flowserve mechanical seal manufacturer

Siewert Equipment is the exclusive provider of Flowserve mechanical seals for Upstate, NY. Flowserve seals are the industry’s top choice for the most challenging environments. We offer a complete line of seals, including cartridge seals, dry-running seals, metal bellows, elastomeric bellows, mixer seals, split seals, and bearing protection devices.

The Flowserve company was registered in 1997, having already 230 years of experience in the field of fluid flow control, and is today a world-renowned corporation (represented in more than 50 countries around the world). Sealing technologies are an effective direction of the brand. Creating reliable products, Flowserve supplies mechanical seals and sealing systems for a variety of equipment – pumps, compressors, agitators, steam turbines, etc.

Micro Sealsis one of the leading specialists in the design and manufacture of Pump Mechanical seals, Seal support systems ,Sealing Components,and Rotary Unions/Rotary Joints for Pumps, Agitator, Reactors, Blowers, mixers, steam turbines and other rotary-motion equipment. For over 15 years we’ve been committed to designing and manufacturing sealing products and accessories of the highest quality. We leads the way in high-efficiency solutions using the latest technologies for maximum sealing performance.

Since 1959, Pioneer Equipment has served the Southwest United States with Flowserve mechanical seal solutions for pumps used in a wide range of commercial and industrial applications.

Based in Phoenix AZ, Pioneer Equipment, Inc. has stocking branch offices in three states and four metropolitan areas. For nearly sixty years, Pioneer Equipment has been a distributor and servicer of air compressors, pumping systems, and pumping system accessories. We carry a full range of Flowserve mechanical seal products and accessories at our branches in Phoenix and Tucson.

The use of the word “seal” is a misnomer; as a mechanical seal is a restrictive flow path,that is either an angular or radial gap.The flow through this gap is generally so low it goes unnoticed if a liquid or inconsequential if a gas.

A mechanical seal works byretaining a liquid or gas inside a rotating piece of equipment. Mechanical seals can be designed to prevent contamination of the process by the environment and prevention of leakage of the process into environment.

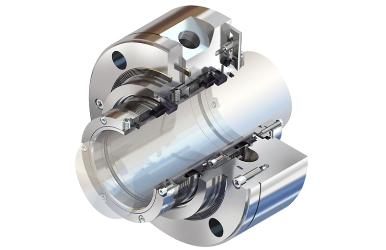

The basic components of a mechanical seal are a Rotating Part and a Stationary Part. The primary seal of a mechanical seal consists of a rotating face and a stationary face. The faces are kept lubricated by maintaining a thin film of fluid between each face. There is a very small gap between these 2 components which creates a restrictive flow path.

There are other components namely o-rings or gaskets which are used as secondary seals and hardware which is used to support the seal faces and to attach them to the rotating part (i.e shaft) and stationary part (i.e cover plate).

The primary seal of a mechanical seal is made up of 2 seal faces where these two parts meet is where the seal gap is located. The mating surface of the seal face is machined to a very tight tolerance.

Double Seal (Barrier) => consists of two primary seals in various arrangements. There is a barrier fluid between the two primary seals which is at a higher pressure than the process. There is always some leakage of the barrier fluid in process & out to atmosphere. As long as barrier pressure is maintained there is no leakage of process to atmosphere or contamination of process by environment.

Double Seal (Barrier) – Wet => is a double seal where the barrier is a liquid. It is generally the most robust seal. It has a good pressure, speed and temperature capabilities.

Gas Contacting Seal– the seal faces are in contact, the soft face wear acts as a lubricant. Low pressure, speed and temperature capabilities and possibilities of wear getting into the process.

Gas Non Contacting Seal – the seal faces are NOT in contact. They are kept apart by a flow of gas between the faces. Good temperature, speed and pressure capabilities. If operated correctly their is no wear but care must be taken in order to minimise shaft run out.

Cartridge seal =>is where the rotating and the stationary hardware are pre-assembled before mounting onto the pump/mixer. Cartridge seals are much easier to fit & maintain compared to the component seal.

A lip seal is a specific type of seal, it is a radial seal, where the part that seals against the rotating surface is a narrow cross section, soft material i.e the lip and it is made from an elastomer or non-elastomer material with a backup spring. Most commonly used to seal bearings in Mixers/Agitators. A lip seal rotates too quickly to be used on pumps.

Abarrier fluid is any gas or liquid which is used to pressurise a double mechanical seal. It must be compatible with the process, generally non-toxic and a good lubricant.

Please consult the pump manufacturer/distributor for guidance on these calculations for mixer seals, the barrier pressure is set at a certain value above the maximum vessel pressure.

Packing is a material that is stuffed between a rotating shaft and a stationary part gland to maintain pressure. Packing is a low cost alternative to mechanical seals.

