cartridge mechanical seal free sample

2. The product features low maintenance. No sealers or special polishes are needed. People can only use soap and water to maintain. Lepu seals are designed and manufactured rigorously

AES cartridge mechanical seal convertor II LP318 is designed to replace two-part component seals and conventional packing arrangements. This seal is a cartridge seal type with Short external length.

AES cartridge seal convertor made by lepu seal with a longer durable and resistance even running in bad environment, strong quality stainless steel for the cartridge seal frame, and high density silicon for the seal face, Viton rubber offer more resistance against corrosive medium.

As a leading mechanical seal manufacturer, Lepu seal factory make this AES cartridge seal for a long period, and sell this seal to hundreds of clients, 100% a right replacement for original AES seal.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

A dry gas seal is a revolutionary way of sealing machines and protecting them from dust, moisture and other contaminants. A dry gas seal is a sealing device that uses pressurized gas to keep two surfaces from touching. The most common type of dry gas seal is the O-ring, which is used in many applications, including mechanical seals, piston rings, and gaskets. Dry gas seals are also used in many other industries, such as the food and beverage industry, where they are used to seal containers and prevent contamination. This type of seal not only helps to keep the machine running with maximum efficiency but also significantly reduce downtime, making it cost-effective in the long run. In this article, we"ll explore what a dry gas seal is, how it works and why you should consider using it for your machinery. By understanding the benefits of a dry gas seal and its uses, you can make an informed decision about the best sealing system for your needs. How does a dry gas seal work?Dry gas seals work by using a series of labyrinths to separate the high pressure seal gas from the atmosphere. The labyrinths are formed by a series of grooves and ridges on the surface of the seal ring. The seal ring is rotated at high speed, causing the gas to flow through the labyrinths. The gas is then forced through an aperture in the center of the seal ring, where it escapes into the atmosphere. What is a dry gas seal used for?Dry gas seals are used on rotating equipment to help minimize the leakage of high pressure gases from the inside of the machinery. This helps to reduce maintenance costs and improve safety. Dry gas seals are commonly used in applications such as pumps, compressors, turbines, and blowers. Advantages of a dry gas sealThere are many advantages of a dry gas mechanical seal. One advantage is that they are much simpler in design than other types of seals, making them more reliable and easier to maintain. Additionally, dry gas seals do not require the use of any lubricating fluids, which can leak or evaporate over time. This makes them more environmentally friendly and cost-effective in the long run. Finally, dry gas seals have a much longer lifespan than other types of seals, meaning that they need to be replaced less often.Disadvantages of a dry gas sealThere are several disadvantages of dry gas seals, including: - they can be expensive to purchase and install- they require careful maintenance and regular inspection- they can be susceptible to wear and tear- they can leak if not maintained properlyHow to choose the right dry gas seal for your applicationThere are a few key factors to consider when choosing the right dry gas mechanical seal for your application. The most important factor is the type of fluid being sealed. Gas seals are designed to seal either liquids or gases, but not both. Make sure to choose a gas seal that is compatible with the fluid you are sealing.Another important factor to consider is the pressure of the fluid being sealed. Gas seals are rated for different maximum pressures, so make sure to choose one that can handle the pressure of your application.Finally, take into account the size and shape of the sealing surfaces. Gas seals come in a variety of sizes and shapes to fit different applications, so make sure to choose one that will fit your needs.ConclusionDry gas seals are an extremely important component for many industrial operations, and their ability to prevent leaks has made them invaluable in a variety of applications. Understanding the basics of how dry gas mechanical seal work and how they can be used effectively is helpful when considering the various options available for any specific application. With the right choice, dry gas seals can provide reliable, leak-free performance which will save time, money and resources while ensuring safety and reliability. Lepu dry gas seal manufacturer provides best quality flowserve dry gas seal and dry gas seal. Welcome to contact us!

