what is a mechanical seal quotation

A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.

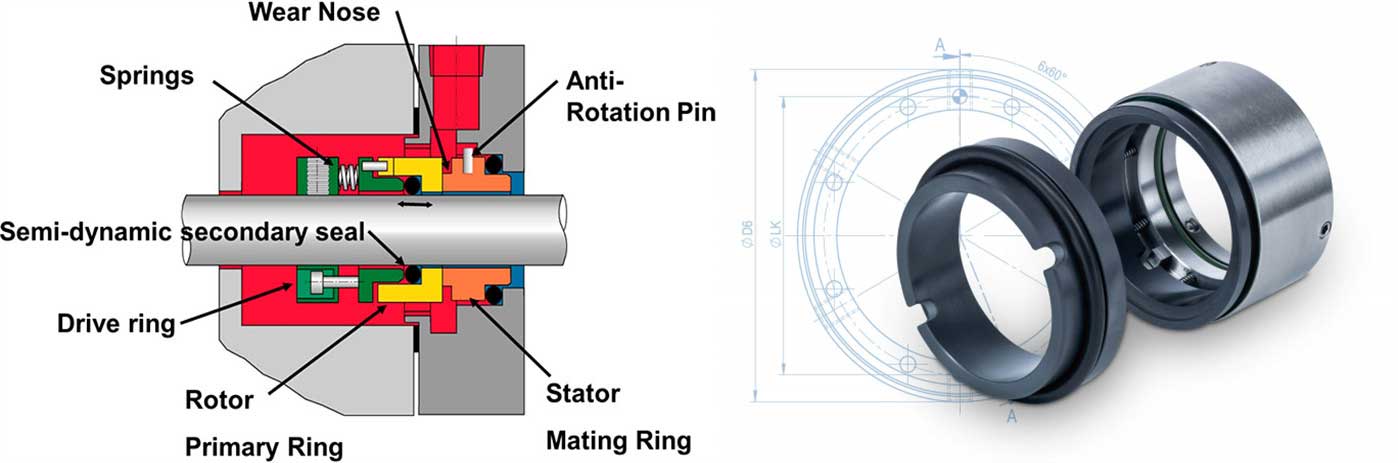

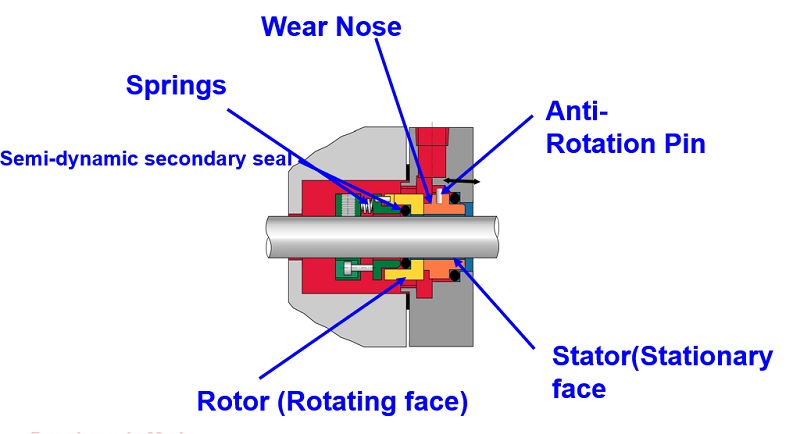

The stationary part of the seal is fitted to the pump housing with a static seal –this may be sealed with an O-Ring or gasket clamped between the stationary part and the pump housing.

The rotary portion of the seal is sealed onto the shaft usually with an O ring. This sealing point can also be regarded as static as this part of the seal rotates with the shaft.

