agitator mechanical seal supplier

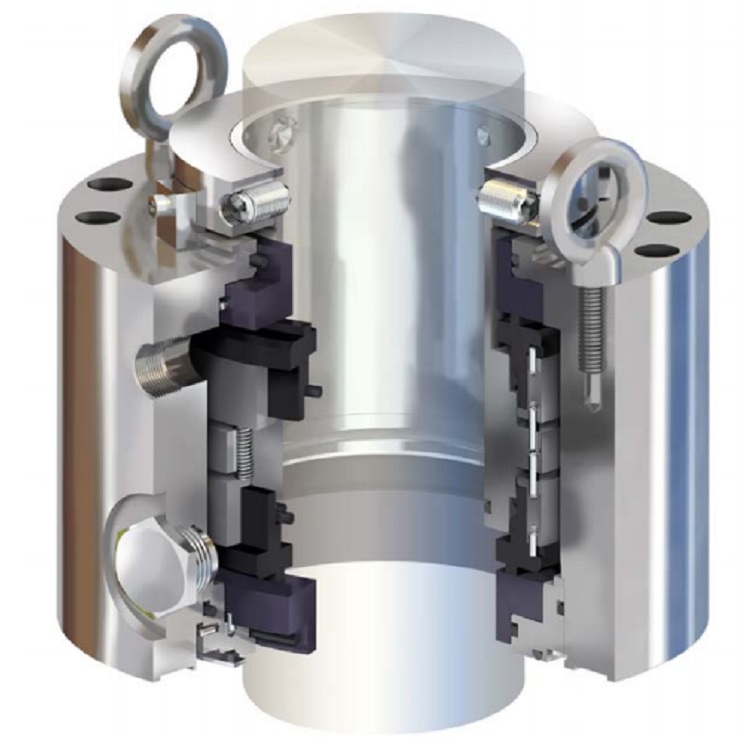

There is no one universal seal for all mixer applications. Every mixer, agitator, and reactor model is distinctive and engineered for a specific application. Many of these applications require seals to perform in environments that would destroy common seals due to extreme drag and shear forces, abrasive materials, or other challenges. That means successful sealing requires clearly defining the type of equipment, the product, and the sealing conditions. Flexaseal’s design and engineer team are capable of providing innovative solutions for your toughest challenges.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. You can use John Crane’s range of mixer and agitator mechanical shaft seals for reaction vessels to optimize safety and equipment performance, and conform to industry regulations, no matter where you are. Modern dry running mechanical seal technology and optional hygienic design features maintain product purity in mission-critical pharmaceutical applications.

Mechanical Seals play an important role in the chemical process industries. These devices prevent product leakage and toxic emission during the mixer service under pressure. Since the ...

... secondary lip seal (MTM602/605/607) or with a secondary labyrinth seal (MTM603/606/608). They are easy to install and they are provided with significant thicknesses in key parts such as sleeved shaft ...

... MTM351), a single seal with a floating bearing inserted (MTM352), cartridges seal with double seal (MTM361) and double seal with the floating bearing (MTM362). There ...

... entry mixers and bottom entry agitators on sealed tanks will have a mechanical seal of some sort. For many sanitary process vessels, the mixer must have ...

... 30 years of split seal experience, from sophisticated marine propeller shaft seals to thousands of industrial pump and mixer applications, John Crane has established itself as the worldwide ...

