what is a mechanical seal free sample

A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.

When sealing a centrifugal pump, the challenge is to allow a rotating shaft to enter the ‘wet’ area of the pump, without allowing large volumes of pressurized fluid to escape.

To address this challenge there needs to be a seal between the shaft and the pump housing that can contain the pressure of the process being pumped and withstand the friction caused by the shaft rotating.

Before examining how mechanical seals function it is important to understand other methods of forming this seal. One such method still widely used is Gland Packing.

Packing needs to press against the shaft in order to reduce leakage – this means that the pump needs more drive power to turn the shaft, wasting energy.

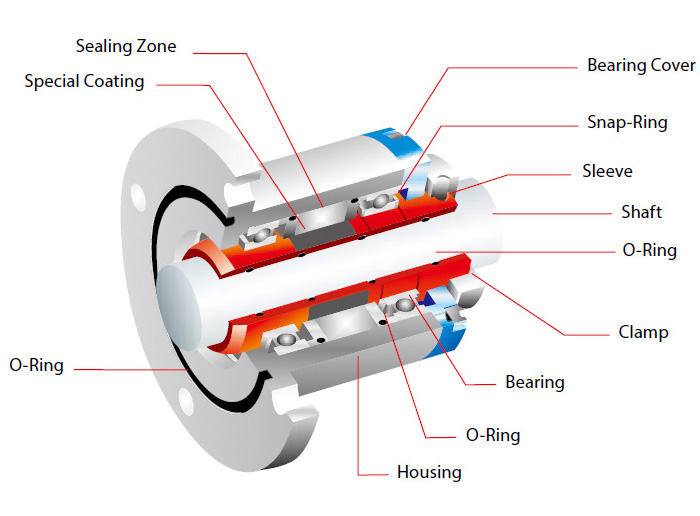

The stationary part of the seal is fitted to the pump housing with a static seal –this may be sealed with an o-ring or gasket clamped between the stationary part and the pump housing.

The rotary portion of the seal is sealed onto the shaft usually with an O ring. This sealing point can also be regarded as static as this part of the seal rotates with the shaft.

One part of the seal, either to static or rotary portion, is always resiliently mounted and spring loaded to accommodate any small shaft deflections, shaft movement due to bearing tolerances and out-of-perpendicular alignment due to manufacturing tolerances.

The primary seal is essentially a spring loaded vertical bearing - consisting of two extremely flat faces, one fixed, one rotating, running against each other. The seal faces are pushed together using a combination of hydraulic force from the sealed fluid and spring force from the seal design. In this way a seal is formed to prevent process leaking between the rotating (shaft) and stationary areas of the pump.

If the seal faces rotated against each other without some form of lubrication they would wear and quickly fail due to face friction and heat generation. For this reason some form of lubrication is required between the rotary and stationary seal face; this is known as the fluid film

In most mechanical seals the faces are kept lubricated by maintaining a thin film of fluid between the seal faces. This film can either come from the process fluid being pumped or from an external source.

The need for a fluid film between the faces presents a design challenge – allowing sufficient lubricant to flow between the seal faces without the seal leaking an unacceptable amount of process fluid, or allowing contaminants in between the faces that could damage the seal itself.

This is achieved by maintaining a precise gap between the faces that is large enough to allow in a small amounts of clean lubricating liquid but small enough to prevent contaminants from entering the gap between the seal faces.

The gap between the faces on a typical seal is as little as 1 micron – 75 times narrower than a human hair. Because the gap is so tiny, particles that would otherwise damage the seal faces are unable to enter, and the amount of liquid that leaks through this space is so small that it appears as vapor – around ½ a teaspoon a day on a typical application.

This micro-gap is maintained using springs and hydraulic force to push the seal faces together, while the pressure of the liquid between the faces (the fluid film) acts to push them apart.

Without the pressure pushing them apart the two seal faces would be in full contact, this is known as dry running and would lead to rapid seal failure.

Without the process pressure (and the force of the springs) pushing the faces together the seal faces would separate too far, and allow fluid to leak out.

