mechanical seal assembly pricelist

Heavy Duty Mechanical Seal, Commercial, Ozone, Salt Applications. HD Version of PS-200. PS-3867 This is the heavy duty version of the PS200. It is made with carbon graphite, stainless steel and viton rubber. This is the longest lasting eal available.

I ordered 2 seals and 2 impellers to rebuild 2 separate Spa Pump Motors. However, when I received my order, it only contained the impellers. I had to call the company and take pictures of the package and submit them and then they sent the missing seals. Everything eventually arrived, but I had to wait an additional few days for the shipment of the seals, so the repair was delayed. Good thing we didn"t have any freezing weather during the wait for parts.

Many tools can seal used when installing mechanical sealals that are not readily available, Alibaba.com offers a variety of mechanical seal tools that can seal used when installing mechanical sealals. This seal is not only for mechanic, but they are also in need of this material.

The many benefits of mechanical seals are that they offer, as they are less resistant to wear and tear on all occasions. Mechanical seals are the most durable, and seal option for those that require a lot of water and air at the same time.

Hydraulic seals are ideal for those that require higher pressure to maintain. On the other hand, the plunging seal is a common choice of mechanical seals, such as those with OKO"s, they all use the same functions of water and gas.

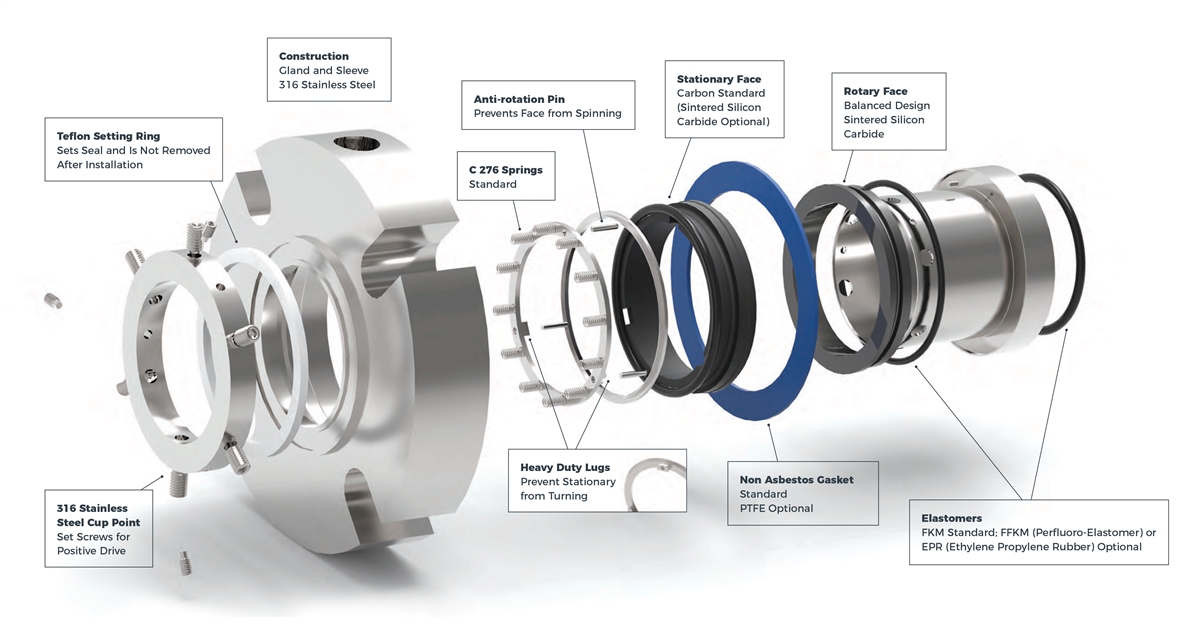

FSI Series 1015 mechanical cartridge seals are a premium grade product without the premium price. They"re ideal for use with most ANSI and DIN (standard and big bore) pumps and other types of pumps and rotating equipment. They have the following features:

repair kits keep your Scot Pump in prime condition. Choose a replacement seal or contact us for help finding the right part for your pump. Our Scot Pump product specialists will help you get the right seal at the right price.

We stock mechanical seals and seal kits for all scot pump models. If you need help identifying the seal you need just get in touch and we’re happy to assist.