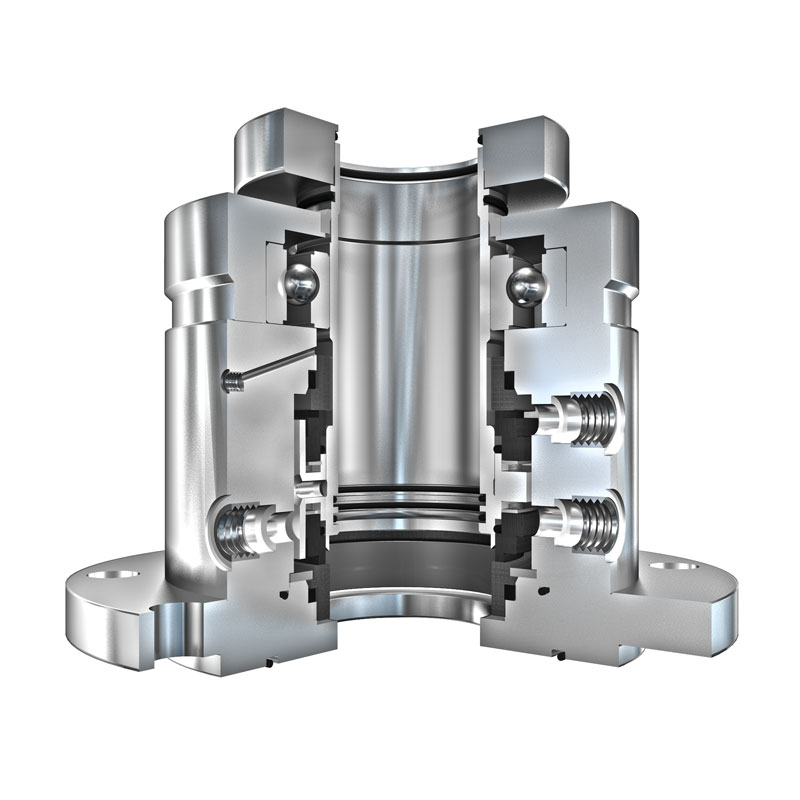

This double mechanical seal allows for a new, higher level of reliability and performance with the convenience of a cartridge seal. The Chesterton ...

The SEPCO OMS is an externally mounted single component seal capable of handling up to 1/4" shaft deflection. This makes it ideal for use on augers, belt driven pumps, mixers, agitators and slow moving ...

... papermaking, nuclear power, power plant, metallurgy, food, pharmaceuticals, etc. Main products are mechanical seal, dry gas seal and many kinds of seal control systems, ...

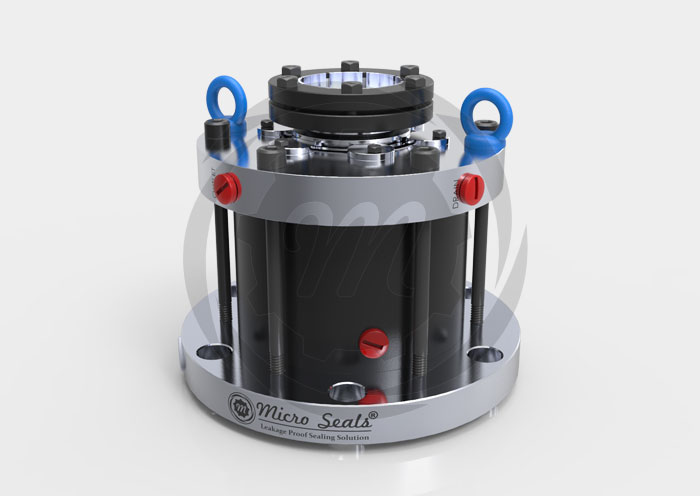

Micro Seal is professional manufacturer of Agitator Mechanical Seal in USA. We design and manufacture Agitator mechanical seal in USA mainly for the oil & gas, chemical, pharmaceutical, pulp & paper, power, mining and many more industrial applications. Manufacturer of Agitator Mechanical Seal - Agitator Double Mechanical Seal, Agitator Dry Running Mechanical Seal, Reactor Double Mechanical Seal in USA.

A Cartridge Seal assembly is "pre-set" so that no installed length calculations must be performed for determining where to set the seal. Only the external seal in a double cartridge have "set tabs" that are removed once the seal is installed and the pump assembled.

Some products are not compatible with a single cartridge mechanical seal. Examples include toxic liquids whose leakage into the environment would be hazardous, liquids whose suspended abrasives would rapidly wear the faces, or corrosive liquids requiring seals made of costly materials. In recent years most states are requiring double mechanical seals to maintain fugitive emissions limitation requirements. In an effort to limit water usage, many users are converting to double seals. There are two ways to design for such products.

Agitator Mixer Seals are factory assembled cartridge units used on mixtures, agitators and reactor vessels . Agitator mixer seals shows good performance in high vacuum conditions.