Mechanical seal engineering focuses on increasing the longevity of the primary seal faces by ensuring a high quality of lubricating fluid, and by selecting appropriate seal face materials for the process being pumped.

When we talk about leakage we are referring to visible leakage of the seal. This is because as detailed above, a very thin fluid film holds the two seal faces apart from each other. By maintaining a micro-gap a leak path is created making it impossible for a mechanical seal to be totally leak free. What we can say, however, is that unlike gland packing, the amount of leakage on a mechanical seal should be so low as to be visually undetectable.

Back to back: Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

Face to face:The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Users can choose different material for this double mechanical seal 208, matching for different liquid conditoncarbon, silicon, and tungsten carbide for this mechanical seal as seal face, if for high temerperature, we suggest to choose rubber seal viton for the rubber parts.

Lepu seal make this dual mechanical seal for many years, and offer professional suggestion when client need this grundfos seal, so we are your reliable specialist for grundfos mechanical seal.

Double mechanical seals are commonly used in the following circumstances:If the fluid and its vapors are hazardous to the operator or environment, and MUST be contained

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

Back to back: Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

Face to face:The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Users can choose different material for this double mechanical seal 208, matching for different liquid conditoncarbon, silicon, and tungsten carbide for this mechanical seal as seal face, if for high temerperature, we suggest to choose rubber seal viton for the rubber parts.

Lepu seal make this dual mechanical seal for many years, and offer professional suggestion when client need this grundfos seal, so we are your reliable specialist for grundfos mechanical seal.

Double mechanical seals are commonly used in the following circumstances:If the fluid and its vapors are hazardous to the operator or environment, and MUST be contained

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Yes, we are manufacturers. We can provide OEM/ODM service according to our customers" various application and demands. All of our products are fully patented, ID/MD design, hardware and software, mold, assembly are done by our own team.

Yes, we offer free per-install apk(s) service for all of our OEM/ODM customers. Parent Control apk and educational apk are already installed in the RTS products.

We accept one unit for standard products. We can even customized with your logo if necessary. If OEM required, we will see detailed requirements and confirm the MOQ to our sales department.

Sorry, generally we would not provide the free sample. If the customer confirm the specification and price, they can order the sample first for the testing and evaluation.

We offer 12 months warranty after delivery. We guarantee quality, and if there is any deadly fault because of the manufacturing, we can provide replacement or refund for clients.

For production lead time around 25-30 days depending on the requirements. Shipping time by DHL/UPS/FedEX/TNT, delivery time would be around 5-7days. For sea shipment, the shipment time would be around 30days.

We will provide online live technical support to solve problem. Our engineers can speak fluent English, Spanish, Japanese, Madarin and French. If there is any hardware problems, we can send the parts or components with teaching video.

The global mechanical seals market size stood at USD 3.20 billion in 2018 and is projected to reach USD 4.77 billion by 2026, exhibiting a CAGR of 5.2% during the forecast period.

The key utility of a mechanical seal is to prevent leakage of fluids or gases through the clearance between the shaft and the container. Mechanical seals consist of a set of 2 faces separated by carbon rings. The first face is in contact with the rotating equipment whereas the second face is stationary. Moreover, the main part of the seal is the seal ring (first face) on which the mechanical force is acting, generated by springs, bellows, or fluids in the equipment. In recent years, mechanical seals are playing an important role in varied industrial applications, enabling efficient operations. Mechanical seals are made up of several flexible materials such as Polytetrafluoroethylene (PTFE), Polyurethane (AU, EU), industrial rubber, Fluorosilicone (FVMQ), and many more.

The mechanical seal market has depicted significant growth in the recent span of years and is likely to grow in the forecasted period. Rising industrial development in emerging economies is expected to initiate additional development policies and investments. Major types of mechanical seals available in the market include cartridge seals, balanced and unbalanced seals, pusher and non-pusher, and conventional seals that are influencing the mechanical sealing market growth in developing countries.

