aesseal mechanical seal quotation

We offer a range of standard inventory cartridge mechanical seals, including single and double seals to suit even the most demanding application and thanks to our modular design system we offer them with the best on-time delivery performance in the industry.

For unusual applications our Standard Plus seal range offers all the benefits of a standard seal while meeting our customer’s specific needs. This covers competitor replacement seals, seals designed for specific pumps and seals designed for pumping specific processes.

Cartridge mechanical seal construction is a proven reliability improvement. The seals are pre-assembled at the factory, pressure tested and shipped as a unit, leading to improved performance as errors due to incorrect installation are reduced. Cartridge construction eliminates the need to measure and set spring compression, and having a mechanical seal pre-assembled means that the seal faces are protected from damage during installation.

A double or dual mechanical seal consists of two independent seals mounted within a seal chamber outside the pump, which is flushed with an independent supply. This makes them ideal for sealing hazardous liquids, liquids with abrasives or liquids that are corrosive, as the seal faces only see clean lubrication greatly increasing mechanical seal life.

AESSEAL® double mechanical seals have independent seal-face designs, to enhance safe containment of process fluid in the event of damage to any individual sealing element.

The AESSEAL® DMSF™ range of double cartridge mechanical seals ( Double Monolithic Stationary Flow / Convection ) has been designed as a high-performance sealing solution for arduous applications.

AESSEAL®cartridge mechanical sealsare used in a wide variety of pumps and rotating equipment to prevent liquids and gases from escaping into the environment. Here are three benefits of AESSEAL®cartridge mechanical seals.

AESSEAL®cartridge mechanical sealsare pre-assembled at the factory, pressure tested, and shipped as a unit. This seal configuration eliminates the requirement for seal setting measurements at installation.

Spring tension is another crucial factor in a successful seal installation. Withcomponent seals, you must set the tension manually by adjusting the length of the installed seal spring. Withcartridge seals, the spring tension is preset, eliminating the time and potential errors of manual installation. A retaining device holds the rotating and stationary elements in correct alignment until the seal is mounted.

Cartridge seals are capable of handling the most demanding applications, including slurry applications and hazardous process fluid containment. AESSEAL®’s standardcartridge sealline includes the following.

For unusual applications, AESSEAL® also has a Standard Plus line that offers the same benefits as their standard seals while also meeting specific customer needs. This includes competitor replacement seals and seals designed for specific pumps and processes.

Cartridge mechanical sealscost more thancomponent seals. However,cartridge seals will save you money in the long run, thanks to lower maintenance costs. Potential savings come from reduced labor costs and less downtime when in-service seal replacement is required.

Are you interested in improving pump reliability, increasing uptime, and reducing maintenance costs? The experts at C&B Equipment can help you implement the bestAESSEAL®cartridge mechanical sealsand seal support systems for your application. We also offer a suite ofpreventative maintenance programs and repair servicesto ensure your equipment remains in top shape for the duration of its life!

![]()

Micro Sealsis one of the leading specialists in the design and manufacture of Pump Mechanical seals, Seal support systems ,Sealing Components,and Rotary Unions/Rotary Joints for Pumps, Agitator, Reactors, Blowers, mixers, steam turbines and other rotary-motion equipment. For over 15 years we’ve been committed to designing and manufacturing sealing products and accessories of the highest quality. We leads the way in high-efficiency solutions using the latest technologies for maximum sealing performance.

Harini Engineering came into being in the year 2010 and carved a niche as the leading Manufacturer, Supplier and Exporter of the wide range of Industrial Spring Seal, O Ring, Pneumatic Diaphragm, Heat Exchanger, Dyeing Machine, Silicone Gasket, Rubber Gasket, Pulley Spindle and many more.