Agitator Seals are available with us in precision design and construction standards. The range offered include single dry running seals that are used in Top Entry Agitators, Top entry low RPM mixers and agitators,High Pressure Dual Mixer Seal that provide working as high pressure double seals that find use for top entry mixers and Bottom Entry Mixer Seals that come internally balanced.

Available Range:Balanced Mixer seal, High Pressure Double Mixer seal, Top Entry Agitator seal,Reactor Seal and Bottom Entry glass Lined Reactor seals, and Double Mechanical Seals.

Agitator or Reactor Mechanical Seals are specifically designed for Mixer, Agitator and Reactor applications, to combat the inevitably radial and / or axial shaft movement that occurs in these applications. Rota-Tech mechanical seals can be configured to operate wet, dry or with a gas barrier. Agitator & Reactor Mechanical Seals are available in a wide range of seal face, Elastomer and alloy combinations, to suit individual applications. Externally and Internally Mounted seal, well balanced faces and inclusion of steady bearings incorporates in many design features to increase seal life.Our Seals are a family of engineered and standard Mixer, Agitator & Reactor Seal Designs in different configurations for Top, Side and Bottom Entry installation.

We also manufacture and supply Rotary Joint, Rotary Union, Mechanical Seals, Cartridge Mechanical Seals and Replacement Sealsin Mumbai as well as known as one of the most precise rotary joints and rotary unions manufacturing companies in India.

By having experience of more than 25 years, we are engaged in offering extensive collection of Double Mechanical Agitator Seals. Provided mechanical seals are used in pharmaceutical and chemical industries. Offered mechanical seals are manufactured at our state-of-the art manufacturing unit using quality tested raw materials and latest technology under the strict supervision of our deft professionals. In addition, our highly valued clients can easily avail these Double Mechanical Agitator Seals in numerous specifications as per their exact needs at pocket friendly prices.

The use of the word “seal” is a misnomer; as a mechanical seal is a restrictive flow path,that is either an angular or radial gap.The flow through this gap is generally so low it goes unnoticed if a liquid or inconsequential if a gas.

A mechanical seal works byretaining a liquid or gas inside a rotating piece of equipment. Mechanical seals can be designed to prevent contamination of the process by the environment and prevention of leakage of the process into environment.

The basic components of a mechanical seal are a Rotating Part and a Stationary Part. The primary seal of a mechanical seal consists of a rotating face and a stationary face. The faces are kept lubricated by maintaining a thin film of fluid between each face. There is a very small gap between these 2 components which creates a restrictive flow path.

There are other components namely o-rings or gaskets which are used as secondary seals and hardware which is used to support the seal faces and to attach them to the rotating part (i.e shaft) and stationary part (i.e cover plate).

The primary seal of a mechanical seal is made up of 2 seal faces where these two parts meet is where the seal gap is located. The mating surface of the seal face is machined to a very tight tolerance.

