mechanical seal assembly supplier

We specialize in hard-to-find seals and demanding applications. Our extensive network of resources enables us to locate the right manufacturer and part, every time.

At All Seals we know down time is not an option. We specialize in hard-to-find seals and demanding applications. With over 40 years of experience in supplying quality replacement mechanical seals, we can help you identify the seal you need and solve your sealing problem. Our technical staff is available to help you – just give us a call. Our comprehensive stock of components ensures that we can build almost any seal combination for same day shipment. Whether you need a new seal or you have a seal to be repaired, we welcome the opportunity to help you with your rotary sealing needs.

We carry a comprehensive inventory of mechanical seal components, which allows us to build the right seal for your application. We’ll even design custom seals for one-of-a-kind applications.

Need hard faces or specialty elastomers? Give us a call. We can quickly build a repair kit to withstand any medium being pumped. You’ll find All Seals’ pump repair kits an invaluable part of your operation.

![]()

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

ISO 9001:2015 certified. Custom manufacturer of abrasion, acid, alcohol, alkali, oxidation, ozone, radiation, sunlight and water resistant rubber and plastic O-ring seals. Made from EPDM, butyl, fluoroelastomer, fluorosilicone, natural rubber, neoprene, nitrile, NBR, HNBR, SBR, silicone, high tear strength silicone, TPR, TPU, TPE, thermoplastics and polyurethane. Capabilities include injection molding, die cutting and prototyping. Assembly and PTFE coating additional services are also provided. Serves the aerospace, automotive, commercial, construction, dental, electrical, food handling, laboratory, marine, mining, municipal, oil and gas, recreational, retail, transportation and wastewater industries. Meets ASTM and SAE standards. Six Sigma certified. JIT delivery. Overseas sourcing options also offered.

Our NUTECH cartridge mechanical seals are designed to fit all ANSI pumps for ease of installation and are pressure tested at our Texas manufacturing facility prior to shipping. We can custom design any cartridge style seal to fit your most demanding applications. We use premium grade materials of construction throughout. All seals are made in the USA.