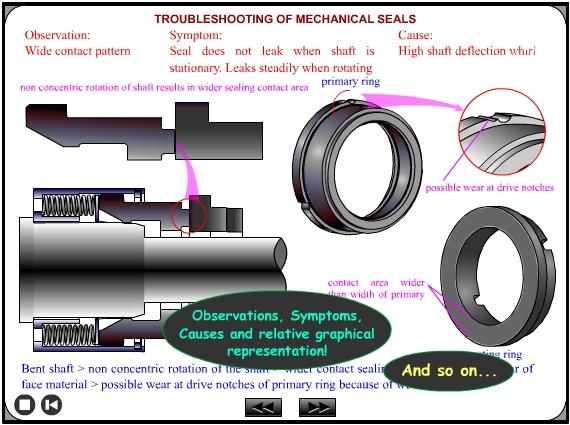

One part of the seal, either to static or rotary portion, is always resiliently mounted and spring loaded to accommodate any small shaft deflections, shaft movement due to bearing tolerances and out-of-perpendicular alignment due to manufacturing tolerances.

While two of the sealing points in a seal design are simple static seals, the seal between the rotating and stationary members needs a little more consideration. This primary seal is the basis of all seal design and is essential to its effectiveness.

The primary seal is essentially a spring loaded vertical bearing - consisting of two extremely flat faces, one fixed, one rotating, running against each other. The seal faces are pushed together using a combination of hydraulic force from the sealed fluid and spring force from the seal design. In this way a seal is formed to prevent process leaking between the rotating (shaft) and stationary areas of the pump.

If the seal faces rotated against each other without some form of lubrication they would wear and quickly fail due to face friction and heat generation. For this reason some form of lubrication is required between the rotary and stationary seal face; this is known as the fluid film

In most mechanical seals the faces are kept lubricated by maintaining a thin film of fluid between the seal faces. This film can either come from the process fluid being pumped or from an external source.

The need for a fluid film between the faces presents a design challenge – allowing sufficient lubricant to flow between the seal faces without the seal leaking an unacceptable amount of process fluid, or allowing contaminants in between the faces that could damage the seal itself. This is achieved by maintaining a precise gap between the faces that is large enough to allow in a small amounts of clean lubricating liquid but small enough to prevent contaminants from entering the gap between the seal faces.

A: An end-face mechanical seal is a device used on a rotating shaft to seal fluids. It consists of two flat faces that are installed perpendicular to the shaft. One of the faces is mounted stationary to the seal chamber or housing. The other face rotates with the shaft to provide the primary seal. Axial mechanical force and fluid pressure maintain the contact between the wearable seal face materials.

A: Component, end-face mechanical seals (a component seal) consist of a separate rotating member and stationary seat that mount in a gland or housing. Since they are not preset, installation and maintenance are generally more difficult requiring experienced technicians to properly install and adjust them.

A: Rotating equipment used in processing gases, liquids, and slurries are the primary applications where end-face mechanical seals can be cost effectively considered and applied. Some types of rotating equipment that are not equipped with a seal chamber or stuffing box for installing a gland require that a component seal be used.

