agitator mechanical seal pricelist

Explore a wide variety of agitator seal for pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These agitator seal for pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these agitator seal for pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right agitator seal for pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of agitator seal for pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

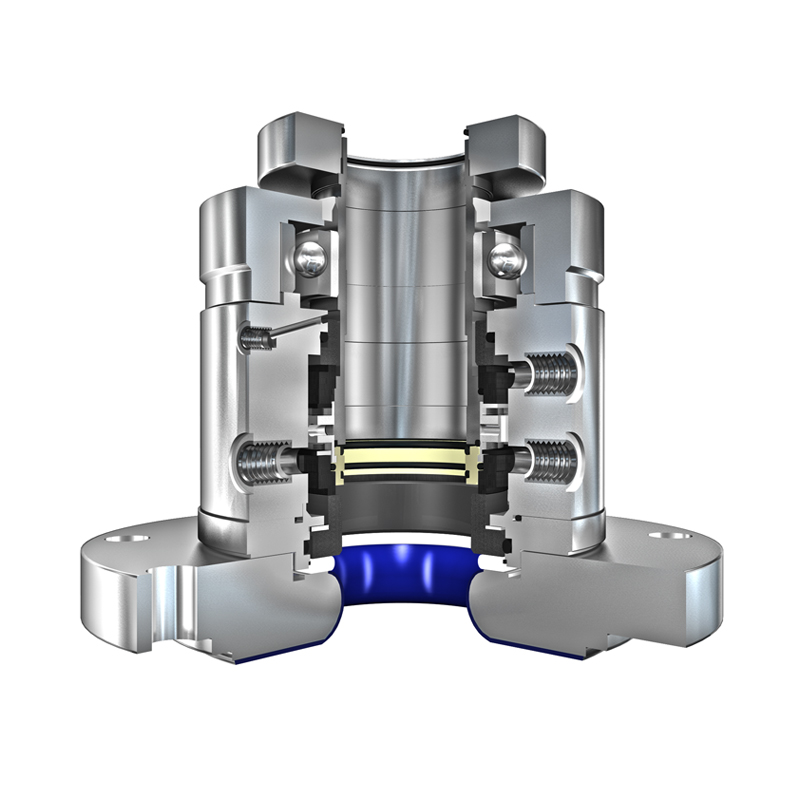

A basic mechanical seal contains three sealing points: – The stationary part of the seal is fixed to the pump housing with a static seal –this may be sealed with an O-ring or gasket clamped between the stationary portion and the pump housing. The rotary part of the seal is sealed on the shaft generally with an O ring. This sealing point can also be considered as static as this part of the seal revolves with the shaft.

One portion of the seal, either to the static or rotary part, is always resiliently mounted and spring loaded to accommodate any minor shaft deflections, shaft movement due to bearing tolerances and out-of-perpendicular arrangement due to manufacturing tolerances.

Sealing PointsWhile two of the sealing points in a seal arrangement are simple static seals, the seal between the stationary and rotating member requires a little more consideration. This primary seal is the foundation of all seal design and is vital to its efficiency.

The primary seal is basically a spring loaded vertical bearing – consisting of two extremely flat faces, one fixed, one rotating, running against each other. The seal faces are pushed together using a combination of hydraulic force from the sealed fluid and spring force from the seal design. In this way a seal is designed to prevent process leaking between the rotating (shaft) and stationary areas of the pump.

If the seal faces revolved against each other without any form of lubrication they would wear and quickly fail due to face friction and heat generation. For this purpose, some form of lubrication is necessary between the rotary and stationary mechanical seals face; this is known as the fluid film

The Fluid FilmIn most mechanical face seals the faces are kept lubricated by maintaining a thin film of fluid between the seal faces. This film can either come from the process fluid being pumped or from an outside source.

The requirement for a fluid film between the faces presents a design challenge – enabling ample amounts of lubricant to flow between the seal faces without the seal leaking an unacceptable amount of process fluid, or letting contaminants in between the faces that could damage the seal itself.

This is achieved by maintaining a particular gap between the faces that is big enough to allow in a small amount of clean lubricating liquid but small enough to stop contaminants from entering the gap between the mechanical seal faces.

The gap between the faces on a typical seal is as tiny as 1 micron – 75 times thinner than a human hair. Because the gap is so small, particles that would otherwise damage the seal faces are unable to enter, and the amount of liquid that escapes through this space is so minor that it appears as vapour – around ½ a teaspoon a day on a typical application. This micro-gap is upheld using springs and hydraulic force to push the seal faces together, while the pressure of the liquid between the faces (the fluid film) acts to push them away from each other. Without the pressure pushing them apart the two seal faces would be in full interaction, this is known as dry running and would lead to rapid seal failure.

Without the process pressure (and the force of the springs) pushing the faces together the seal faces would separate too far, and allow fluid to leak out.

