allweiler ntt pump mechanical seal manufacturer

Since the 1860’s, *Allweiler® Pumps have been produced in Germany making them one of the oldest pump manufacturers in Europe and worldwide. *allweiler"s® innovative designs and technology have made them recognized leaders in Pump manufacturing.

At Shanley Pump and Equipment, Inc. we stock *Allweiler® pumps and replacement parts for whatever your pumping necessity. We have the right pumps for many applications and every industry.

The *Allweiler® NTT Series Centrifugal Pump for heat transfer applications is an ideal solution for the handling of organic heat-transfer oils. The NTT"s unique self-cooling design eliminates the need for additional cooling in any form due to its self-cooling design during operation.

At Shanley Pump and Equipment, Inc. we stock a complete line of *Allweiler® NTT thermal oil pumps. These are horizontal centrifugal pumps that are capable of pumping thermal oil at 660° degrees F (350°C) at up to 6,400 GPM with up to 430" feet of head and require no additional cooling.

Mechanical seals for pump series Allweiler: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

The oldest German pump manufacturer, founded in 1860, Allweiler GmbH is today the European market and technology leader in fluid handling solutions for shipbuilding, power generation and special industrial applications. Our product portfolio is unrivaled in the industry and includes centrifugal, propeller, screw spindle and progressive cavity pumps, as well as complete pump systems. We also manufacture peristaltic pumps and macerators. In addition to our Allweiler-branded pumps and systems, we sell the pumps and solutions of our sister company Zenith - gear pumps.

We’ve built our success on putting our customers’ needs as the top priority in the development of every individual Allweiler product. Our customers benefit from a deep knowledge of pump technologies and expertise in fluid handling applications that has grown over generations. They know our pumps are precisely manufactured to address specific applications areas and trust the quality and reliability of Allweiler pump performance. We back our pumps with expert, personal, onsite and comprehensive services.

Mechanical seal for pump Allweiler NTT 25-16, NTT 25-200 NTT 2 /25-20 NTT 32-160 NTT 32-200 NTT 2 /32-20 NTT 40-160 NTT 40-200 NTT 40-250 Allweiler NTT 2 /40-250 NTT 50-160 NTT 50-200 Allweiler NTT 100-160 Allweiler NTT Allweiler NTT 65-200 Allweiler NTT 80-200 Allweiler NTT 80-2NTT 100-200 NTT 100-250 NTT 125-250 LV 25/2, LV 25 /3, LV 25/4, LV 25/5, LV 25/6, LV 25/7, LV 25/7, LV 25/9, LV 25/10, LV 25/11, LV 25/12, LV 25 /13, LV 25/14, LV 25/15 V 32/2, LV 32/3, LV 32/4, LV 32/5, LV32 /6, LV 32/7, LV 32/7, LV 32/9 , LV 32/10, LV 32/11, LV 32/12, LV 32/13, LV 32/14, LV 32/15 LV 40/2, LV 40/3, LV 40/4, LV 40/5, LV 40/6, LV 40/7, LV 40/7, LV 40/9, LV 40/10, LV 40/11, LV 40/12, LV 40 LV 50/2, LV 50/3, LV 50 /4, LV 50/5, LV 50/6, LV 50/7, LV 50/7, LV 50/9, LV 50/10, LV 50/11, LV 50/12 LV 65/2, LV 65/3 , LV 65/4, LV 65/5, LV 65/6, LV

Application of the pump: heating heavy oils, fuel oil, in the production of asphalt and roofing cardboard, drying plants, agitators, the production of mineral wool, the supply of hot glue, varnish in the furniture industry, the production of tires, rubber in the automotive industry, the entire rubber and plastic industry - heating presses, smelting boilers, processing of dark oil products - heating bitumen tanks at oil depots, tankers, oil industry - heating vehicles, pipes and storage facilities, preheating oils, in the production of bitumen, heating main pumps on an oil pipeline, impoverished industry - heating bakery and roasting ovens, installations for the production of fatty acids, edible oils, glycerin, dry masses, textile, leather and pulp and paper industry - heating of calenders, drying chambers, rollers, drying cylinders, paint and varnish industry - heating of mixers and mixing tanks, laundry factories: heating in dryers, ironing machines.