Growth in machine tool industry is impelling the overall market share, owing to the usage of power machines in centrifugal pumps and compressors for sealing and separating the fluid in the rotating shafts. Hence, the increasing market demand for mechanical seals in various industries is anticipated to drive the market growth in the near future. Furthermore, the highest market growth is projected to be witnessed in Asia-Pacific, followed by North America.

According to the United Nations Conference on Trade and Development (UNCTAD), the global foreign direct investment (FDI) will grow vigorously in 2018. This implies that there will be strong growth in the manufacturing sector in the coming decade. Moreover, many countries are now adopting investment policies that will boost the manufacturing sector and drive the mechanical seals market trends. For instance, in 2017, several countries and economies adopted investment policy measures across the globe, of which 84% of countries were favorable to investors. This will allow investors to invest their funds in various industries, with primary focus on energy, transportation, and manufacturing.

Furthermore, many manufacturing and industrial studies are more focused on the production or supply side and less on the demand side. This practice has reduced the importance of the manufacturing sector over the last few decades. This situation can get balanced by placing the demand side at center in the manufacturing sector ecosystem.

Therefore, the demand for manufacturing is increasing with the changes in investment policies of multiple developed and developing countries. This growth will increase the adoption of machine tools and industrial equipment for the manufacturing process, which will directly boost the mechanical seals market growth, globally.

The global mechanical seals market is segmented by type, which is further segmented into pusher and non-pusher, conventional seals, balanced and unbalanced seals, and cartridge seals.

Continuous adoption of advanced sealing material in several industries is expected to grow the cartridge seals segment in the forecast period. The cartridge seals segment is estimated to have exponential market opportunities as they are designed as universal shaft seals for the seal chamber of pumps, containers, or pipelines.

The pusher and non-pusher seals segment depicts substantial growth, owing to the increasing usage of small and large diameter ring shaft in the light end services to handle high temperatures. The balanced and unbalanced mechanical seals segment is anticipated to grow moderately, owing to the rise in the industry sector worldwide. Balanced seals are preferred for most of the industrial applications as they generate less heat at the surface of the machine, enabling longer seal life and efficient sealing method.

Comparatively, the conventional seal segment is projected to witness progressive growth owing to the requirement of heat exchanger mating ring advances offered by these seals. The other segment consists of bellows seals and is likely to represent steady growth due to limited demand in the mechanical sealing market.

By industry, the market is bifurcated into metals and mining, food and beverage, oil and gas, energy and power, aerospace, marine, construction and manufacturing, and others (chemical, etc.).

Oil and gas industry is anticipated to grow exponentially at a higher growth rate owing to increasing demand of petroleum from developed and emerging countries, hence boosting the demand of mechanical seals. Energy utilization is growing worldwide and influencing the demand for electricity generation and consumption rate, thus leading to remarkable market growth. In the current scenario, 70% of the electricity is generated from the renewable sources such as wind and solar power, which bodes well for the mechanical seals market demand.

The construction and aerospace sectors are projected to depict significant market opportunities owing to the rising infrastructural developments as a result of increasing population and technological advancements in the aerospace operating and navigation systems.

Mechanical seals demand is increasing in the food and beverage and mining sectors due to increasing implementation of pumps, food tanks, and many other centrifugal machines to manage the intensity of fluid. Marine sector is expected to depict substantial market growth as the need for the mechanical seals at naval ships and ports will remain steady in the forecast period. The others segment consists of chemical industry and is likely to showcase steady growth, owing to minimum demand in the mechanical sealing market.

Asia-Pacific is anticipated to lead the mechanical seals market share and is projected to depict exponential growth over the forecast period due to the increasing industrial applications in the emerging countries including India and China. Along with that, strong economic growth in the manufacturing sector is expected to fuel the development of the market in the region. Furthermore, favorable regulatory framework and regulations by governments for increasing investment in the manufacturing industry is expected to have a substantial impact in the growth of the market. Additionally, rapid industrialization and increasing demand of mechanical seals from industries such as construction, marine, energy and power, and oil and gas is expected to boost the growth of the market. Moreover, the region has several small and medium mechanical seals manufacturers which will increase the market share of the Asia-Pacific region in the forecasted period.