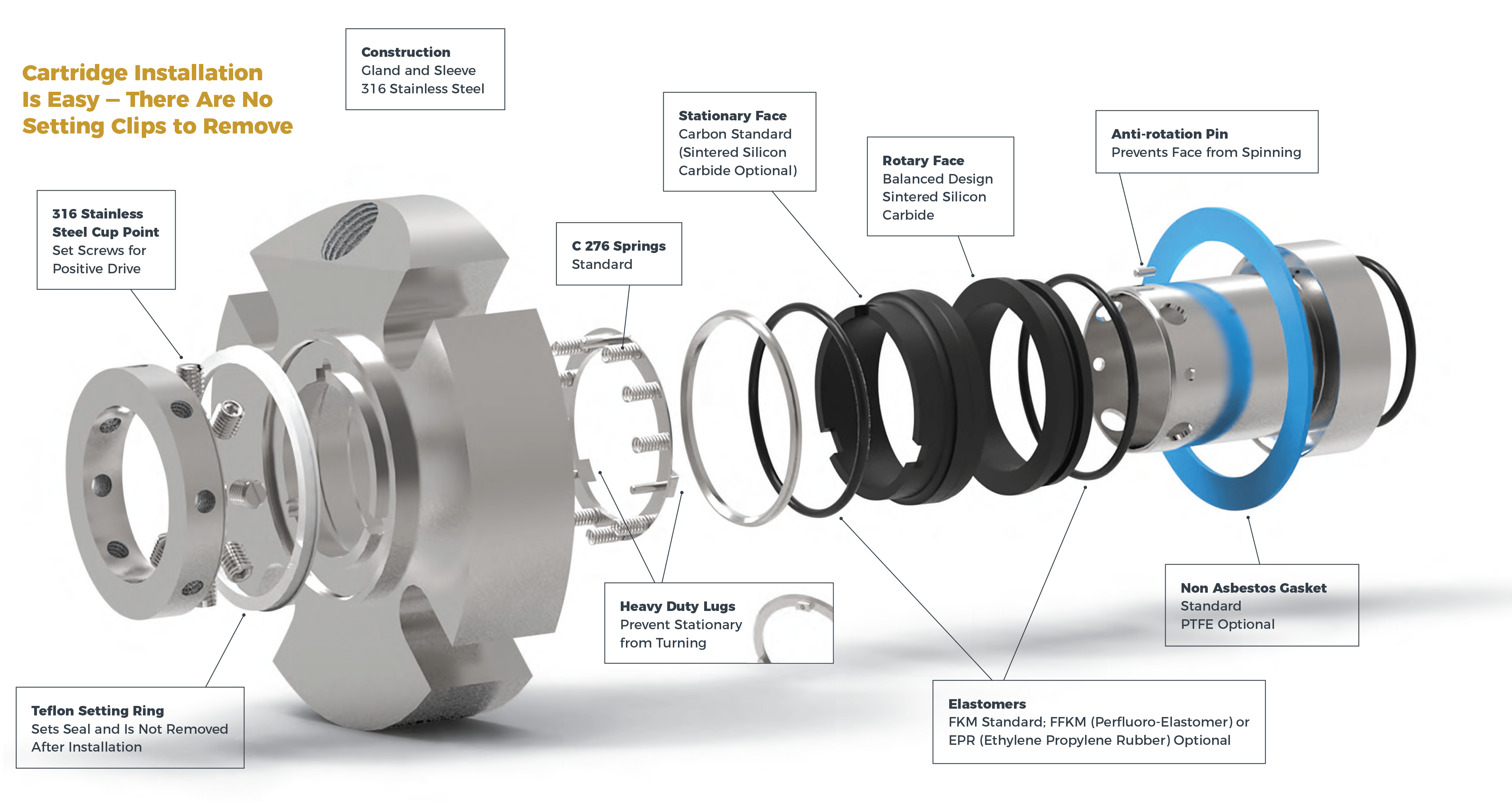

Cartridge-mounted, end-face seals were primarily introduced for installation on American National Standards Institute centrifugal pumps on which axial shaft adjustments can be made. The simplicity and ease of installation and maintenance they offer makes cartridge-mounted single and dual units a primary consideration for all types of rotating equipment that are equipped with a stuffing box or seal chamber in which a gland can be installed.

Mechanical seals come in different configurations, and each variant has its advantages and disadvantages. Among the most common variants are component mechanical seals and cartridge mechanical seals.

When selecting a mechanical seal type, pump users must consider the cost of installation, long term running costs, pump characteristics, and the anticipated operational conditions (heat, vibration, and pressure). Keep your technical staff in mind as well, because having a skilled technician on-hand for regular maintenance vs. having to outsource maintenance and repairs makes a significant difference.

A cartridge mechanical seal is a completely enclosed seal system with preassembled components. Typically, this seal type is composed of a gland, sleeve, and other hardware that make pre-assembly possible.

Component mechanical seals are composed of separate dynamic and stationary parts. Unlike cartridge seals, component seals are not preassembled and require skilled technicians to install them. Incorrect installation of seal faces, O-rings, and seal axial setting on the pump shaft will result in reduced seal life or in some cases, immediate seal failure.

The major cons for non-cartridge mechanical seals are their susceptibility to damage. Other than cartridge type seals that are completely encased within secure housings, component mechanical seals usually have exposed parts that are more susceptible to damage during transportation or installation.

Further, non-cartridge type seals require precise measurements during installation to prevent seal failure. Properly installing this type of seal requires more operator time and thus a higher cost to install or re-install after a repair.

