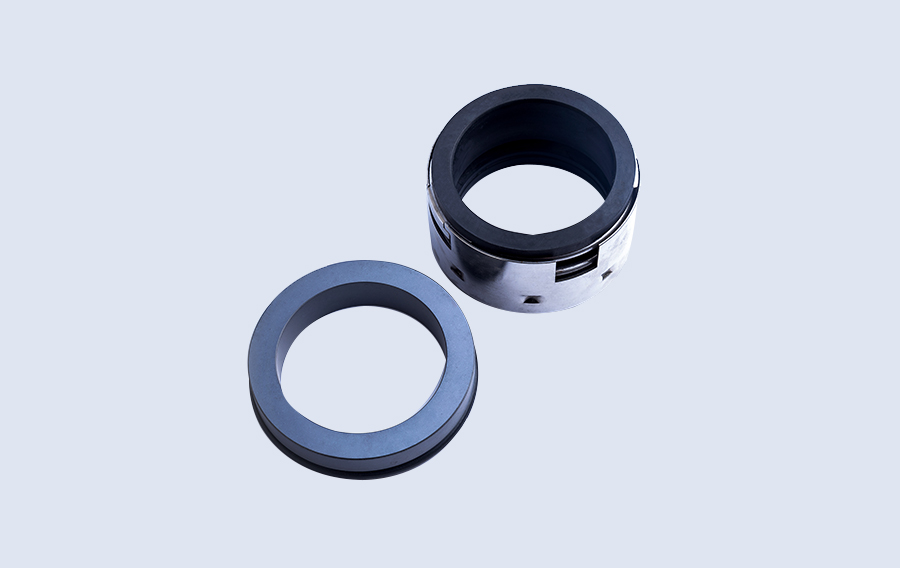

carbon mechanical seal free sample

Back to back: Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

Face to face:The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Users can choose different material for this double mechanical seal 208, matching for different liquid conditoncarbon, silicon, and tungsten carbide for this mechanical seal as seal face, if for high temerperature, we suggest to choose rubber seal viton for the rubber parts.

Lepu seal make this dual mechanical seal for many years, and offer professional suggestion when client need this grundfos seal, so we are your reliable specialist for grundfos mechanical seal.

Double mechanical seals are commonly used in the following circumstances:If the fluid and its vapors are hazardous to the operator or environment, and MUST be contained

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

A dry gas seal is a revolutionary way of sealing machines and protecting them from dust, moisture and other contaminants. A dry gas seal is a sealing device that uses pressurized gas to keep two surfaces from touching. The most common type of dry gas seal is the O-ring, which is used in many applications, including mechanical seals, piston rings, and gaskets. Dry gas seals are also used in many other industries, such as the food and beverage industry, where they are used to seal containers and prevent contamination. This type of seal not only helps to keep the machine running with maximum efficiency but also significantly reduce downtime, making it cost-effective in the long run. In this article, we"ll explore what a dry gas seal is, how it works and why you should consider using it for your machinery. By understanding the benefits of a dry gas seal and its uses, you can make an informed decision about the best sealing system for your needs. How does a dry gas seal work?Dry gas seals work by using a series of labyrinths to separate the high pressure seal gas from the atmosphere. The labyrinths are formed by a series of grooves and ridges on the surface of the seal ring. The seal ring is rotated at high speed, causing the gas to flow through the labyrinths. The gas is then forced through an aperture in the center of the seal ring, where it escapes into the atmosphere. What is a dry gas seal used for?Dry gas seals are used on rotating equipment to help minimize the leakage of high pressure gases from the inside of the machinery. This helps to reduce maintenance costs and improve safety. Dry gas seals are commonly used in applications such as pumps, compressors, turbines, and blowers. Advantages of a dry gas sealThere are many advantages of a dry gas mechanical seal. One advantage is that they are much simpler in design than other types of seals, making them more reliable and easier to maintain. Additionally, dry gas seals do not require the use of any lubricating fluids, which can leak or evaporate over time. This makes them more environmentally friendly and cost-effective in the long run. Finally, dry gas seals have a much longer lifespan than other types of seals, meaning that they need to be replaced less often.Disadvantages of a dry gas sealThere are several disadvantages of dry gas seals, including: - they can be expensive to purchase and install- they require careful maintenance and regular inspection- they can be susceptible to wear and tear- they can leak if not maintained properlyHow to choose the right dry gas seal for your applicationThere are a few key factors to consider when choosing the right dry gas mechanical seal for your application. The most important factor is the type of fluid being sealed. Gas seals are designed to seal either liquids or gases, but not both. Make sure to choose a gas seal that is compatible with the fluid you are sealing.Another important factor to consider is the pressure of the fluid being sealed. Gas seals are rated for different maximum pressures, so make sure to choose one that can handle the pressure of your application.Finally, take into account the size and shape of the sealing surfaces. Gas seals come in a variety of sizes and shapes to fit different applications, so make sure to choose one that will fit your needs.ConclusionDry gas seals are an extremely important component for many industrial operations, and their ability to prevent leaks has made them invaluable in a variety of applications. Understanding the basics of how dry gas mechanical seal work and how they can be used effectively is helpful when considering the various options available for any specific application. With the right choice, dry gas seals can provide reliable, leak-free performance which will save time, money and resources while ensuring safety and reliability. Lepu dry gas seal manufacturer provides best quality flowserve dry gas seal and dry gas seal. Welcome to contact us!

