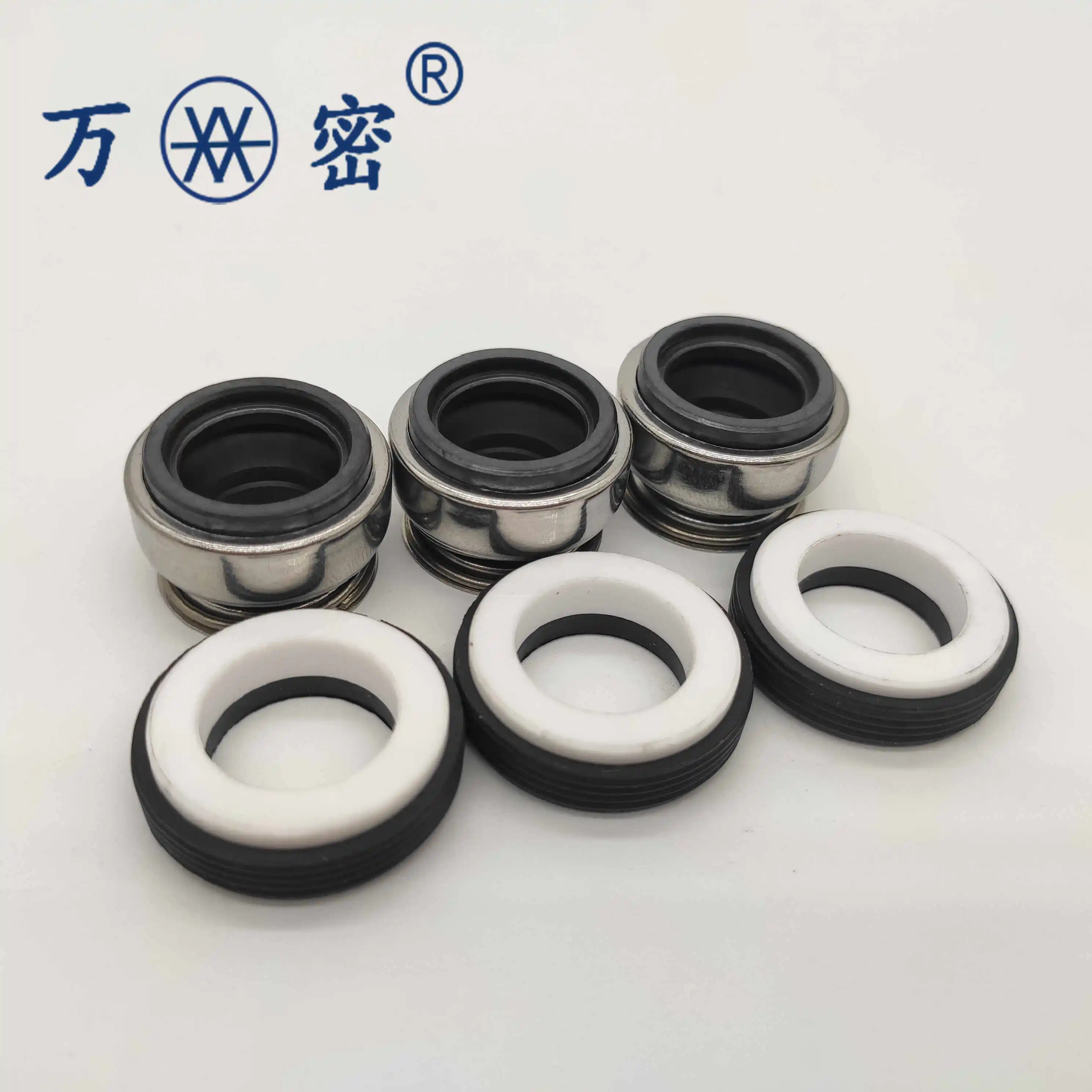

mechanical seal parts free sample

Back to back: Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

Face to face:The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Users can choose different material for this double mechanical seal 208, matching for different liquid conditoncarbon, silicon, and tungsten carbide for this mechanical seal as seal face, if for high temerperature, we suggest to choose rubber seal viton for the rubber parts.

Lepu seal make this dual mechanical seal for many years, and offer professional suggestion when client need this grundfos seal, so we are your reliable specialist for grundfos mechanical seal.

