aes mechanical seal catalog pdf quotation

If you are in need of an ASI©seal replacement, Gaddis Mechanical Seals is here to help. We offer replacement mechanical seals for a variety of applications, and our team is highly experienced in mechanical seal repair and installation. We understand the importance of keeping your machinery running smoothly, and we will work diligently to get your mechanical seals repaired or replaced as quickly as possible. With ASI© Mechanical Seals, you can rest assured that your mechanical seal repair needs will be handled promptly and professionally. Contact us today to learn more about our mechanical seal repair services.

Robco"s Mechanical Seal Division manufactures, distributes and customizes mechanical seals, as well as being a repair facility for virtually any mechanical seal brand, utilizing the latest technology and state-of-the-art manufacturing equipment. Robco’s seal designs are customer driven to provide the best possible solutions to sealing problems.

Robco will repair: Borg-Warner, Chesterton, John Crane, Durametallic, EG&G, Flex-A-seal, Flexibox, Flowserve, Garlock, Pac-Seal, U.S. Seal, and virtually any other brand.

Mechanical seals are used everywhere liquids and gases are transferred through rotating equipment. Robco’s seals and packing are the first step to efficiently control leakage and reduce operation costs.

The ideal seal for alumina applications, specifically designed to operate in this challenging environment, the Robco DRYTEK seal will provide maintenance-free operation at least five to twenty times longer than your average alumina screw conveyor seal.

•Better abrasion resistance •Dry-seal, no lubricant required •Sealing components rotate with the shaft, maintaining an airtight seal •Adapts to axial and radial movements of the shaft •Available in C.E.M.A. and METRIC standard shaft sizes.

Double balanced cartridge seal for pumps, agitators and mixers that prevents the leakage of toxic, hazardous, corrosive and costly fluids to the atmosphere.

Robco uses specialized equipment to ensure that rebuilt seals operate equal to brand new, with mechanical seal manufacturing and rebuilding experience dating back to 1978, servicing petrochemical, pulp & paper, steel, mining, waste water, utilities, boilers and more...

We rebuild all major brands at competitive prices with premium quality parts that meet all OEM specifications. We offer a free estimate and failure analysis. Rebuild outlay normally varies from a third to half the cost of a new seal, so lower your inventory value and reduce your overall operations cost.

By centralizing your repairs: Robco rebuilds all major brands in one location, simply complete our Seal Repair Form to be enclosed along with your seal shipment and we’ll take care of the rest, returning your seal looking and working like new. Robco tags all rebuilt seals for future rebuild identification, tracking seal life and failure patterns.

Flexaseal has grown from a small manufacturer to an industry leader at the forefront of sealing solution technical advances, including the development of the world’s first patented two-piece split cartridge mechanical seal. Today, our distributors cover over 30 countries and our operations include locations in Vermont, Louisiana, Texas, and Brazil. For four decades, we’ve remained committed to our mission to produce the highest quality products and provide the best customer service in the world.

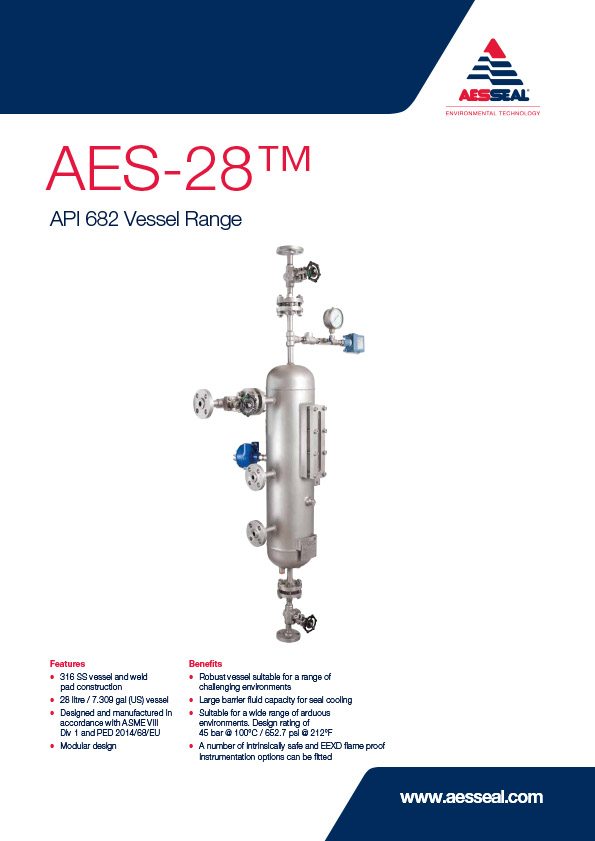

AESSEAL®cartridge mechanical sealsare used in a wide variety of pumps and rotating equipment to prevent liquids and gases from escaping into the environment. Here are three benefits of AESSEAL®cartridge mechanical seals.

AESSEAL®cartridge mechanical sealsare pre-assembled at the factory, pressure tested, and shipped as a unit. This seal configuration eliminates the requirement for seal setting measurements at installation.

Spring tension is another crucial factor in a successful seal installation. Withcomponent seals, you must set the tension manually by adjusting the length of the installed seal spring. Withcartridge seals, the spring tension is preset, eliminating the time and potential errors of manual installation. A retaining device holds the rotating and stationary elements in correct alignment until the seal is mounted.

Cartridge seals are capable of handling the most demanding applications, including slurry applications and hazardous process fluid containment. AESSEAL®’s standardcartridge sealline includes the following.

For unusual applications, AESSEAL® also has a Standard Plus line that offers the same benefits as their standard seals while also meeting specific customer needs. This includes competitor replacement seals and seals designed for specific pumps and processes.

Cartridge mechanical sealscost more thancomponent seals. However,cartridge seals will save you money in the long run, thanks to lower maintenance costs. Potential savings come from reduced labor costs and less downtime when in-service seal replacement is required.

Are you interested in improving pump reliability, increasing uptime, and reducing maintenance costs? The experts at C&B Equipment can help you implement the bestAESSEAL®cartridge mechanical sealsand seal support systems for your application. We also offer a suite ofpreventative maintenance programs and repair servicesto ensure your equipment remains in top shape for the duration of its life!

SWFF-TF™ FLOWTRUE™ AES-15™ PUMPPAC™

AESSEALplc AESSEALInc.

Fax: +44 (0) 1709 720788 that they need never consider alternative sources of supply.’ www.aesseal.com E-mail: usa@aesseal.com

Important:Sincetheconditionsandmethodsofuseofthisproductarebeyondourcontrol,AESSEALplcexpresslydisclaimsanyandallliabilityresultingorarisingfromanyuseofthisproduct

orrelianceonanyinformationcontainedinthisdocument-AESSEALplcstandardconditionsofsaleapply.Allsizesaresubjecttomanufacturingtolerances.Wereservetherighttomodify

8613371530291

8613371530291