aes mechanical seal in stock

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

AESSEAL Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs.Seacoast Supply maintains a large inventory of AESSEAL products.

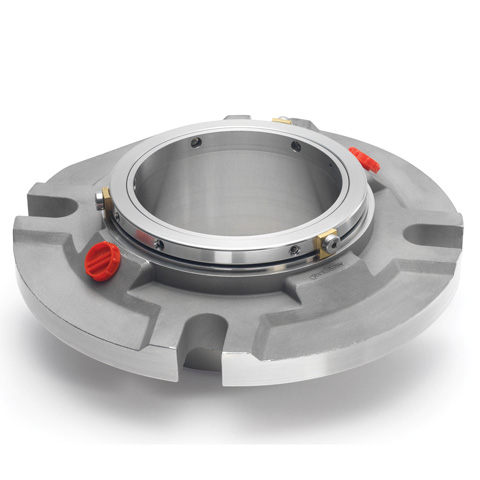

Cartridge mechanical seal construction is a proven reliability improvement. The seals are pre-assembled at the factory, pressure tested and shipped as a unit, leading to improved performance as errors due to incorrect installation are reduced. Cartridge construction eliminates the need to measure and set spring compression, and having a mechanical seal pre-assembled means that the seal faces are protected from damage during installation.

A double or dual mechanical seal consists of two independent seals mounted within a seal chamber outside the pump, which is flushed with an independent supply. This makes them ideal for sealing hazardous liquids, liquids with abrasives or liquids that are corrosive, as the seal faces only see clean lubrication greatly increasing mechanical seal life.

AESSEAL® double mechanical seals have independent seal-face designs, to enhance safe containment of process fluid in the event of damage to any individual sealing element.

This means that no matter how well designed your mechanical seal or bearing systems are, without a reliable Seal Support System there is still the possibility of your mechanical seal failing. The innovative and reliable Seal Support System Range at AESSEAL® gives customers the confidence to remove this root cause of mechanical seal failure.

AESSEAL® offer a range of bearing protection devices suitable for most applications. The innovative LabTecta® and MagTecta™ products include patented features that deliver the best possible bearing housing sealing solution for your motor, pump, plummer block, gear boxes or steam turbine.

![]()

Qseals is your one-stop-shop for supplying and refurbishing all your AES seals. Almost all AES seals can directly be supplied from stock in all common sizes and face material and elastomer combinations.

There are currently 635 AES typenumbers registered within our custom database.For all of these AES numbers there are currently 4445 suited alternatives from other brands, for at least 5103 different applications, known to us.In other words, we have probably come across your specific situation or problem before. We gladly help you with advice without any obligations.

If your AES seal can still be refurbished Qseals can also assist you with this. Read more about mechanical seal refurbishment.

The AESSEAL® DMSF™ range of double cartridge mechanical seals ( Double Monolithic Stationary Flow / Convection ) has been designed as a high-performance sealing solution for arduous applications.

AESSEAL® has one of the most comprehensive component seal product portfolios available. With some 10,000 product lines available from stock, our inventory incorporates seals to suit an extensive range of pump types and applications.

Our unique, patented range of re-engineered component seals enables 44,000 permutations to be configured, allowing AESSEAL® to offer our customers the greatest possible product availability and service. AESSEAL® provides the sealing solutions you require – direct from one source.

Our component seals offer 100% compatible solutions with OEM parts and backwards compatibility ensures our products can be used with our customers’ existing stock holding. AESSEAL® component seals are designed with modularity at their core, allowing faster service whilst also incorporating design features which reduce the lifetime cost of the product.

* The John Crane and Flexibox trademarks are trademarks of their respective owners, and neither entity is affiliated with NE Seal Ind. Prod. LTD, its products, or its website, and does not manufacture, sponsor, or endorse its products.

Cartridge seals are a modern alternative designed to eliminate common causes of component seal failure. Check pump unit for defects before installing a cartridge seal to avoid damage to seal parts.

Single cartridge or double cartridge seals are self-contained units comprised of a shaft sleeve, seal, and gland plate. Cartridge seals are fitted onto the pump shaft as a single unit with no further fitting or assembly required.

Protect the integrity, efficiency, and flow of your site operations with help from AFT. No matter the size or complexity or your system, AFT and our partner AESSEAL offer the highest quality seals and support systems for your industry.

At ProSeal Service Group, state-of-the-art mechanical seal products are a way of life. After more than two decades, our partnership with AESSEAL®—a world specialist in mechanical seal R&D—has granted us exclusive rights to distribute in Michigan, Ohio, and Alaska. This allows us to deliver some of the most technologically advanced seal products in Component, Single Cartridge, Double Cartridge, Split, Metal Bellows, Mixer, and API seals to keep you operational.

In addition to cutting-edge modular mechanical seals, we specialize in bearing protectors, gasketing products, and gland packings. All of ProSeal’s products are designed to limit operational and maintenance costs throughout the lifetime of your equipment for maximum ROI. From double bellows to single pushers, we can help you find and maintain the right mechanical seal products for your operation.

AESSEAL®cartridge mechanical sealsare used in a wide variety of pumps and rotating equipment to prevent liquids and gases from escaping into the environment. Here are three benefits of AESSEAL®cartridge mechanical seals.

AESSEAL®cartridge mechanical sealsare pre-assembled at the factory, pressure tested, and shipped as a unit. This seal configuration eliminates the requirement for seal setting measurements at installation.

Spring tension is another crucial factor in a successful seal installation. Withcomponent seals, you must set the tension manually by adjusting the length of the installed seal spring. Withcartridge seals, the spring tension is preset, eliminating the time and potential errors of manual installation. A retaining device holds the rotating and stationary elements in correct alignment until the seal is mounted.

Cartridge seals are capable of handling the most demanding applications, including slurry applications and hazardous process fluid containment. AESSEAL®’s standardcartridge sealline includes the following.

For unusual applications, AESSEAL® also has a Standard Plus line that offers the same benefits as their standard seals while also meeting specific customer needs. This includes competitor replacement seals and seals designed for specific pumps and processes.

Cartridge mechanical sealscost more thancomponent seals. However,cartridge seals will save you money in the long run, thanks to lower maintenance costs. Potential savings come from reduced labor costs and less downtime when in-service seal replacement is required.

Are you interested in improving pump reliability, increasing uptime, and reducing maintenance costs? The experts at C&B Equipment can help you implement the bestAESSEAL®cartridge mechanical sealsand seal support systems for your application. We also offer a suite ofpreventative maintenance programs and repair servicesto ensure your equipment remains in top shape for the duration of its life!

8613371530291

8613371530291