Double mechanical seals are commonly used in the following circumstances:If the fluid and its vapors are hazardous to the operator or environment, and MUST be contained

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

A dry gas seal is a revolutionary way of sealing machines and protecting them from dust, moisture and other contaminants. A dry gas seal is a sealing device that uses pressurized gas to keep two surfaces from touching. The most common type of dry gas seal is the O-ring, which is used in many applications, including mechanical seals, piston rings, and gaskets. Dry gas seals are also used in many other industries, such as the food and beverage industry, where they are used to seal containers and prevent contamination. This type of seal not only helps to keep the machine running with maximum efficiency but also significantly reduce downtime, making it cost-effective in the long run. In this article, we"ll explore what a dry gas seal is, how it works and why you should consider using it for your machinery. By understanding the benefits of a dry gas seal and its uses, you can make an informed decision about the best sealing system for your needs. How does a dry gas seal work?Dry gas seals work by using a series of labyrinths to separate the high pressure seal gas from the atmosphere. The labyrinths are formed by a series of grooves and ridges on the surface of the seal ring. The seal ring is rotated at high speed, causing the gas to flow through the labyrinths. The gas is then forced through an aperture in the center of the seal ring, where it escapes into the atmosphere. What is a dry gas seal used for?Dry gas seals are used on rotating equipment to help minimize the leakage of high pressure gases from the inside of the machinery. This helps to reduce maintenance costs and improve safety. Dry gas seals are commonly used in applications such as pumps, compressors, turbines, and blowers. Advantages of a dry gas sealThere are many advantages of a dry gas mechanical seal. One advantage is that they are much simpler in design than other types of seals, making them more reliable and easier to maintain. Additionally, dry gas seals do not require the use of any lubricating fluids, which can leak or evaporate over time. This makes them more environmentally friendly and cost-effective in the long run. Finally, dry gas seals have a much longer lifespan than other types of seals, meaning that they need to be replaced less often.Disadvantages of a dry gas sealThere are several disadvantages of dry gas seals, including: - they can be expensive to purchase and install- they require careful maintenance and regular inspection- they can be susceptible to wear and tear- they can leak if not maintained properlyHow to choose the right dry gas seal for your applicationThere are a few key factors to consider when choosing the right dry gas mechanical seal for your application. The most important factor is the type of fluid being sealed. Gas seals are designed to seal either liquids or gases, but not both. Make sure to choose a gas seal that is compatible with the fluid you are sealing.Another important factor to consider is the pressure of the fluid being sealed. Gas seals are rated for different maximum pressures, so make sure to choose one that can handle the pressure of your application.Finally, take into account the size and shape of the sealing surfaces. Gas seals come in a variety of sizes and shapes to fit different applications, so make sure to choose one that will fit your needs.ConclusionDry gas seals are an extremely important component for many industrial operations, and their ability to prevent leaks has made them invaluable in a variety of applications. Understanding the basics of how dry gas mechanical seal work and how they can be used effectively is helpful when considering the various options available for any specific application. With the right choice, dry gas seals can provide reliable, leak-free performance which will save time, money and resources while ensuring safety and reliability. Lepu dry gas seal manufacturer provides best quality flowserve dry gas seal and dry gas seal. Welcome to contact us!

Henan Dingmi Seal Co., Ltd is a professional manufacturer of high-quality oil seals and offers sealing solutions. Our factory with twenty years of experience .We offer full line of various products including standard and metric International standard oil Seals, seal repair kits , rod seals, piston seals wiper seals and non-standard parts. Professional OEM and ODM processing factory.We focus on maintaining the highest quality, lowest prices and all best services. There are ready items on stock or orderable items according to customer"s specific request. Our products are widely applied in automotive, mechanical engineering, stationary hydraulics, mobile hydraulics, pneumatics, fluid power engineering and electrical engineering, chemical industry, process engineering, oil and gas equipment, as well as agriculture industry.

We are the source manufacturer with 20 years of experience, producing and selling standard and non-standard seals of various materials.We are based in Henan, China.Our business covers more than 100 countries around the world.

We will provide online live technical support to solve problem. Our engineers can speak fluent English, Spanish, Japanese, Madarin and French. If there is any hardware problems, we can send the parts or components with teaching video.

With your inquiry you submitted a sample of the complete mechanical seal, as well as samples of two seal rings and a casing which are components of the seal. The seal, designated as part number 07904043800, basically consists of a spring, spring holder, sleeve, bellows, cup gasket, ceramic and graphite sealing rings, cartridge, and driving band. The seal is intended for use in an automobile water pump, and is designed to prevent coolant from leaking around the pump shaft as it enters the pump body. The tension exerted by the spring against the ceramic and graphite seal rings creates a mechanical seal while permitting high speed and slight off-axis rotation of the pump shaft.

The applicable subheading for the complete mechanical seal will be 8484.20.0000, Harmonized Tariff Schedule of the United States (HTS), which provides for mechanical seals. The duty rate will be 3.9 percent ad valorem.

In your letter you stated that the sintered carbide (graphite) sealing ring, the silicon carbide (ceramic) sealing ring, and the stainless steel case used in this mechanical seal are separately imported and then assembled domestically by your client. You suggested that these parts, when imported separately, should be classified in subheading 8484.90.0000, HTS. However, since heading 8484 does not provide for parts of mechanical seals or any of the other goods classifiable in that heading, we are unable to concur with your assertion.