Mechanical seal manufacturing focuses on increasing the durability of the primary seal faces by ensuring a high quality of lubricating fluid, and by selecting suitable mechanical seal faces materials for the process being pumped.

Agitator Seal – globe seal is largest manufacturer and exporter of agitator seal in India. We provide the world best quality agitator seal with made by top grade of raw materials. Agitator Mechanical Seals: we offer finest agitator mechanical seals by quality row materials. We are leading agitator mechanical seals exporter firm in India. The Globe Star Engineer is one of the leading manufacturer, supplier and exporter of the high quality agitator seal. We provide the agitator seal of best qualit

Mechanical seals are usually made of moving rings, stationary rings, compression elements and sealing elements. These parts are tightly bonded to form a sealing surface to avoid leakage. The liquid in the sealed chamber causes the end face to press against the end face of the stationary ring, and the mechanical seal occurs on the end faces of the two rings and the adhesion is to maintain the compression of the component pressure. The pump can not only work in the state, but also adhere to the end of the paste to ensure that the sealing medium does not leak, and avoid impurities into the sealed end. The sealing element acts as a gap between the sealing ring and the shaft, the action of the static ring and the gap of the gland, and the oscillation of the pump with the elastic element. When running with other components of the pump, the condition of the mechanical seal is closely linked with the external conditions. Only if the parts, auxiliary sealing equipment and technical requirements are ensured that the mechanical seal works well.

First, we need to turn off the pump, and then clean and inspect each part of the pump. Second, remove the impeller by rotating it in the anticlockwise direction. Then take out the seal at the backside of the impeller, and place the mechanical seal on to the shaft. Fix the mechanical seal and screw the impeller onto the motor shaft. Here are some notes of installation:

With its wide range of designs, the mechanical seals can also be made of different materials. In fact, the seal face materials decide the service time of mechanical seals. The most popular materials include rubber, stainless steel, PTFE, carbon, ceramic, Sic, and TC.

In SEALCON, equipped with advanced CNC processing equipment, you can not only buy the mechanical seals, but also buy the mechanical spare parts: sealing rings, spring, O-ring, sleeve and gland. All of our products conform to the standard of DIN24960, EN12756, ISO3069 API610, API682.

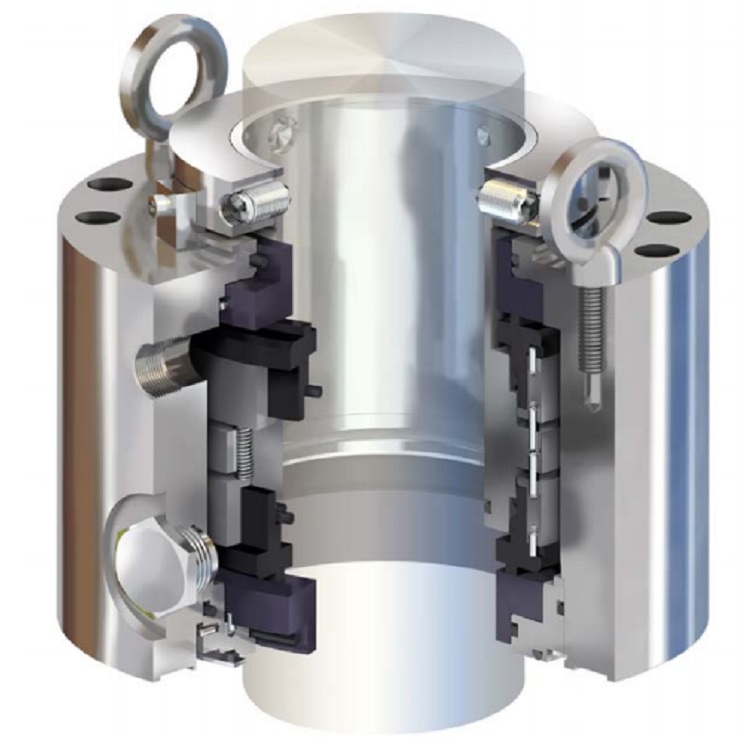

By having experience of more than 25 years, we are engaged in offering extensive collection of Double Mechanical Agitator Seals. Provided mechanical seals are used in pharmaceutical and chemical industries. Offered mechanical seals are manufactured at our state-of-the art manufacturing unit using quality tested raw materials and latest technology under the strict supervision of our deft professionals. In addition, our highly valued clients can easily avail these Double Mechanical Agitator Seals in numerous specifications as per their exact needs at pocket friendly prices.

There is no one universal seal for all mixer applications. Every mixer, agitator, and reactor model is distinctive and engineered for a specific application. Many of these applications require seals to perform in environments that would destroy common seals due to extreme drag and shear forces, abrasive materials, or other challenges. That means successful sealing requires clearly defining the type of equipment, the product, and the sealing conditions. Flexaseal’s design and engineer team are capable of providing innovative solutions for your toughest challenges.

