api mechanical seal plans factory

Please contact AESSEAL Systems Division for further details. Tel: +44 (0)28 9266 9966 Email: systems@aesseal.com For more information, and a video demonstrating the piping plan in operation, select a plan below

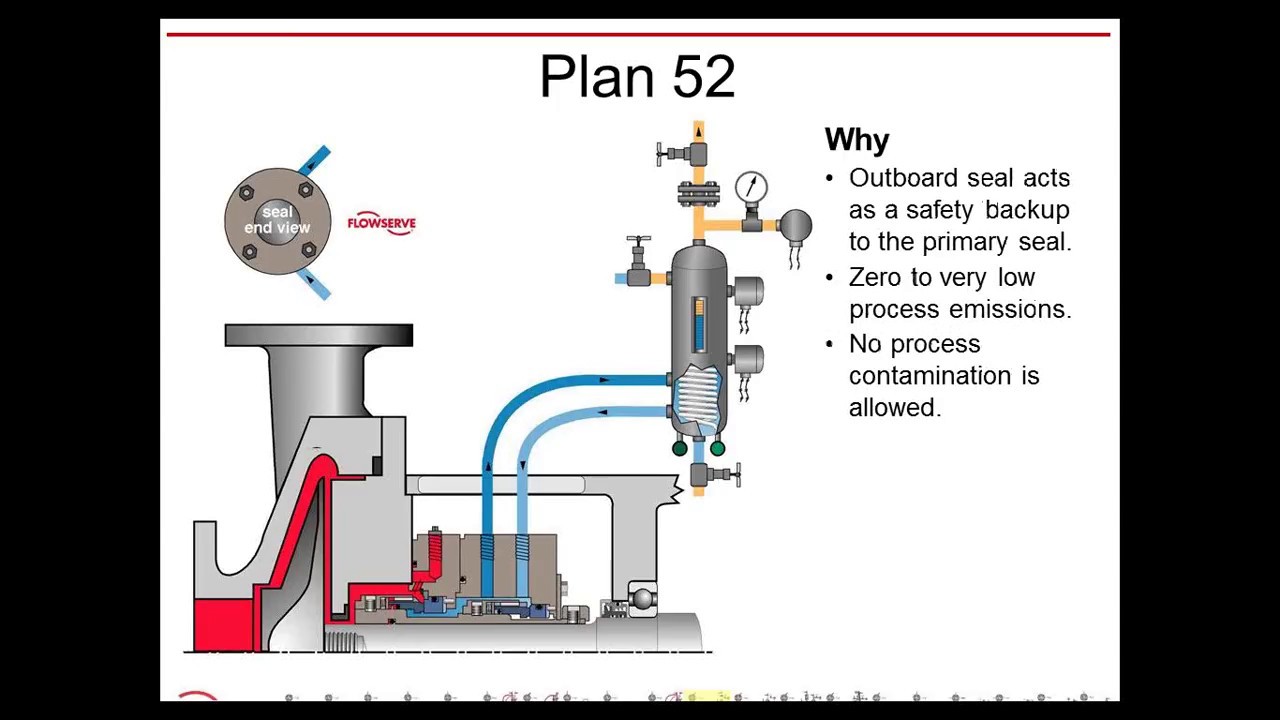

Depressurised buffer fluid circulation in outboard seal of a dual seal configuration through a seal support system. Circulation is maintained by using pumping ring in running condition and by thermosyphon effect in stand still condition.

1. Keep the sealant vessel vent continuously open, which is necessary to maintain buffer fluid pressure close to atmospheric pressure and vent the vapors to flare.

Seal support systems are vital to the reliable functioning of the thousands of pumps that keep a refinery running around the clock. When they are properly designed, installed, and maintained, the seal support systems help ensure pump reliability and maximize the pump life by maintaining the optimum seal chamber conditions. In Northern California, pump reliability takes on an added dimension—environmental compliance. Any leakage of hydrocarbons could result in sanctions from the California Division of Occupational Safety and Health (Cal/OSHA) or Bay Area Air Quality Management District (BAAQMD).

If you’re new to API plans, you’ll quickly realize that the range of options available in API seal flush plans reflects the range and complexity of the various pumping processes and conditions across a refinery. Choosing the right API seal flush plan is a critical step in ensuring pump reliability. In my years of experience in working with process engineers and maintenance teams at Northern California refineries, we’ve always achieved better outcomes when I have the opportunity for on-site analysis of pumping processes and can advise them on the latest advancements and configuration options available.

The tables below provide an overview of the three standard categories of API seal flush plans—process side, between seals, and atmospheric. It’s not a comprehensive list of all API plans, but I hope they provide enough information to help you understand the range of options available in each category and take the first steps in matching plans with your specific pumping processes.

Description: Process side API seal flush plans use a single mechanical seal to prevent pump (process) fluid from leaking. In this arrangement, the process fluid is the lubricant. It provides a thin film between the seal faces to reduce friction and absorb heat. In doing this, the pressurized process fluid “leaks” across the seal faces and returns to the process flow.

Recirculates process fluid from pump discharge through a cooler, then to the seal chamber; Preferred for viscous process fluids that could clog seal flush cooler

Recirculates process fluid from the seal chamber through a cooler, then back into the seal chamber using a pumping ring; By continually recirculating seal chamber fluid through the seal flush cooler, it provides greater cooling capacity compared to Plan 21

Recirculates process fluid from pump discharge through a cyclone separator, sending clean process fluid to the seal chamber and particulates back to pump suction; For optimum performance, particulates should have a specific gravity twice the process fluid

Delivers clean or cool flush fluid to the seal chamber from an external source; Employs a close-clearance throat bushing to ensure seal chamber higher pressure; Because flush fluid will migrate past the bushing it must be chemically compatible with process fluid

Recirculates process fluid from pump discharge through a cyclone separator, sending clean process fluid to the seal chamber and particulates back to pump suction; Particulates should have a specific gravity twice the process fluid

Each of these API seal flush plans has options to help tailor the plan to the requirements of the specific pumping process. Instrumentation such as temperature, pressure, and flow gauges help monitor system performance. If you’re not using process fluid to lubricate the mechanical seal, flush fluids can be water, water/glycol, or mineral- or synthetic-based hydraulic and lubricating oils. Cooling capacity needs to be carefully calculated based on process fluid temperature, pressure, and mechanical seal type. When you’re faced with choosing among these options, the guidance of an experienced, local seal support system vendor is critical. Well-informed design decisions are the foundation for long-term reliability.

