mechanical seal manufacturers in usa in stock

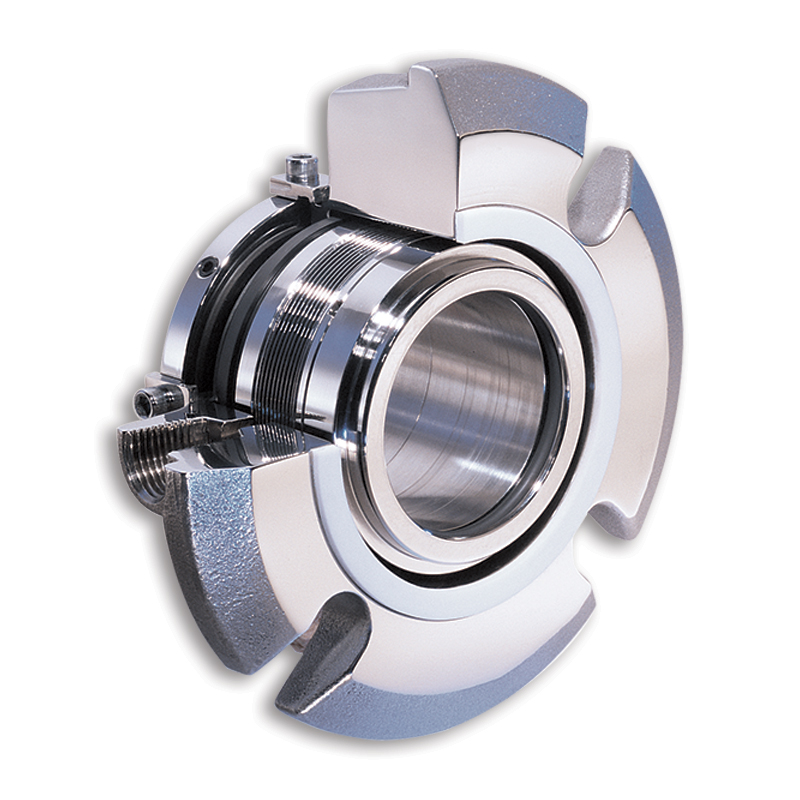

Mechanical seals are intended for applications in which a rotating shaft and its housing are under a state of stress, including a combination of high pressure, temperature, and speed.

Most mechanical seals are specially designed to prevent leaks in particular applications and cannot be interchanged with those seals used in other mechanisms. A piston seal, for example, cannot be used as a flange gasket; they are shaped differently, made out of different materials, and feature different mechanical properties of a given mechanical seal always depends on the conditions in which it will be applied.

Also, depending on the narrowness or broadness of a given understanding of the words “mechanical seal,” certain kinds of seals may or may not qualify. Simple plastic lids qualify by the broadest definitions, while some of the strictest definitions might only include seals applied in industrial process equipment or in heavy machinery. In either case, mechanical seals perform the same task: to isolate and contain materials in an enclosure.

Correctly pairing seals with their applications is essential to the safe and effective use of the equipment in which they are installed. For example, Teflon is often chosen for use in hydraulic cylinders because it is resistant to corrosion induced by exposure to hydraulic fluids. Natural rubber, on the other hand, may degrade when exposed to such chemicals. The decision to employ a given seal material should always be chosen carefully; this will ensure sustained effective and safe operation of the seal and the equipment it protects.

ISO 9001:2015 certified. Custom manufacturer of abrasion, acid, alcohol, alkali, oxidation, ozone, radiation, sunlight and water resistant rubber and plastic O-ring seals. Made from EPDM, butyl, fluoroelastomer, fluorosilicone, natural rubber, neoprene, nitrile, NBR, HNBR, SBR, silicone, high tear strength silicone, TPR, TPU, TPE, thermoplastics and polyurethane. Capabilities include injection molding, die cutting and prototyping. Assembly and PTFE coating additional services are also provided. Serves the aerospace, automotive, commercial, construction, dental, electrical, food handling, laboratory, marine, mining, municipal, oil and gas, recreational, retail, transportation and wastewater industries. Meets ASTM and SAE standards. Six Sigma certified. JIT delivery. Overseas sourcing options also offered.

