced counterparts in conditions where the operating temperatures are higher than normal. Heat sensitive components are better preserved in balanced mechanical seals compared to other seal types.

As it goes for all types of machinery, operator safety is the top priority. The use of double mechanical seals in centrifugal pumps provides additional protection as they have increased sealing capacity and are generally more reliable.

A pusher-type seal consists of a primary sealing ring assembled with an "O" ring and springs which force the sealing liquid across the face and keep it from leaking to the ID side of the seal.

The dynamic O-ring is designed to be pushed axially along the shaft. The surface underneath the dynamic Oring must therefore be very smooth to allow for axial movement. If solids are abundant in the sealing fluid, they can build up on the o-ring and prevent this axial movement.

Pusher types seals are less expensive and are readily available in a wide range of sizes and designs. The only disadvantage being a tendency to hang up and fretting of the shaft.

The global mechanical seals market size stood at USD 3.20 billion in 2018 and is projected to reach USD 4.77 billion by 2026, exhibiting a CAGR of 5.2% during the forecast period.

The key utility of a mechanical seal is to prevent leakage of fluids or gases through the clearance between the shaft and the container. Mechanical seals consist of a set of 2 faces separated by carbon rings. The first face is in contact with the rotating equipment whereas the second face is stationary. Moreover, the main part of the seal is the seal ring (first face) on which the mechanical force is acting, generated by springs, bellows, or fluids in the equipment. In recent years, mechanical seals are playing an important role in varied industrial applications, enabling efficient operations. Mechanical seals are made up of several flexible materials such as Polytetrafluoroethylene (PTFE), Polyurethane (AU, EU), industrial rubber, Fluorosilicone (FVMQ), and many more.

The mechanical seal market has depicted significant growth in the recent span of years and is likely to grow in the forecasted period. Rising industrial development in emerging economies is expected to initiate additional development policies and investments. Major types of mechanical seals available in the market include cartridge seals, balanced and unbalanced seals, pusher and non-pusher, and conventional seals that are influencing the mechanical sealing market growth in developing countries.

Growth in machine tool industry is impelling the overall market share, owing to the usage of power machines in centrifugal pumps and compressors for sealing and separating the fluid in the rotating shafts. Hence, the increasing market demand for mechanical seals in various industries is anticipated to drive the market growth in the near future. Furthermore, the highest market growth is projected to be witnessed in Asia-Pacific, followed by North America.

According to the United Nations Conference on Trade and Development (UNCTAD), the global foreign direct investment (FDI) will grow vigorously in 2018. This implies that there will be strong growth in the manufacturing sector in the coming decade. Moreover, many countries are now adopting investment policies that will boost the manufacturing sector and drive the mechanical seals market trends. For instance, in 2017, several countries and economies adopted investment policy measures across the globe, of which 84% of countries were favorable to investors. This will allow investors to invest their funds in various industries, with primary focus on energy, transportation, and manufacturing.

Furthermore, many manufacturing and industrial studies are more focused on the production or supply side and less on the demand side. This practice has reduced the importance of the manufacturing sector over the last few decades. This situation can get balanced by placing the demand side at center in the manufacturing sector ecosystem.

Therefore, the demand for manufacturing is increasing with the changes in investment policies of multiple developed and developing countries. This growth will increase the adoption of machine tools and industrial equipment for the manufacturing process, which will directly boost the mechanical seals market growth, globally.

The global mechanical seals market is segmented by type, which is further segmented into pusher and non-pusher, conventional seals, balanced and unbalanced seals, and cartridge seals.

Continuous adoption of advanced sealing material in several industries is expected to grow the cartridge seals segment in the forecast period. The cartridge seals segment is estimated to have exponential market opportunities as they are designed as universal shaft seals for the seal chamber of pumps, containers, or pipelines.

The pusher and non-pusher seals segment depicts substantial growth, owing to the increasing usage of small and large diameter ring shaft in the light end services to handle high temperatures. The balanced and unbalanced mechanical seals segment is anticipated to grow moderately, owing to the rise in the industry sector worldwide. Balanced seals are preferred for most of the industrial applications as they generate less heat at the surface of the machine, enabling longer seal life and efficient sealing method.