Description: The majority of refinery processes deal with hydrocarbons. In comparison to process side API seal flush plans, between seal plans provide a higher degree of protection against leakage. As a result, between seal plans (or dual mechanical seals) are used in the majority of refinery pumping applications.

These API seal flush plans deliver a barrier (pressurized) or buffer (unpressurized) fluid delivered from an external source to the space between the inboard and outboard seals. Barrier fluids can be a water/glycol mix, or mineral- or synthetic-based hydraulic and lubricating oils.

Uses a pressurized bladder accumulator to isolate pressurized gas from barrier fluid and delivers clean barrier fluid between the inboard and outboard seals at a pressure higher than the process fluid pressure; An internal pumping ring circulates the nitrogen barrier fluid; Bladder prohibits gas absorption into the barrier fluid and facilitates higher operating pressures than Plan 53A

Preferred for applications where the seal chamber pressure varies during pump operation; Uses a sensing line from the seal chamber into the piston accumulator to deliver barrier fluid from a reservoir at a constant, but higher pressure than the process fluid pressure; An internal pumping ring circulates the barrier fluid

Delivers buffer gas (typically plant nitrogen) from an external source to the seal chamber at a lower pressure than the process pressure; Uses a coalescing filter to remove any moisture and particulate present in the plant nitrogen supply; Any process fluid vaporizing across the inboard seal is then swept into a closed collection system

Delivers barrier gas (typically plant nitrogen) from an external source to the seal chamber at a higher pressure than the process pressure; Uses a coalescing filter to remove any moisture and particulate present in the plant nitrogen supply; Allows a small amount of nitrogen to leak into the process fluid

These plans also can also have a significant number of design options. Plans 54 and 55 lend themselves to a high degree of customization regarding reservoir volume, pump, filters, coolers, and instrumentations. These plans can also be configured to support multiple pumps with similar pumping characteristics. Plan 72 has the option of adding a condensing or non-condensing leakage collection system. For each of these, determining the proper pressure is one of the most critical factors regarding system performance.

If you’re making an investment in a new or upgraded seal support system, it’s well worth the time to work with an experienced Field Engineer who understands the importance of configuring the options for the specific pumping process.

Description: In comparison to the range of options in the above API seal flush plan categories, atmospheric side plans are much simpler. Their purpose is to provide a non-pressurized cooling flush to a mechanical seal"s faces on the atmosphere side to prevent or remove solid formations—crystallization, icing, and coking. Water, steam, and nitrogen are the typical flush fluids.

A quench improves atmospheric seal performance by absorbing or removing any process fluid leakage, preventing process fluid from being exposed to the atmosphere, and cooling or heating (relative to the process fluid temperature) to prevent the formation of solids proximate to the mechanical seal.

Delivers clean flush fluid from an external reservoir to the atmospheric side of a single seal preventing icing at ambient temperatures on the atmospheric side; Used for vertical pump applications

Delivers a low rate (2 to 4 PSI) of quench fluid (nitrogen, water, steam) from an external source to the atmosphere side of the seal. Typically uses a throttle bushing for containment.

Each of the atmospheric side plans has an option to collect condensing process fluid leakage into a reservoir. In the event of excessive leakage, a level transmitter on the reservoir triggers an alarm.

The proper design of your flush plan is the biggest factor in ensuring long-term performance and reliability. You may have the in-house expertise to determine the appropriate API flush plans for the various pumps in a new installation or upgrades of existing pumps, but your outcomes will improve if you engage the service of an experienced, local partner. In working with process engineers for over the years, I can tell you first-hand that you’ll:

An experienced API seal flush plan partner has Field Engineers to evaluate each process and pumping conditions, fluid compatibility issues, and infrastructure considerations (on-site or virtually) to help determine plan requirements.

Swagelok has decades of expertise in helping refineries determine the proper API seal flush plans. We can design, fabricate, and thoroughly test the API seal plans prior to delivery. For over 50 years, Swagelok has been meeting the seal support needs of refineries in Northern California. We offer a complete range of API seal flush plans, available as kits or assemblies.

To learn howSwagelok Northen Californiacan assist you in choosing API seal flush plans that are right for your process needs by providing expert consultation, design, and fabrication,contact our teamtoday by calling

To keep mechanical seal systems functioning as long as possible, we recommend using standardized seal piping plans. Detailed API seal piping plans ensure minimal seal face wear by maintaining the optimal seal chamber environment.

Since they were first formulated, seal piping plans have been maintained and remodeled by the American Petroleum Institute (API). Current plans are based on API 682 and are sorted numerically. In some cases, designated letters are also used to differentiate between plans.

The mechanical seal is the most likely part of the pump to fail. Approximately 70% of the pumps removed from service for maintenance are victims of mechanical seal failure. Mechanical seal parts are highly engineered with very close tolerances and any upset in the pump or associated system can cause seal failure, including:

Mechanical seals are based on positioning two very flat and smooth discs called seal faces, one rotating on the shaft and one stationary in the pump, against each other. The discs are flat and smooth enough to ALMOST prevent the pumped fluid from leaking out between them. However, the faces do rely on a very thin film of fluid between the faces to lubricate that rubbing fit. Without this film of fluid, the seals will overheat and fail. Lack of lubrication is the PRIMARY cause of seal failure. If the fluid is very hot, it can flash to a vapor as the fluid moves across the faces, again resulting in lack of lubrication. Note that gas seals use a gas film between the faces to minimize face contact and heat buildup.