At ROC Carbon, we’re pleased to manufacture carbon/graphite mechanical seal faces from your drawings or samples, using the same high-quality materials and tolerances that are found in original equipment manufacturer parts. As experienced mechanical face seal manufacturers, our team at ROC is experienced in machining intricate details such as flow channels and ports. Our lapping capabilities encompass both carbon and hard faces up to 16 inches in diameter and to as flat as 1 helium light band. We can insert the carbon seals in metal housings (machined by us or furnished by you) by heat shrink fitting or by using specialty high-temperature adhesives.

Xingtai Wanmai Machinery Seals Co., Ltd.is a manufacturer of Machinery Seals with well-equipped testing facilities and strong technical force .With a widerange, good quality, reasonable prices and stylishdesigns, our products are extensively used in machineries, chemical industry, petroleum , Pharmaceutical Engineering, cars and other industries .Our products are widely recognized and trusted by usersand can meet continuously changing economic andsocial needs. We welcome new and old customersfrom all walks of life to contact us for future businessrelationships and mutual success!

No carbon dust contamination, eliminates process contamination from mechanical seal face wear. True dry-running design, balanced double cartridge seal, can be run with a barrier fluid.

![]()

The global graphite and carbon sealing gasket market size is estimated to be USD 833.8 million in 2022. The global COVID-19 pandemic has been unprecedented and staggering, with graphite and carbon sealing gasket experiencing higher-than-anticipated demand across all regions compared to pre-pandemic levels. As per our research, the market is projected to touch USD 995.6 million by 2028, exhibiting a CAGR of 3.0% during the forecast period. The sudden spike in CAGR is attributable to demand returning to pre-pandemic levels once the pandemic is over.

Graphite and carbon sealing gasket is used for dynamic mechanical seal. It creates a seal between a rotating and stationary body. They can be also used in mixing seals to prevent leakage and entering anything in the gap.

Increasing demand to improve sealing performance along with chemical resistance and temperature is expected to increase market growth. Rising demand from rubber industry is anticipated to accelerate market growth. Increasing industrialization and urbanization are predicted to increase product adoption. Rising demand for non-metallic gaskets and seals from plastics industry is projected to drive market growth. Growing demand for expensive sealing products made from advanced materials is expected to accelerate product demand. Further, the availability of the product in different shapes and sizes is estimated to surge graphite and carbon sealing gasket market growth during the forecast period.

Increasing need for aerospace industry is estimated to fuel market growth. The product has a layered structure that helps to boost high-performance in aircraft. It has a heat resistance and self-lubricating characteristics which strengthen requirements for better performance. Such qualities of the product are estimated to boost product adoption in aerospace industry. Further, the product has self-lubricant and heat transfer properties that increase aircraft longevity. It also helps to save fuel economy by allowing engineers to manage oil temperature in the engine. The properties such as weight saving as it has a lower density which is anticipated to surge market growth during the forecast period. In addition, the product helps to prevent overheating of the engine. Such benefits of heat transferring are estimated to increase graphite and carbon sealing gasket market growth. It also helps to enhance materials’ stiffness and strength. Such advantages of the product in the aerospace industry are estimated to boost market growth.

Increasing demand for product in the rubber industry is expected to fuel market growth. The product has a high resistance capacity which is projected to boost product demand. It has better form of sealing which is commonly used in rubber industry. Growing demand for 100% pure flexible graphite in rubber industry is estimated to fuel product adoption. Increasing demand from petrochemical industry due to its high thermal quality is estimated to surge market growth during the forecast period. The product has improved sealing performance which is predicted to drive market growth. It has excellent resiliency and zero-leakage such qualities are estimated to drive market growth during the forecast period. Growing research and development (R&D) activities in the product are projected to drive graphite and carbon sealing gasket market growth during the forecast period.