We specialize in hard-to-find seals and demanding applications. Our extensive network of resources enables us to locate the right manufacturer and part, every time.

At All Seals we know down time is not an option. We specialize in hard-to-find seals and demanding applications. With over 40 years of experience in supplying quality replacement mechanical seals, we can help you identify the seal you need and solve your sealing problem. Our technical staff is available to help you – just give us a call. Our comprehensive stock of components ensures that we can build almost any seal combination for same day shipment. Whether you need a new seal or you have a seal to be repaired, we welcome the opportunity to help you with your rotary sealing needs.

We carry a comprehensive inventory of mechanical seal components, which allows us to build the right seal for your application. We’ll even design custom seals for one-of-a-kind applications.

Our goal is to make your repair easy without compromising on quality. Repair kits greatly reduce costly downtime, saving costs while sustaining production. Our pump rebuild kits are supplied with the same components you’ll find in an OEM kit; however, we offer them at a fraction of the price.

Need hard faces or specialty elastomers? Give us a call. We can quickly build a repair kit to withstand any medium being pumped. You’ll find All Seals’ pump repair kits an invaluable part of your operation.

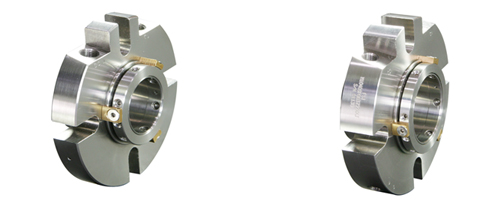

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

Mechanical seal varieties are used to prevent the unwanted release of pressure, lubricants, hydraulic fluids and other properties of a system that makes use of them. Seals are also used to prevent the contamination of those systems by dirt and other hazards. Equipment like agitators, mixers, gas seals, pumps, valves, actuators and many other kinds of machinery all involve the use of some variety of mechanical seal.

In addition to preventing leaks, mechanical seals also keep contaminants from entering and help to maintain pressure levels. Piston seals, flange gaskets and diaphragm seals are also kinds of mechanical seals, and they are all essential to the functioning of certain kinds of equipment.

Most mechanical seals are specially designed to prevent leaks in particular applications and cannot be interchanged with those seals used in other mechanisms. A piston seal, for example, cannot be used as a flange gasket; they are shaped differently, made out of different materials and feature different mechanical properties. The shape, size, and composition of a given mechanical seal always depends on the conditions in which it will be applied.

Also, depending on the narrowness or broadness of a given understanding of the words "mechanical seal," certain kinds of seals may or may not qualify. Simple plastic lids qualify by the broadest definitions, while some of the strictest definitions might only include seals applied in industrial process equipment or in heavy machinery.

In either case, mechanical seals perform the same task: to isolate and contain materials in an enclosure. Correctly pairing seals with their applications is essential to the safe and effective use of the equipment in which they are installed. For example, Teflon is often chosen for use in hydraulic cylinders because it is resistant to corrosion induced by exposure to hydraulic fluids.

Natural rubber, on the other hand, may degrade when exposed to such chemicals. The decision to employ a given seal material should always be chosen carefully; this will ensure sustained effective and safe operation of the seal and the equipment it protects.

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

Our NUTECH cartridge mechanical seals are designed to fit all ANSI pumps for ease of installation and are pressure tested at our Texas manufacturing facility prior to shipping. We can custom design any cartridge style seal to fit your most demanding applications. We use premium grade materials of construction throughout. All seals are made in the USA.

Seals Unlimited Inc. is the leading supplier of American-made mechanical seals and rebuild kits. We stock over 15,000 seals and serve all industry professionals. Seals Unlimited Inc. has been family owned and operated since it opened in 1980. Learn more about Seals Unlimited Inc.

Seals Unlimited Inc. is the leading supplier of American-made mechanical seals and rebuild kits. We stock over 15,000 seals and serve all industry professionals. Seals Unlimited Inc. has been family owned and operated since it opened in 1980. Learn more about Seals Unlimited Inc.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Power machines that have a rotating shaft, such as pumps and compressors, are generally known as “rotating machines.” Mechanical seals are a type of packing installed on the power transmitting shaft of a rotating machine. They are used in various applications ranging from automobiles, ships, rockets and industrial plant equipment, to residential devices.