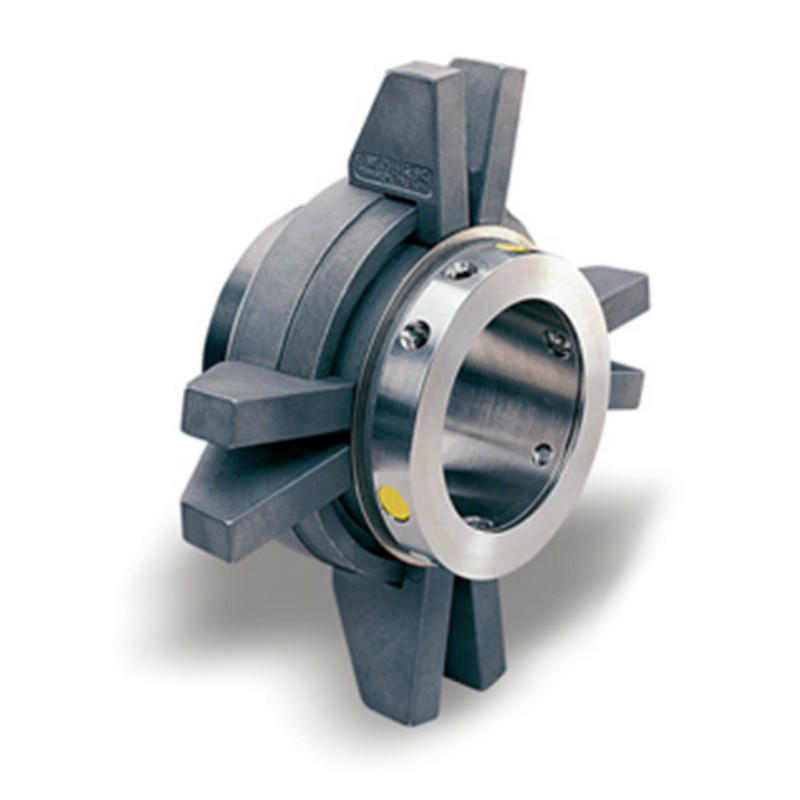

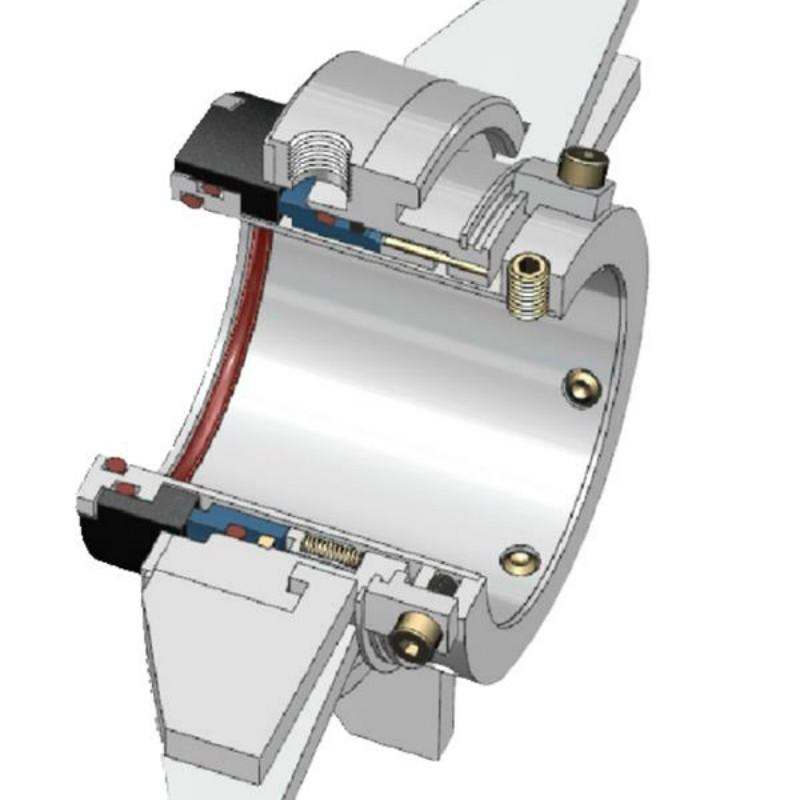

Chesterton is the world leader in design innovation of split seals. Our innovative split seals have been used to seal thousands of process-critical pieces of rotating equipment with exceptional results and many years of leak-free operations.

Chesterton was the first company to offer commercially-viable split seals for plant-wide use, which revolutionized pump sealing across industries. Since that time, we"ve launched a number of innovative split seal designs now used as a standard by companies around the globe. We offer shaft diameters ranging from 25-914 mm (1-36 in.)

A split seal has components split into two equal halves which are secured as one unit on the seal shaft. The major advantage of the split seal design is that it allows you to install the seal with no dismantling of the pump (or equipment)—an enormous time-saver! Chesterton"s split seals offer virtually leak-free performance. This leads to improved safety and environmental compliance and nearly eliminates sleeve wear, and flush water usage, among many benefits.

1.375" / 1.750" / 1.875" Shaft Diameter Type 98 Cartridge Seals are available for daily sales or exchanges. The WSC98 Cartridge Mechanical Seal is available with different Small Bore and Large Bore Seal Gland configurations to adapt to hundreds of different Centrifugal pumps.

The WSC15 Single Cartridge Mechanical Seal, an exclusive WSC design, fits every Allis Chalmers/RO-FLO Compressor without any modifications needed, with a low face load, worry-free installation approach and low face wear, the WSC15 cartridge Mechanical Seal

From standard materials, to top of the line abrasive resistant seal faces, these seals have been proven to out perform any OEM supplied mechanical seal in any market.

