mechanical seal manufacturers in usa quotation

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

Mechanical seals are intended for applications in which a rotating shaft and its housing are under a state of stress, including a combination of high pressure, temperature, and speed.

Most mechanical seals are specially designed to prevent leaks in particular applications and cannot be interchanged with those seals used in other mechanisms. A piston seal, for example, cannot be used as a flange gasket; they are shaped differently, made out of different materials, and feature different mechanical properties of a given mechanical seal always depends on the conditions in which it will be applied.

Also, depending on the narrowness or broadness of a given understanding of the words “mechanical seal,” certain kinds of seals may or may not qualify. Simple plastic lids qualify by the broadest definitions, while some of the strictest definitions might only include seals applied in industrial process equipment or in heavy machinery. In either case, mechanical seals perform the same task: to isolate and contain materials in an enclosure.

Correctly pairing seals with their applications is essential to the safe and effective use of the equipment in which they are installed. For example, Teflon is often chosen for use in hydraulic cylinders because it is resistant to corrosion induced by exposure to hydraulic fluids. Natural rubber, on the other hand, may degrade when exposed to such chemicals. The decision to employ a given seal material should always be chosen carefully; this will ensure sustained effective and safe operation of the seal and the equipment it protects.

Mechanical seal varieties are used to prevent the unwanted release of pressure, lubricants, hydraulic fluids and other properties of a system that makes use of them. Seals are also used to prevent the contamination of those systems by dirt and other hazards. Equipment like agitators, mixers, gas seals, pumps, valves, actuators and many other kinds of machinery all involve the use of some variety of mechanical seal.

In addition to preventing leaks, mechanical seals also keep contaminants from entering and help to maintain pressure levels. Piston seals, flange gaskets and diaphragm seals are also kinds of mechanical seals, and they are all essential to the functioning of certain kinds of equipment.

Most mechanical seals are specially designed to prevent leaks in particular applications and cannot be interchanged with those seals used in other mechanisms. A piston seal, for example, cannot be used as a flange gasket; they are shaped differently, made out of different materials and feature different mechanical properties. The shape, size, and composition of a given mechanical seal always depends on the conditions in which it will be applied.

Also, depending on the narrowness or broadness of a given understanding of the words "mechanical seal," certain kinds of seals may or may not qualify. Simple plastic lids qualify by the broadest definitions, while some of the strictest definitions might only include seals applied in industrial process equipment or in heavy machinery.

In either case, mechanical seals perform the same task: to isolate and contain materials in an enclosure. Correctly pairing seals with their applications is essential to the safe and effective use of the equipment in which they are installed. For example, Teflon is often chosen for use in hydraulic cylinders because it is resistant to corrosion induced by exposure to hydraulic fluids.

Natural rubber, on the other hand, may degrade when exposed to such chemicals. The decision to employ a given seal material should always be chosen carefully; this will ensure sustained effective and safe operation of the seal and the equipment it protects.

ISO 9001:2015 certified. Custom manufacturer of abrasion, acid, alcohol, alkali, oxidation, ozone, radiation, sunlight and water resistant rubber and plastic O-ring seals. Made from EPDM, butyl, fluoroelastomer, fluorosilicone, natural rubber, neoprene, nitrile, NBR, HNBR, SBR, silicone, high tear strength silicone, TPR, TPU, TPE, thermoplastics and polyurethane. Capabilities include injection molding, die cutting and prototyping. Assembly and PTFE coating additional services are also provided. Serves the aerospace, automotive, commercial, construction, dental, electrical, food handling, laboratory, marine, mining, municipal, oil and gas, recreational, retail, transportation and wastewater industries. Meets ASTM and SAE standards. Six Sigma certified. JIT delivery. Overseas sourcing options also offered.

We specialize in hard-to-find seals and demanding applications. Our extensive network of resources enables us to locate the right manufacturer and part, every time.

At All Seals we know down time is not an option. We specialize in hard-to-find seals and demanding applications. With over 40 years of experience in supplying quality replacement mechanical seals, we can help you identify the seal you need and solve your sealing problem. Our technical staff is available to help you – just give us a call. Our comprehensive stock of components ensures that we can build almost any seal combination for same day shipment. Whether you need a new seal or you have a seal to be repaired, we welcome the opportunity to help you with your rotary sealing needs.