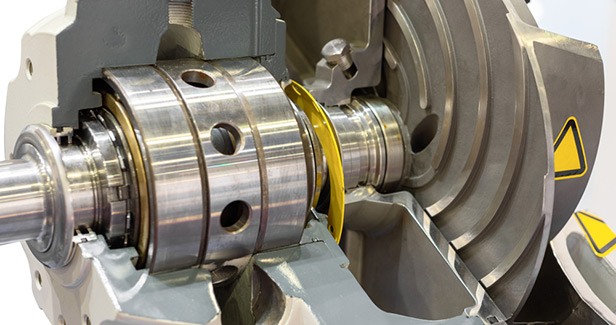

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

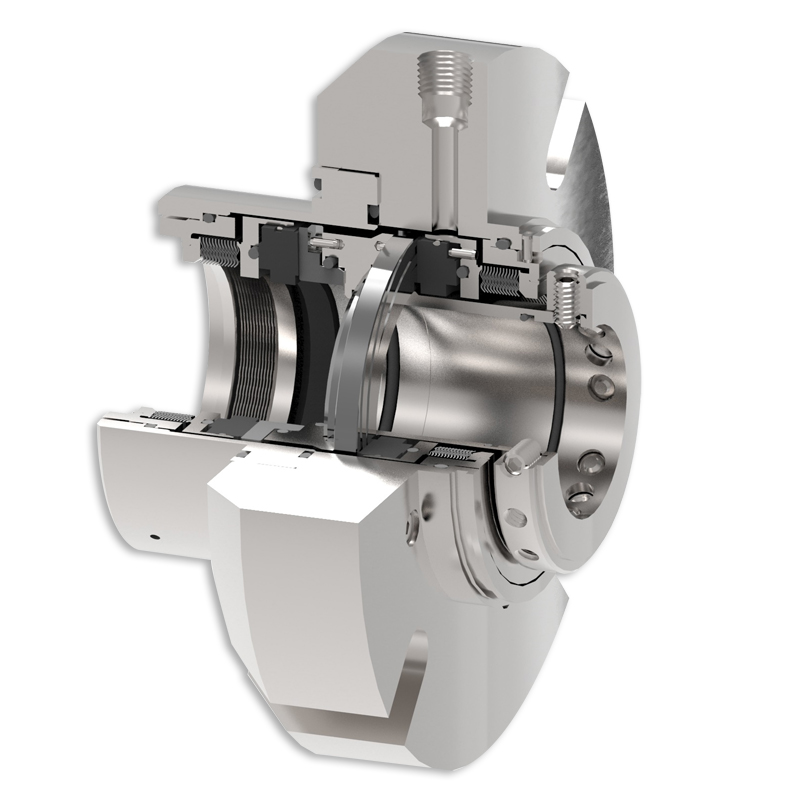

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

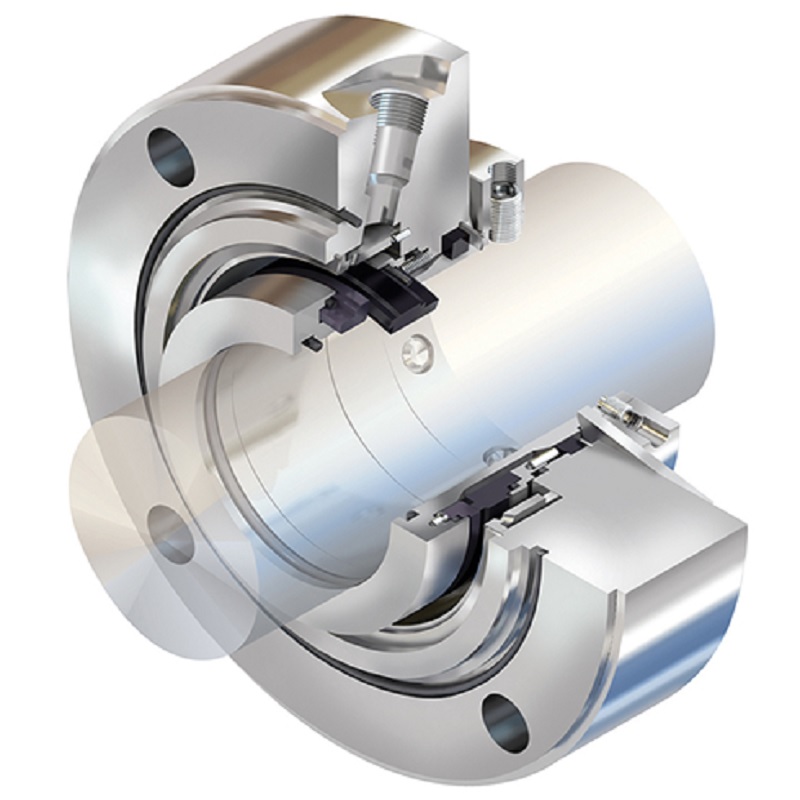

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

AESSEAL Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs.Seacoast Supply maintains a large inventory of AESSEAL products.