Seal flush plans are intended to keep the area around the seal in the most seal friendly environment practical, usually meaning clean and cool. Dual seal plans also provide backup and leak detection for safety.

Note that seal flush plans use pressure differences at the pump to drive the flush fluids. The pump suction is low pressure, the seal chamber is a medium pressure, and the pump discharge is at high pressure.

As the seal faces faces rub together (with their thin film of lubricating fluid), they generate heat. The heat can build up in the seal chamber and push the fluid towards its boiling point, resulting in premature flashing, lack of lubrication, and failure. This first set of seal plans is intended to create circulation through the seal chamber to dissipate the heat out of the seal chamber and back into the pumped fluid.

Flush fluid flows from high pressure at pump discharge to the medium pressure seal chamber and back into the main flow to remove heat from seal chamber

Can be used to increase seal chamber pressure. Increased chamber pressure may be required to keep chamber fluid from flashing to vapor or to provide enough pressure to push the fluid between the faces for lubrication. (Seal chamber must be 5 psi minimum above external atmospheric pressure).

These seal plans are intended to provide the seal with the friendliest environment possible by cooling and/or cleaning the fluid in the seal chamber. The throat that separates the seal chamber from the main pumped fluid can be further restricted by adding a close clearance bushing in the bottom of the seal chamber, better isolating the cool, clean seal chamber fluid from the hot, abrasive fluid in the pump.

Rather than a Plan 21 single pass system, a Plan 23 is a multi-pass system. Fluid comes FROM THE SEAL CHAMBER instead of the pump discharge, is cooled, and directed back to the seal chamber.

Fluid is driven out of the chamber and through the cooler by “pumping ring” or other “pumping feature” built into the seal. These features provide very little differential pressure. Connecting tubing must have long, sweeping bends, well vented high points, and low point blowouts to ensure fluid flows.

Quench piping does NOT change conditions inside the seal chamber, at the wet side of the seal faces. Rather, it affects or monitors the environment on the ATMOSHPERIC side of the seal faces.

Pumps that leak when they are filled, even before they are started, often have a flush line intended for a Plan 11 or 13 connected to the QUENCH port, leading to the atmospheric side of the seal. There should be a “Q” or the work “QUENCH” stamped in the gland at this port.

For flush plans Plan 65A, 65B, 66A, and 66B, facility owners may want to know if their seals are leaking excessively without going to the expense of dual seals. These seal plans direct excessive leakage on the outside of the seal to an alarm instrument. Remember that seals leak a little bit. They need to in order to lubricate the faces and function correctly. The plans below handle the nuisance leakage in different ways.

Used in salting services like sodium hydroxide. The leakage across the seal faces will turn to salt when it reaches atmosphere. The salt crystals can wear the faces or build up in the seal, preventing the movement necessary to keep the seal faces in contact. The salt on the outboard of the seal can be washed away with a water quench through the quench and drain ports. Usually a close clearance bushing is installed at the extreme outboard end to the seal assembly to help keep the quench fluid moving from the quench to the drain port (or vice versa) and not just run out along the shaft. Also used for slurry services.

Grease can be introduced into the quench port. This external grease can provide temporary lubrication to the seal in case the pump sees large air or vapor pockets which would normally rob the seal faces of the required lubricating fluid film.

Quench can also be gas. In hot hydrocarbon services, the fluid will turn to solid coke when it reaches the atmospheric side of the seal. The fluid would remain a liquid if the area outside the seal faces is robbed of oxygen with a flood of nitrogen or steam.

An alarm does NOT necessarily mean a failed seal. The collection vessel might be full from years of nuisance leakage. Try emptying the vessel and observing how fast the vessel fills.

Two throttle bushings are used to ensure that the vapor (or fluid) leakage is limited along the shaft and out of the drain. A pressure switch picks up a rise on pressure above nuisance levels on the outboard side of the seal.

Dual seals provide a backup seal in case the primary seal fails. They prevent hazardous fluids from leaking to the surrounding area, desirable for both environmental protection and the safety of nearby personnel. Dual seals also capture and control any leakage of pumpage across the primary seal. The backup seal is kept lubricated by introducing a buffer/barrier fluid (often a mineral or synthetic oil, a water/glycol mix, or diesel) into the space between the primary (inboard) and secondary (outboard or backup) seals. The buffer/barrier fluid is contained in a tank (5 gallons is most common) adjacent to the pump. Instrumentation on the tank indicates what is happening with the seals.

Remember that a lubricating fluid film will flow from high pressure to low pressure. If the pump seal chamber pressure is higher than the pressure on the other side of the seal, the pumpage will be the lubricating film. If the pump’s seal chamber pressure is lower than the external pressure, the external atmosphere will migrate into the pump. Pumps under vacuum cannot use an ordinary single seal, since air from the atmosphere would be drawn between the faces, causing them to run dry and fail. Using a dual seal allows a fluid to be present at the outside of the seal. In a pump under vacuum, the buffer fluid would be pulled into the pump between the seal faces, keeping the inboard seal well lubricated.

If the pump seal chamber pressure is higher than the BUFFER fluid between the primary and backup seal faces, then the pumped fluid will flow from the high seal chamber pressure into the low pressure buffer fluid. This is called a DUAL UNPRESSURIZEDseal (formerly called a tandem seal), and the fluid is called a BUFFER fluid.

If the pump seal chamber pressure is lower than the BARRIER fluid between the primary and backup seal faces, then the barrier fluid will flow across the primary seal from the space between the primary and backup seals into the pump. This is called a DUAL PRESSURIZEDseal (formerly called a double seal), and the fluid is called a BARRIER fluid.

Buffer fluid circulates from the buffer fluid reservoir, through the space between the primary and backup seal, and back to the reservoir. Fluid is circulated by a weak pumping action built into the seal.

It the fluid flashes to vapor at low pressure, the vapor is piped to a flare or vapor recovery system, through an orifice at the top of the tank. If the primary seal is allowing too much leakage, the vapor will build pressure in the reservoir against the orifice and a pressure instrument can alert the operator.