We carry a comprehensive inventory of mechanical seal components, which allows us to build the right seal for your application. We’ll even design custom seals for one-of-a-kind applications.

Our goal is to make your repair easy without compromising on quality. Repair kits greatly reduce costly downtime, saving costs while sustaining production. Our pump rebuild kits are supplied with the same components you’ll find in an OEM kit; however, we offer them at a fraction of the price.

Need hard faces or specialty elastomers? Give us a call. We can quickly build a repair kit to withstand any medium being pumped. You’ll find All Seals’ pump repair kits an invaluable part of your operation.

Cytiva is a global provider of technologies and services that advance and accelerate the development and manufacture of therapeutics. We have a rich heritage tracing back hundreds of years, and a fresh beginning since 2020. Our customers undertake ...

Cytiva is a global provider of technologies and services that advance and accelerate the development and manufacture of therapeutics. We have a rich heritage tracing back hundreds of years, and a fresh beginning since 2020. Our customers undertake ...

ENERPAT Group established ENERPAT Jiangsu Environmental Protection Industry Co., Ltd. in China, and start to enter the China"s. The Enerpat name has become synonymous with recycling equipment. Established in 1936 it now has a 66,000 ft main factory ...

ENERPAT Group established ENERPAT Jiangsu Environmental Protection Industry Co., Ltd. in China, and start to enter the China"s. The Enerpat name has become synonymous with recycling equipment. Established in 1936 it now has a 66,000 ft main factory ...

Plugco is manufacturer of inflatable pipe plugs, packers, pipe balloons, pipe stoppers, point repair, pillow packers, drain and sewer pipeline testing equipment. PlugCo is the largest, most experienced supplier of high-quality infrastructure testing ...

High Pressure Pipe Plug is mainly made of metal body bonded to extra reinforced rubber used to seal or test high pressure pipelines. High pressure Pipe Plugs are mainly made up of a metal body bonded to extra reinforced rubber. ...

Plugco is manufacturer of inflatable pipe plugs, packers, pipe balloons, pipe stoppers, point repair, pillow packers, drain and sewer pipeline testing equipment. PlugCo is the largest, most experienced supplier of high-quality infrastructure testing ...

Proco Products, Inc. is a global leader in the design and manufacturing of piping/ducting system expansion joints. We offer the most complete line of rubber and molded PFA expansion joints, fabric fan connectors, braided flexible hose assemblies and ...

Proco Products, Inc. is a global leader in the design and manufacturing of piping/ducting system expansion joints. We offer the most complete line of rubber and molded PFA expansion joints, fabric fan connectors, braided flexible hose assemblies and ...

Since 1966, we"ve helped customers solve their toughest pumping and dredging challenges. SRS Crisafulli customers choose from a broad line of high-performance SRS Crisafulli trailer, vertical, and submersible pumps, dredges, and power units, which ...

, sealed bearings and are an ideal choice for moving relatively clean water. For sand, silt, mud, sludge or abrasives, choose the rugged Severe Duty version, which are constructed with abrasion-resistant heat treated steel (450 ...

Since 1966, we"ve helped customers solve their toughest pumping and dredging challenges. SRS Crisafulli customers choose from a broad line of high-performance SRS Crisafulli trailer, vertical, and submersible pumps, dredges, and power units, which ...

VEGA is a global manufacturer of sensors for measuring level, point level, pressure as well as devices and software for integrating them into process control systems. Every year, more than half a million sensors leave VEGA Grieshaber KG. Each one ...

For the most extreme process conditions. Application area: Cable, rod or coaxial sensor. Its robust, mechanical design and the second process seal, the Second Line of Defense, protect the sensor for demanding ...

VEGA is a global manufacturer of sensors for measuring level, point level, pressure as well as devices and software for integrating them into process control systems. Every year, more than half a million sensors leave VEGA Grieshaber KG. Each one ...

Since 1984, Sebright Products, Inc. has been designing and manufacturing waste and recyclable compaction equipment and hydraulic dumpers. Founded in 1978 and Incorporated in 1984 by Brent Sebright, President and Lee Murray, Vice President, in ...

