allweiler pump mechanical seal for sale

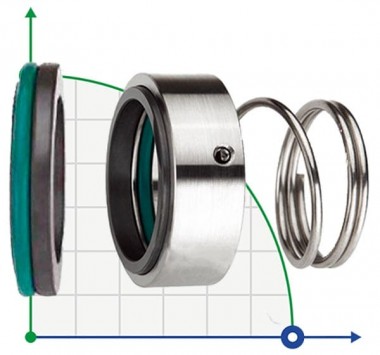

Mechanical seal for the ALLWEILER R-M3.ALW pump is used for the screw pumps ALLWEILER BAS, ZAS, ZASV, SPF10, SPF20. Mechanical seal with conical spring and O-ring for shaft sizes 15 and 20 mm. Materials of execution R-M3.ALW imply different areas of use, in particular when working with oils, fuels and reactive compounds.

Mechanical seal for the ALLWEILER R-M3.ALW pump is used for the screw pumps ALLWEILER BAS, ZAS, ZASV, SPF10, SPF20. Mechanical seal with conical spring and O-ring for shaft sizes 15 and 20 mm. Materials of execution R-M3.ALW imply different areas of use, in particular when working with oils, fuels and reactive compounds.

Seals with shaft size 1, 1.375, 1.813, 1.875, 2, 10 mm, 11, 12 mm, 14 mm, 15 mm, 17, 21, 22 mm, 23, 24 mm, 26 mm, 27, 28 mm, 30 mm, 34, 35 mm, 37.5, 48 mm, 50 mm, 53 mm, 55 mm, 57, 68 mm, 72, 73, 74, 75 mm, 80 mm, 85, 95, 100, 110, 120, 129, 185, 189, 200, 242, 275, 300, 335, 385

Mechanical seals are available in a variety of sizes, including 1 or 1.375 or 1.813 or 1.875 or 2 or 10 mm or 11 or 12 mm or 14 mm or 15 mm or 17 or 21 or 22 mm or 23 or 24 mm or 26 mm or 27 or 28 mm or 30 mm or 34 or 35 mm or 37.5 or 48 mm or 50 mm or 53 mm or 55 mm or 57 or 68 mm or 72 or 73 or 74 or 75 mm or 80 mm or 85 or 95 or 100 or 110 or 120 or 129 or 185 or 189 or 200 or 242 or 275 or 300 or 335 or 385. Selecting the right size mechanical seal is important for optimal performance and reliability. A mechanical seal with the correct shaft size ensures an accurate and secure fit on the pump shaft, distributing pressure correctly and preventing leakage.

Mechanical seals specifically suited for pumps can make a significant difference in the performance and reliability of your system. Mechanical seals from brands such as Allweiler are designed to meet these challenges, providing a reliable and durable seal for pumps in a wide range of applications. Whether conveying chemicals, water, oil or other liquids, Allweiler mechanical seals are tested and proven to provide high performance under various conditions. Plus, these seals are easy to install and maintain, which means you can spend less time on maintenance and more time doing what you do best.

Mechanical seals are essential to the operation of rotating devices, such as pumps. When selecting the right mechanical seal for a specific pump, it is important to consider factors such as pressure, temperature, and speed. Type number NB 50-125/01 U3.1D is specifically designed for use in pumps and provides the necessary performance and specifications to prevent leakage and extend pump life.

Mechanical seal to the pump Allweiler: NTT 25-160, NTT 25-200, NTT 2/25-200, NTT 32-160, NTT 32-200, NTT 2/32-200, NTT 40-160, NTT 40-200, NTT 40-250, NTT 2/40-250, NTT 50-160, NTT 50-200, NTT 50-250, NTT 2/50-250, NTT 65-160, NTT 65-200, NTT 80-160, NTT 100-160.

Mechanical seals for pump series Allweiler: AEB, ALLCHEM CNH-B, CNB, CNI, ALLMAG CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, NSL, NST, MI, MA, NISM, NIM, NAM, NAM-F, ALLUB NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF10, SPF20, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S.

The mechanical seal design consists mainly of two parts: a moving part and a stationary part. The stationary part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the stationary part by means of a spring.

The mechanical seal is sealed by secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to select the material of the secondary seals and the friction pair.

8613371530291

8613371530291