flowserve mechanical seal supplier

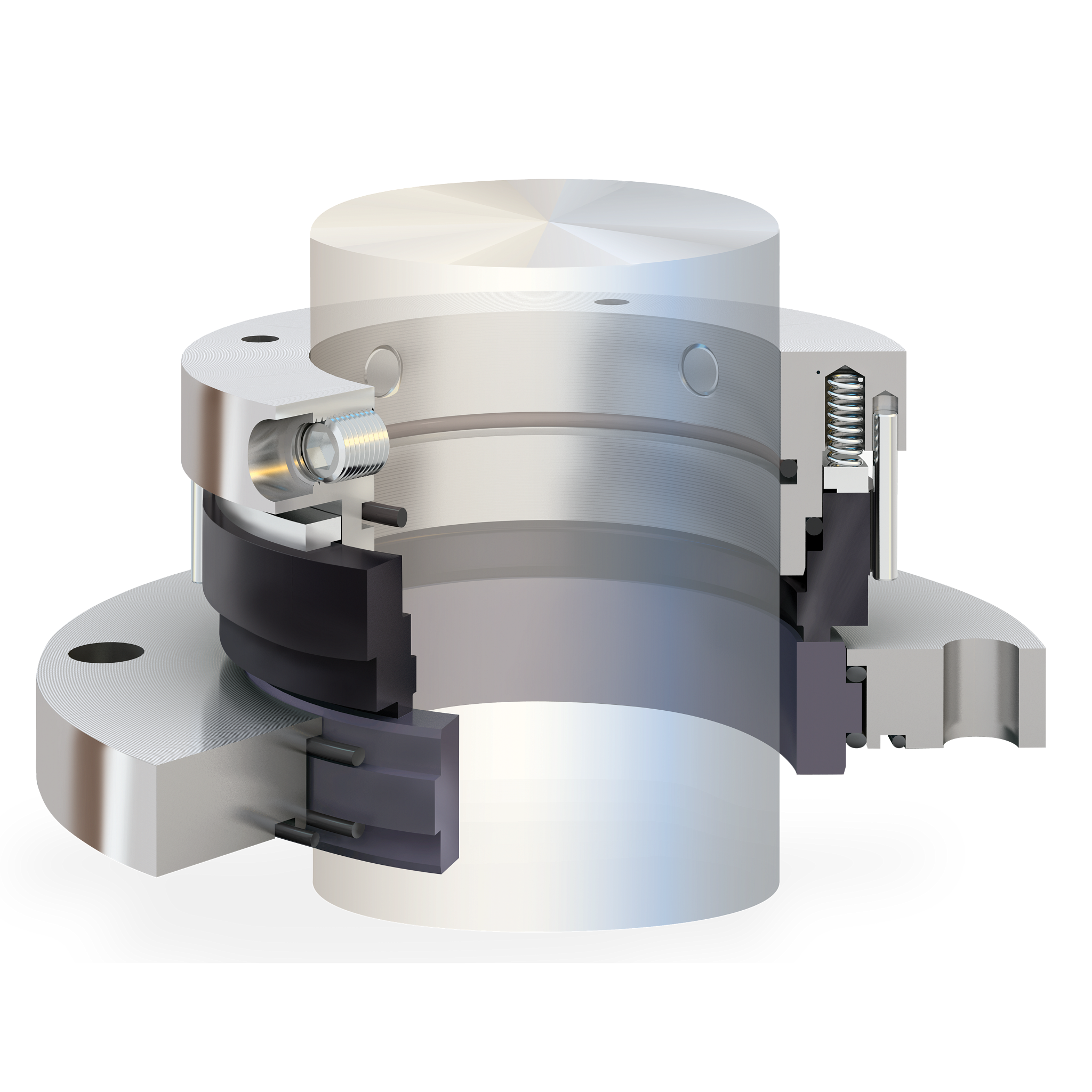

Siewert Equipment is the exclusive provider of Flowserve mechanical seals for Upstate, NY. Flowserve seals are the industry’s top choice for the most challenging environments. We offer a complete line of seals, including cartridge seals, dry-running seals, metal bellows, elastomeric bellows, mixer seals, split seals, and bearing protection devices.