North America is predicted to show a dynamic growth rate over the projected timeline due to the rising number of infrastructure and other development projects in the region, the mechanical seals market analysis points out. This growth in the region is attributed to the presence of key players in the market along with increasing demand for mechanical seals in several industries such as manufacturing, oil & gas, and other mining industries. The growth is owed to deep involvement of workers with technology research and development (R&D) and STEM (science, technology, engineering, and mathematics) in the industries such as energy & power, oil & gas, and aerospace. Furthermore, the demand for the sealing products is accounted for increasing presence of manufacturing industries such as automotive and aerospace to energy industries such as oil and gas extraction to high-tech services such as computer software and computer system design, including health applications.

Furthermore, Europe is witnessing rapid growth owing to rising presence of chemical manufacturing industries along with growing use of sealing products in aerospace, rail, and marine industries. Additionally, demand for sealing products is comparatively stable as the large range of industries in the market offers a relatively balanced market growth over the years. The stability in demand can be seen in the period 2020-2024. Countries such as Italy and Spain are expected to show substantial growth compared to other countries in the region owing to the demand from major industries such as oil & gas and food & beverage.

The mechanical sealing market value in the Middle East and Africa is growing due to presence of more than 65% of global oil refineries in the region. Increasing investment in the oil industry will result in increased demand for mechanical seals. Moreover, countries of the Middle East are shifting their focus from oil and gas production to other industries such as tourism and other manufacturing industries which will result in decreasing market value of mechanical seals.

The manufacturing sector has declined in Latin America over the past few years owing to the decline in the production of cars and other equipment. Moreover, in 2015, the manufacturing production index of Latin America had declined by 0.9%, according to MAPI Foundation. The construction and oil and energy sub-segments are expected to grow at higher rate, owing to the increasing population and demand for the adoption of natural resources. Governments of Brazil, Mexico, and Argentina are working continuously on investing in green energy projects, which in turn will boost the adoption of mechanical seals in several different industries.

SKF (SKF AB), John Crane (Smiths Group Plc.), and Flowserve Corporation are the leading market players. SKF holds the largest market share, as per the mechanical seals market report. This is a result of SKF’s market understanding, along with demand forecasting, which is growing with customer-specific value propositions, giving the company an uptime for designing and production of mechanical seals. This fits with company’s existing engineering skills and asset management approach, with strategic focus on new technology providing value for money and digitalizing of the entire value chain.

Flowserve shares five unconsolidated joint ventures located in Latin America, Middle East, and Asia-Pacific regions, mainly in Saudi Arabia, India, The United Arab Emirates, South Korea, and two in China. The company has a portion of the products manufactured, assembled, or serviced in the territories. The joint venture has provided different strategic opportunities, including increased access to the potential markets, along with access to added manufacturing capacity and development of an efficient platform.

Furthermore, John Crane announced that it completed its purchase of the Engineering Division of Advanced Diamond Technologies. The acquisition of ADT will result in enhanced reliability and performance of mechanical seals in key settings in pumps along with other industrial equipment, bringing significant benefits to customers. Also, these strategies offer an enhanced product portfolio to their clients with minimum timelines.

The research report offers an in-depth analysis of the mechanical seals market. It further provides details on the adoption of mechanical seals products across several regions. Information on trends, drivers, opportunities, threats, and restraints of the market can further help stakeholders to gain valuable insights into the market. The report offers a detailed competitive landscape by presenting information on key players, along with their strategies, in the market.

March 2019:John Crane announced its new T4111 cartridge seal. The seal, called the Elastomer Bellows Cartridge Seal, is single-use and is designed to seal rotary and centrifugal pumps, along with similar rotating shaft machines.

April 2019:Dover announced the latest Air Mizer solutions design for the AM Conveyor Equipment Manufacturers Association shaft seal, which is explicitly developed for CEMA equipment & screw conveyors.

March 2018: Hallite Seals continued its third-party authentication with Milwaukee School of Engineering (MSOE) for the reliability & integrity of the design of its seals & sealing materials.