Since 1984, Sebright Products, Inc. has been designing and manufacturing waste and recyclable compaction equipment and hydraulic dumpers. Founded in 1978 and Incorporated in 1984 by Brent Sebright, President and Lee Murray, Vice President, in ...

Founded in 1980, OR-TEC specializes in the manufacture and sales of wastewater treatment equipment for the municipal and industrial marketplace. Since its inception, OR-TEC has gained a reputation throughout the U.S., Mexico, Canada and ...

openings help to prevent matting or ragging forming on items such as pumps, mechanical seals, diffusers and rotating equipment. Maintenance on these items is reduced to practically zero as ragging and matting no ...

Founded in 1980, OR-TEC specializes in the manufacture and sales of wastewater treatment equipment for the municipal and industrial marketplace. Since its inception, OR-TEC has gained a reputation throughout the U.S., Mexico, Canada and ...

Fluence is a leader in the decentralized water, wastewater and reuse treatment markets, setting the industry pace with its Smart Products Solutions, including Aspiral, NIROBOX and SUBRE. Fluence offers an integrated range of services across the ...

Fluence is a leader in the decentralized water, wastewater and reuse treatment markets, setting the industry pace with its Smart Products Solutions, including Aspiral, NIROBOX and SUBRE. Fluence offers an integrated range of services across the ...

J.U.M. Engineering is an independent privately owned developer and manufacturer of FID based hydrocarbon analyzers since 1973. A complete line of Heated Total Hydrocarbon Analyzers using the Flame Ionization Detector (FID) technology in an array of ...

J.U.M. Engineering is an independent privately owned developer and manufacturer of FID based hydrocarbon analyzers since 1973. A complete line of Heated Total Hydrocarbon Analyzers using the Flame Ionization Detector (FID) technology in an array of ...

Sauereisen - A Leader in the manufacture of speciality cements and corrosion-resistant materials of construction. Sauereisen is a third-generation company that has grown into one of the best-known corrosion-resistant material manufacturers in the ...

Sauereisen Low Expansion Cement No. 29 is an inorganic cement used for embedding heating elements, insulating thermocouples, coating resistors and coils, and mechanically sealing parts where high resistance to ...

Sauereisen - A Leader in the manufacture of speciality cements and corrosion-resistant materials of construction. Sauereisen is a third-generation company that has grown into one of the best-known corrosion-resistant material manufacturers in the ...

Worldwide industrial plants are being provided with gaseous media by the use of AERZEN blowers and compressors. The innovative AERZEN machine technology benefits from experiences of 150 years company history. The entire product range comprising ...

Worldwide industrial plants are being provided with gaseous media by the use of AERZEN blowers and compressors. The innovative AERZEN machine technology benefits from experiences of 150 years company history. The entire product range comprising ...

WITTE Pumps and Technology not only produces special solutions for industry but also offers a standard range of pumps. The latest technical innovations are incorporated into our standard model range, thus ensuring a very high level of technology. In ...

The single mechanical seal (ED) is the standard seal for WITTE CHEM pumps. It is suitable for max. viscosity of 10 to 50 Pas. Min. suction pressure: 1 bar (15 psig), Max. suction pressure: 15 bar ...

WITTE Pumps and Technology not only produces special solutions for industry but also offers a standard range of pumps. The latest technical innovations are incorporated into our standard model range, thus ensuring a very high level of technology. In ...

The original Environamics Corporation was founded in 1991. In 2008 EnviroPump and Seal, Inc. purchased the assets of Environamics. EnviroPump and Seal is aimed to provide great customer service along with true reliability. Following several years ...