Comparatively, the conventional seal segment is projected to witness progressive growth owing to the requirement of heat exchanger mating ring advances offered by these seals. The other segment consists of bellows seals and is likely to represent steady growth due to limited demand in the mechanical sealing market.

By industry, the market is bifurcated into metals and mining, food and beverage, oil and gas, energy and power, aerospace, marine, construction and manufacturing, and others (chemical, etc.).

Oil and gas industry is anticipated to grow exponentially at a higher growth rate owing to increasing demand of petroleum from developed and emerging countries, hence boosting the demand of mechanical seals. Energy utilization is growing worldwide and influencing the demand for electricity generation and consumption rate, thus leading to remarkable market growth. In the current scenario, 70% of the electricity is generated from the renewable sources such as wind and solar power, which bodes well for the mechanical seals market demand.

The construction and aerospace sectors are projected to depict significant market opportunities owing to the rising infrastructural developments as a result of increasing population and technological advancements in the aerospace operating and navigation systems.

Mechanical seals demand is increasing in the food and beverage and mining sectors due to increasing implementation of pumps, food tanks, and many other centrifugal machines to manage the intensity of fluid. Marine sector is expected to depict substantial market growth as the need for the mechanical seals at naval ships and ports will remain steady in the forecast period. The others segment consists of chemical industry and is likely to showcase steady growth, owing to minimum demand in the mechanical sealing market.

Asia-Pacific is anticipated to lead the mechanical seals market share and is projected to depict exponential growth over the forecast period due to the increasing industrial applications in the emerging countries including India and China. Along with that, strong economic growth in the manufacturing sector is expected to fuel the development of the market in the region. Furthermore, favorable regulatory framework and regulations by governments for increasing investment in the manufacturing industry is expected to have a substantial impact in the growth of the market. Additionally, rapid industrialization and increasing demand of mechanical seals from industries such as construction, marine, energy and power, and oil and gas is expected to boost the growth of the market. Moreover, the region has several small and medium mechanical seals manufacturers which will increase the market share of the Asia-Pacific region in the forecasted period.

North America is predicted to show a dynamic growth rate over the projected timeline due to the rising number of infrastructure and other development projects in the region, the mechanical seals market analysis points out. This growth in the region is attributed to the presence of key players in the market along with increasing demand for mechanical seals in several industries such as manufacturing, oil & gas, and other mining industries. The growth is owed to deep involvement of workers with technology research and development (R&D) and STEM (science, technology, engineering, and mathematics) in the industries such as energy & power, oil & gas, and aerospace. Furthermore, the demand for the sealing products is accounted for increasing presence of manufacturing industries such as automotive and aerospace to energy industries such as oil and gas extraction to high-tech services such as computer software and computer system design, including health applications.

Furthermore, Europe is witnessing rapid growth owing to rising presence of chemical manufacturing industries along with growing use of sealing products in aerospace, rail, and marine industries. Additionally, demand for sealing products is comparatively stable as the large range of industries in the market offers a relatively balanced market growth over the years. The stability in demand can be seen in the period 2020-2024. Countries such as Italy and Spain are expected to show substantial growth compared to other countries in the region owing to the demand from major industries such as oil & gas and food & beverage.

The mechanical sealing market value in the Middle East and Africa is growing due to presence of more than 65% of global oil refineries in the region. Increasing investment in the oil industry will result in increased demand for mechanical seals. Moreover, countries of the Middle East are shifting their focus from oil and gas production to other industries such as tourism and other manufacturing industries which will result in decreasing market value of mechanical seals.

The manufacturing sector has declined in Latin America over the past few years owing to the decline in the production of cars and other equipment. Moreover, in 2015, the manufacturing production index of Latin America had declined by 0.9%, according to MAPI Foundation. The construction and oil and energy sub-segments are expected to grow at higher rate, owing to the increasing population and demand for the adoption of natural resources. Governments of Brazil, Mexico, and Argentina are working continuously on investing in green energy projects, which in turn will boost the adoption of mechanical seals in several different industries.