The mechanical seal will be used as a part of an automobile water pump. Accordingly, the applicable subheading for the stainless steel case, imported separately, will be 8413.91.9010, HTS, which provides for parts of pumps of subheading 8413.30.90 (fuel, lubricating or cooling medium pumps for internal combustion piston engines: other). The rate of duty will be free.

Notes 1(a) and 1(b) to chapter 84 exclude graphite and ceramic articles from classification in any heading of chapter 84. The applicable subheading for the sintered carbide (graphite) seal ring, imported separately, will be 6815.10.0000, HTS, which provides for nonelectrical articles of graphite or other carbon. The rate of duty will again be free.

Your inquiry does not provide enough information for us to give a classification ruling on the silicon carbide (ceramic) seal ring when imported separately. Your request for a classification ruling should include information as to the type of ceramic (i.e., porcelain or stoneware) of which the seal ring is composed. In addition, you should provide an analysis from a certified laboratory indicating whether this article has a hardness equivalent to 9 or more on the Mohs scale. When this information is available, you may wish to consider resubmission of your request. We are returning any related samples, exhibits, etc. If you decide to resubmit your request, please include all of the material that we have returned to you.

Mechanical seals are essential in many industrial applications, including pumps, compressors, and agitators, as they prevent the leakage of liquids or gases. Mechanical seals consist of several parts, including a primary ring, a secondary ring, a spring, and other components designed to create a sealing barrier between two rotating surfaces. Mechanical seals are widely used in various industrial applications, including chemical, pharmaceutical, oil and gas, and water treatment, among others. The increasing demand for mechanical seals in various industrial applications, coupled with the growing demand for energy-efficient and long-lasting sealing solutions, is driving the growth of the mechanical seals market.

The demand for mechanical seals in various pumps and compressors applications is driving the global mechanical seals market. Using mechanical seals instead of packing reduces power consumption and extends bearing life. During the forecast period, the mechanical seals market is expected to be driven by the transition from packing to mechanical seals. Mechanical seals in pumps and compressors minimize system repair and operating costs while also ensuring leakage prevention and emissions mitigation. The global mechanical seals market is expected to be driven by an increase in the acceptability of mechanical seals by processing industries. Additionally, rising applications of mechanical seals in various industry verticals is also expected to fuel market growth.

MARKET SCOPEThe "Global Mechanical seals Market Analysis to 2028" is a specialized and in-depth study of the Mechanical seals Market with a special focus on the global market trend analysis. The report aims to provide an overview of Mechanical seals market with detailed market segmentation by type and industry. The global mechanical seals market expected to witness high growth during the forecast period. The report provides key statistics on the market status of the leading mechanical seals market player and offers key trends and opportunities in the mechanical seals market.

MARKET SEGMENTATIONThe global mechanical seals market is segmented on the basis of type and industry. On the basis of type the market is segmented as, cartridge seals, balanced and unbalanced seals, pusher and non-pusher, conventional seals and others. Further, On the basis of industry the market is bifurcated as, metals, mining, food and beverages, oil and gas, energy and power, construction and manufacturing.

The report provides a detailed overview of the industry including both qualitative and quantitative information. It provides overview and forecast of the global mechanical seals market based on various segments. It also provides market size and forecast estimates from year 2020 to 2028 with respect to five major regions, namely; North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America. The mechanical seals market by each region is later sub-segmented by respective countries and segments. The report covers analysis and forecast of 18 countries globally along with current trend and opportunities prevailing in the region.

The report analyzes factors affecting mechanical seals Market from both demand and supply side and further evaluates market dynamics effecting the market during the forecast period i.e., drivers, restraints, opportunities, and future trend. The report also provides exhaustive PEST analysis for all five regions namely; North America, Europe, APAC, MEA and South America after evaluating political, economic, social and technological factors effecting the mechanical seals market in these regions.

The reports cover key developments in the mechanical seals market organic and inorganic growth strategies. Various companies are focusing on organic growth strategies such as product launches, product approvals and others such as patents and events. Inorganic growth strategies activities witnessed in the market were acquisitions, and partnership & collaborations. These activities have paved way for expansion of business and customer base of market players. The market players from mechanical seals market are anticipated to lucrative growth opportunities in the future with the rising demand for mechanical seals market. Below mentioned is the list of few companies engaged in the Mechanical seals market.

The report also includes the profiles of key mechanical seals market companies along with their SWOT analysis and market strategies. In addition, the report focuses on leading industry players with information such as company profiles, components and services offered, financial information of last 3 years, key development in past five years.A.W. Chesterton Company

8613371530291

8613371530291