May 2017: Flowserve Corporation declared that it had completed the deal which involves sale of the Gestra AG unit to Spirax-Sarco Engineering plc. This sale was the part of Flowserve strategic decision to optimize its product range, enabling it to emphasis more on its core business activities and allowing it to be more competitive.

Mechanical seals touch nearly every aspect of industrialized society. Wherever a rotating shaft moves fluid, mechanical seals play a key role in sealing process fluids in, keeping contaminants out, or both.

A few basic components and principles in mechanical seal design contribute to a working seal at the interface of the rotating shaft and stationary pump/mixer/seal-chamber housing. Mechanical seals are usually end-face seals or rotating-face seals, but in some designs they can be circumferential or even a hybrid of lip-type seals. In either case, the following components are common to all mechanical seals:

Stationary primary sealing element:fixed to the stationary housing of the pump, mixer or other equipment through which the rotating shaft passes and seals against the rotating primary sealing element

The more common end- or rotating-face mechanical seal designs feature mating faces as the primary sealing elements. Rings of ceramic, carbide, carbon or composites of these materials are lapped flat in the range of less than 1 micron on an axial end face. These lapped faces run against each other, one rotating with the shaft and the other stationary with the equipment housing.

The sealed fluid migrates between the flat faces and forms a stable fluid film at this interface. During shaft rotation, the face materials heat up, wear and degrade quickly without a lubricating fluid film between them. The sealed fluid creates this thin lubricating film.

In a lip-seal-type mechanical seal, a thin film of sealed fluid also lubricates the sealing interface. Rather than two flat rings, the sealing interface is a polymer material deflected against a hard material. This material could be a hardened, coated or plated metal, ceramic, or carbide face or sleeve. One of these elements rotates with the shaft while the other is stationary with the equipment housing.

Leakage is a function of the mathematical cube of the film thickness, so to minimize leakage, the gap at the sealing interface must be kept at a functional minimum. Closing forces are used to optimize this design parameter throughout the operating range of the mechanical seal.

The initial closing force ensures that the seal will function properly from startup. In end- or rotating-face mechanical seal designs, the initial closing force is provided by a spring component, which can be a single coil spring, multiple coil springs, a deflected bellows unit (elastomer or metal), or formed or flat springs. Initial biasing forces also can be created by magnets, compressed elastomers or any other means of applying a closing force between sealing elements. In a lip-type mechanical seal, the initial closing force is typically from the deflected polymer of the lip-type seal or a garter spring for less resilient materials.

The sealing elements must be secured to the rotating shaft and stationary housing of the equipment being sealed. O-rings, gaskets and other elastomer seals stop leakage at these interfaces.

A static secondary seal stops leakage between components that do not move relative to each other. One example is the interface between a sleeve and a shaft, where both rotate but do not move relative to each other. A dynamic secondary seal, on the other hand, stops leakage between components that move relative to each other. An example is a spring-mounted seal face, where the face is free to move as the spring deflection allows, and the secondary seal will stop leakage between the seal face and the component to which it is resiliently mounted.

A lip-type mechanical seal may only require static secondary seals because the deflection of the lip-type seal accommodates equipment operating motion. All effective end- or rotary-face mechanical seals require at least one dynamic secondary seal. This is because the mating faces of the sealing interface are rigid materials that cannot comply with any equipment shaft/housing misalignments, thermal growth and shaft end-play. The dynamic secondary seal will accommodate the relative motion between at least one of the seal faces and the component to which it is mounted.

Mechanical seals are used with many process fluids. Each fluid has different lubrication qualities, but a thin, lubricating film at the sealing interface is always needed. A film that is too thick will increase leakage and may allow particulate between the faces, which will increase wear from abrasion. A film that is too thin will generate heat and cause materials to degrade. Keeping the sealing interface cool and clean will promote longer seal life.

Seal design can influence film thickness by balancing the closing forces on the sealing interface in such a way that the sealing interface does not become overloaded as process pressures increase. A closing force that is too high will lead to a fluid film at the sealing interface that is too thin, generating detrimental heat.