SKF (SKF AB), John Crane (Smiths Group Plc.), and Flowserve Corporation are the leading market players. SKF holds the largest market share, as per the mechanical seals market report. This is a result of SKF’s market understanding, along with demand forecasting, which is growing with customer-specific value propositions, giving the company an uptime for designing and production of mechanical seals. This fits with company’s existing engineering skills and asset management approach, with strategic focus on new technology providing value for money and digitalizing of the entire value chain.

Flowserve shares five unconsolidated joint ventures located in Latin America, Middle East, and Asia-Pacific regions, mainly in Saudi Arabia, India, The United Arab Emirates, South Korea, and two in China. The company has a portion of the products manufactured, assembled, or serviced in the territories. The joint venture has provided different strategic opportunities, including increased access to the potential markets, along with access to added manufacturing capacity and development of an efficient platform.

Furthermore, John Crane announced that it completed its purchase of the Engineering Division of Advanced Diamond Technologies. The acquisition of ADT will result in enhanced reliability and performance of mechanical seals in key settings in pumps along with other industrial equipment, bringing significant benefits to customers. Also, these strategies offer an enhanced product portfolio to their clients with minimum timelines.

The research report offers an in-depth analysis of the mechanical seals market. It further provides details on the adoption of mechanical seals products across several regions. Information on trends, drivers, opportunities, threats, and restraints of the market can further help stakeholders to gain valuable insights into the market. The report offers a detailed competitive landscape by presenting information on key players, along with their strategies, in the market.

March 2019:John Crane announced its new T4111 cartridge seal. The seal, called the Elastomer Bellows Cartridge Seal, is single-use and is designed to seal rotary and centrifugal pumps, along with similar rotating shaft machines.

April 2019:Dover announced the latest Air Mizer solutions design for the AM Conveyor Equipment Manufacturers Association shaft seal, which is explicitly developed for CEMA equipment & screw conveyors.

March 2018: Hallite Seals continued its third-party authentication with Milwaukee School of Engineering (MSOE) for the reliability & integrity of the design of its seals & sealing materials.

May 2017: Flowserve Corporation declared that it had completed the deal which involves sale of the Gestra AG unit to Spirax-Sarco Engineering plc. This sale was the part of Flowserve strategic decision to optimize its product range, enabling it to emphasis more on its core business activities and allowing it to be more competitive.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Power machines that have a rotating shaft, such as pumps and compressors, are generally known as “rotating machines.” Mechanical seals are a type of packing installed on the power transmitting shaft of a rotating machine. They are used in various applications ranging from automobiles, ships, rockets and industrial plant equipment, to residential devices.

Mechanical seals are intended to prevent the fluid (water or oil) used by a machine from leaking to the external environment (the atmosphere or a body of water). This role of mechanical seals contributes to the prevention of environmental contamination, energy saving through improved machine operating efficiency, and machine safety.

Shown below is a sectional view of a rotating machine that requires the installation of a mechanical seal. This machine has a large vessel and a rotating shaft at the center of the vessel (e.g., a mixer). The illustration shows the consequences of cases with and without a mechanical seal.

If the aim is solely to prevent leakage from the machine, it is effective to use a seal material known as gland packing on the shaft. However, a gland packing tightly wound around the shaft hinders the motion of the shaft, resulting in shaft wear and therefore requiring a lubricant during use.

Separate rings are installed on the shaft and on the machine housing to allow minimal leakage of the liquid used by the machine without affecting the rotating force of the shaft.

To ensure this, each part is fabricated according to a precise design. Mechanical seals prevent leakage even with hazardous substances that are difficult to mechanically handle or under harsh conditions of high pressure and high rotating speed.

A mechanical seal is installed on the impeller rotating shaft. This prevents the liquid from leaking through the clearance between the pump body and the shaft.