A single mechanical seal is a type of mechanical seal which consists of one primary seal and it seals from process to atmosphere.There is always some leakage either to atmosphere or into process depending on the process pressure.

-Found as Wet-running (liquid phase between sealing faces) on liquid pumps, Dry-running (gaseous phase between sealing faces) on blowers/compressors/mixers.

-Nearly always dry running contacting seal (mechanical seal face wear) for top mounted mixers. For side and bottom mounted (seal is submerged) a wet-running seal is normally specified.

If you have any query around how to install a single mechanical seal for agitators or mixers or have some concerns around the seal failures, why not contact one of our mechanical seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process back up and running reliably again.

A singlemechanical seal consists of two very flat seal faces that are forced together by a spring and slide against one another. Between these two faces is a thin fluid film generated by the process fluid or pumped product. This fluid film (typically gap of 1 micron or 75 times narrower than a human hair), lubricates and cools the seal. An absence of this thin fluid film (pump running dry or product flashing) results in frictional heat and ultimately the destruction of the mechanical seal.

The sealed fluid typically enters the gap between the seal faces as a liquid. As it migrates across the seal faces from the high-pressure side to the atmosphere, its pressure drops, and temperature rises. The liquid may vaporize so there may be no visible liquid leakage. A correctly specified seal operating properly will typically meet VOC emissions standards.

A dual mechanical seal consists of two seals arranged in a series. The inboard seal keeps the product contained within the pump housing. The outboard seal prevents the barrier or buffer liquid from getting into the atmosphere.

Double Seal: With barrier fluid pressure higher than product pressure the seal prevents leakage of toxic or hazardous fluids into the environment. The barrier fluid provides lubrication to seal gasses and non-lubricating fluids.

Tandem Seal: By using a buffer fluid with pressure to lower than process, the seal can reduce the pressure differential across a single set of seal faces.

Spare Seal: With unpressurized buffer fluid the outboard seal operates “at idle” as a standby seal. If the inboard seal fails, the outboard seal provides primary protection, eliminating unscheduled shutdown of batch processes.

Mechanical seals form a critical part of any mechanical operation involving fluid movement through rotational shafts, such as in the case of pumps. These seals ensure that the fluid does not leak out of a closed system and contaminants do not enter the system. In pumping applications, mechanical seals are placed at the point of entry or exit of a rotating shaft, preventing the pressurized fluid from escaping the pump housing and withstanding the friction generated from the shaft rotations.

Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. While different mechanical seal designs are available for pumping applications, most have three sealing points.

These three sealing points ensure that the fluid contained within the pump housing does not leak while also preventing dust particles in the atmosphere from entering the housing.The mechanical seals are usually made up of different materials to prevent sticking. Typically, one side of the seal uses softer materials like carbon graphite, and the other is made of harder materials such as silicon carbide or ceramic alumina. However, hard materials are preferred for both surfaces if the pumping application involves abrasive fluids.

In addition to the two materials, the sealing unit also comes with O-rings to seal the stationary face on the housing side and the rotating face on the shaft side. Springs are also used to keep both faces pressed.

In most cases, the two faces of the seals are also lubricated to prevent friction and wear. Depending on the application, this fluid film can either be a separate lubricant or the process fluid itself.

Mechanical seals can be selected based on the type of pump application. Choosing the wrong seal can affect pump performance and lead to damage and costly repairs.An unbalanced mechanical seal is preferred if the pump needs to operate at a lower pressure. However, high pressure pumping applications require balanced mechanical seals. Balanced seals also perform better in high temperature operating conditions. Cartridge seals require less maintenance but are more expensive, hence used for limited applications.

At Hayes Pump, we have a fully staffed, factory-trained parts department to help you quickly with the correct mechanical seal for your pump. You canrequest a quotefor your part orcontact usto get further assistance.

Mechanical seals are devices that seal machines between rotating parts (shafts) and stationary parts (pump housing) and are an integral part to the pump. Their main job is to prevent the pumped product from leaking into the environment and are manufactured as single or double seals. What"s the difference between the two?