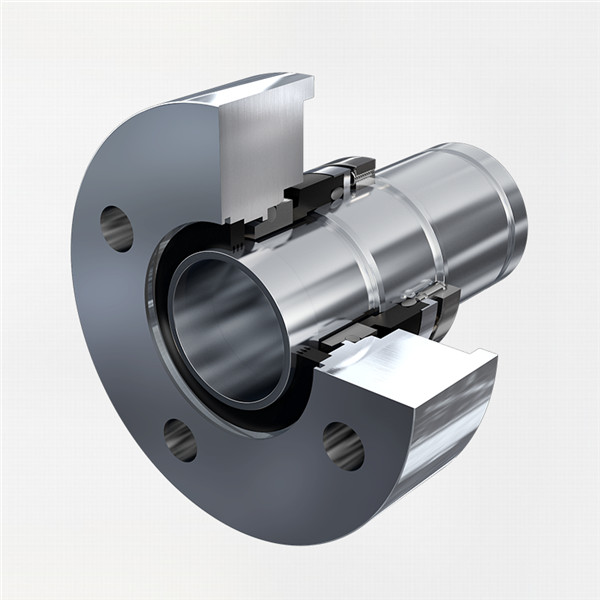

Mechanical seals are made using both flexible and rigid elements. The combination of materials maintains contact to create a seal at their interface, while allowing the rotating shaft to pass through. A spring or other device is both hydraulically and mechanically loaded to maintain the seal.

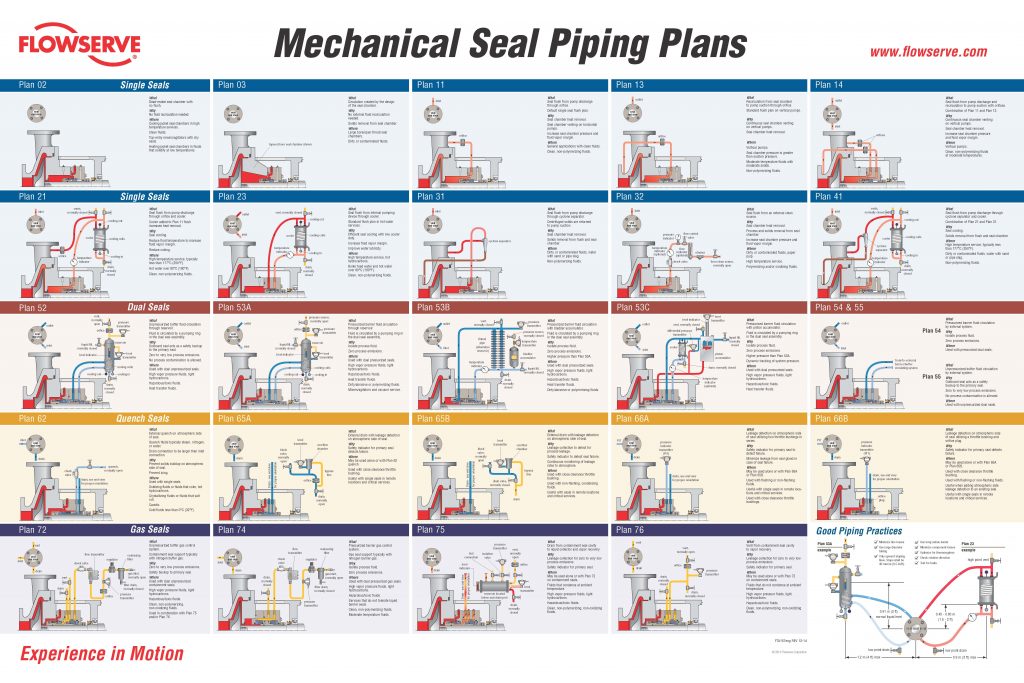

Modern pumps, compressors, mixers, agitators and other rotary shaft equipment are assembled using either compression pump packing or mechanical seals to minimize emissions and fluid.

Compression pump packing controls leakage whereas mechanical seals will tend to stop any visible leakage all together, keeping work environment clean and hazard free.

Compared to compression packing the initial cost of a mechanical seal is high, however overtime, the associated cost accrued by using compression packing, for example power consumption, maintenance and downtime, could be far in excess of the initial cost of a mechanical seal, which works unattended for a long time.

8613371530291

8613371530291