If the fluid remains as a liquid under low pressure, any leakage will cause the fluid level in the buffer tank to rise, where a high level alarm can be tripped. Just because the high level alarm is tripped does not mean that the primary seal is failing; it is the rate of leakage filling the tank which matters. The high level may have been reached after collecting years of nuisance leakage. Often, an oil change to the original level is all that is required. Be sure the fluid is disposed of properly.

Seal face friction or hot pumpage can add heat to the buffer fluid. A cooling water coil is often installed in the reservoir to cool the buffer fluid.

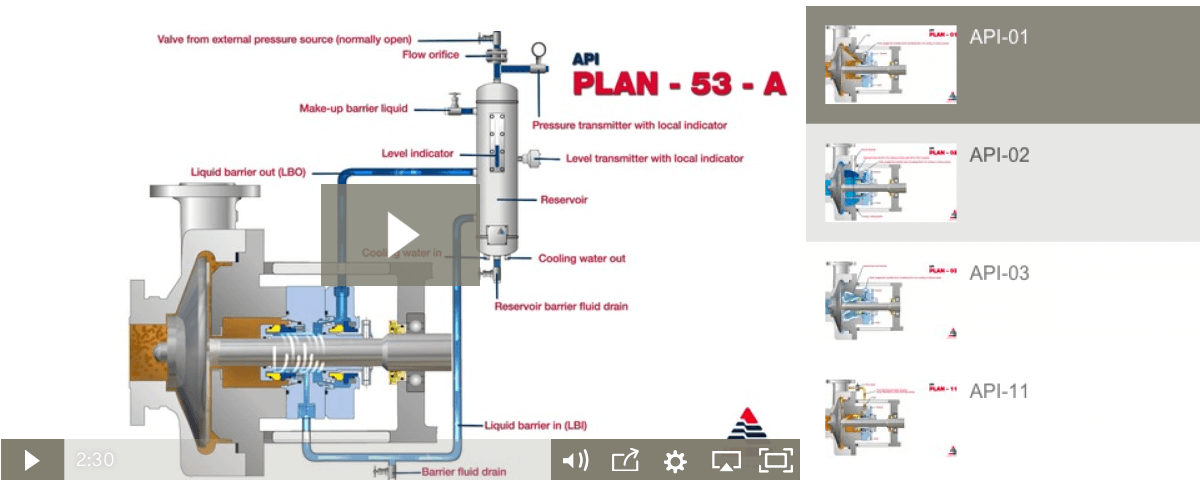

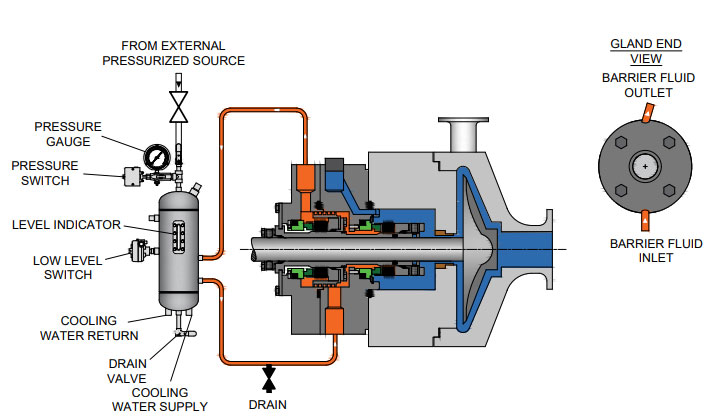

Dual pressurized system (seal barrier fluid is at a higher pressure than the pump seal chamber). Pressurized systems are used to ensure that very dangerous fluids remain in the pump. The difference between 53A, 53B, and 53C is the method of pressurizing the barrier fluid. Pressure in the barrier fluid should be at least 10 psi over the pressure in the pump seal chamber.

Barrier fluid circulates from the barrier fluid reservoir, through the space between the primary and backup seal, and back to the reservoir. Fluid is circulated by a weak pumping action built into the seal.

A low level alarm in the reservoir alerts the operator that a seal may be failing, allowing the barrier fluid to enter the pump through the primary seal or the atmosphere through the backup seal.

Seal faces can be designed to maintain a gas film between them rather than a fluid film. These piping plans are intended to work with theses gas film (dry running) seals. Plan 72 and 74 bring the buffer or barrier gas into the seal; plans 75 and 76 are for the gas exiting the seal.

Secondary seal is ordinarily running with a gas film between the faces. When the primary seal fails, the pumped fluid will fill the space between the primary and backup seal. The backup seal is now working as a liquid seal rather than a gas seal and is designed to run for about 8 hours, allowing the operators time for an orderly pump shutdown.

Plan 72 buffer gas flow keeps the gas in the seal from becoming concentrated from nuisance leakage over time so that any leakage from the gas backup seal is mostly inert flush gas and not toxic pump vapors.

Mechanical seals are used in millions of process pumps; the many available seal configurations are described in the standards of the American Petroleum Institute (API-682). These standards also describe the many flush plans (piping plans) used by modern industry. Except for automotive, home appliance and similar applications where the pumpage fully envelops the sealing components, a flush liquid stream and associated piping plans are used to remove heat from the seal faces.

There are many manufacturers of mechanical seals and their overall strategies appear similar: each desires to deliver safe products at reasonable cost. However, the business objectives of the very best mechanical seal manufacturers go beyond the obvious. Their objectives are expressed in marketing approaches which consistently represent value.

Superior service and high customer satisfaction are among the discernibly beneficial aspects of good marketing. Additional benefits accrue if the seal’s service and asset provider conveys educational or training updates to the ultimate seal user.

Such opportunities exist based on new flush plans found in the 4th edition of API-682; they are Plans 03, 55, 65A and B, also Plans 66 and 99. Although these five flush plans and their derivatives are little known, they can be of great advantage in certain services.

