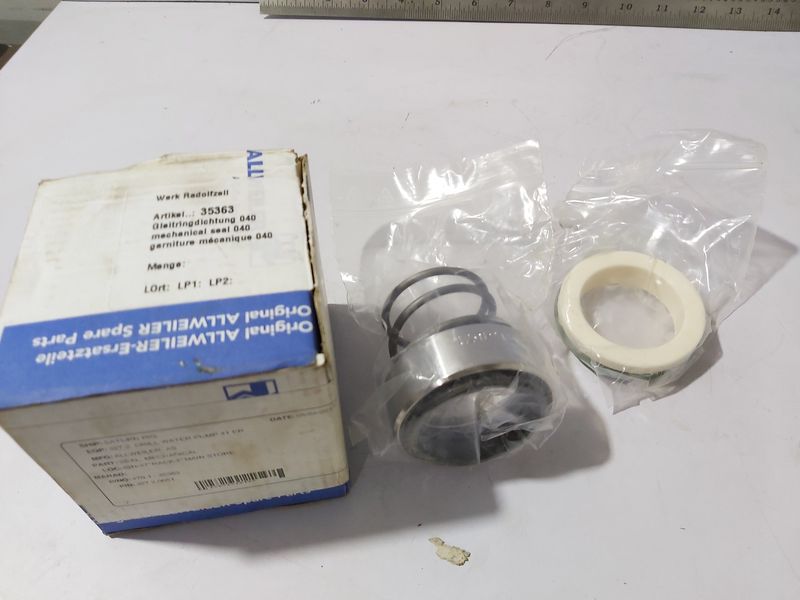

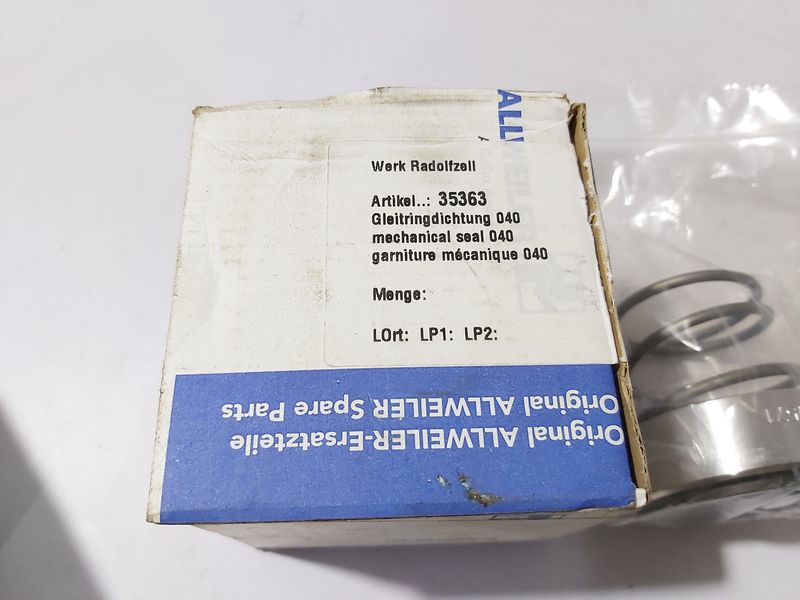

allweiler pump mechanical seal quotation

Mechanical seals for pump series Allweiler: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

Mechanical seals for Allweiler pump series: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH , CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L , LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF , SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

The design of the mechanical seal consists mainly of two parts: a movable part and a fixed part. The fixed part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the fixed part by means of a spring.

Mechanical sealing is achieved using secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to choose the material of the secondary seals and friction pairs.

We have tens of thousands of pumps and parts on our racks ready-to-ship (and new stuff arriving daily.) It"s far too much for our team of helper monkeys to list online. Contact us and we"ll check the rack!

Allweiler GmbH, a business unit of CIRCOR, was founded in Germany in 1860. As a German manufacturer of pumps, today Allweiler is a leading supplier in the fields of shipbuilding, power generation and special industrial applications. Its product portfolio includes centrifugal pumps, propeller pumps, screw pumps, as well as complete pump systems.

Allweiler GmbH is a premium manufacturer of pumps of all styles and types. In addition to individual pumps, they also offer a variety of complete pump units for various industry applications. So you can save money as early as the proposal stage and continue to benefit from simplified installation, maintenance of the pumps.

As one of trusted Allweiler mechanical seal suppliers in China for years, OKmarts can provide a broad series of Allweiler mechanical seals/ Allweiler mechanical shaft seals. Here you can get the quickest response, largest available inventory, shortest lead times and competitive Allweiler mechanical seal price.

Allweiler, a business unit of CIRCOR, will exhibit at the Pumps & Valves trade fair in Dortmund, Germany February 12th and 13th 2020 (Hall 6, Booth R19-6).

Highlights of their exhibit will be the new AEB-DE dosing pump with an extremely flexible and space-saving design as well as OptiFix™, a next-generation progressing cavity pump, designed to reduce service costs. Allweiler"s team of experts will demonstrate its functionality by guiding visitors through five easy steps to dismantle the pumps.

With its quick-change design, the OptiFix progressing cavity pump is valued for its ability to save time and money. Its new service solution offers the shortest average repair time in its class. This results in less downtime; reduced maintenance and lower service costs.

OptiFix can reduce service times by as much as 85%. Due to its patented design, this pump can be serviced, repaired, and retrofitted in a fraction of the normal time. The pump"s rotor and stator can be removed without dismantling the discharge and suction casings. “If combined with the patented ALLDUR® stator, service life can be increased by as much as five times,” according to Jannik Röben, Director of Sales in Germany.

This opens up new opportunities for standardisation, easier stock-keeping, and straightforward adaptation of pump capacity. The pumps are delivered with high-quality stainless steel casings as standard so they can be used universally.

Its vertical installation option also allows users to design flexible and space-saving systems. Advanced pumping elements and the resulting optimised clamping give AEB-DE high dosing accuracy and stable performance curves.

CIRCOR’s comprehensive selection of pumps, valves, controllers, and services from leading brands allow it to serve a wide range of user markets and sales regions.

In addition to a variety of pump solutions, CIRCOR will also exhibit RTK, a feedwater valve with an integrated freewheel that was specially designed to protect feedwater pumps from cavitation.

This unique valve serves two purposes: to act as a feedwater control valve and to provide a bypass function to protect the pump from damage. The feed water valve has a hardened trim that resists wearing for lower overall maintenance costs and extended pump service life.

The Allweiler Allheat NTWH pumps are perfect for use with organic and synthetic thermal oils at temperatures up to 660 °F (350 °C) and hot water at temperatures up to 360 °F (183 °C).

The ALLHEAT NTWH series centrifugal pump was designed specifically for safe pumping of hot fluid medias. This versatile and universally applied pump series offers the best technical solution at an excellent price for pumping mineral and synthetic thermal oils. The main features this product brings to the marketplace include:

This depends on several factors; how frequently are spare parts required? how long has the pump been in operation? and the price of the required spare parts versus the cost of a complete new pump. For example, if a new casing, impeller, shaft and mechanical seal are required, then it is more cost effective to purchase a complete new pump as a large proportion of the high value parts are required. If the pump is wearing frequently and prematurely, then this may be an indication that the wrong type or size of pump is installed. It is a good idea to talk to us in this situation as we may be able to identify the issue with your pump or system and select a more suitable pump for your requirements.

8613371530291

8613371530291