mechanical seal distributor price

We recognize and understand the vital role of mechanical seal price in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale mechanical seal price in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider mechanical seal price requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Siewert Equipment is the exclusive provider of Flowserve mechanical seals for Upstate, NY. Flowserve seals are the industry’s top choice for the most challenging environments. We offer a complete line of seals, including cartridge seals, dry-running seals, metal bellows, elastomeric bellows, mixer seals, split seals, and bearing protection devices.

Hayes Pump distributes the vast selection of John Crane mechanical seals. The range of seals available includes high performance, low emission petroleum seals, vessel and agitator seals, heavy-duty slurry seals and a variety of elastomer, formed and metal bellows seals suited to numerous applications. Hayes Pump is a factory-trained, stocking distributor for John Crane and provides local support and inventory.

John Crane has a strong legacy that dates back to the creation of the Crane Packing Company in 1917. Innovators from the start, John Crane designed the world’s first automotive mechanical seal in 1949. The groundbreaking design was soon followed by the development and introduction of the John Crane Type 1, end-face, elastomer bellows shaft seal. This patented product revolutionized sealing technology and is still one of the most widely used seals in the industry. Today, they are part of Smiths Group.

Hayes Pump carries the widest selection of seals in the market. We have the right solution for virtually any application. We will deliver unequaled performance, reduced installation times and lower maintenance costs. Rapid shipments are available from our stocked warehouse.

Dry Gas Mechanical Seals are non-contacting, dry-running mechanical seals and are designed to not contaminate a process. These seals are optimal for harsh working environment such as oil exploration, extraction and refining, petrochemical industries, gas transmission and chemical processing.

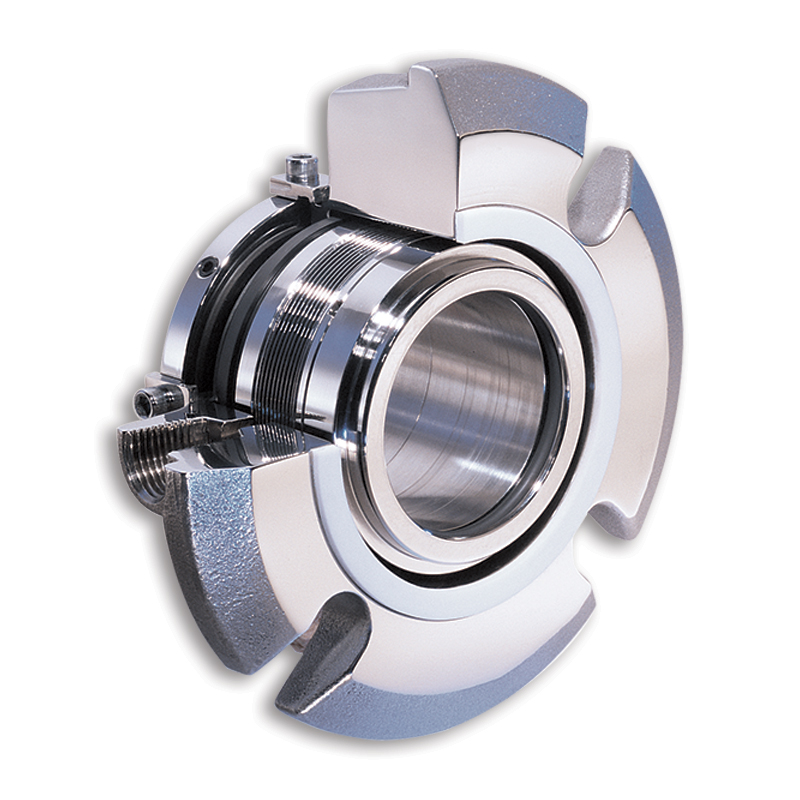

Metal Bellows Mechanical Seals allow for higher flow rates and less clogging than traditional spring seals. Bellows technology creates a uniform outside wall for uniform movement under hydraulic pressure. These seals are known for their reliability, tight tolerances, and compatibility with harsh media in pump systems.

PTFE Bellows Mechanical Seals are engineered for maximum reliability in extremely corrosive applications such as high concentrations of acids, salts, strong oxidizing and reducing agents and chemically active organic compounds.

Split Mechanical Seals use the latest modular split seal technology from John Crane. This combines the unique design requirements for wet-running and dry-running services onto one common seal platform.

Elastomer Bellows Mechanical Seals are widely recognized as the industry’s workhorse and suitable for a wide range of service conditions ranging from water and steam to chemicals and corrosive materials.

PTFE Wedge Mechanical Seals are used on corrosive applications, typically for chemical or hydrocarbon processing. Choices range from graphite-based wedges for corrosion resistance or high-temperature applications to DIN seals for general, low, medium and high pressure duties. Alternative seat designs options are available to suit product and operating conditions of applications.

Vessel and Agitator Mechanical Seals range from single Dry-running Mixer and Agitator Seals suitable for explosive atmospheres to Modular, high-performance, Agitator seals for glass-lined vessels. John Crane’s DIN vessel seal family has been specifically designed to suit all DIN vessel and agitator applications for the chemical and pharmaceutical industries.