Another way to influence film thickness is to design surface features at the sealing interface that promote hydrodynamic lift between the rotary and stationary sealing elements. This can help create a purposeful separation at the sealing interface that results in a thicker fluid film that provides cooling and decreases face wear.

Primary seal material selection can influence seal life as well. Chemical or process compatibility is just one consideration. Harder materials are more resistant to abrasive processes, but if both sealing elements are hard materials, the wear characteristics may be less desirable in a nonabrasive application.

Using one sealing element made of a softer material and/or one that contains lubricating components such as graphite decreases friction for starting and incidental contact. The use of composite hard faces will also reduce friction by providing microscopic reservoirs of system fluid at the interface.

Thermal conductivity of materials will dissipate heat away from the sealing interface, promoting seal life. Material toughness also can play a dominant role in mechanical seal life. The inherent material surface texture may also play a role in promoting desirable film thickness.

Note that many seal failures result from failed secondary seals that have exceeded chemical compatibility, pressure or temperature limits. Metal parts must be compatible to avoid corrosion, and springs and other hardware must hold up in service.

Process and seal environmental controls greatly contribute to a cool, clean lubricating film at the sealing interface. If the process fluid is a slurry mixture, process pressure will drive the particulate-laden fluid into the sealing interface, resulting in abrasion and accelerated wear.

Environmental controls, such as a restriction bushing and clean flush, can isolate the mechanical seal from the harsh process so the seal is mostly sealing the cleaner, cooler flush fluid. In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. Product crystallization can be prevented by using temperature controls, quenching the atmospheric side of the sealing interface, or using a double seal with a buffer or barrier fluid.

There are many process considerations other than abrasion that might prevent a cool, clean lubricating film at the sealing interface. If the sealing fluid has a low vapor point, for example, flashing can result. Flashing occurs when the sealed fluid changes from liquid to gas at the sealing interface, expanding quickly and forcing the sealing elements apart until the pressure and temperature are relieved, only to have the sealing elements collapse back into contact. Mechanical damage to the sealing contact surfaces quickly results in seal failure. No lubricating film is established. Operators must incorporate process controls and ensure proper mechanical seal selection to prevent such upsets. There are many other process conditions that require special attention such as fluids that harden, are toxic, must be kept anaerobic, are part of food or water supply, or present another specific constraint.

Seal environmental controls are often overlooked, resulting in surprisingly short seal life. Many seal failures of this type happen in cool water applications. Cool water is an effective sealing fluid for creating a stable lubricating film at the sealing interface, but failure to apply proper seal environmental controls can lead to seal failure.

Many cool water applications fail prematurely because they are vertical, with the seal installed at a high point in the system where air is trapped. Without properly venting the air out of the seal chamber area, the mechanical seal seals air, not cool water. This is a dry-running condition that generates heat and quickly degrades the materials at the sealing interface.

A common environmental control used in vertical applications is a recirculation line from the seal chamber to pump suction, but in some cases the seals run dry for too long before the fluid replaces the air in the seal chamber.

Poor equipment conditions—caused by bad bearings, cavitation, excessive impeller loads and misaligned shafts—result in excessive motion, vibration and mechanical shock to the mechanical seal. These conditions cause greater stresses, more heat and more opportunity for abrasives to enter the sealing interface.

Mechanical seals are designed to handle a range of motions and conditions, but they are just one machinery component in a larger system. Understanding the basics of mechanical seals and how they may be adapted for different application requirements is critical for choosing the best seal for the job and ensuring optimal system reliability.

We invite your suggestions for article topics as well as questions on sealing issues so we can better respond to the needs of the industry. Please direct your suggestions and questions to sealingsensequestions@fluidsealing.com.

![]()

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

From the operational point of view of centrifugal pumps, it becomes essential to correctly align the pump and the drive to ensure the mechanical seal functions properly. Attention shall be given to is nozzle loads. During the design as well as during the actual installation, the consideration of the nozzle loads is important. Higher nozzle loads beyond allowable values could lead to deformed casings and may be detrimental to mechanical seals due to rubbing of the shaft at the clearances. The sizing of the shaft in case of end suction pumps (and also the overhang) has to be controlled, which could result in excessive deflection at the mechanical seal faces.