The new API Plan 03 (Figure 1) is a great addition; it relates to a taper-bore seal chamber for an API pump. For decades API pumps have been using closed (cylindrical) seal chambers and have relied on piping plans to maintain a chosen seal environment. However, because taper-bore stuffing boxes are now very well proven in American National Standards Institute (ANSI) pumps in contaminated services, we also now can specify tapered bores for API-compliant pumps.

In Plan 03 the flush fluid flows into the pumpage. Circulation between the seal chamber and the pump is facilitated by the tapered geometry. Solids accumulation risk is greatly reduced by the tapering and the former stuffing box is now part of the back pull-out cover of this pump. New pumps can accommodate the tapered design, as will pre-existing pumps through a modification or upgrading process. It should be noted that the taper should be relatively steep; 30 to 45 degree inclination has worked well. Very shallow taper angles should be avoided.

This seal chamber geometry promotes circulation which, in turn, provides cooling for the seal and vents air or vapors from the seal chamber. Flush Plan 03 is most often used in applications where the seal faces generate relatively small amounts of heat. Plan 03 is also used in applications where the old-style cylindrical chamber would have allowed solids to collect. Occasionally, the tapered bore is fitted with anti-swirl vanes (sometimes called “swirl interrupting ribs”) for even greater assurance against solids accumulation.

In Plan 55 (Figure 2), there is an unpressurized external buffer fluid system supplying clean liquid to the buffer fluid seal chamber. Plan 55 is used with dual (double, tandem) liquid seal arrangements. The buffer liquid is typically maintained at a pressure less than seal chamber pressure and less than 0.28 MPa (2.8 bar or 40 psi).

Plan 55 is similar to Plan 54 except the buffer liquid is unpressurized. The Plan 55 representation in Figure 2 shows an efficient bi-directional tapered pumping ring. This particular ring greatly assists in moving the buffer fluid to and from an external reservoir and/or through an external heat exchanger (cooler). Also, the potential advantages of using a tapered pumping ring can be significant. One such model, as seen in Figure 2, is offered with bi-directional functionality and a wide clearance between its vane tips and the opposing stationary parts. In the event of pump bearing distress, this wide clearance gap protects against scraping and extreme heat generation.

The outboard seal in Figure 2 is a wet containment seal (API calls it configuration 2CW-CW—dual contact wet seal) and is normally used in services where process fluid leakage to atmosphere must be avoided, which is to say minimized and contained. Many users found Plan 55 advantageous in applications where the process was prone to solidify in contact with atmosphere or in applications where additional heat removal from the inner seal was required.

Examining major seal manufacturer Websites allows users to see how Plan 55 differs from Plan 52. In Plan 52 the buffer liquid is not necessarily self-contained; with Plan 52 buffer liquid circulation is created by an external pump or pressure system. If Plan 55 is

In Plan 65A/B there is an atmospheric leakage collection and detection system for condensing leakage. Failure of the seal will be detected by an excessive rate of flow into the leakage collection system. Figure 3A and Figure 3B is intended to convey that many different seal configurations are allowed; the emphasis is largely on leakage monitoring. The central port is equipped with one of many feasible instruments. In any event, Figure 3 depicts a standard setup when pumped fluid condenses at ambient temperatures.

Plan 65A/B is normally used with single seals in services where the anticipated seal leakage is mostly liquid, not gas. Piping is connected to the drain connection in the gland plate and directs any primary seal leakage to an exterior collecting volume or system.

The exterior collecting reservoir (the “volume”) is not usually provided by the seal manufacturer; the “volume” could be an oily water sewer or some other environmentally acceptable liquid collection system in the plant. Within the seal, excessive flowrates would be restricted by the orifice located downstream of the reservoir and are redirected to it, causing the level transmitter to activate an alarm.

Plan 65B is very similar, as seen in Figure 5. A needle valve can be trimmed to suit the user’s needs. Major leakage bypasses this valve and flows away. The rate of leakage can be safely tracked by the LIT. The leakage collecting reservoir again has to be mounted below the seal gland to allow gravity flow from seal to reservoir. A valve is usually located between seal and reservoir; it has to remain open during operation and should be closed during controlled maintenance events only.

Plan 66 (Figure 6) is a leakage detection plan often used by the pipeline industry sector for duty in remote applications. Here, high leakage flow is of prime interest. Note how a suitably orificed (or valve-equipped) pressure transmitter would be connected to the central port of this cartridge seal. Under conditions of high leakage flow, the resulting pressure rise would trigger an alarm.

This approach will probably be similarly effective with more viscous fluids. Indeed, alternative versions have appeared in production areas with a closed valve on the outlet rather than the orifice. The valve will require periodic opening to drain off the “normal” or reasonably expected seal leakage. By trending the time interval between drain-downs users obtain accurate data on the condition (or even failure trend) of a single seal.

Bearing protection takes on a special significance in remote pipeline pumping. Figure 6 prompts the author to bring this to the reader’s attention. An advanced bearing housing protector seal is illustrated, as in several of the preceding figures.

There could also be an engineered piping plan not covered by present API standards—a plan executed to the customer’s orders. A knowledgeable customer still wants to listen to manufacturer’s advice and experience.

To recap and summarize our opening paragraphs: There are many manufacturers of mechanical seals and their overall strategies seem similar. Special seals and special applications are of interest to reliability-focused users. Such users often seek out seal manufacturers whose overarching desire it is to go beyond delivering safe products at reasonable cost.

These may be companies other than your traditional alliance partners; they will, by definition, be manufacturers whose marketing approaches consistently represent value. They must be able to point to superior service and high customer satisfaction. And they must have the desire to teach. We consider them seal service and asset providers who willingly convey educational and training updates to the ultimate seal user.

Mechanical seals are a great cause of concern and failures in many operating plants. This is especially true of systems that are pumping or compressing dirty fluids. Some examples include bottoms pumps, sulfur pumps, or equipment that is handling abrasive or challenging process media. Mechanical seals are often redesigned, replaced and repaired simply because of the challenging conditions these seals face during operation. This has continually led to excessive costs in terms of repair or redesign, not to mention production loss and cost associated on a critical unspared asset.