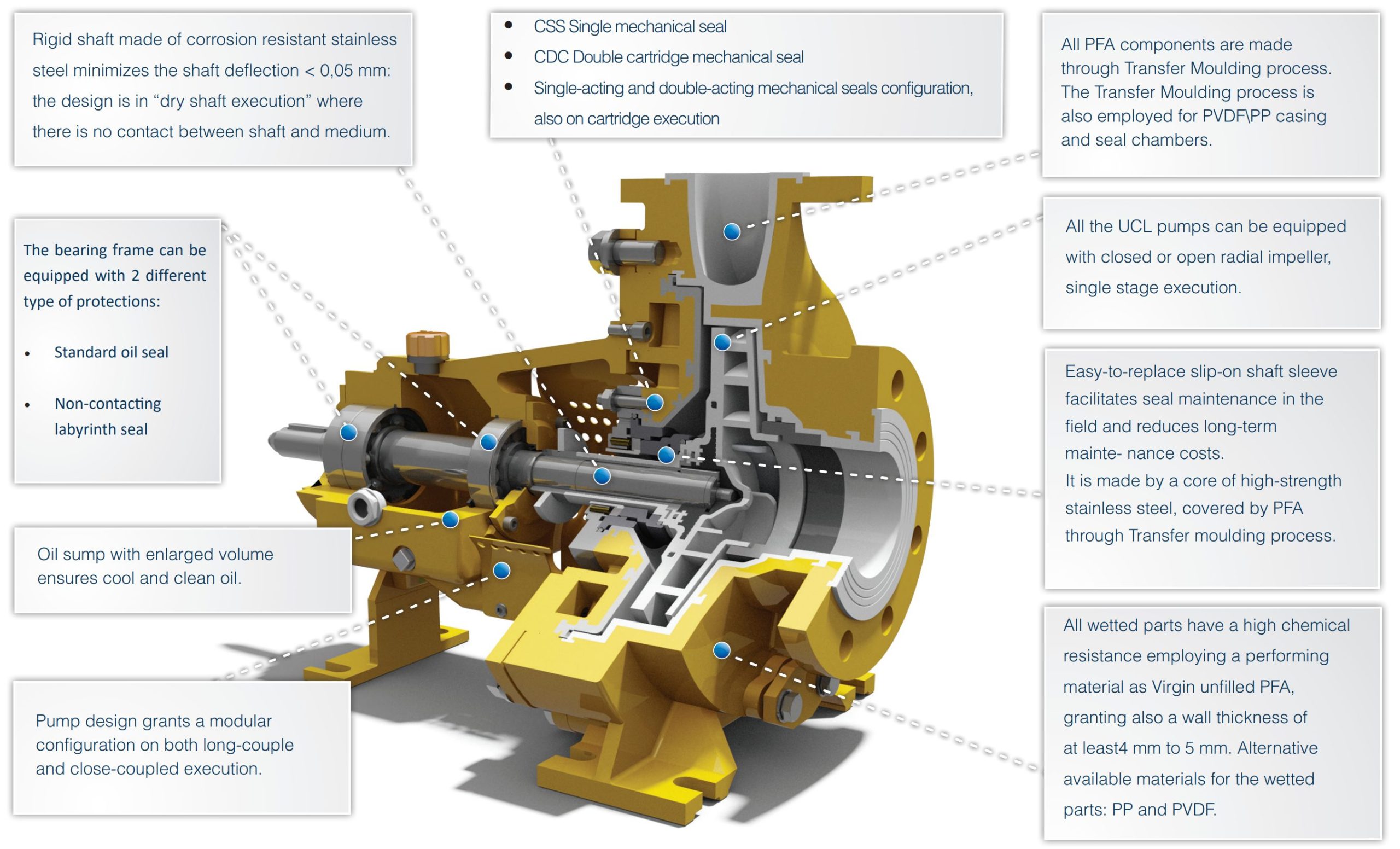

Modern pumps, compressors, mixers, agitators and other rotary shaft equipment are assembled using either compression pump packing or mechanical seals to minimize emissions and fluid.

Compression pump packing controls leakage whereas mechanical seals will tend to stop any visible leakage all together, keeping work environment clean and hazard free.

Compared to compression packing the initial cost of a mechanical seal is high, however overtime, the associated cost accrued by using compression packing, for example power consumption, maintenance and downtime, could be far in excess of the initial cost of a mechanical seal, which works unattended for a long time.

Cartridge seals are a modern alternative designed to eliminate common causes of component seal failure. Check pump unit for defects before installing a cartridge seal to avoid damage to seal parts.

Single cartridge or double cartridge seals are self-contained units comprised of a shaft sleeve, seal, and gland plate. Cartridge seals are fitted onto the pump shaft as a single unit with no further fitting or assembly required.

Zigong Ke Yu Seal Science and Technology Co.,LTD located in hightech industry of zigong city in sichuan province. We are large manufacturer and exporter of high pressure,high temperature, high speed mechanical seal. Our products widely used in KSB pumps, Grundfos pumps, Flowserve pumps, etc. And our mechanical seal can exactly replace original mechanical seal in sharpe agitator, ekato agitator, lightnin agitator, sardik agitator, mut agitator, mixpro agitator etc. We design and manufacture mechanical seal up to 60 bar, 3000rpm, 300C°in different material of constructions like ss316/316L,ss304, Sillicon Carbide, Tungsten Carbide, Carbon, Viton, NBR, EPDM ,PTFE, etc. From pumps to reactor for various application. We can also provide ODM and OEM precision machined parts according to your drawings or design requirements. For exmple,customized shaft, shaft sleeve, as well as a variety of high-precision, high request products. Materials that can be produced include stainless steel, titanium and any other metal material of different grade.

8613371530291

8613371530291