A single mechanical seal consists of two very flat surfaces that are pressed together by a spring and slide against each other. Between these two surfaces is a fluid film generated by the pumped product. This fluid film prevents the mechanical seal from touching the stationary ring. An absence of this fluid film (dry running of the pump) results in frictional heat and ultimate destruction of the mechanical seal.

Mechanical seals tend to leak a vapor from the high pressure side to the low pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it"s common practice to use a single mechanical seal if the pumped product poses little to no risk to the environment.

A double mechanical seal consists of two seals arranged in a series. The inboard, or “primary seal” keeps the product contained within the pump housing. The outboard, or “secondary seal” prevents the flush liquid from leaking into the atmosphere.

Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Are you still using packing for your pumps? Read about the differences between packing and mechanical seals to see if switching to mechanical seals makes sense for your plant. A qualified engineer will help you decide which type of mechanical seal is best for your application.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

The SEPCO RBD is a stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerated and where positive ...

Dual seal Available for standard (CMS-ASDN) and big bore (CMS-ABDN) seal chambers Balanced Cartridge Double pressure balanced Independent of direction of rotation Integrated pumping device

We manufacture face seals for hydraulic and pneumatic applications in the following designs:- rod seals and piston seals - single-acting - double-acting - rotatory ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Flexaseal offers a wide variety of single cartridge mechanical seals, each designed as a reliable solution for the toughest applications. Our single cartridge seals are easy to install and minimize the number of moving parts that can lead to equipment failure. Specially designed single cartridge seals are also available for highly corrosive or high-temperature environments. Cost-effective upgrades are available when circulation, vent, & drain glands are required.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Style 57 design serves to keep the sealing faces in contact and positively transmits the drive evenly 360° around the full circumference of the rotary face. This is accomplished by the special spring design, which provides an interference fit. The compression spring is wound either right or left hand depending on shaft rotation.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Stationary design accommodates higher shaft-to-stuffing box misalignment. The stationary bellows design only flexes once during installation unlike a rotating design which flexes on every revolution. This reduces face movement and increases seal life.

Upgradable to API design specifications with piloted gland and metal-to-metal confined gland gasket which prevents blow out or extrusion of the gasket

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

These two single cartridge seals are engineered for the most demanding corrosive applications. By minimizing the number of troublesome O-rings and eliminating any media exposure to the sleeves and glands, we have produced two very cost effective solutions to industries’ toughest applications.

In highly corrosive conditions that require expensive upgrades to higher alloy metals like duplex stainless steel, Alloy 20, Hastelloy® C276, the PH seals are an ideal economical solution. Only the wetted parts need to be constructed of these alloys while the larger metal parts such as the gland and sleeve can be 316 stainless steel since they are located out of the product

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

API compliant with piloted gland to positively center seal assembly and metal-to-metal confined gland gasket which prevents blow out or extrusion of the gland packing

Multi-point injection feature available which ensures maximum uniformity of cooling around the entire circumference of the sealing faces, thus eliminating face distortion due to uneven cooling. Ideal for boiler feed and light flashing hydrocarbon services.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Conventional pump stuffing boxes were originally designed to accommodate packing materials. Over the years mechanical seals edged out packing as a preferred sealing method, however stuffing boxes essentially remained the same. This situation posed complications for the effective operation of mechanical seals including installation issues, potential damage from abrasive product, and poor dispersion of seal-generated heat.

The ANSI Standard ASME B73.1 Specifications for Horizontal End Suction Centrifugal Pumps for Chemical Process includes specifications to improve the reliability and safety of the B73.1 pump design. One major specification focuses on cylindrical (big bore) and self-venting (tapered bore) seal chambers. Both of these seal chamber designs address the issues that plagued conventional pump chambers by providing additional radial clearance for mechanical seal operation and for increased liquid circulation around the seal, enabling the seal to run cooler and longer.