Mechanical seals are intended to prevent the fluid (water or oil) used by a machine from leaking to the external environment (the atmosphere or a body of water). This role of mechanical seals contributes to the prevention of environmental contamination, energy saving through improved machine operating efficiency, and machine safety.

Shown below is a sectional view of a rotating machine that requires the installation of a mechanical seal. This machine has a large vessel and a rotating shaft at the center of the vessel (e.g., a mixer). The illustration shows the consequences of cases with and without a mechanical seal.

If the aim is solely to prevent leakage from the machine, it is effective to use a seal material known as gland packing on the shaft. However, a gland packing tightly wound around the shaft hinders the motion of the shaft, resulting in shaft wear and therefore requiring a lubricant during use.

Separate rings are installed on the shaft and on the machine housing to allow minimal leakage of the liquid used by the machine without affecting the rotating force of the shaft.

To ensure this, each part is fabricated according to a precise design. Mechanical seals prevent leakage even with hazardous substances that are difficult to mechanically handle or under harsh conditions of high pressure and high rotating speed.

A mechanical seal is installed on the impeller rotating shaft. This prevents the liquid from leaking through the clearance between the pump body and the shaft.

The rotary ring rotates with the shaft. The stationary and rotary rings rub against each other ensuring a clearance in the order of micrometers maintained between them. Where they rub against each other, they are referred to as “face materials.”

The face materials where the stationary ring and the rotary ring rub against each other are the most important portions as a barrier to the fluid. If the clearance is too small, the friction increases, hindering the shaft motion or resulting in seal breakage. Conversely, if the clearance is too large, the liquid will leak. Consequently, it is necessary to control the clearance in the order of micrometers to prevent leakage, but at the same time ensuring lubrication by the fluid, thereby reducing the sliding torque and avoiding hindrance to the machines’ rotation.

The mechanical seal technology is a sum of mechanical engineering and physical property technology due to the above-mentioned functions and applications. More specifically, the core of the mechanical seal technology is the tribology (friction, wear and lubrication) technology used to control the surfaces where the stationary and rotary rings rub (slide) against each other.

Mechanical seals with improved functionality will not only prevent the liquid or gas handled by a machine from leaking to the outside, but also improve machine operating efficiency, thereby helping achieve energy saving and prevent environmental contamination. Moreover, in some cases, rotating machines handle media that, in the case of leakage, can lead to a dangerous accident. Therefore, mechanical seals are required to be highly reliable through manufacturing backed by solid engineering expertise.

These functions and roles will make mechanical seals increasingly important functional parts in the future. Their further technical innovation is anticipated. To positively respond to these expectations, Eagle Industry is working on technical research and development every day.

The mechanical seal technology was fundamentally established in the 1960s. Thereafter, it has been making significant progress by introducing various leading-edge technologies, and innovative mechanical seals created from the above advanced technology are continuously being put to practical use.

To meet the demands of the market sufficiently, an applicable range of the “pressure” and “rotation speed” of mechanical seals has been considerably extended since the beginning of the 2000s. This is due to advancing of the tribology technology such as to enhance a function of the sliding materials (e.g., composite material composition, coating technology) and/or a performance of the sliding surfaces based on the fluid lubrication theory (e.g., non-contact mechanical seal, surface textured mechanical seal). These advanced technologies are sustained by improvement in the element technology of numerical analysis, processing/production, physical property/composition analysis, measurement, verification test, and so on.

Source: “Current status and future prospects of a wind/hydraulic machinery industry from 2021 to 2025”, The Japan Society of Industrial Machinery Manufacturers (2021).

MINKIX is a professional mechanical seal company that provides all kinds of inventory mechanical shaft seals for pumps, along with the same-day dispatch, and assures the aftermarket of higher quality, precision and performance.

We pride ourselves on being the in-stock supplier of mechanical seals that uses ERP to manage inventory. By doing so we are ensuring our clients are getting the right mechanical seals in the fastest manner possible.

With years of commitment to manufacturing quality seals and providing an excellent customer service, MINKIX is growing and gaining reputation and trust among wholesalers, distributors, and repair businesses.

8613371530291

8613371530291