1. The manufacture of Lepu cartridge mechanical seal is divided into a few aspects. They are mainly materials preparation, mechanical components" cleaning, cutting, milling, welding, and parts assembly. Equipped with professional operation system, Lepu seal"s quality is ensured

3. The product is excellently resistant to color fading. Even it is under the blazing sun for quite a long time or exposed to strong lighting, it is less prone to fade. Lepu seals can ensure high efficiency

AES cartridge mechanical seal convertor II LP318 is designed to replace two-part component seals and conventional packing arrangements. This seal is a cartridge seal type with Short external length.

AES cartridge seal convertor made by lepu seal with a longer durable and resistance even running in bad environment, strong quality stainless steel for the cartridge seal frame, and high density silicon for the seal face, Viton rubber offer more resistance against corrosive medium.

As a leading mechanical seal manufacturer, Lepu seal factory make this AES cartridge seal for a long period, and sell this seal to hundreds of clients, 100% a right replacement for original AES seal.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

1. Throughout years of exploration, Guangzhou Lepu Machinery CO., LTD has become a competitive and reliable manufacturer specializing in the design and production of aesseal component seals. With expanded overseas markets, more products have been sold extensively to different countries. We have made a new record of the number of customers this year and we estimate the number will continue to grow.

3. The factory is equipped with first-class automation production lines and testing equipment. With these advanced machines, we are able to offer a broad range of products with high quality. Guangzhou Lepu Machinery CO., LTD aims to help the Chinese aes seal industry become bigger and stronger. Get price!

AESSEAL® provides a comprehensive dry gas seal refurbishment program, for AESSEAL® and non AESSEAL® designs. The dry gas seal repair program supports all customers, regardless of the original equipment manufacturer.

Unique, patented hydrostatic and hydrodynamic Dry Gas Compressor seal technology offers robust protection for the sealing surfaces during start-up, coast down, slow roll and upset conditions

The advantages of sealing pumps with dual pressurized dry gas seals are becoming widely recognized throughout industry. AESSEAL® has developed a range of pump dry gas seals to suit every application.

The CCS™ is a tandem cartridge seal where the inboard seal is designed to seal up to 82 bar (1200 psi), and an outboard seal that acts as a low pressure tandem seal.

AESSEAL® has unique patented hydrostatic and hydrodynamic Dry Gas Compressor seal technology, offering robust protection for the sealing surfaces during start-up, shutdown, slow roll and upset conditions.

The STS mechanical seal has been developed in conjunction with a major oil refinery to replace existing carbon ring seals normally fitted to steam turbines.

We recognize and understand the vital role of mechanical seal aesseal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale mechanical seal aesseal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider mechanical seal aesseal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

We provide expert Mechanical Seal Repair of all major brands, including John Crane®, Flowserve®, Burgmann®, and more. With locations in Gonzales, LA, and Williston, VT, we are the reliable, convenient single source repair for all styles of mechanical seals.

Our comprehensive library of manufactured design solutions addresses applications in the field and pump-specific challenges providing upgrades and replacement seals manufactured to perform better and last longer.

Flexaseal’s experienced maintenance and repair technicians have worked with mechanical seals from the world"s largest pump and seal manufacturers, including John Crane® and Flowserve®. Below is just a sampling of the many manufacturers and styles that we have repaired. If your seal isn’t listed, just click “Request A Quote” to send us a message.

Each repair that comes to our repair departments in Louisiana or Vermont - whether it is a third-party design or a Flexaseal model - goes through a detailed, 5-step process to ensure customer satisfaction.

Flexaseal offers repair kits for on-site seal repair. These kits are specific to your Flexaseal cartridge and are a great way to have parts on hand for an emergency situation. All items in the kit are packaged and labeled to ensure efficient change-out.

Every mixer, agitator, and reactor model is distinctive and engineered for specific applications. When repairing a mixer seal, Flexaseal evaluates the conditions in which the seal operates. This evaluation ensures we are repairing your seal to your parameters.