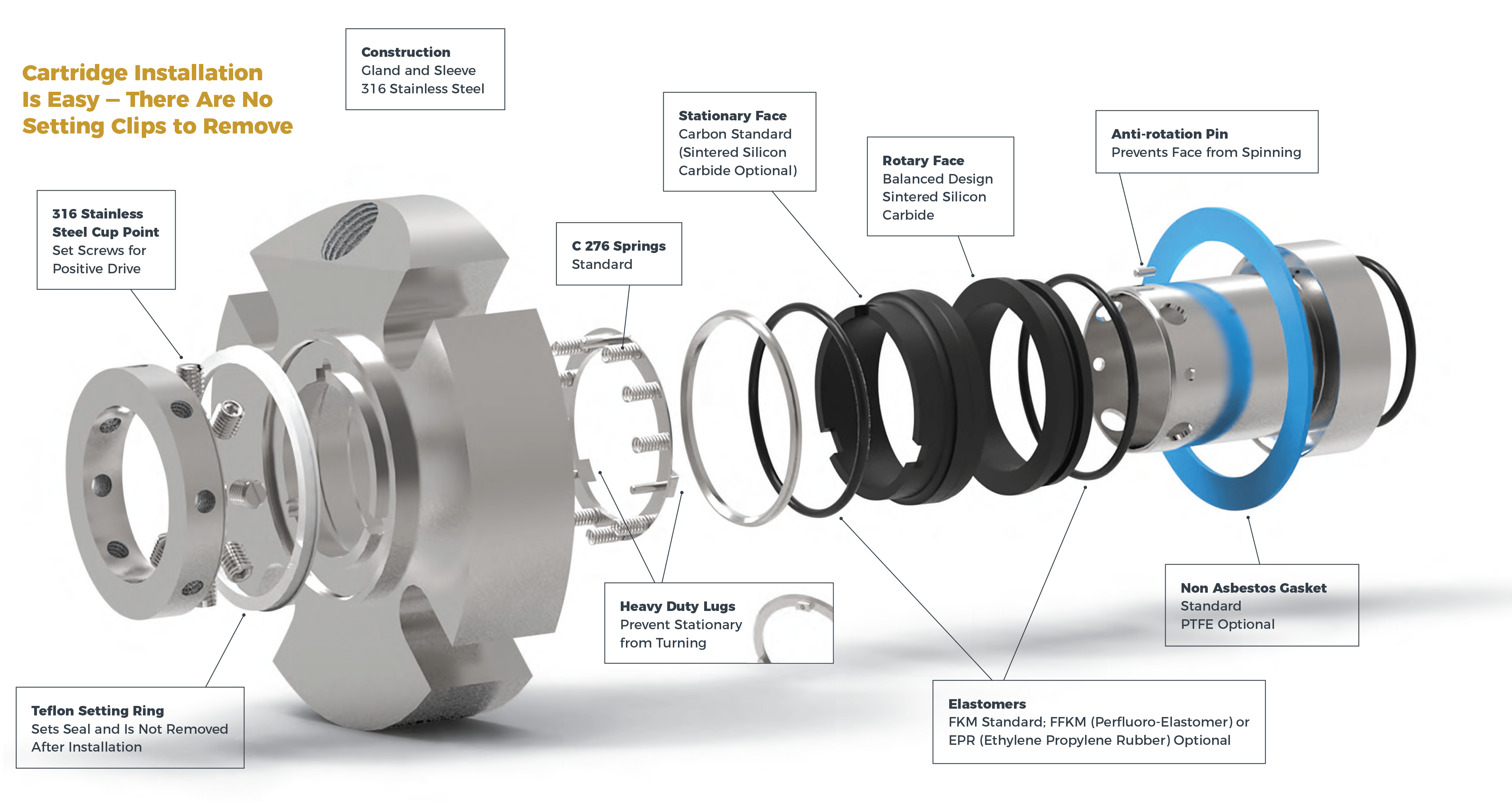

Cartridge Design – No measuring, self centering installation. Just slide over shaft, tighten gland bolts and set screws, remove centering clips, and the seal is ready to operate. Double Balance – World’s first ...

The original Environamics Corporation was founded in 1991. In 2008 EnviroPump and Seal, Inc. purchased the assets of Environamics. EnviroPump and Seal is aimed to provide great customer service along with true reliability. Following several years ...

Established in 1992, Pump Pro"s has been continually expanding to encompass any fluid handling need that customers may have. In 2003 Pump Pro"s purchased Wagner-Smith Pumps and Systems (est. 1917) then in 2008 purchased Jenkins Equipment (est. ...

Pump Pro’s is fully equipped and ready to provide expert testing, repair and renewal of all your mechanical seals including: John Crane, Chesterton, Durametallic, Flowserve, Burgman, EKATO, SEALOL, AES. ...