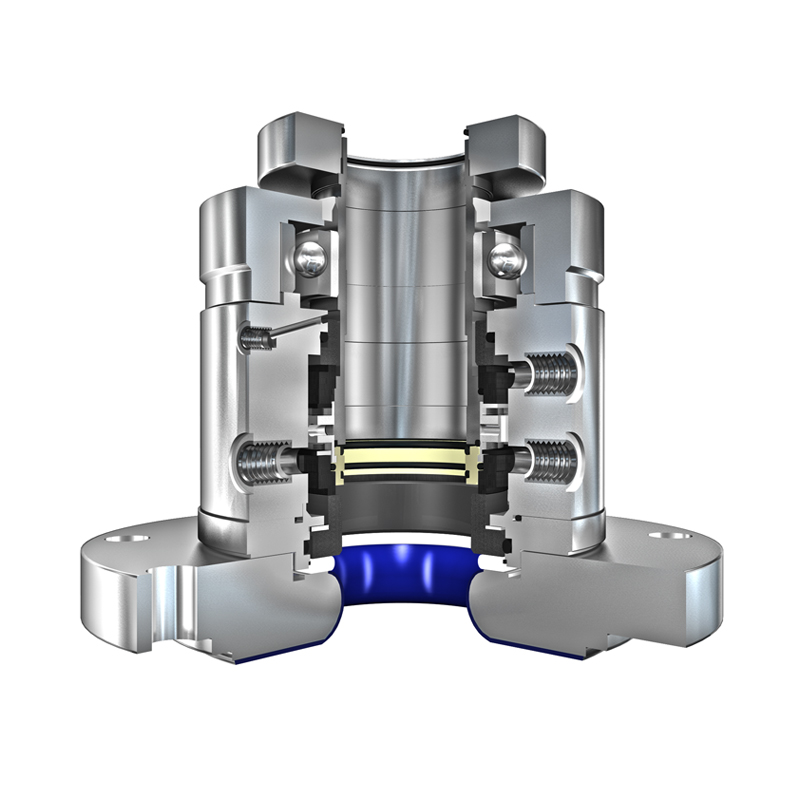

Double Seal (Barrier) => consists of two primary seals in various arrangements. There is a barrier fluid between the two primary seals which is at a higher pressure than the process. There is always some leakage of the barrier fluid in process & out to atmosphere. As long as barrier pressure is maintained there is no leakage of process to atmosphere or contamination of process by environment.

Double Seal (Barrier) – Wet => is a double seal where the barrier is a liquid. It is generally the most robust seal. It has a good pressure, speed and temperature capabilities.

Gas Contacting Seal– the seal faces are in contact, the soft face wear acts as a lubricant. Low pressure, speed and temperature capabilities and possibilities of wear getting into the process.

Gas Non Contacting Seal – the seal faces are NOT in contact. They are kept apart by a flow of gas between the faces. Good temperature, speed and pressure capabilities. If operated correctly their is no wear but care must be taken in order to minimise shaft run out.

