single cartridge mechanical seal brands

Flexaseal offers a wide variety of single cartridge mechanical seals, each designed as a reliable solution for the toughest applications. Our single cartridge seals are easy to install and minimize the number of moving parts that can lead to equipment failure. Specially designed single cartridge seals are also available for highly corrosive or high-temperature environments. Cost-effective upgrades are available when circulation, vent, & drain glands are required.

Single cartridge mechanical seals are engineered to reliably operate in a wide range of temperature and applications. We partner with the industry-leading mechanical seal manufacturers such as — Flex-A-Seal — to deliver single cartridge seals that are engineered to withstand demanding fluid-handling applications. All of our single cartridge mechanical seals, regardless of application, are designed to provide extended seal life.

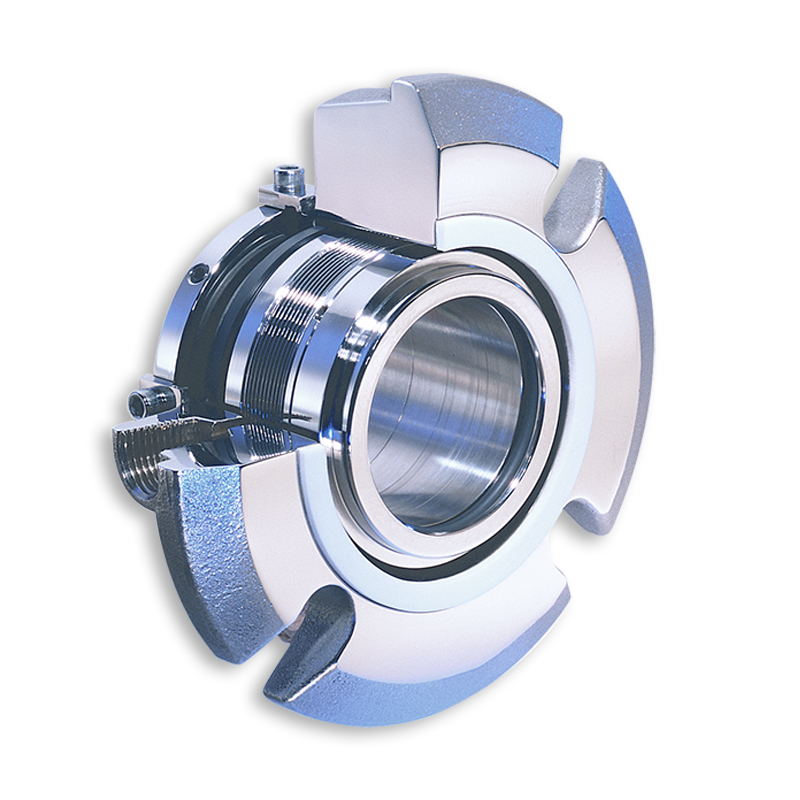

Anderson Process offers single cartridge seals that come in a variety of stationary and rotating configurations with various gland types such as, welded metal bellows, single spring, and multi-spring types. The single cartridge seals are a single piece, pre-assembled and preset by the manufacturer prior to installation.

With the many different options, we have a single cartridge seal available for your low/high temperature, corrosive, and heavy duty application. Elastomers include Viton®, Ethylene Propylene, Aflas®, Buna, Neoprene, and Perfluorelastomers. Faces come in Premium Grade Antimony Impregnated Carbon, Nickel Bound Tungsten Carbide, and Silicon Carbide. Single Cartridge models come in the following variations; rotating bellows, stationary multi-spring, stationary single-spring, stationary metal bellows, rotating multi-spring, rotating single-spring, high temperature rotating/stationary bellows, heavy duty API stationary multi-spring and standard/large/taper-bore options.

