allweiler ntt pump mechanical seal quotation

Mechanical seals for pump series Allweiler: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

Their great advantage is that the heat from the pumped liquid is blocked very effectively by a special barrier located between the pump body and the wheel. In addition, the special fins effectively dissipates heat from the pump housing and maintains an adequate operating temperature allowing the use of a standard mechanical seal.

Compared to the standard version, the TCD/SP model is fitted with an intermediate cover behind the mechanical seal, which acts as a spacer, attached to a tank containing oil compatible with the pumped one.

This is particularly important in food oil transfer applications. An intermediate chamber filled with a food fluid prevents the entry of air or contaminations with the lubricating oil in the process in case of breakage of the mechanical seal.

This precaution avoids that, in the event of damage to the mechanical seal, air can not enter the pump and oxidize the oil pumped, or that the oil of the bearings enters the pumping circuit, or vice versa.

Since the 1860’s, *Allweiler® Pumps have been produced in Germany making them one of the oldest pump manufacturers in Europe and worldwide. *allweiler"s® innovative designs and technology have made them recognized leaders in Pump manufacturing.

At Shanley Pump and Equipment, Inc. we stock *Allweiler® pumps and replacement parts for whatever your pumping necessity. We have the right pumps for many applications and every industry.

The *Allweiler® NTT Series Centrifugal Pump for heat transfer applications is an ideal solution for the handling of organic heat-transfer oils. The NTT"s unique self-cooling design eliminates the need for additional cooling in any form due to its self-cooling design during operation.

At Shanley Pump and Equipment, Inc. we stock a complete line of *Allweiler® NTT thermal oil pumps. These are horizontal centrifugal pumps that are capable of pumping thermal oil at 660° degrees F (350°C) at up to 6,400 GPM with up to 430" feet of head and require no additional cooling.

This depends on several factors; how frequently are spare parts required? how long has the pump been in operation? and the price of the required spare parts versus the cost of a complete new pump. For example, if a new casing, impeller, shaft and mechanical seal are required, then it is more cost effective to purchase a complete new pump as a large proportion of the high value parts are required. If the pump is wearing frequently and prematurely, then this may be an indication that the wrong type or size of pump is installed. It is a good idea to talk to us in this situation as we may be able to identify the issue with your pump or system and select a more suitable pump for your requirements.

Allweiler GmbH, a business unit of CIRCOR, was founded in Germany in 1860. As a German manufacturer of pumps, today Allweiler is a leading supplier in the fields of shipbuilding, power generation and special industrial applications. Its product portfolio includes centrifugal pumps, propeller pumps, screw pumps, as well as complete pump systems.

Allweiler GmbH is a premium manufacturer of pumps of all styles and types. In addition to individual pumps, they also offer a variety of complete pump units for various industry applications. So you can save money as early as the proposal stage and continue to benefit from simplified installation, maintenance of the pumps.

As one of trusted Allweiler mechanical seal suppliers in China for years, OKmarts can provide a broad series of Allweiler mechanical seals/ Allweiler mechanical shaft seals. Here you can get the quickest response, largest available inventory, shortest lead times and competitive Allweiler mechanical seal price.

Mechanical seals for Allweiler pump series: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH , CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L , LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF , SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

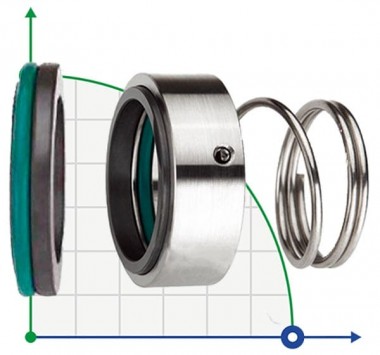

The design of the mechanical seal consists mainly of two parts: a movable part and a fixed part. The fixed part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the fixed part by means of a spring.

Mechanical sealing is achieved using secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to choose the material of the secondary seals and friction pairs.

The ALLWEILER NTT 80-200/02/225 U5A W4 is a thermal oil circulating pump manufactured by ALLWEILER GmbH, a German company that specializes in pumping solutions for various industries.

This specific pump is designed for circulating thermal oil, which is a type of heat transfer fluid used in various industrial processes. The model number, NTT 80-200/02/225 U5A W4, provides information about the specific design of the pump.

The "NTT" in the model number indicates that this pump is part of ALLWEILER"s NTT series of thermal oil pumps. The numbers "80-200" indicate the nominal diameter of the inlet and outlet flanges, in millimeters. The "02" indicates the number of stages, and "225" indicates the pump"s nominal flow rate, in cubic meters per hour.

The "U5A" in the model number indicates the specific design of the pump, including its materials of construction and other features. The "W4" at the end of the model number indicates that the pump is equipped with a mechanical seal.

Overall, the ALLWEILER NTT 80-200/02/225 U5A W4 thermal oil circulating pump is designed to provide reliable and efficient circulation of thermal oil in industrial processes.

Explore a wide variety of circulation oil pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These circulation oil pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these circulation oil pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right circulation oil pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of circulation oil pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

8613371530291

8613371530291