mechanical seal catalogue quotation

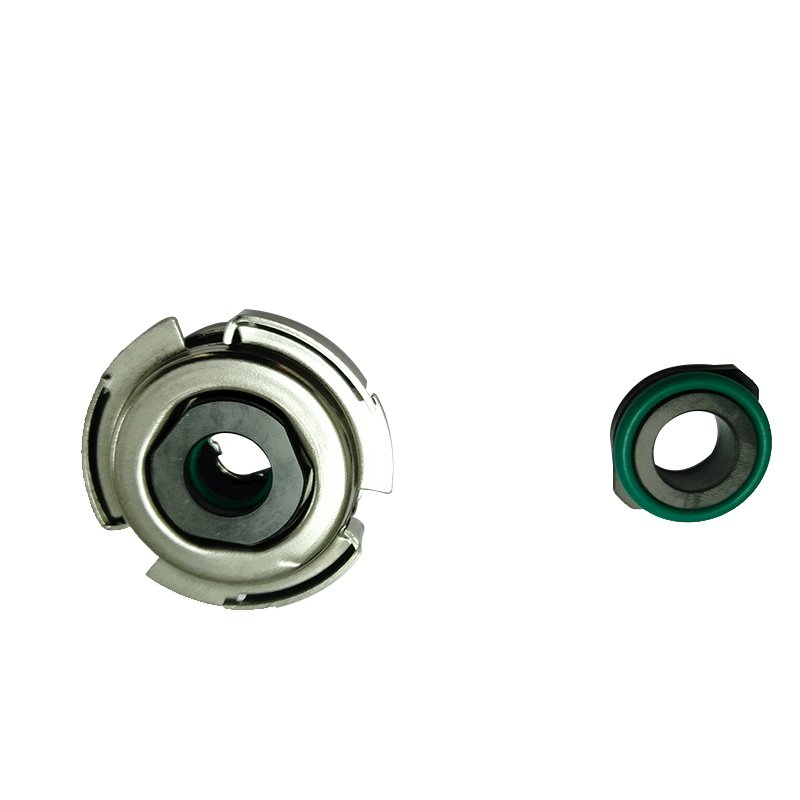

Grundfos mechanical seal GRF-D is a kind of seal for grundfos air conditioning pumps, like CH2-30, CH4-30, CH8-12, also working for SPK1, SPK2, SPK4,SPK8 grundfos pumps.

People can use carbon, silicon, and tungsten carbide for this mechanical seal as seal face, if for high temerperature, we suggest to choose rubber seal viton for the rubber parts.

It is a low cost seal in grundfos mechanical seal series, popular using in many factories. We follow original grundfos seal design 100%, and make sure all mechanical seal from factory can fit the grundfos pump perfect.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

1. Guangzhou Lepu Machinery CO., LTD is a manufacturing company based in China. We have been providing quality grundfos mechanical shaft seals throughout our region and beyond.

3. Lepu makes decisions to achieve to be a nationally professional grundfos mechanical seal catalogue supplier. Ask! We always stick to high quality for grundfos seal . Ask! Accurate market positioning of Lepu Machinery allows you the highest return on investment. Ask! Lepu will never give up on its ambition to serve each customer well. Ask!

1. The production environment of Lepu Burgmann Mechanical Seal Wholesale is required to be neat, clean, noise and dust free. Workers are required to wear dust suit in the work plant. During the operation, Lepu seals enjoy higher precision

Mechanical seals of the HJ92N series from EagleBurgmann are designed for media containing, solids or with high viscosity e.g. sugar, paper, sewage and waste water industry. The springs are product protected. There is no sticking or clogging making the design rugged and reliable. The seal is independent of direction of rotation.

LEPU SEAL is a professional supplier for mechanical seal products, focus in making mechanical seal since 1998, our mechanical seal products cover almost all range of the famous mechanical seal, like grundfos seal, flygt seal, burgmann seal, john crane seal, and apv seal, alfa laval seal, nissin pump seal, and so on.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

1. Guangzhou Lepu Machinery CO., LTD has been providing high-quality Burgmann Mechanical Seal Wholesale over the years. We mainly concentrate on the innovation of our products. Our produced eagleburgmann mechanical seal catalogue enjoys good warranty and maintaince period to be responsible for you.