Only two (2) static elastomers – eliminate seal failures caused by dynamic O-ring “hang up” and offers cost savings when upgrading to Perfluorelastomers

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Chennimalaipalayam, Tiruppur, Dist. Coimbatore 7/250, B-1, Ground Floor, Srinagar Ganapathipalayam Road, Chennimalaipalayam, Tiruppur - 641605, Dist. Coimbatore, Tamil Nadu

Jogeshwari West, Mumbai No. 5/1 - A, Ramjanaksingh Compound, S. V. Road, Opposite Veena Dalwai Industrial Estate, Oshiwara, Jogeshwari West, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Jogeshwari West, Mumbai Unit No-BF-10, 1st Floor B Wing, Saraf Kaskar Industrial Premises Co-Op Society Ltd, SV Road, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Single Cartridge Mechanical Seals" are used where there is corrosion and erosion in the seal media. This seal have good demand in sealing of rotation equipments.read more...

In continuation to our legacy journey as a customer-centric company "Expert Engineering" which started in 2021, we are now delighted to expand our business portfolio to Mechanical Seal and Seal Support System under the name of "Maffs Seals Pvt Ltd".

Pune Near Indrayani Sweets, 1st Floor, Pap-j-90 / Shop No 6, Sankeshwar Complex, Anandrao Lande Road Bhosari, Pimpri Chinchwad, Pune - 411026, Dist. Pune, Maharashtra

Jogeshwari West, Mumbai Unit No. 3, Joshi & Qureshi Compound Behind Safey Himalaya Hotel, SV Road, Ajeet Glass, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Jogeshwari W, Mumbai B508-9TH FLOOR- EE HIGHT BUILDING- S V ROAD- JOGESHWARI W MUMBAI 400102 NEAR RAILWAY STATION, Jogeshwari W, Mumbai - 400102, Dist. Mumbai, Maharashtra

Jogeshwari West, Mumbai Unit no. 30, Mishra Compound, behind Tashkend Hotel, opp, Ruby hospital.S.V.Road, jogeshwari (w) Mumbai-400102., Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Pune Navale Bridge, First Floor, Flat No. 104, S.no. 8/1b/1, Sai Kiran Pruthvi Developers, Sinhgad Road, Ambegaon, Pune - 411046, Dist. Pune, Maharashtra

Virar West, Mumbai B-5/108, floor-1ST FLOOR, 5-STAR SOCIETY, VEERA DESA- 306, Shagun CHS, Uni Tech Road, Tirupati Nagar Phase 2, Boolinj, Virar West, Virar West, Mumbai - 401303, Dist. Mumbai, Maharashtra

Split Mechanical Seals can be installed without disassembly of the equipment, simply attach two halves over the shaft and mount like any other cartridge seal. The only split seal that can be fully pressure tested at the factory before shipping can convert a packed pump to a sealed pump easily.

Mechanical seal varieties are used to prevent the unwanted release of pressure, lubricants, hydraulic fluids and other properties of a system that makes use of them. Seals are also used to prevent the contamination of those systems by dirt and other hazards. Equipment like agitators, mixers, gas seals, pumps, valves, actuators and many other kinds of machinery all involve the use of some variety of mechanical seal.

In addition to preventing leaks, mechanical seals also keep contaminants from entering and help to maintain pressure levels. Piston seals, flange gaskets and diaphragm seals are also kinds of mechanical seals, and they are all essential to the functioning of certain kinds of equipment.

Most mechanical seals are specially designed to prevent leaks in particular applications and cannot be interchanged with those seals used in other mechanisms. A piston seal, for example, cannot be used as a flange gasket; they are shaped differently, made out of different materials and feature different mechanical properties. The shape, size, and composition of a given mechanical seal always depends on the conditions in which it will be applied.

Also, depending on the narrowness or broadness of a given understanding of the words "mechanical seal," certain kinds of seals may or may not qualify. Simple plastic lids qualify by the broadest definitions, while some of the strictest definitions might only include seals applied in industrial process equipment or in heavy machinery.

In either case, mechanical seals perform the same task: to isolate and contain materials in an enclosure. Correctly pairing seals with their applications is essential to the safe and effective use of the equipment in which they are installed. For example, Teflon is often chosen for use in hydraulic cylinders because it is resistant to corrosion induced by exposure to hydraulic fluids.

Natural rubber, on the other hand, may degrade when exposed to such chemicals. The decision to employ a given seal material should always be chosen carefully; this will ensure sustained effective and safe operation of the seal and the equipment it protects.

8613371530291

8613371530291