Labyrinth Mechanical Seals are known for their long life and lack of friction to help prevent leakage. Many gas turbine engines, having high rotational speeds, and pistons use them to store oil and seal against high pressure.

O-Ring Pusher Mechanical Seals range from single cartridge pusher seals designed to help prevent emissions leakage in most refinery applications. Additional high-performance, low-emission cartridge seals designed to provide additional safety for hazardous to the Type 8B1 design which has been the preferred choice for safe, reliable, un-pressurized tandem and pressurized dual seal arrangements in petroleum services for more than four decades.

Slurry Mechanical Seals are designed to operate in the harshest abrasive slurry environments. These seals have unique design features allowing seal to operate without a flush, reducing total cost of ownership.

Backed by rich industry exposure, we are engaged in offering an extensive range of Mechanical Seals. The offered range of product is made from the optimum quality material under the assistance of best industry experts and is highly acclaimed for its accuracy, durability, reliability and longer service life. Further, our clientsread more...

Expert Gasket & Seal is an authorized distributor for Advanced Sealing International cartridge seals that are made in the USA. Expert Gasket & Seal can help customize solutions for even the most unique specifications or applications. Our seal line includes:

Our Encore Express Repair Program for ASI’s standard ANSI cartridge seals provides a precision factory rebuilt seal at substantial savings. The seal repair cost is 60% of a new seal, even if the old seal is scrapped. You will receive a new seal at the repair cost for the life of that seal should your old seal be unrepairable. ASI seals are serial numbered for traceability. The Encore Seal, repaired or replaced, is shipped within 3-5 days of arrival at ASI’s Baton Rouge LA facility.

Our Competitor Swap Program: Trade in a competitor seal and the ASI replacement seal is discounted 15-20% from list price. Purchase a new seal for little more than the cost of an average seal repair.

Expert Gasket & Seal provides the right seal for your application, whether a component seal from Apex Sealing, or a state-of-the art cartridge seal from Advanced Sealing International.

Lepuseal have more than 20 years experience in manufacturing mechanical seal, we established a strong technology team include 20+ engineer R&D team, more than 150 skilled workers team, more than 10 person quality control team, that help us to provide strong technology support to our users.

Various types of textile seals for used to yarn & fiber dyeing plants & cloth dyeing application plants, high speed jet dyeing plants, Specially designed U1951 type seal used for diaphragm elastomer to normal pressure machine like a mercerizing machine & pretreatment machine (Benninger -Make) for used different type of caustic & acidic media. In one machine required two pairs of diaphragm seals to fit opposite side of machine.

Located in Fountain Inn, SC, we are known for our pump expertise, application understanding, knowledge of mechanical sealing technologies, and stocking philosophy. Operating from a 2,790 sq ft office and a 5,551 sq ft. stocked warehouse, we have a substantial customer base in the area and are continuing to grow.

Pump South, Inc. was formed and incorporated in 1997, with the singular goal of providing customers with quality parts, pumps, and service at a competitive price from local inventory. As other companies reduced inventory levels in the region, we saw the need locally for a stocking distributor of pumps, pump parts, and mechanical seals. Through hard work and the addition of key sales people and other employees over the years, Pump South, Inc. now represents over 15 pump lines and has approximately $1 million in new inventory.

Over the past several years, Pump South has worked hard at improving its repair and overhaul capabilities. We are now equipped with a jib crane, enhanced compressed air capabilities, on site sandblast cabinet, air test jigs, and several full-time mechanics on staff. We can handle many overhauls, break downs, and repairs on multiple size pumps and agitator/reactor seals at our location. We use laser optical alignment on our motor and pump skids, and offer on-location laser alignment upon request. Don’t send your pump/seal to some unknown factory location, only to wait weeks for a response.

At Pump South, we will break your pump down, analyze the possible failure point, quote repair pricing, and handle the entire repair directly from Fountain Inn, SC. We can also do some mechanical seal repairs on site, in emergency situations. We may not be able to do every repair in our shop, but the repairs we do will be fast, reliable, and first quality. In addition to several full time mechanics on staff, Pump South maintains a dedicated sales team in Fort Mill, Moncks Corner and Saluda, SC, standing by and ready to serve our valuable customers throughout the Carolinas.

Having a definite quality administration system, we are providing a comprehensive assortment of Mechanical Seal to our customers. Valued for their perfect finish, sturdy built and longer life; these are hugely commended. Along with this, the offered product is designed by hard-working engineers, who ensure to comply it with the industry laid standards and norms. The offered product is extremely praised by our clients all over the country. Also the customers can avail these at affordable rates from us within the assured time.

Flexaseal has grown from a small manufacturer to an industry leader at the forefront of sealing solution technical advances, including the development of the world’s first patented two-piece split cartridge mechanical seal. Today, our distributors cover over 30 countries and our operations include locations in Vermont, Louisiana, Texas, and Brazil. For four decades, we’ve remained committed to our mission to produce the highest quality products and provide the best customer service in the world.

8613371530291

8613371530291