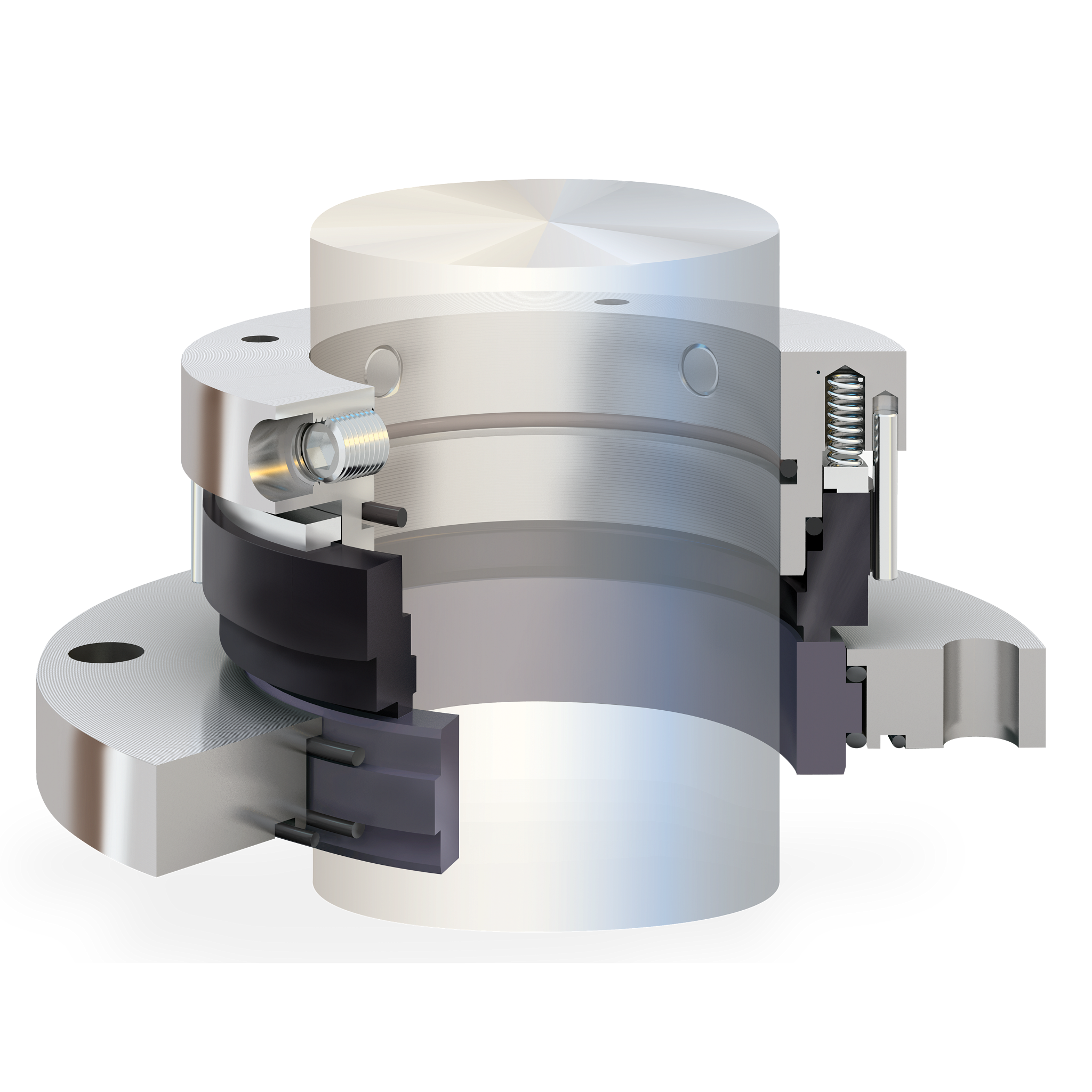

Cartridge seal =>is where the rotating and the stationary hardware are pre-assembled before mounting onto the pump/mixer. Cartridge seals are much easier to fit & maintain compared to the component seal.

A lip seal is a specific type of seal, it is a radial seal, where the part that seals against the rotating surface is a narrow cross section, soft material i.e the lip and it is made from an elastomer or non-elastomer material with a backup spring. Most commonly used to seal bearings in Mixers/Agitators. A lip seal rotates too quickly to be used on pumps.

Abarrier fluid is any gas or liquid which is used to pressurise a double mechanical seal. It must be compatible with the process, generally non-toxic and a good lubricant.

Please consult the pump manufacturer/distributor for guidance on these calculations for mixer seals, the barrier pressure is set at a certain value above the maximum vessel pressure.

Packing is a material that is stuffed between a rotating shaft and a stationary part gland to maintain pressure. Packing is a low cost alternative to mechanical seals.

We supply mechanical seals into the pharmaceutical, bio-technology, chemical processing, mineral and ore processing, semi-conductor and general industries.

Depending on your particular application, if you are looking mechanical seals to suit a pump application; Mechanical Seal for Pumps, or if you are trying to source mechanical seals for an agitator or tank mixer; Mechanical Seal for Agitator, or perhaps you have a hygienic application in mind, take a look at our range of Mechanical seal for Hygienic & Aseptic applications.

Our Mechanical Seal specialists can advise you on the appropriate selection of a seal support system which will deliver years of reliable service and operating cost savings in the longer term.

If you have any query around how to install mechanical seals or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running reliably again.

This is best illustrated by the Flowserve standard cartridge seal. This was originally designed as a pump seal. It was then modified to be able to operate as a mixer seal (ISC2-MW). The main difference is that the mixer version is designed to work with increased run-out associated with mixers.

– Cleaning – a mechanical seal for agitator is generally run during CIP (Clean In Place) at low speeds. A mechanical seal can be SIP’d internally for sterilisation.

We supply mechanical seals for agitators & tank mixers to the pharmaceutical, bio-pharma, chemical processing, mineral and ore processing and general industries.

If you have a technical query around the installation of mechanical seals for agitators or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

A double (or dual) agitator mechanical seal is basically a kind of cap that is designed in such a manner that it offers maximum sealing safety. This type of double agitator mechanical seal practically eliminates the leakage of the fluid and even the seepage of gases in pumps or mixers. The main work of the double mechanical seal is to provide a fixed level of safety and the assurance of zero emissions from the fixers. The mechanism that is being added in the double agitator mechanical seal is best in terms of design, which is not possible using the single seals. Such a mechanical seal stands high and essential when pumping or mixing the dangerous or toxic substance.