Flexaseal offers a wide variety of single cartridge mechanical seals, each designed as a reliable solution for the toughest applications. Our single cartridge seals are easy to install and minimize the number of moving parts that can lead to equipment failure. Specially designed single cartridge seals are also available for highly corrosive or high-temperature environments. Cost-effective upgrades are available when circulation, vent, & drain glands are required.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Style 57 design serves to keep the sealing faces in contact and positively transmits the drive evenly 360° around the full circumference of the rotary face. This is accomplished by the special spring design, which provides an interference fit. The compression spring is wound either right or left hand depending on shaft rotation.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Stationary design accommodates higher shaft-to-stuffing box misalignment. The stationary bellows design only flexes once during installation unlike a rotating design which flexes on every revolution. This reduces face movement and increases seal life.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

These two single cartridge seals are engineered for the most demanding corrosive applications. By minimizing the number of troublesome O-rings and eliminating any media exposure to the sleeves and glands, we have produced two very cost effective solutions to industries’ toughest applications.

In highly corrosive conditions that require expensive upgrades to higher alloy metals like duplex stainless steel, Alloy 20, Hastelloy® C276, the PH seals are an ideal economical solution. Only the wetted parts need to be constructed of these alloys while the larger metal parts such as the gland and sleeve can be 316 stainless steel since they are located out of the product

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

API compliant with piloted gland to positively center seal assembly and metal-to-metal confined gland gasket which prevents blow out or extrusion of the gland packing

Multi-point injection feature available which ensures maximum uniformity of cooling around the entire circumference of the sealing faces, thus eliminating face distortion due to uneven cooling. Ideal for boiler feed and light flashing hydrocarbon services.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Conventional pump stuffing boxes were originally designed to accommodate packing materials. Over the years mechanical seals edged out packing as a preferred sealing method, however stuffing boxes essentially remained the same. This situation posed complications for the effective operation of mechanical seals including installation issues, potential damage from abrasive product, and poor dispersion of seal-generated heat.

The ANSI Standard ASME B73.1 Specifications for Horizontal End Suction Centrifugal Pumps for Chemical Process includes specifications to improve the reliability and safety of the B73.1 pump design. One major specification focuses on cylindrical (big bore) and self-venting (tapered bore) seal chambers. Both of these seal chamber designs address the issues that plagued conventional pump chambers by providing additional radial clearance for mechanical seal operation and for increased liquid circulation around the seal, enabling the seal to run cooler and longer.

Only two (2) static elastomers – eliminate seal failures caused by dynamic O-ring “hang up” and offers cost savings when upgrading to Perfluorelastomers

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

... pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact cartridge that fits ANSI ...

Specially designed for applications where flush circulation is useless or prohibited, CARTseal B 24610 PP offers all the internal proven benefits of CARTseal B 24610 on a thinner ...

... Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge ...

• Static grafoil gaskets;• Temperatures up to 425 ºC;• Inconel bellows available;• Cartridge easy to install;• Metal bellows provide better faces alignment;• Does not have dynamic gaskets;• Self-cleaning;• Adapts to API ...

The Cartridge mechanical seal is manufactured by Chinabase Machinery (Hangzhou). The product is composed of stationary, made of U1, Q1, Q2, U2, rotary which is made of A, Q1, Q2, U2, ...

The Mechanical Seal, manufactured by Chinabase Machinery, is designed with the PT05 and PT07 version. The PT05 is utilized in SHARPE blender, Chemineer blender and KATO blender of smog desulfurized tower ...

The MTM600 is the series of cartridge mechanical seals for general applications perfectly interchangeable with all other cartridge solutions existing on the market.

... MTM351), a single seal with a floating bearing inserted (MTM352), cartridges seal with double seal (MTM361) and double seal with the floating bearing ...

... agitators on sealed tanks will have a mechanical seal of some sort. For many sanitary process vessels, the mixer must have some type of sealing barrier to provide either a dust tight vapor seal, ...

The 3-D Seal is designed to be the foremost solution for high radial misalignment and high run out applications. By combining Garlock’s proven P/S®-II and ...

Aura™ reduces operational and transactional costs using a patented polymeric sealing device. Aura reduces leakage rates by up to 15 percent, lowering the total cost of operation while protecting the environment. An enhanced rotor design ...