Established in 1992, Pump Pro"s has been continually expanding to encompass any fluid handling need that customers may have. In 2003 Pump Pro"s purchased Wagner-Smith Pumps and Systems (est. 1917) then in 2008 purchased Jenkins Equipment (est. ...

Since 1997 BISAN, Inc. has serviced the municipal, industrial, residential & commercial sectors with various equipment and systems. Ontario based manufacturer and distributor of inline static mixers, compact design wafer technology, chemical feed ...

Since 1997 BISAN, Inc. has serviced the municipal, industrial, residential & commercial sectors with various equipment and systems. Ontario based manufacturer and distributor of inline static mixers, compact design wafer technology, chemical feed ...

The American-Marsh Pump Group is a leading manufacturer of centrifugal & positive displacement pumps, electrical motors, mechanical seals and fire protection fittings, couplings and pumping equipment. The American-Marsh Pump Group is over 135 ...

American-Marsh Model 810 non-pusher bellow seals are general purpose seals for use in many applications. The seal utilizes an elastomeric bellow for positive sealing. The spring is ...

The American-Marsh Pump Group is a leading manufacturer of centrifugal & positive displacement pumps, electrical motors, mechanical seals and fire protection fittings, couplings and pumping equipment. The American-Marsh Pump Group is over 135 ...

The FLUX name has been synonymous with pump technology for more than 60 years. It was the invention of the electric drum pump that sparked it all off. In the meantime, of course, the technology has become more sophisticated. FLUX company innovations ...

Features and benefits: for transferring low flammabiltiy liquids from containers, either open topped or closed. consisting of an inner tube and outer tube; the drive shaft is supported within the inner tube. a mechanical ...

The FLUX name has been synonymous with pump technology for more than 60 years. It was the invention of the electric drum pump that sparked it all off. In the meantime, of course, the technology has become more sophisticated. FLUX company innovations ...

Since 1985 your process reliability has been our #1 priority. We are dedicated to being a leader in the pump industry. Magnatex heavy-duty, state of the art, sealless, magnetic drive, all-metallic centrifugal and regenerative turbine vane pumps, ...

Heavy-duty, rugged, world-class quality, ANSI process pumps manufactured to meet the latest ASME B73.1-2001 standard (revision of ASME B73.1M-1991). Pumps are manufactured in 29 sizes from a wide variety of materials, and offer seal ...

Since 1985 your process reliability has been our #1 priority. We are dedicated to being a leader in the pump industry. Magnatex heavy-duty, state of the art, sealless, magnetic drive, all-metallic centrifugal and regenerative turbine vane pumps, ...

Magna-Safe International, Inc. designs and manufactures top, side, and bottom entry mixers and vessels for High Pressure Reactors, Hydrogenators, Blending, and Storage, covering a wide range of products and industries. Each application is closely ...

Magna-Safe will retrofit and recondition your existing mechanical seal mixer using mag-drive technology. Reuse your existing wetted parts. Or upgrade to new, more efficient and high productivity impeller technology. ...

Magna-Safe International, Inc. designs and manufactures top, side, and bottom entry mixers and vessels for High Pressure Reactors, Hydrogenators, Blending, and Storage, covering a wide range of products and industries. Each application is closely ...

We have experience and expertise in all industries, including manufacturing, chemical processing, defense, power generation, agricultural, water treatment and filtration, hydraulics, fluid power, heavy truck, automotive, aerospace, oil and gas, medical and life sciences, food and beverage, electronics and industrial controls, refineries, logistics and supply chain suppliers and transportation.

Micro Seal is professional manufacturer of Agitator Mechanical Seal in USA. We design and manufacture Agitator mechanical seal in USA mainly for the oil & gas, chemical, pharmaceutical, pulp & paper, power, mining and many more industrial applications. Manufacturer of Agitator Mechanical Seal - Agitator Double Mechanical Seal, Agitator Dry Running Mechanical Seal, Reactor Double Mechanical Seal in USA.

Fluid Sealing International is a mechanical seal manufacturer focused on the needs and requirements of its customers. Since 1982, the FSI policy has been to design, manufacture, provide, and service the most reliable sealing systems available to today’s industries. Our goal is to make a difference in, and an impact on the global sealing marketplace.