An increasing number of industrialization and urbanization globally is predicted to fuel market growth. Growing demand for machinery, mechanical instruments, automobiles, and manufacturing plants is projected to boost product adoption. The product has pressure fluctuations and dimensional stability which are predicted to increase product demand in industries. It is flexible and high strength and rigidity. Such benefits are projected to drive market growth. Increasing use of the product in paper mills, chemical plants, and thermal applications are predicted to accelerate graphite and carbon sealing gasket market growth during the forecast period.

Asia Pacific is estimated to largest part of graphite and carbon sealing gasket market share due to rapid industrialization. Increasing development in aerospace industry in the region is estimated to boost product adoption. Growing demand from petrochemical and rubber industry are projected to drive market growth. Strict government regulation and low land and labor cost is predicted to stimulate market growth during the forecast period. Presence of raw materials and market players is anticipated to drive market growth during the forecast period.

Machine lapping is the production method of lapping Mechanical Seal Faces. Kemet Lapping Systems are used in both manufacturing and reconditioning processes. The following techniques are applicable to Bench Mounted and Free Standing Machines, as well as Kemet Hand Lapping Systems.

The machine size to be used would normally be determined by the largest seal to be lapped. For example, a Kemet 15 machine could lap seals up to approximately 125mm diameter (5”), whereas a Kemet 24 machine would be required if seals up to 200mm (8”) diameter were to be lapped. In most cases, if the following procedures are adopted, it should be possible to produce high quality reflective surfaces flat to less than 2LB.(0.0006mm)

Many materials used for the manufacture of mechanical seals are now too hard to be lapped using old fashioned conventional abrasives like aluminium oxide and silicon carbide. A Kemet composite lapping plate with a diamond slurry will generate a good cutting rate, and a highly reflective surface finish meaning a secondary polishing stage is not needed.

Kemet Flat Lapping Systems are available to fit most Lapping Machines up to 72” diameter, but for the majority of seal repair workshops 15” or 24” machines are adequate.

Flat Mechanical Seals can only be produced on flat lapping plates. It is therefore essential to regularly check plate flatness. This is the most important skill to master when operating a flat lapping machine.

Seals can then be lapped by placing them inside the machine’s control rings and applying a pressure. If multiple parts are to be lapped inside the same conditioning ring, it is essential that they are the same thickness (+/- 0.5mm). To keep the parts in position during lapping either a work-holder, (sometimes called a nest), should be manufactured. This is typically a 3mm disc of Tufnell with the profile of the parts to be lapped machined into it. Alternatively the pressure weights themselves can be faced with a Kemet Facing Kit. This special material has non-skid properties that hold the parts in position during lapping without the need for a work-holder.

Single seals may be allowed to run freely inside a control ring, but it is important to apply a weight to obtain optimum stock removal. This weight should be balanced. An ideal weight is a large steel ball that can simply be placed on top of the seal. It is also recommended that a rubber band be placed around single seals as this gives them drive within the control rings, thus avoiding tracking on the lapping plate. .

If a large seal is to be lapped on a relatively small lapping machine, then it is possible to remove a control ring and substitute the seal, which will then run in the Roller Yoke Assembly.

Parts were lapped for 10 minutes on the diamond lapping machine and then lapped by hand on the Kemet Copper plate until they were polished. Hand lapping took up to 30 seconds. As the parts were spring loaded the parts had to be put on top of an optical flat to get a light band reading. rather than putting an optical flat on top of the seal.

The PSS Shaft Seal is a mechanical face seal. The sealing surface is created between the flat surfaces of the rotating stainless-steel rotor and the stationary carbon flange. The stationary carbon flange is attached to the front side of the bellows with hose clamps, and the back end of the bellows fits over the stern tube and is secured with hose clamps. The stainless-steel rotor is fitted on the shaft in front of the carbon flange. The stainless-steel rotor compresses the bellows before the rotor is secured to the shaft with set screws. This compression (pre-load) maintains constant contact between the two flat faces of the stainless-steel rotor and carbon flange, allowing the PSS to compensate for the variable fore and aft movement due to propeller thrust. In addition, the carbon flange is over-bored to the shaft diameter allowing it to float around the shaft and thus compensate for most misalignment and vibration problems. The stainless-steel rotor is sealed to the shaft by two O-rings recessed into the collar"s bore. These O-rings rotate with the shaft and stainless-steel rotor and do not experience wear during operation.

8613371530291

8613371530291