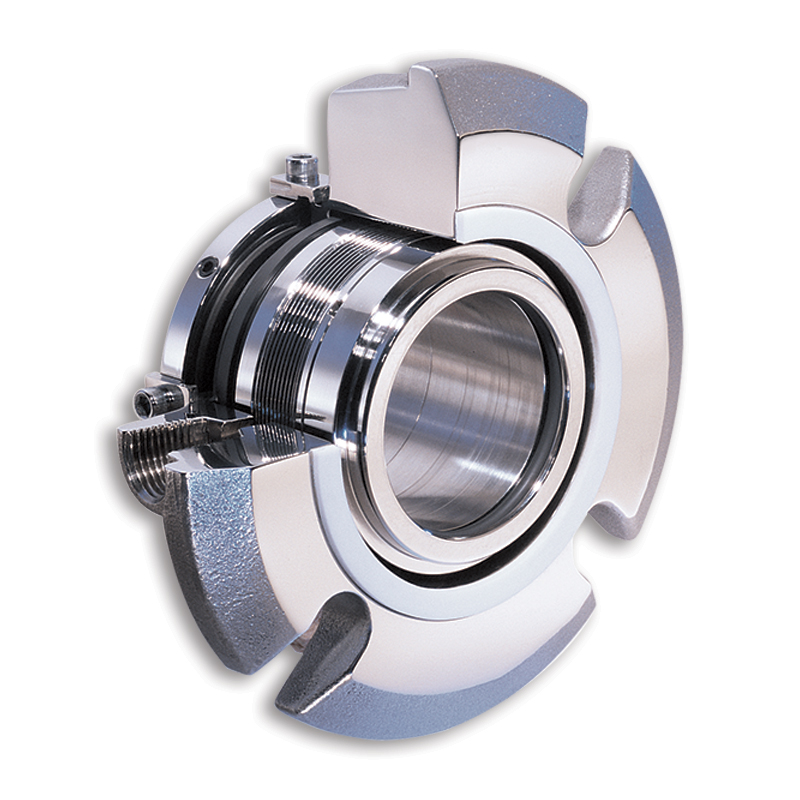

Cartridge mechanical seal construction is a proven reliability improvement. The seals are pre-assembled at the factory, pressure tested and shipped as a unit, leading to improved performance as errors due to incorrect installation are reduced. Cartridge construction eliminates the need to measure and set spring compression, and having a mechanical seal pre-assembled means that the seal faces are protected from damage during installation.

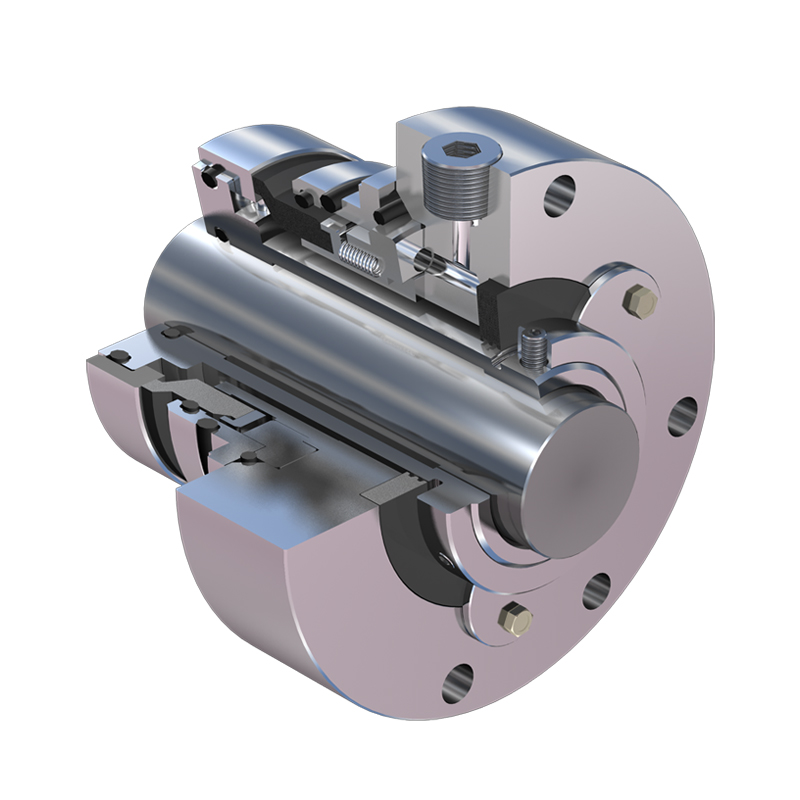

A double or dual mechanical seal consists of two independent seals mounted within a seal chamber outside the pump, which is flushed with an independent supply. This makes them ideal for sealing hazardous liquids, liquids with abrasives or liquids that are corrosive, as the seal faces only see clean lubrication greatly increasing mechanical seal life.