While seals have to be properly selected and designed for the application during the project’s engineering stages, it is equally critical to select the right and most cost-effective seal plan to help support the seal’s operating environment. The seal flush plan is as equally critical and perhaps more so to help establish a reliable operating mechanical seal. API Standard 682 from the American Petroleum Institute provides various seal plan configurations, their advantages and disadvantages and a good description of each of the plans. To gain an in-depth understanding of the various types of applications and plans available for selection, refer to API 682. In addition, a lot of seal vendors publish handy booklets that contain good, brief and quick references and explanations of the different API seal plans.

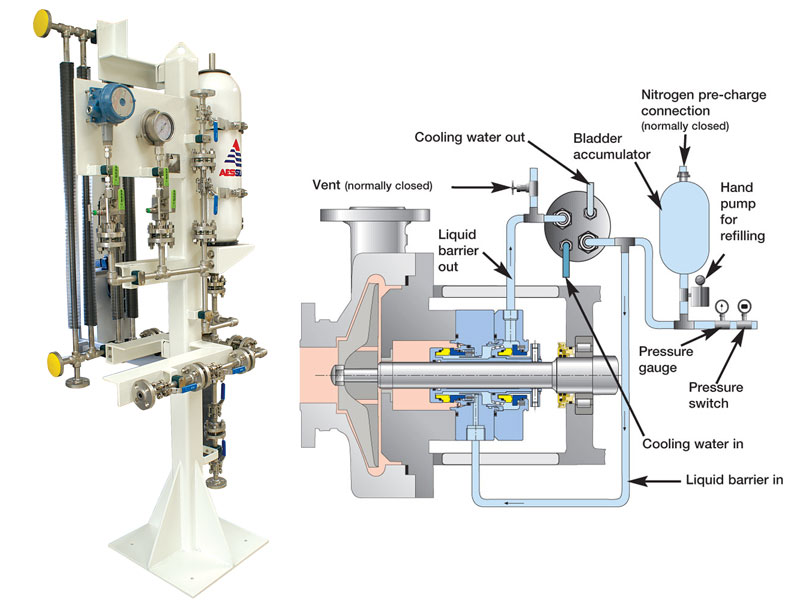

This particular article looks at API Plan 53B and how paying careful attention to some aspects of this plan can ensure a proper and reliable running seal in many applications. Of course, the mechanical seal should be correctly and most optimally designed for the particular application at hand.

Figure 1 shows a basic overview of what a 53B seal flush plan looks like. It is a pressurized flush plan that gets used with a dual seal (i.e., two seals) configuration. The accumulator contains a bladder that is pre-charged at a certain calculated bladder pre-charge pressure value through the bladder charge connection shown in Figure 1. Next, the barrier fluid, which can be royal purple or another process compatible based media, is injected into the system at a certain calculated hydraulic charge pressure through the make-up barrier fill or a similar port provided on the piping setup. The idea is that when the seal fails (leaks are more than expected since all seals leak to some extent), then the barrier fluid, being at a higher pressure, will push the leakage back into the process rather than letting the process media leak outside into the ambient. This helps prevent environmental release and avoids wastage of costly process media to the atmosphere. It is quite clear based on this that such plans are best suited for applications that are toxic and hazardous and where negligible leakage is allowed into the atmosphere due to such concerns. Consider reading ample literature available from various sources to gain a deeper understanding of this particular plan.

One of the key advantages of this particular plan is the cost associated with implementing it in a given plant compared to other similar options (i.e., Plan 54 or others). However, it is imperative to realize that the reliability of a 53B plan and the mechanical seal it supports is highly dependent on the plant operator who maintains this and checks on the system on a regular basis. While a number of seal failures can be attributed to incorrect designs or other issues, equally, if not more, causes can be attributed to how a plan 53B is operated and maintained on a running asset.

Here are a few important points that should be considered while working with any plan 53B in a maintenance and operating organization.It is important to vent a 53B through the appropriate vent points provided to ensure there is no vapor entrapment prior to seal start-up. Attention should be paid to horizontal versus vertical heat exchangers provided on the system. Based on experience, it is easier to vent out vertical heat exchanger configurations versus horizontal systems. However, horizontal systems are provided or should be provided with block valves to help ensure proper venting.

In colder climates where a plan 53B is installed outside, the system should be properly heat traced and winterized. This includes the seal flush piping, the accumulator and the exchangers. The accumulator contains a nitrogen bladder with a pre-charge pressure as previously indicated. Fluctuations in the ambient temperature can have a dramatic effect on system pressure and lead to seal failures and loss of seal system reliability.

Operations should confirm and check with engineering that the right calculated values are provided for the pre-charge pressure for the bladder and also the hydraulic system charge pressures. These are quite critical to ensuring system and seal reliability. Any discrepancies in these calculated values can risk reverse pressurization (i.e., seal reversal) and subsequent failure of the sealing system. It is important to note that some plants consider playing around with the pre-charge and hydraulic charge values to buy more time between system failure and low-level alarm of the barrier fluid so the operator has sufficient time to fill and make up the loss of barrier in the system. However, experience has shown the best way to address this issue is to procure accumulators of higher volumes to provide for this as opposed to modifying pressures to buy more volume in the system. The latter seems to have much smaller effects compared to sizing the accumulator correctly in the first place. Also, if consideration is being given to changing pre-charge and hydraulic pressures, this should be in discussions with the original equipment manufacturer (OEM) seal vendor since excess pressures on a given seal can compromise and affect seal leakage rates, thus reducing the time and volume present in the system.

It is equally important that the operator only charge (i.e., make-up fill with hand-pump) the system when the low-level alarm pressure is initiated. Charging the system at every minor occasion when the barrier pressure and level drops is not warranted. This, on the contrary, will lead to a poor seal system and seal reliability as a result of multiple pressure charging in short intervals.