Since 1959, Pioneer Equipment has served the Southwest United States with Flowserve mechanical seal solutions for pumps used in a wide range of commercial and industrial applications.

Based in Phoenix AZ, Pioneer Equipment, Inc. has stocking branch offices in three states and four metropolitan areas. For nearly sixty years, Pioneer Equipment has been a distributor and servicer of air compressors, pumping systems, and pumping system accessories. We carry a full range of Flowserve mechanical seal products and accessories at our branches in Phoenix and Tucson.

The Flowserve company was registered in 1997, having already 230 years of experience in the field of fluid flow control, and is today a world-renowned corporation (represented in more than 50 countries around the world). Sealing technologies are an effective direction of the brand. Creating reliable products, Flowserve supplies mechanical seals and sealing systems for a variety of equipment – pumps, compressors, agitators, steam turbines, etc.

Micro Sealsis one of the leading specialists in the design and manufacture of Pump Mechanical seals, Seal support systems ,Sealing Components,and Rotary Unions/Rotary Joints for Pumps, Agitator, Reactors, Blowers, mixers, steam turbines and other rotary-motion equipment. For over 15 years we’ve been committed to designing and manufacturing sealing products and accessories of the highest quality. We leads the way in high-efficiency solutions using the latest technologies for maximum sealing performance.

We take pride in having premium products of robust design that are manufactured from the best materials. The peak performance of Flowserve mechanical seals begins in the design stage. The unique Flowserve designs are a direct results of years of experience with customers’ varying shaft sealing applications. Today, utilizing the most sophisticated FEA and CAD equipment, we continue to analyze the most challenging problems and respond with a high-tech product line that meets our customers’ demands for seal solutions. Look to Flowserve to be a source for unique, cost effective designs for the mechanical seal market.

Amechanical seal is the most common type of sealing component used on pumps in modern industry. Replacing out packing over the last 50 or so years, they have served to drastically reduce industry emissions, energy usage and downtime globally.

A mechanical seal for pumps can be subdivided into variable options depending on the type/specific application/design components/location and mechanical seal characteristics;

The major advantage of a cartridge seal over a component seal is ease of installation. Incorrect installation is a major cause of seal failure, cartridge seals remove many of the problems associated with seal change-out in the field.

Slurry Seal – mechanical seal engineered to cope with a heavy slurry process – i.e. abrasive, corrosive and viscous. Can handle up to 60% slurrys by weight.

A Pusher Seal is where there is a spring element in the seal (used to maintain contact of the seal faces). Spring types include Belleville, multi-spring, etc. This type of seal requires a dynamic secondary seal.

A gas seal is a double seal where the barrier fluid is a gas – in pumps, this is usually a gas lift-off seal. In a gas lift-off seal the faces are not in contact while the machine is running. They are separated by a thin gas film (flow). If operated correctly they have very low wear.

The above seal types can be combined (though it is not always best to do so i.e. a component gas lift off seal would require very close collaboration between the machine and seal manufacturers to achieve a reliable installation).

There are many other options for mechanical seals, if you have any technical queries on other combinations not listed above, just contact one of our Mechanical Seal Specialists who will gladly discuss your application.

A mechanical seal flush is a piping set-up on a pump and seal assembly where a flow is induced in the seal chamber in order to improve MTBF of the mechanical seal. It is used to improve cooling, heating, remove solids and increase pressure (in combination with a neck or throat bush).

A mechanical seal quench is a piping set-up where a fluid is piped over the atmospheric side of a seal. It is generally used to prevent precipitation or crystallisation of a product or in some cases to aid cooling.

High Slurry process using Flowserve’s UNCD ® – Ultrananocrystalline diamond seal face technology. Flowserve UNCD ® coatings offer material properties and performance advancement over all other seal face materials.

Slurry seal design expertise applications which previously required double mechanical seals can now be reliably run by using single mechanical seals, saving costs of barrier fluid systems, the costs of the barrier fluid itself & the associated running costs. This reduces energy usage & carbon footprint.