Sometimes a failed seal is no longer a candidate for repair. Flexaseal provides straightforward solutions from our comprehensive seal lines or upgraded options designed for your unique operating environment.

The Flexaseal Gulf South location is a fully functional, self-sufficient mechanical seal repair and service facility for mechanical seals. Our Southern U.S. shop - located between Baton Rouge and New Orleans in Gonzales, LA - is a brand new 5,000 square foot, state-of-the-art facility ready for your mechanical seal repair and service needs.

Machining Capabilities – Our Gulf Coast technicians have extensive knowledge and machining experience. These skills enable the team to quickly and efficiently process seal repairs, getting your equipment back into operation with minimal interruption.

Stocking Location – The Gonzales store front has a range of Flexaseal sealing products for immediate off-the-shelf delivery. We are also an assembly and stocking location forseal support systems including barrier fluid reservoirs.

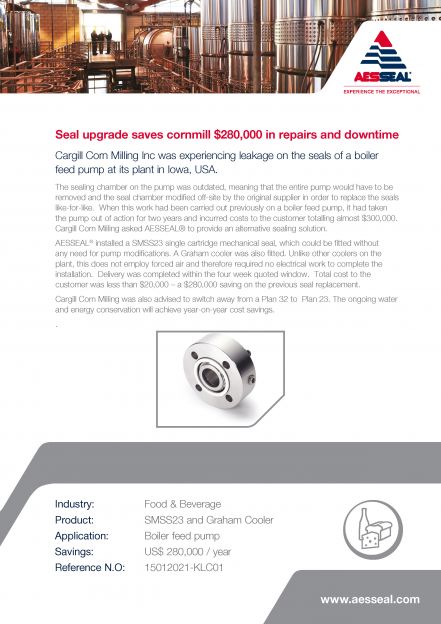

With more than 40 years of experience in designing and manufacturing mechanical seals, AESSEAL is one of the world"s leading mechanical seal manufacturers. The company manufactures products to enhance the performance and reliability of rotating equipment. AESSEAL is a global employer, with a workforce of over 1750 people operating in 104 countries.

The company is known for its entrepreneurial spirit and commitment to innovation, values exhibited in the impressive 13 Queen"s Awards it holds. They are also aware of the concerns of the manufacturing industry and are committed to mitigating climate change. In 2020, AESSEAL achieved net zero emissions for its UK operations and targets global net zero emissions by 2029.

Audacia has been working with AESSEAL in a partnership for 8 years, which initially began with the redevelopment of their legacy systems; this project is the latest development in the suite of products that we have delivered collaboratively.

AESSEAL were operating a sales quotation system that, while powerful, primarily suited the needs of experienced Sales Engineers who were adept at performing technical calculations and had an extensive knowledge of their product range.

Our most recent delivered project is an online sales quotation platform - "eVE" - a platform allowing AESSEAL to rapidly quote for products that would otherwise require in-depth technical knowledge and ties together three pre-existing systems, also integrated with SAP, drawing service and a mobile app.

On top of this, the platform is equipped to handle AESSEAL’s client base around the world, with built in internationalisation, allowing for automatic quote regeneration across global sites in multiple different languages.

Success of the project has led to AESSEAL committing to phase two of the project, which plans to enable AESSEAL customers to use the application to carry out the quoting process themselves.

The SEPCO RBD is a stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerated and where positive ...

Dual seal Available for standard (CMS-ASDN) and big bore (CMS-ABDN) seal chambers Balanced Cartridge Double pressure balanced Independent of direction of rotation Integrated pumping device

We manufacture face seals for hydraulic and pneumatic applications in the following designs:- rod seals and piston seals - single-acting - double-acting - rotatory ...

A&S Seals Co., Ltd is a global supplier of Aesseal Cartridge Mechanical Seals IADC, Aesseal IADC , Standard Plus Series, Aesseal Cartridge Mechanical Seals and many more. focusing on the various brands of seals supply.

8613371530291

8613371530291