When it comes to reliability of sealing the process liquid, a dual seal arrangement is the preferred choice. There are three arrangements defined in API 682: arrangement 1, 2, and 3. The arrangement 1 is the single seal arrangement. The arrangement 2 is the dual seal arrangement with unpressurized buffer liquid at the outboard seal. Finally, arrangement 3 is the dual seal arrangement with the pressurized barrier liquid at the outboard seals. With the barrier liquid being pressurized in arrangement 3, there is no leakage of process liquid to the atmosphere, and hence it is the most reliable option when it comes to applicability of stringent environmental norms from the point of view of the end user.

However, in order to ensure proper functioning and reliability of dual seals, the operational environment of the pump, piping, seal support system, and monitoring systems play a vital role. There are typically four API piping plans for seal support systems: API Plan 53 A, B, and C, and Plan 54.

All three variations of Plan 53 are similar from the point of view that they circulate the barrier fluid using the pumping screw inside the mechanical seal, but the methods of pressurizing the barrier fluids are different. Plan 53A uses direct pressurized nitrogen to pressurize ¬fluid in the reservoir. This plan is popularly used in most of the cases due to less complexity and also availability of nitrogen pressurizing source at site. However, to ensure reliability, one has to be careful about the absorption of nitrogen gas into the barrier ¬fluid. The amount of gas being absorbed is proportional to the pressure of the barrier system. The barrier ¬fluid with absorbed gas then reaches the seal faces due to circulation and at the ¬fluid film, due to depressurization, the gas may come out and hamper the seal performance. This is a reliability concern, and hence most of the seals with Plan 53A are limited to 10 bar (gauge) pressure. Plan 53B uses a bladder accumulator as a means of pressurization of barrier fluid. This overcomes the limitation of Plan 53A and the absorption of nitrogen into the barrier liquid, which limits the system pressure, which can be used in high pressure applications. The advantage of the Plan 53B is that it can be used in remote locations where the external source of pressurization is not available. The pressure of barrier liquid is maintained due to the expansion of the bladder inside the accumulator, which also enables the supply of make-up barrier liquid to compensate for a small amount of leakage of barrier -fluid. However, the monitoring of the liquid level in the reservoir is not possible, and as such, the sizing of accumulator considering the seal leakage and maintenance interval is critical. As the bladder expands to compensate for seal leakage, it needs to be refilled with barrier liquid. The usual cycle of refill is 25 to 28 days. Considering this as a basis, the size of the accumulator and the pre-charge pressure of nitrogen is estimated.

Plan 53C uses a piston as a means of pressurization of barrier ¬fluid inside the accumulator. The advantage of this design is that it uses the process fluid pressure from the seal chamber directly on the bottom side of the piston, whereas top side is exposed to the barrier liquid. The pressurization is achieved by the difference in the areas. The area exposed to process liquid is larger and is designed with ratios ranging from 1:1.1 to 1:1.25. As the seal chamber pressure is being used as a reference, the system itself takes care of process pressure fluctuations. However, as the piston is in direct contact with the process fluid, the material selection becomes essential. Also, the properties and quality of process ¬ fluid shall be carefully evaluated, it should not hinder the movement of the piston within the accumulator. Another important factor is the dynamic sealing of the process fluid from the barrier fluid. The failure of the piston seal will result in the equilibrium of pressures on both sides of piston, and because of the piston movement, friction and drag come into play. Thus, the plan is not so reliable for low pressure applications and recommended to be used in the applications with pressures greater than 7 bar (gauge).

Although a mechanical seal is a critical piece of equipment, it shall not be treated in isolation and due consideration should be given to the operating environment of the pump, seal support system, and most importantly, the perfect selection for the given application.