If you have a technical query around the installation of mechanical seals for pumps or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

Being a prominent firm, we are engaged in manufacturing and supplying a distinct assortment of Flowserve Pump Mechanical Seals which is used in a wide variety of applications, our entire range of cartridge and semi cartridge seal is manufactured, keeping in mind the quality norms using optimum quality steel and leading techniques. We are giving this seal to our customers within a given time frame with numerous stipulations.

We also manufacture and supply KSB Pump Seals, Grundfos Pump Seals, Kirloskar Pump Mechanical Seals, John Crane Seals and Burgmann Seals as being top most replacement mechanical seal manufacturers in Mumbai as well as known as one of the most precise replacement seal manufacturing companies in India.

The welded metal bellow seals products make use of the durability, pressure resistance and uniform displacement include bellows seals and vacuum bellows in semiconductor or electronic parts manufacturing facilities, and have earned a reputation for high performance.

Flowserve is a company still going strong and has managed to keep their title amongst their peers as a world leader in the motor pump industry. Holding strong at 15,000 employees spread out throughout several countries, Flowserve has no plans of minimizing or cutting back their production. The merger between two companies formed what is now known as Flowserve; allowing for a stronger more experienced team.

Flowserve seals and other products are so diversified that this company’s products are used to meet the water flow supply needs of several industries. Listed below you will see a number of Flowserve Products and the history they have served and are still serving in.

Flowserve pumps have a history reaching back to 1790 when steam pumping engines were used and needed. Today Flowserve proudly boast of their specialty pumps and systems.

Flowserve seals have been produced over the last eighty years. Flowserve seals are known throughout the industry as being a trustworthy product that can assist in all sealing needs. The use of Flowserve seals can be found on various rotating application to help provide a safer and more efficient workplace as a result.

Flowserve valves are unique in that the company allows the customer the ability to customize the valve to whatever his or her water supply needs might be. The goal of Flowserve is to produce top quality valve that are able to endure their tough working environment effectively and efficiently.

Priest Electric offers mechanical seals sales and installation for Flowserve and many other trusted manufacturer brands. Call 208-459-6351 or Request a bid online

PusherPusher seals incorporate secondary seals, called the dynamic gasket, that are pushed by springs axially along the shaft or sleeve to compensate for seal face wear or wobble due to misalignment.

Bellows seals are very similar , but they use a welded metal bellows to achieve flexibility in the design. A bellows seal avoids the use of a "dynamic" gasket which can be very beneficial in specific applications.

Whether you have a slury liquid that requires economic value, standard application, or extreme service seals, Flowserve is uniquely positioned to provide solutions for virtually all slurry services.

Gas seal technology and gas seal operation depends on aerostatic and aerodynamic forces. Careful design keeps the two faces separated by a gas film. Aerodynamic forces are created by the presence of a "pattern" on one of the faces.

CompressorCentrifugal compressors and other turbomachinery are critical to the operation of a process plant. Selecting a manufacturer with well proven state-of-the-art low friction dry gas seals who can offer full field maintenance support is very important.

OEM & Special DutyOriginal Equipment Manufacturers (OEM"s) are very important for Flowserve FSD. Therefore Flowserve is committed to develop and supply designs for special equipment and for special duty requirements.

OutsideOutside mounted seals are used in strongly corrosive applications. This arrangement allows seal designs that have no metal parts in contact with the process liquid.

Standard cartridge seals such as the ISC seals are designed for general purpose applications on ANSI and DIN process pumps serving chemical processing, pulp and paper, oil and refining, food and beverage, water and wastewater, and other industries.

For optimum performance of mechanical seals, control over the sealing environment is very important. If the seal is kept clean and well lubricated by the product or barrier it will deliver years of reliable service.

Flowserve seals are used on various rotating equipment, including pumps, compressors, mixers, steam turbines, and other specialty equipment, primarily in the oil and gas, pharmaceutical, chemical processing, mineral and ore processing, and general industries.

8613371530291

8613371530291