Operations should keep a log of charging frequencies, depending on the low-level alarm. This, along with visual inspections, can provide a good clue to seal failures and acceptable leakage rates. The question most often asked by an operator is: What is considered an acceptable leakage? While engineering, along with the seal OEM, can provide acceptable leakage rates, to get a very good measure of seal reliability, the operator can keep an eye out for the frequency of fill and also, if correctly done, the volume filled during the initial fill cycle.

Since the pump throat bushing controls the stuffing box environment, it would be beneficial to incorporate the throat bushing on the seal cartridge itself to help with maintenance, as opposed to locating it within the pump. This holds true not just for the 53B seal plan, but for others as well.

Having a temperature gauge located on both the inlet and outlet of the seal helps in establishing a temperature gradient between the seal’s in and out flow. A difference of around 20 to 30 degrees C is acceptable; any more delta T changes can point to possible issues with the seal, cooling water, or other variables. This can help the operator make on-site decisions to engage or escalate the issue to engineering in the event of a potential problem.

While there are many individual experiences connected to running a 53B seal flush plan, these important points most certainly can help the operator make an informed decision to help seal reliability and mean time between failures (MTBF) in a running plant. Engineering should perform a detailed root cause analysis on complex seal issues and provide the appropriate solutions sought to address repeated failures. This will help the plant’s bottom line: Cost and Revenue.

Many process fluids are at a temperature that can prove challenging for mechanical seals.High temperatures can result in low fluid viscosity, high vapor pressure, and coking/thermal breakdown ofthe process fluid. Reducing the fluid temperature in the seal chamber can often lead to improved sealperformance and equipment reliability.

There are several standardized piping plansdefined in API-682which can achieve the desired cooling. While both can reduce the temperature, there are significant differences in the efficiency of the cooling and impact on the plantoperations.

Plan 21 is defined as a circulation of process fluid from ahigh-pressureregion of the pump, through a seal cooler and flow control orifice, back into the seal chamber.

Since theprocess fluidis circulated through a cooler, the fluid injected into the seal chamber will be lower than the process fluid. The flow rate of the fluid and desired reduction in temperature will dictate the type and capacity of the seal cooler in the system. Both water-cooled and air-cooled seal coolers have been used successfully in the field.

A Plan 21 creates circulation due to the differential pressure in the pipingplan. For this reason, there aregenerally no issues with overcoming friction losses in the piping and the seal cooler itself. This allows for the selection of a greater variety ofseal coolersandmoreflexibility in the design of the system.

The greatest challenge with a Plan 21 is the amount of cooling which must continuously occur in operation. Process fluidenters the cooler at process temperature and it must be cooled to the desired temperature. This continual removal of heat can require a larger capacity seal coolerand higherdemand for cooling water from the plant. Depending upon the conditions, it mayalsobe difficult to achieve the desired temperature reduction.

Process fluid enters the seal cooler at the maximum temperature ofthe process.In high temperature applications, this can result in fouling in water-cooled seal coolers. As high temperature process fluid enters the cooler, local boiling can occur. Most plants have less than ideal cooling water quality and the resulting boiling causes solids to build up on the heat transfer surfaces reducing cooling performance.

Plan 23is defined as a circulation ofprocess fluid from the seal chamber, through a sealcooler, back into the seal chamber.A bushing is required in the back of the seal chamber tominimizethe interchange of the lower temperature process fluid in the seal chamber and the higher temperature fluid in the pump casing.

Since the cooled fluid is recirculated in the piping plan and not lost back into the pump, the Plan 23 can more easily create a lower temperature environment in the seal chamber. The seal cooler primarily removes heat entering the seal chamber from seal generated heat and heat soak through the pump casing. This is significantly less than the heat loads in a Plan 21 resulting not only in lower seal chamber temperatures but also a lower heat loss from the pump and process.

The lower heat loads in a Plan 23cancreate additional benefits. The lower cooling capacity requirements can allow for smaller seal coolers to be selectedandhavereducedcooling waterrequirements. The lower operating temperatures in the piping plan also reduces the potential for fouling in the seal cooler.

Fluid circulation in a Plan 23 is created by a pumping device on the rotating seal. While these pumping devices (or pumping rings) can create flow, they cannot overcome significant friction losses in the piping system. For this reason, the system is designed with features such as large diameter tubing,aminimum number of fittings, smooth bends, and short piping runs.

A Plan 23 is also a “closed” system. Fluid circulates around from the seal chamber to the seal cooler and back without a natural means for venting gases or vapor from the system. All Plan 23smust be designed with a high point vent (or vents) to fully remove all vapor from the seal chamber, piping, and seal cooler prior to operation. Processes fluids which continually produce vapors may require additional periodic venting while the system is in operation.

Thermosyphoning– Fluids at different temperature will have different densities. In a Plan 21 and 23, this can be used to enhance fluid flow. A properly designed system can have this natural flow (or thermosyphoning) add to the pressure or pumping ring induced flow. For this to occur, the seal cooler must be mounted at an elevation slightly higher than the seal. Even when the pump is on standby, thermosyphoning can produce enough fluid flow to lower the seal chamber temperature.

Heat soak– Since the seal chamber is at a temperature lower than the process temperature in the pump, heat will be transferred into the seal chamber. There are design practices which can reduce heat soak. All seal chambers must have an effective bushing at the back of the seal chamber. This will help prevent intermixing of the high and low temperatures fluids in this region. The bushing canalsobe designedto reduce heat transferthrough conduction (by using materials withlowthermal conductivity) and convection (by reducing the heat transfer areain the seal chamber).Seal glands canalsobe designed with thermal breaks to reduce conductive heat transfer.

Seal coolers– Seal coolers can be eitherwater-cooled or air-cooled. While both options could be used in either the Plan 21 or 23, in practice one will generally be a better choice depending on applicationconditions. In cases where cooling water is not available, the air-cooled seal cooler is the only option. In very high temperature applications with a Plan 21, air-cooled may be a better option since itisnot prone to fouling. In moderate temperature applications, water-cooled seal coolers can provide lower temperatures. Water cooling also relies on the cooling water temperature in the plant and therefore provides more stable temperatures than an air-cooled unit relying on ambient temperatures.