We supply mechanical seals into the pharmaceutical, bio-technology, chemical processing, mineral and ore processing, semi-conductor and general industries.

Depending on your particular application, if you are looking mechanical seals to suit a pump application; Mechanical Seal for Pumps, or if you are trying to source mechanical seals for an agitator or tank mixer; Mechanical Seal for Agitator, or perhaps you have a hygienic application in mind, take a look at our range of Mechanical seal for Hygienic & Aseptic applications.

Our Mechanical Seal specialists can advise you on the appropriate selection of a seal support system which will deliver years of reliable service and operating cost savings in the longer term.

If you have any query around how to install mechanical seals or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running reliably again.

Flowserve seals are used on various rotating equipment, including pumps, compressors, mixers, steam turbines, and other specialty equipment, primarily in the oil and gas, pharmaceutical, chemical processing, mineral and ore processing, and general industries.

Being a prominent firm, we are engaged in manufacturing and supplying a distinct assortment of Flowserve Pump Mechanical Seals which is used in a wide variety of applications, our entire range of cartridge and semi cartridge seal is manufactured, keeping in mind the quality norms using optimum quality steel and leading techniques. We are giving this seal to our customers within a given time frame with numerous stipulations.

We also manufacture and supply KSB Pump Seals, Grundfos Pump Seals, Kirloskar Pump Mechanical Seals, John Crane Seals and Burgmann Seals as being top most replacement mechanical seal manufacturers in Mumbai as well as known as one of the most precise replacement seal manufacturing companies in India.

Flowserve is a company still going strong and has managed to keep their title amongst their peers as a world leader in the motor pump industry. Holding strong at 15,000 employees spread out throughout several countries, Flowserve has no plans of minimizing or cutting back their production. The merger between two companies formed what is now known as Flowserve; allowing for a stronger more experienced team.

Flowserve seals and other products are so diversified that this company’s products are used to meet the water flow supply needs of several industries. Listed below you will see a number of Flowserve Products and the history they have served and are still serving in.

Flowserve pumps have a history reaching back to 1790 when steam pumping engines were used and needed. Today Flowserve proudly boast of their specialty pumps and systems.

Flowserve seals have been produced over the last eighty years. Flowserve seals are known throughout the industry as being a trustworthy product that can assist in all sealing needs. The use of Flowserve seals can be found on various rotating application to help provide a safer and more efficient workplace as a result.

Flowserve valves are unique in that the company allows the customer the ability to customize the valve to whatever his or her water supply needs might be. The goal of Flowserve is to produce top quality valve that are able to endure their tough working environment effectively and efficiently.

Priest Electric offers mechanical seals sales and installation for Flowserve and many other trusted manufacturer brands. Call 208-459-6351 or Request a bid online

JCI Industries, Inc. is the exclusive provider of Flowserve Fluid Sealing Devices in Kansas, Western Missouri, and Nebraska. We offer a complete line of seals including cartridge seals, dry-running seals, metal bellows, elastomeric bellows, split seals and gas barrier seals for zero emissions.We also carry bearing protection devices and seal chamber auxiliary equipment.

We stock complete cartridge and component seals for all ANSI and API pumps, and maintain over $250,000 of seal related inventory. JCI’s seals specialist has 60+ years of experience, including seal application design & recommendation, seal failure analysis, and complete seal repair and installation.

Flowserve heritage product lines include BW/IP, Pacific Wietz, Durametallic, Five Star, and Pac-Seal. BW/IP was engineered API type seal, Pacific Wietz the gas seals came from, Durametallic and Five Star were the ANSI market seals and the Pac-Seal are for the OEM market.

In the past, external clean, cool fluid was used to lubricate seal faces or dual seals operating on clean barrier fluid. Now, the solution is to use Diamond Coated Silicon Carbide Faced Seal (UNCD) and let the process fluid itself lubricate the seal even with challenging applications.

Flowserve Mechanical Seal Piping Plan Flip Book – reference book that provides a concise summary of the most essential piping plans used successfully in today’s process plants. Each plan shows all the standard and optional auxiliary components referenced in API Standard 682

See improved performance of replacing John Crane Type 21 ™ with a Pac-Seal 21 utilizing a crimped-head rotary unit removing metal contact from the seal ring and preventing foreign material from collecting under the bellows.

Standard cartridge mechanical seals provide exceptional reliability and standardization in a wide variety of industrial applications and service conditions. ISC2 seals are designed to fit hundreds of pump and rotating equipment models from global manufacturers.

Application Guide: mechanical seals in product pipeline pumps, covering the transmission of crude oil and refined products such as fuel oils, gasolines, crude oils, and natural gas liquids (NGL), propane and ethane.

8613371530291

8613371530291