Allweiler"s NTT single-channel centrifugal pumps have a practical modular design and are designed for mounting a drive unit with a base plate (cast iron or steel), DIN EN 733. Ideal for pumping high-temperature oils in various industries. The lineup is represented by a wide selection of dimensions for the selection of the optimal option. One- or two-stage design, mechanical shaft seal, efficient self-cooling. The outlet is directed radially upward, the suction is coaxial, the bearings are maintenance-free. On request, it can be equipped with a spacer coupling. Three-phase squirrel-cage motors on feet are used as a drive in the standard.

Mechanical seals for Allweiler pump series: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH , CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L , LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF , SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

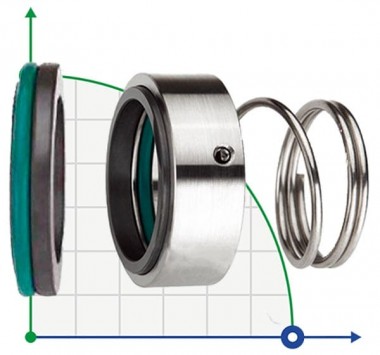

The design of the mechanical seal consists mainly of two parts: a movable part and a fixed part. The fixed part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the fixed part by means of a spring.

Mechanical sealing is achieved using secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to choose the material of the secondary seals and friction pairs.

Mechanical seal to the pump Allweiler: NTT 25-160, NTT 25-200, NTT 2/25-200, NTT 32-160, NTT 32-200, NTT 2/32-200, NTT 40-160, NTT 40-200, NTT 40-250, NTT 2/40-250, NTT 50-160, NTT 50-200, NTT 50-250, NTT 2/50-250, NTT 65-160, NTT 65-200, NTT 80-160, NTT 100-160.

Mechanical seals for pump series Allweiler: AEB, ALLCHEM CNH-B, CNB, CNI, ALLMAG CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, NSL, NST, MI, MA, NISM, NIM, NAM, NAM-F, ALLUB NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF10, SPF20, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S.

The mechanical seal design consists mainly of two parts: a moving part and a stationary part. The stationary part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the stationary part by means of a spring.

The mechanical seal is sealed by secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to select the material of the secondary seals and the friction pair.

The fluids pumped must have lubricating properties and should not contain any solids or particles, as the non drive end bearing and mechanical seal is lubricated by the pumped liquid.

These pumps are further equipped with a safety stuffing box and throttling area in front of the mechanical seal. In case of a seal failure this prevents the pumped liquid from emerging in a hazardous quantity or manner. With drain connection adequate piped up, the safety requirements of DIN 4754 are exceeded. (The pumps have a drain connection to ensure that any seepage past the shaft sealing can be safely drained through this connection).

Any use of company names, trademarks, model no, item no or part no is only for reference purpose only, Sino-Seals Co,.Ltd is not an authorized distributors or serives for the products of any company mentioned in this website

Allweiler GmbH, a business unit of CIRCOR, was founded in Germany in 1860. As a German manufacturer of pumps, today Allweiler is a leading supplier in the fields of shipbuilding, power generation and special industrial applications. Its product portfolio includes centrifugal pumps, propeller pumps, screw pumps, as well as complete pump systems.

Allweiler GmbH is a premium manufacturer of pumps of all styles and types. In addition to individual pumps, they also offer a variety of complete pump units for various industry applications. So you can save money as early as the proposal stage and continue to benefit from simplified installation, maintenance of the pumps.

As one of trusted Allweiler mechanical seal suppliers in China for years, OKmarts can provide a broad series of Allweiler mechanical seals/ Allweiler mechanical shaft seals. Here you can get the quickest response, largest available inventory, shortest lead times and competitive Allweiler mechanical seal price.

8613371530291

8613371530291