AESSEAL® double mechanical seals have independent seal-face designs, to enhance safe containment of process fluid in the event of damage to any individual sealing element.

This means that no matter how well designed your mechanical seal or bearing systems are, without a reliable Seal Support System there is still the possibility of your mechanical seal failing. The innovative and reliable Seal Support System Range at AESSEAL® gives customers the confidence to remove this root cause of mechanical seal failure.

AESSEAL® offer a range of bearing protection devices suitable for most applications. The innovative LabTecta® and MagTecta™ products include patented features that deliver the best possible bearing housing sealing solution for your motor, pump, plummer block, gear boxes or steam turbine.

Our technicians are familiar with the wide variety of seal families, materials and their applications. Through each stage of the repair / rebuilding process the seal is tested to exceed manufacturer’s specifications.

Our technicians are familiar with the wide variety of seal families, materials and their applications. Through each stage of the repair / rebuilding process the seal is tested to exceed manufacturer’s specifications.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

At Sealing Specialties, we are the go-to source for all of your mechanical seal needs. As an authorized distributor of the complete John Crane mechanical seal product line, we have access to the largest and most comprehensive selection of mechanical seals in the world.

Sealing Specialties handles the complete John Crane mechanical seal product line. John Crane is the largest and most complete mechanical seal manufacturer in the world.Market segment use of John Crane mechanical seals includes chemical, power generation, pulp and paper, pharmaceutical, life science/ biotech, wastewater, mining, refining, and petrochemical.

Bellows seals are used to seal rotary shafts and prevent the escape of gases or liquids, and are often used in high-temperature or high-pressure applications.

Siewert Equipment is the exclusive provider of Flowserve mechanical seals for Upstate, NY. Flowserve seals are the industry’s top choice for the most challenging environments. We offer a complete line of seals, including cartridge seals, dry-running seals, metal bellows, elastomeric bellows, mixer seals, split seals, and bearing protection devices.

Inferior mechanical seals for pump-based systems are a potential “Achilles’ heel” on the production floor, and in some industries fugitive emissions pose a significant environmental threat.

Calkins seals and seal support systems combine great design, high-quality construction and consistent performance in real-life field operations. With the right seals, your “Achilles heel” can become your hero, delivering trouble-free performance over extended periods without excessive maintenance, power usage or repair downtime.

Calkins supplies and services mechanical and cartridge seals for a variety of design groups, and in a wide range of configurations, including Single, Double, Split, Mixer, Bellows and Specialized. Calkins also provides and services bearing protection systems.

Slurry mechanical seal as a simple "pre-set cartridge seal" that requires no measuring or special tools for assembly into the equipment housing easily disassembled and rebuilt either in the field or plant workshop, without the need of any special tools.

Sealing many products in various types of fluid handling equipment WITHOUT any type of flush thereby eliminating product dilution or contamination from barrier fluids or gases. (Some services a flush has been shown to prolong seal life).

Optimum sealing performance while running totally submerged, but to also withstand intermittent dry running situations, and still maintain a positive seal when the fluid returns to the seal area.

Design features have minimized the number of parts facilitating ease of assembly and installation. Fewer o-rings than other slurry seals reducing the number of possible leak paths.

Minimum amount of spares for inventory, thereby minimizing inventory carry costs and freeing up shelf space. (Traditional mechanical seals are sold in 1/8 in. increments. One PANACEAL compared to eight traditional seals).

No seal hang-up due to product crystallization on the atmospheric side of the rotary assembly. (Product crystallization is a normal result of face lubrication).

8613371530291

8613371530291