Saisi Mechanical Seal Co., Lid is specialized in manufacturing of high quality mechanical seals for pumps, mixers, compressors etc with over 20 years experience. We are committed to assist customers with the best sealing solutions at competitive prices.

Not only do we handle all styles of seals and environmental controls, we can also repair, modify and even build what you need when standard products don’t do the job. We repair all brands in-house.

We just don"t know of another company that can do so much for you in the murky world of mechanical seals. With our training programs, we can even make the murkiness go away.

The family of shaft seals known as mechanical seals is the most advanced type of seal used in the mixing industry. They can handle the highest pressures, maintain nearly leak-free operation, and require minimum maintenance if installed and operated properly. The downside is the higher initial cost (both for the seal and for the more complicated equipment required surrounding the seal) and the expertise needed to service the seals. Mechanical seals are increasing in popularity due to the growing environmental restrictions regarding any leakage from process tanks.

There are hundreds of mechanical seal designs, but they all are variations of a basic layout consisting of a collar mounted on the shaft which uses springs to push a ring (which also rotates with the shaft) against another ring that is held stationary. The rings rotate against each other riding on a thin layer of lubricant, and the springs hold them so tightly together that leakage through the seal is reduced to an immeasurable amount. The mating surfaces of the rings must be perfectly flat to seal properly, and are manufactured to tolerance measured “light- bands." The rings must also be extremely hard to endure the pressure and wear, so they are usually made up of ceramic, carbon, silicon carbide, tungsten carbide or similar materials. The stationary “seat” is held in place and maintains a static seal with the mounting housing using gaskets or o-rings. The rotating elements of the seal must attain a static seal with the shaft using o-rings, wedges or packing.

Mechanical SealProminent & Leading Manufacturer from Ghaziabad, we offer mechanical seals, pump seals, pump seal, fristam / zeutec pump seals, carbon seals and reactor seals.

We are reckoned for manufacturing, supplying and exporting Mechanical Seals of high quality to our valued patrons. These seals are extensively made to be used in pumps. We manufacture these seals using high-grade tools and modern technology ensuring high efficiency at customer"s end. Offered product is designed and developed by a team of expert professionals so that they can be easily used in heavy industries. In addition, customers can avail custom-made mechanical seals from us.

Keeping the diverse requirements of customers in mind, our company offers excellent quality array of Pump Seals. This Pump Seals are manufactured by the team of skilled professionals by using advance machines. Our product range is highly appreciated amongst customers for its superior performance and optimum finish. The offered range of products are designed to give an excellent performance to the user. We assure that our clients remain satisfied from our qualitative product range.

Being one of the leading Manufacturers, Exporters and Suppliers of the highly efficient Pump Seal in India, we provide these at the most competitive prices for the global clients. Our Pump Seal are highly demanded by the national as well as international clients, as these can withstand different temperatures.

Our offered range of Mechanical Seals are designed using high quality material, and is widely used in chemical plants and solvent extraction plants industries. These seals are highly appreciated by our clients for their higher performance and low maintenance cost. Also, the range is available in various sizes, and can be customized as per the client"s specifications.

With the assistance of our experienced engineers, we are able to easily fabricate ourSingle Spring Alfa Laval Pump Seals in accordance to the industrial standards. Accurate dimensions, durability, high strength and corrosion resistance are the highlighting features of our Pump Seals. We are an illustrious Manufacturer, Exporter & Supplier of Single Spring Alfa Laval Pump Seals from Uttar Pradesh and known for our fair pricing policy.

We are engaged in manufacturing Carbon Seals for our clients. These are available in various specification and are used where oil and grease lubricants do not work with corrosive liquids and gases helps in contamination by conventional lubricants that are to be avoided. Further, the entire range of Carbon Seals provided by us is mainly used for making carbon seals and mechanical seals.

Based at Ghaziabad, Uttar Pradesh, India, we “Hi-Tech Seals Industries” are engaged in manufacturing and exporting of a wide range of Mechanical Seals and Component. Used in different Plants like Chemical, Solvent Extraction, Refineries, Pharmaceutical, Distilleries, Beverages and Breweries. Our range is appreciated for its impeccable quality. These products adhere to defined industry standards of quality and are produced in our state-of-the-art manufacturing unit. In addition, we also repair all types of used mechanical seals (all brands and styles), thus saving 50% of the cost of buying a new seals.

Our company is a distinguished Manufacturer, Exporter & Supplier of Hydraulic Seals based in Uttar Pradesh. The Seals we make available are known for their leak proof design, reliable performance and long functional life. We maintain a large stock of the Seals in our spacious warehouse, to meet the bulk and urgent requirements of the buyers. The entire range of the Hydraulic Seals is reasonably priced by us.

We are the prime Manufacturer, Exporter and Supplier of Agitator Mixer Seals in India. The product range is prepared as per the industry norms and widely demanded in various industrial applications. Owing to equipped with the latest technology, we are capable to provide Agitator Mixer Seals in customized specifications, defined by buyers.

8613371530291

8613371530291