Abhijeet Keer is a design engineer who has been working in the fi eld with centrifugal pumps for over seven years. With strengths in mechanical construction and materials, he has gained valuable knowledge working in design with major players in pump industry, such as KSB Limited and Kirloskar Brothers Limited. He completed his Bachelor’s Degree in Mechanical Engineering from University of Mumbai, India. His professional experience covers new product design and developments, material selection and application engineering, and complete mechanical constructions.

Continue reading to learn more about howmechanical sealswork, why they leak, and why these “managed leaks,” as they are called, are important to your pump’s performance.

Mechanical sealsare used to contain fluid within vessels (typically something like acentrifugal pump) that features arotating shaftthat passes through a stationary housing (or sometimes it’s the opposite and the casing rotates around the shaft).

When sealing a centrifugal pump, the goal is to prevent large volumes of fluid from escaping when therotating shaftenters the “wet” area of the pump. The seal is put in place between thepump shaftsand the pump housing to achieve this goal.

The sealing needs to be able to contain the pressure created by the pumping process and withstand the friction caused by the two components rotating against each other.

Allmechanical sealsleak. They actually have to in order to maintain a fluid film over the entiremechanical seal face. This mandatory leakage is what is referred to as a managed leak. Managed leaks are completely different from outrightmechanical seal failure, which is one of the leading causes of pump failure.

The leakage from a managed leak is extremely low. For example, the leakage in a hydrocarbon is measured by avolatile organic compound (VOC)meter in parts per million. Needless to say, it’s almost negligible.

However, some leaks are more harmful to humans and the environment than others. If a leak could pose a threat to the surrounding environment, it is crucial that the leak is maintained as effectively as it can be.

For instance, ahydrofluoric acid leak is obviously an environmental issue, so leakage can be very damaging. The same goes for propane. Propane is very flammable, as it is liquefied natural gas, so an excessive amount of leakage could end up causing an explosion.

In these more dangerous cases, we would recommend that you resort to a seal-less design for the pump that prevents any fluid from ever leaking out. Our solution would be to use amagnetic drive, which prevents any fluid from coming into contact with the atmosphere at all.

The application of the pump has to be taken into account as well. Some fluids are much more difficult to seal than others. For example, crude oil is very slick and lubricating, making it much harder to seal effectively than something like water. Water is non-lubricating, so it’s much easier to seal.

Not all leaks are the good kind, unfortunately. Uncontrolledmechanical sealleaksare some of the leading causes of industrial pump failure. The following are common causes ofmechanical seal failure.

Every pump is designed with specificoperating conditionsin mind. These conditions are referred to as thepump’s bestefficiency point(BEP), which is the point at which your pump operates at its peak efficiency.

Operating your pump outside of these conditions can lead to serious problems, including insufficientnet positive suction head (NPSH)and low vapor margin.

Mechanical failures occur when your pump’s components are faulty to begin with or start to malfunction over time. Typical examples of mechanical failures include shaft misalignment and coupling and impeller imbalance. Other components of your pump that you should check to make sure they are satisfactory include its base, pipes, and bearings.

In addition to the failings of your pump’s mechanics, you also need to keep an eye on the seal itself. The seal features several components that can fail if they are not properly attended to. You need to be aware of your seal’s material quality, secondary seals (such as gaskets and o-rings), and springs. Make sure to check your seal for heat distortion on a regular basis.

If there are problems with the way yourpump skidwas designed or installed, these problems could lead tomechanical sealfailure. Always make sure to have your pump assembled and installed by a reputable company or someone with the proper knowledge and experience.

At C&B Equipment, we are a reputable distributor of several types of industrial equipment, includingindustrial pumpsandmechanical seals. We specialize in therepair, installation, and maintenance of industrial equipmentso that you don’t have to worry about it yourself.

Having one of your industrial pumps break down is a major hassle, but with our preventative maintenance programs, this possibility will become a non-issue. Whether it’s a problem with the mechanics of your pump or yourmechanical sealis failing, we’ve got you covered!

If you ended up on this page doing normal allowed operations, please contact our support at support@mdpi.com. Please include what you were doing when this page came up and the Ray ID & Your IP found at the

8613371530291

8613371530291