3. Guangzhou Lepu Machinery CO., LTD has a workforce of highly skilled and reliable staff and talents for burgmann mechanical seal catalogue . Guangzhou Lepu Machinery CO., LTD is committed to becoming a comprehensive eagle burgmann mechanical seals for pumps provider with global influence. Inquire now!

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

Main catalog seal supply systems. The complete product portfolio of systems and components for cooling, flushing, pressurization and supplying liquid and gas-lubricated mechanical seals e.g., quench and thermosiphon systems, heat exchangers, barrier fluid systems, leakage monitoring and seal supply systems in accordance with API682.

Replacement seals for A-C Pump® Mechanical Seals products. Search by the OEM Part Number using the SEARCH function at the top of the page or use search by specification.

OEM names, brands, model or part numbers are for identification purposes only. Our components are designed to provide performance and service life equal to or better than the OE part when properly installed and properly applied. Springer Parts® carry a warranty equal to the OE component. A-C Pump® Mechanical Seals is a registered trademarks of its respective company. Springer Pumps, LLC is not a representative of, nor affiliated with A-C Pump® Mechanical Seals.

Replacement seals for GRUNDFOS CBS, INC.® Mechanical Seals products. Search by the OEM Part Number using the SEARCH function at the top of the page or use search by specification.

OEM names, brands, model or part numbers are for identification purposes only. Our components are designed to provide performance and service life equal to or better than the OE part when properly installed and properly applied. Springer Parts® carry a warranty equal to the OE component. GRUNDFOS CBS, INC.® Mechanical Seals is a registered trademarks of its respective company. Springer Pumps, LLC is not a representative of, nor affiliated with GRUNDFOS CBS, INC.® Mechanical Seals.

The AST60 is a simple and easily installed seal that can be used wherever a highly-reliable, anti-clog seal is needed. Its narrow seal face design and hydraulic balance make it a cool-running seal. The floating rotary seal ring eliminates seal face distortion inherent to shrink fit designs. Since all the springs are isolated from the pumped fluid, flush rates can be reduced to minimize product dilution.

Structural Features: single end, unbalanced, dependent direction of rotation, rubber bellow, bellow transmission. This component has a compact structure with good compatibility and easy installation. The bellow can provide support against the pressure to eliminate indentation and corrugation. The bellow and the spring provide pressure compensation to the seal faces. The rubber bellow design prevents possible radial run-out so that the floatability of the rotary ring is increased.

This mechanical seal is also known as KSB Part No. 433 mechanical seal. Many other pump manufacturers such as WILO are also using the same type of mechanical seal as their standard sealing solutions.

General purpose mechanical seal for work with water, oil, fuels and liquids containing small amounts of abrasive matter, used in impeller pumps and other equipment with rotating shafts.

We are instrumental in offering a wide array of General Pump Seal Catalog. These catalogs are especially designed and developed to fulfill the various water requirements of clients. Our products are designed using advanced technology in order to dynamically balance the catalog’s longer bearing life.

Clark Seals Ltd. was contacted by the largest manufacturer of commercial laundry equipment with a problem they were having with seals leaking in sandy environments. Sand was getting between the sealing surfaces of the mechanical seal, grooving the face and causing leakage.

To solve the problem, we designed a custom two-piece integrated sealing solution that sealed against the top and bottom of the tub. The top seal was designed to press-fit around the tub bearing to improve alignment between the transmission, tub and agitator and a triple sealing lip to prevent water, sand and debris from entering the bearing cavity. The bottom seal was designed with a locking pin to resist torque and press-fit into the top seal during installation. To further reduce sand and other contaminants, our engineers developed and patented a unique negative "R"; sealing lip geometry that allowed the sprung lip to perform as an excluder lip and keep all sand out of the sealing environment.

The end result was a patented sealing solution that eliminated warranty claims, cost 80% less and lasted more than 700% longer than the mechanical seal it replaced.

Mechanical seal pumps are designed to seal the centrifugal pump shaft and prevent leaking. This seal sits on the shaft and is made up of the rotary and stationary parts, and it keeps contaminants out and fluids in. At Mesco, we offer a wide range of mechanical seals compatible with a majority of OEM brands. Our selection includes cartridge mechanical seals, type-1, type-2, type-21, and more. If you don’t see the mechanical seal pump that fits your needs, our specialized team will create custom seals to meet your application. Our products are expertly manufactured from high-quality materials, ensuring that your seal will last for years to come. Check out our selection today!

8613371530291

8613371530291