Fluid properties – It is common for seal OEMs to perform calculations estimating the steady-state temperatures of a Plan 21 and 23. This is critical for activities such as sizing the seal cooler or defining cooling water requirements. It is less common for seal OEMs and end users to consider off-design

When it is necessary to reduce the temperature in the seal chamber, either piping plan may be applied. In most cases, a Plan 23 will providethemost effective and efficient cooling and would be the first choice. Water-cooled seal coolers also are more effective and will provide more stable operating conditions for the seal. There are however applications where a Plan 21 or an air-cooled seal cooler would be more beneficial. The end user should consult their seal OEMs to properly engineer a system for their specific conditions.

In the past there was only one Plan 53, but with the 2nd Edition of API 682 and the 1st Edition of ISO 21049 other variations of Plan 53"s were created.

The major difference in the plans is that Plan 53A uses an external reservoir, while Plans 53B and 53C run within a closed loop system with a make-up system piped to it for replenishment of the barrier fluid.

In dual pressurized sealing arrangements the inner process seal can have its own flush plan; in such applications the complete flush plan system designation should include both plans. For example, Plan 11/53A means that the inner seal has its own flush plan, Plan 11. The API/ISO default is for no separate flush plan when using any of the Plan 53"s, but this can vary with the application conditions.

With the older traditional back-to-back seal arrangement the inboard seal usually does not require a separate flush. In applications such a hydrofluoric acid, where it is both extremely hazardous and corrosive, a Plan 32 can be used in conjunction with a Plan 53. The dual pressurized face-to-back seal arrangement eliminates some of the potential problems associated with the back-to-back design. This face-to-back seal arrangement sometimes incorporates a reverse pressure capability that is not a default with the back-to-back design.

Also, face-to-back arrangements do not have a dead zone underneath the inboard seal that can become clogged by dirty process fluid and lead to seal hang-up. However, the face-to-back arrangement is not a cure-all. With the product on the seal O.D. and with it being used on API pumps that still incorporate throat bushings, it is advantageous to provide a flush for the inboard seal on a number of applications.

Abrasives can accumulate in the more closed API type seal chambers compared to the newer generation chemical duty pumps with large cylindrical bore or tapered bore chambers. The use of a Plan 11 or similar bypass type flush for the inner seal has advantages. It can help keep the seal chamber clean. It also has an improved overall heat transfer setup versus just using a Plan 53 system alone.

In comparison to a Plan 54, Plans 53A/B/C are usually less complex and less expensive. With Plans 53A/B/C, both the inner and the outer seals are lubricated by the barrier fluid, which can be selected for optimum seal performance. Plans 53A/B/C are usually selected for dirty, abrasive, or polymerizing process services which might be difficult to seal directly with single seals or with dual unpressurized seals using a Plan 52. There will always be some leakage of the barrier fluid into the process with any pressurized system.

With some of the Plan 53 systems the volume of barrier fluid is limited, especially compared to a Plan 54 system. Venting of the seal chamber is essential for all Plan 53"s where vapor locking can if vapor bubbles collect near the pumping ring or in the piping.

Plan 53A uses an external reservoir to provide barrier fluid for a pressurized dual seal arrangement. Reservoir pressure is produced by a gas, usually nitrogen, at a pressure greater than the maximum process pressure being sealed. The gas pressure is regulated by a system that is outside the schematic of the piping plan. Circulation of the barrier fluid is maintained by an internal pumping ring.

Like Plan 52 reservoirs, cooling is accomplished internal coil of tubing to remove the heat. Also like Plan 52 reservoirs, the volume of barrier liquid can vary from two gallons to 5+ gallons, where API and ISO standards specify 3-gal and 5-gal, depending upon the shaft diameter.

For non-API specifications, smaller reservoirs - typically 2-gal - are often used, especially at ambient pumping temperatures. Pressure alarms, pressure gages and level switches are typically standard equipment and are required by API 682/ISO 21049.

The usual guideline for Plan 53 barrier pressures is that they be a minimum of 20-psi to 50-psi above the maximum process pressure seen by the seal. Barrier pressure is normally supplied by a plant wide distribution system. Nitrogen bottles should not be used as they require a lot of attention and maintenance.

API 682/ISO 21049 recommends that the system be limited to 150-psig due to gas entrainment into the barrier fluid. Field experience has shown that with the proper barrier fluid, Plan 53A systems can be used up to 300-psig if the temperature is controlled to less than 250-deg F. A variation to this would be to use an accumulator to eliminate gas entrainment.

Installation should be limited to a single seal installation even on between bearing pumps. Therefore for a large number of installations, Plan 53A can be more expensive than Plan 53B or 53C.

Flow in the circulating system is usually induced by an internal pumping device. The make up system can be configured a number of ways based upon the customer"s preference, ranging from a simple hand pump to an elaborate pumping system feeding multiple pumps/seals.

API 682, 3rd edition does not provide guidelines for sizing the accumulator of Plan 53B, but the total fluid volume of the system should be about the same as the volume of a 53A system.

The finite volume of the accumulator requires a designed pressure operating range between refills (in excess of that required for a Plan 53A) and this must be built into the pressure rating of the seals.

Plan 53C is a variation of Plan 53B that uses a piston accumulator to track the pressure of the seal chamber. In Plan 53C, the piston accumulator has a reference line from the seal chamber to the bottom of the accumulator. There are differences in diameter of the internal piston so that a higher pressure is generated on the top half, which in turn is piped to the circuit loop into and out of the seal chamber.

The advantages and disadvantages are the same as the Plan 53B system. Additionally, the disadvantage of this system is that pressure spikes or pressure drops in the process pressure will vary the pressure on the outer seal that may create a temporary leakage condition. Also, tracking pressures can always be subject to delays that can cause a temporary loss of positive pressure differential across the inboard seal.

PHOTO : https://www.eagleburgmann.com/media/literature-competences-products-solutions/division-mechanical-seals/competences/brochure-barrier-buffer-media-for-mechanical-seals

8613371530291

8613371530291