We understand that each customer as well as each seal application is unique. From our standard product line, to a specifically engineered custom seal, we have listened to what our customers want and expect from a mechanical seal manufacturer. This has resulted in Customer – Driven Designs.

We are proud of our company, our products, and our people. We continuously strive to be our customers manufacturer of choice when it comes to fluid sealing products.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Clark Seals Ltd. was contacted by the largest manufacturer of commercial laundry equipment with a problem they were having with seals leaking in sandy environments. Sand was getting between the sealing surfaces of the mechanical seal, grooving the face and causing leakage.

To solve the problem, we designed a custom two-piece integrated sealing solution that sealed against the top and bottom of the tub. The top seal was designed to press-fit around the tub bearing to improve alignment between the transmission, tub and agitator and a triple sealing lip to prevent water, sand and debris from entering the bearing cavity. The bottom seal was designed with a locking pin to resist torque and press-fit into the top seal during installation. To further reduce sand and other contaminants, our engineers developed and patented a unique negative "R"; sealing lip geometry that allowed the sprung lip to perform as an excluder lip and keep all sand out of the sealing environment.

The end result was a patented sealing solution that eliminated warranty claims, cost 80% less and lasted more than 700% longer than the mechanical seal it replaced.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

Mumbai Gala No.bf/15,, Saraf Kaskar Industrial Premises Chs Ltd, S.V.Road, Oshiwara, Jogeshwari West, Mumbai Suburban, Mumbai - 400102, Dist. Mumbai, Maharashtra

Jogeshwari West, Mumbai Unit No-BF-10, 1st Floor B Wing, Saraf Kaskar Industrial Premises Co-Op Society Ltd, SV Road, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Chennimalaipalayam, Tiruppur, Dist. Coimbatore 7/250, B-1, Ground Floor, Srinagar Ganapathipalayam Road, Chennimalaipalayam, Tiruppur - 641605, Dist. Coimbatore, Tamil Nadu

Goregaon West, Mumbai Unit No. 10, First Floor, Shamroz Industrial Estate, Opposite Movie Star Cinema, Ram Mandir Road, Gorgaon West, Goregaon West, Mumbai - 400104, Dist. Mumbai, Maharashtra

Jogeshwari West, Mumbai No. 5/1 - A, Ramjanaksingh Compound, S. V. Road, Opposite Veena Dalwai Industrial Estate, Oshiwara, Jogeshwari West, Jogeshwari West, Mumbai - 400102, Dist. Mumbai, Maharashtra

Vasai East, Thane Unit No. 3, Ground Floor, Building No. 1, Riddhi Siddhi Sagar Industrial Premises Raj Vishnu Compound Wali Road, Vasai East, Thane - 401208, Dist. Thane, Maharashtra

Malad West, Mumbai No. 122, Vinay Heavy Industrial Estate, Near Inorbit Mall Linking Road, Malad West, Malad West, Mumbai - 400064, Dist. Mumbai, Maharashtra

Bapunagar, Ahmedabad 30, Parvati Nagar, Behind Shastri Stadium, Near Biratnagar Bus Stop, N.H. 8, Khodiyar Nagar, Bapunagar, Ahmedabad - 382350, Dist. Ahmedabad, Gujarat

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

The SEPCO RBD is a stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerated and where positive ...

Dual seal Available for standard (CMS-ASDN) and big bore (CMS-ABDN) seal chambers Balanced Cartridge Double pressure balanced Independent of direction of rotation Integrated pumping device

We manufacture face seals for hydraulic and pneumatic applications in the following designs:- rod seals and piston seals - single-acting - double-acting - rotatory ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Bay City Industrial Supply has teamed up with the only mechanical seal manufacturer that produces their own Silicon Carbide from powder to final product with their own equipment, locally!

Minimize your pumps downtime with innovative mechanical seal designs and parts from Bay City Industrial Supply. With superior materials, seal life is extended saving you from costly tear-downs and unnecessary repairs.

New seals can be made to order for your specific application and re-builds/repairs on your existing seals are done much quicker than the large manufacturers as we are focused on serving our local customers.

8613371530291

8613371530291