Ashish Seals India Pvt. Ltd. is a Mumbai-based organization that holds the reputation as one of the most reliable Manufacturers, Exporters, and Distributors of Mechanical Seals in India and worldwide. Its state-of-the-art infrastructure added with the talented and skilled professionals helps in providing the best quality products to the customers based in the nation and worldwide. The Double Agitator Mechanical Seal holds characteristics like Standard design, Double seal, Unbalanced, Cartridge, Independent of the direction of rotation, Operated by pressurized barrier fluid, Top/Side entry agitators.

Owing to the consistent performance and superior quality products, the ISO 9001 – 2015 Certified Company Ashish Seals India Pvt. Ltd. has been able to establish itself as a renowned company catering the products to numerous clients. The precision mechanical seal solutions offered by Ashish Seals are accepted in different applications such as Chemical, Food industry, Pharmaceutical, Petrochemical, Refineries, and many others.

A mechanical seal involved in a single agitator or mostly a device that works to seal a moving or reciprocating part. The mechanical seal acts as a stopper from process to atmosphere and seals leaks on parts of agitators, mixers, and vessels. An Agitator mechanical seal creates a flow path that is constrictive either in an axial position or in radial position. The mechanical seal is very effective in restricting the flow through the gap, which remains undetected when it comes to liquid or gas.

Ashish Seals India Pvt. Ltd. is a Mumbai based one of the most reliable Manufacturers, Exporters, and Distributors of Mechanical Seals in India and worldwide. Our mechanical seals comes with different characteristics that include Standard design, Single and Double agitator mechanical seals, Reverse balanced, Outside mounted, Independent of the direction of rotation, Available With/without bearing, Top/Side entry agitators. The single agitator mechanical seal even finds an application in stainless steel mixers, agitators & reactors.

At Ashish Seals, we manufacture a flawless series of products with our state-of-the-art production machines. Owing to our team of professionals and advanced machinery, we have been able to meet bulk orders from clients throughout the world within the specified time. Here at Ashish Seals, we manufacture the machinery seal without compromising on the quality. Moreover, the expertise and in-depth knowledge of our team of professionals help in carrying out designing and manufacturing requirements accordingly.

Moreover, due to the quality products, our Single Agitator Mechanical Seal is widely used in different industries like Chemical, Food industry, Pharmaceutical, Petrochemical and Refineries.

In mixing technology, the sealing of a rotating agitator shaft in the passage through a vessel wall represents the principal sealing task. Different sealing principles are used depending on operating conditions such as pressure, temperature, and speed. Most mechanical seals of agitators consist of gland plate with Mating ring and sleeve with seal ring and elastomeres for leakage prevention. They are usually top,bottom and side mounted on the vessel.

as being top most mechanical seal manufacturers in Mumbai as well as known as one of the most precise mechanical seal manufacturing companies in India.

Established in the year 2016, Flowway Teknik Private Limited are leading Exporter and Manufacturer of Mechanical Seal, Mechanical Pump Seal, Swing Joints, etc. Today, it provides the most complete selection of engineered mechanical seals and sealing support systems. Our products are recognized as a trusted brand in a process industry.read more... Brochure

We have marked a distinct and dynamic position in the market by providing a high quality array of Agitator Seal for a large spectrum of processing machines like, agitated nutsche filters and dryers, high speed dispersers, rotocon dryers, high pressure autoclaves, etc. Our offered seals are designed by our dexterousread more...

We offer a range of agitator seals that are manufactured using the premium quality raw material. These seals find application in various industries such as chemicals, petrochemicals, oil refineries, solvents, fertilizers and others. Standard compliant, these are available in different specifications to meet the variegated needsread more...

Milan Engineering.having special design and approval for Agitator / Reactor seals, Agitator seals are mostly using in Reactors, Glass line vessels, Agitator, Mixer and Heavy duty of Sturer application. We have various type of Reactor Seals with Bearing arrangement Or Without Bearing Arrangement, Reactor seal are running in lowread more...

8613371530291

8613371530291