The rotary ring rotates with the shaft. The stationary and rotary rings rub against each other ensuring a clearance in the order of micrometers maintained between them. Where they rub against each other, they are referred to as “face materials.”

The face materials where the stationary ring and the rotary ring rub against each other are the most important portions as a barrier to the fluid. If the clearance is too small, the friction increases, hindering the shaft motion or resulting in seal breakage. Conversely, if the clearance is too large, the liquid will leak. Consequently, it is necessary to control the clearance in the order of micrometers to prevent leakage, but at the same time ensuring lubrication by the fluid, thereby reducing the sliding torque and avoiding hindrance to the machines’ rotation.

The mechanical seal technology is a sum of mechanical engineering and physical property technology due to the above-mentioned functions and applications. More specifically, the core of the mechanical seal technology is the tribology (friction, wear and lubrication) technology used to control the surfaces where the stationary and rotary rings rub (slide) against each other.

Mechanical seals with improved functionality will not only prevent the liquid or gas handled by a machine from leaking to the outside, but also improve machine operating efficiency, thereby helping achieve energy saving and prevent environmental contamination. Moreover, in some cases, rotating machines handle media that, in the case of leakage, can lead to a dangerous accident. Therefore, mechanical seals are required to be highly reliable through manufacturing backed by solid engineering expertise.

These functions and roles will make mechanical seals increasingly important functional parts in the future. Their further technical innovation is anticipated. To positively respond to these expectations, Eagle Industry is working on technical research and development every day.

The mechanical seal technology was fundamentally established in the 1960s. Thereafter, it has been making significant progress by introducing various leading-edge technologies, and innovative mechanical seals created from the above advanced technology are continuously being put to practical use.

To meet the demands of the market sufficiently, an applicable range of the “pressure” and “rotation speed” of mechanical seals has been considerably extended since the beginning of the 2000s. This is due to advancing of the tribology technology such as to enhance a function of the sliding materials (e.g., composite material composition, coating technology) and/or a performance of the sliding surfaces based on the fluid lubrication theory (e.g., non-contact mechanical seal, surface textured mechanical seal). These advanced technologies are sustained by improvement in the element technology of numerical analysis, processing/production, physical property/composition analysis, measurement, verification test, and so on.

Source: “Current status and future prospects of a wind/hydraulic machinery industry from 2021 to 2025”, The Japan Society of Industrial Machinery Manufacturers (2021).

We offer a range of standard inventory cartridge mechanical seals, including single and double seals to suit even the most demanding application and thanks to our modular design system we offer them with the best on-time delivery performance in the industry.

For unusual applications our Standard Plus seal range offers all the benefits of a standard seal while meeting our customer’s specific needs. This covers competitor replacement seals, seals designed for specific pumps and seals designed for pumping specific processes.

Cartridge mechanical seal construction is a proven reliability improvement. The seals are pre-assembled at the factory, pressure tested and shipped as a unit, leading to improved performance as errors due to incorrect installation are reduced. Cartridge construction eliminates the need to measure and set spring compression, and having a mechanical seal pre-assembled means that the seal faces are protected from damage during installation.

In many cases, Cartridge Seals may contain the exact same major items that are sold separately as Component Seals. These pieces include the Rotary Seal and Stationary Face as well as other minor parts like O-rings or Gaskets all required at assembly. The advantage of using a Cartridge Seal is that the time required for installation, and even more importantly, the possibility of error during installation is dramatically reduced. When installing a Cartridge Seal, the necessity of having to measure internal components positioning on the shaft to achieve proper face loading is eliminated. Cartridge Seals come pre-assembled from the factory with all internal components assembled with proper face loading and all pieces in place, exactly where they should be. Cartridge Seals eliminate the need to handle delicate, polished parts such as Seal Faces that can be compromised by the presence of dirt, smudges and oils that can result from handling during assembly. So, for the easiest and most reliable Seal installation, Cartridge Seals go a long way towards helping you achieve trouble free startup and extended service life from your equipment.

8613371530291

8613371530291