allweiler mechanical seal supplier

The oldest German pump manufacturer, founded in 1860, Allweiler GmbH is today the European market and technology leader in fluid handling solutions for shipbuilding, power generation and special industrial applications. Our product portfolio is unrivaled in the industry and includes centrifugal, propeller, screw spindle and progressive cavity pumps, as well as complete pump systems. We also manufacture peristaltic pumps and macerators. In addition to our Allweiler-branded pumps and systems, we sell the pumps and solutions of our sister company Zenith - gear pumps.

We’ve built our success on putting our customers’ needs as the top priority in the development of every individual Allweiler product. Our customers benefit from a deep knowledge of pump technologies and expertise in fluid handling applications that has grown over generations. They know our pumps are precisely manufactured to address specific applications areas and trust the quality and reliability of Allweiler pump performance. We back our pumps with expert, personal, onsite and comprehensive services.

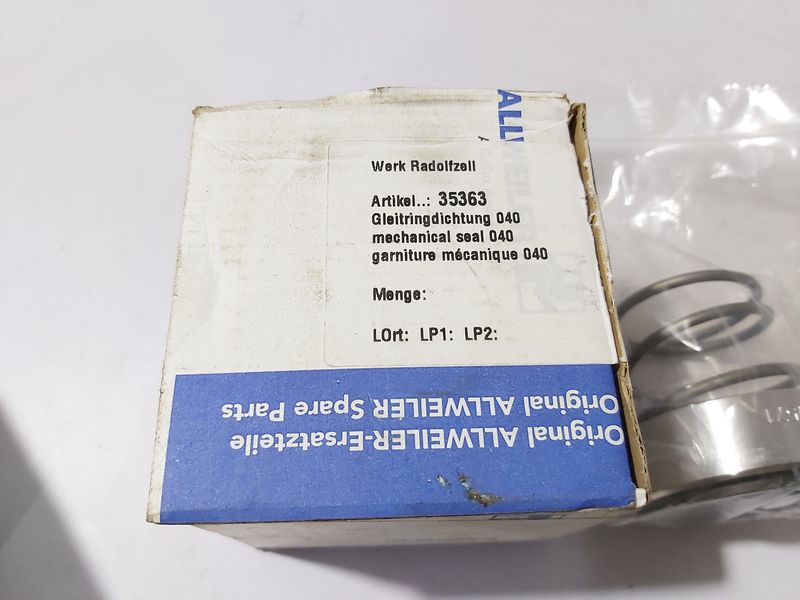

Mechanical seals for pump series Allweiler: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH, CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L, LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF, SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

Shanley Pump and Equipment carries a full line of the most popular sizes and styles in Centrifugal Pump Seals and Progressive Cavity Pump Seals ready to ship in stock the same day you order. We carry mechanical pump seals and standard single-spring pump seals as well as cartridge pump seals for you centrifugal pumps and progressive cavity pumps.

We carry allweiler pump seals, EDUR pump seals, Speck Pump Seals, Hilge pump seals, Seim pump seals and more in both standard cartridge design and mechanical seals for both single and double set installations.

Pump seals are available as either OEM or replacement from some of the best names in pump sealing today like John Crane, Smith and Loveless and more and are designed to work under the most adverse of conditions.

Our Pump Seals use the very best in Ceramics, Carbon, Tungsten Carbides and other exotic materials for a quality fit and operation in-between servicing and maintenance.

We also carry Progressive Cavity Pump Seals for our entire Liberty Process Equipment line of progressive cavity pumps that work with Moyno®, and Tarby®.

If you are looking to purchase any of the seals we carry, or are having difficulty finding the seal you need for your existing pump, please contact us with your pump model and serial number. We"ll be glad to assist you!

We offer a complete range of standardized POWERseal mechanical seals for most pump manufacturers . Our mechanical seals are among the best on the market.

Mechanical seals for Allweiler pump series: CNH-B, CNB, CNI, CMA, CMAL, CNB-M, CNI-M, CNH-ML, CMAT, CMIT, CNH-M, NT, NB, NBWH, NIWH, CTWH, CBWH , CIWH, NTWH, NTT, NBT, NIT, NTWH, NBWH, NIWH, CTWH, CBWH, CIWH, NT, NI, NB, NS, MI, MA, NISM, NIM, NAM, NAM-F, NSSV, MELO, L , LV, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, SVG, SVM, SRBS, SRZ, SRZS, SOHB, SOH, SFH, SEMA, ASL, ASH, BAS, ZAS, ZASV, SPF , SPF-M, SPZ, SPZ-M, TRILUB, SN, SM, VH, SN-M, RU, S

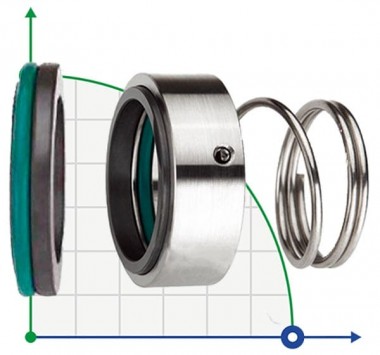

The design of the mechanical seal consists mainly of two parts: a movable part and a fixed part. The fixed part is usually a ring that is fixed in the pump housing. The movable part is mounted on the shaft and is pressed against the fixed part by means of a spring.

Mechanical sealing is achieved using secondary seals (bellows, rubber rings) and a friction pair. When choosing a mechanical seal, it is important to choose the material of the secondary seals and friction pairs.

We recognize and understand the vital role of allweiler pump seals in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale allweiler pump seals in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider allweiler pump seals requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

8613371530291

8613371530291