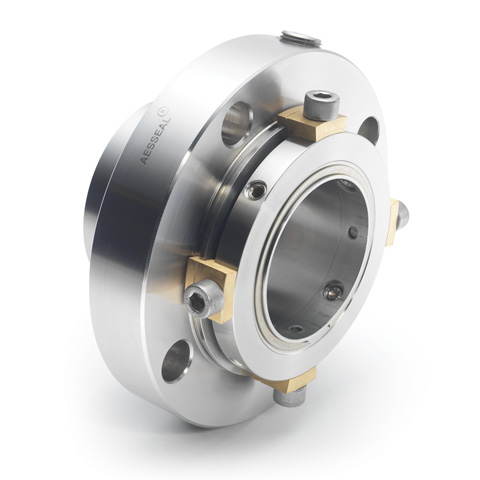

The AESSEAL® API Type A, B and C single-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application ...

This Chesterton® single cartridge seal offers you the ultimate in seal quality, flexibility, and convenience. ...

Cartridge Seals by CinchSeal are customized mechanical seals for rotary air locks in bulk handling equipment. They are designed to replace lip and packing seals ...

Single sealAvailable for standard and big bore(CMS-ASPN) seal chambersBalancedCartridgeIndependent of direction of rotationSingle seals with flush (-ASPN, -ABPN)and with quench combined with lip seal(- ...

We provide our range in readymade unit, which is easy for installation with saving of time. These Cartridge Mechanical Seal are ready to install on any type of clear liquids. Such seal do not require adjustment in fitting due to factory pre-assembly hence avoid installation problem. The seals we offer are used as absolute leak proof sealing and effective against toxic, hazardous and volatile fluids. Known for their unmatched quality, chemical resistance and uniform shaft diameter, these seals are demanded in food, chemical and petrochemical industries.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

John Crane offers a wide range of standard cartridge seals that are versatile and easy to install, suit a wide range of duties and are commonly used in applications in the chemical, pulp & paper, power, food & beverage, mining, water/wastewater and general industries.

Designed to fit standard ANSI, DIN and ISO seal chambers they can also be used in a variety of rotary equipment. Our standard cartridge range provides you with reduced installation times, lower maintenance costs and optimal equipment performance.

A&S Seals Co., Ltd is a global supplier of Chesterton Mechanical Seals 150 Single Cartridge Mechanical Seal, Chesterton 150 Single Cartridge Mechanical Seal , Cartridge Seals Series, Chesterton Mechanical Seals and many more. focusing on the various brands of seals supply.

![]()

A single cartridge type mechanical seal consists of two very flat surfaces that are pressed together by a spring and slide against each other. The single mechanical seal is a mechanical seal composed of 1 set of seal face. the sealing structure is simple, easy to manufacture and install features. Generally, cartridge type mechanical seal is used for the medium with good lubricity and allows a slight leakage. Single cartridge seals are one of the most commonly used centrifugal pump seal types. Single cartridge pump seals do not work well when the media is the toxic, flammable, explosive and strict requirement of leakage.

Mechanical seals tend to leak a vapor from the high-pressure side to the low-pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it"s common practice to use a single cartridgemechanical seal if the pumped product poses little to no risk to the environment.

When a single cartridge seals used in the oil-filled motor, it is not only necessary to prevent the machine outside the impurities, sandandwater to enter, but also to prevent the leakage of oil within the machine, so sealing requirements is higher, sealing ring material requirements need to be good, its sealing face material is made of tungsten carbide or silicon carbide. If it is installed on the shaft of the water-filled motor shaft, it only requires sand control. The sealing ring can be made of alumina ceramic, silicon nitride or other harder materials, so the cost is relatively low.

The installation error rate of the Common non-cartridge mechanical sea is higher than the cartridge mechanical seal. Therefore, use cartridge shaft seal can greatly reduce the occurrence of mechanical seal failure.

Since the cartridge mechanical seal does not require any adjustment of the mechanical seal by the installer (such as spring, sealing surface, etc.), only the bolts need to be tightened, which greatly improves the reliability of the mechanical seal installation.

Micro Seal is professional manufacturer of Cartridge Mechanical Seal in USA. We design and manufacture cartridge mechanical seal in USA mainly for the oil & gas, chemical, pharmaceutical, pulp & paper, power, mining and many more industrial applications. Manufacturer of Cartridge Mechanical Seal - Double Cartridge Mechanical Seal, Single Cartridge Mechanical Seal, High Pressure Cartridge Mechanical Seal in USA.

8613371530291

8613371530291