api 682 mechanical seal factory

-1.jpg?width\u003d901\u0026name\u003dimage3%20(1)-1.jpg)

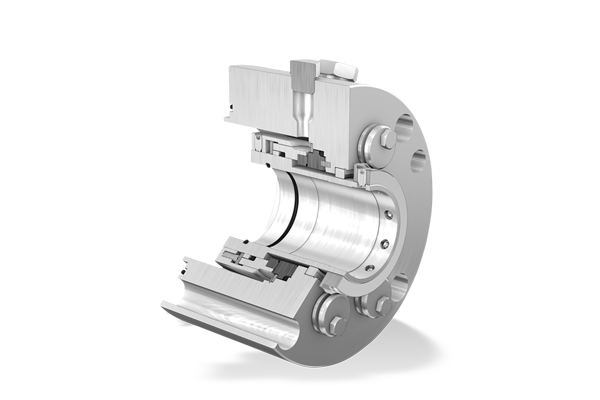

The Stein Seal® Company has developed API1 STANDARD 682 seals for the oil and gas industry. Stein Seal® has designed, manufactured and tested the seals according to the rigorous API Standard 682 test protocols. In general, these are balanced seals with cartridge construction. These seals are classified in to Types, Category, Arrangements and Configurations. The seals are designed and tested to operate continuously for 25,000 hours without need for replacements.

Type A seal is a balanced, internally-mounted, cartridge design, pusher seal with multiple springs. Secondary sealing elements are elastomeric O-rings.

Category 1 are intended for use in non API 610 pump seal chambers, meeting the dimensional requirements of ASME B 73.1 and ASME B73.2 seal chamber dimensions and their application is limited to seal chamber temperatures from -40°F to 500°F (-40°C ~ 260°C) and gauge pressures up to 300 psi (2 MPa / 20 bar).

Category 2 are intended for use in API 610 pump seal chambers dimensional requirements. Their application is limited to seal chamber temperatures from -40°F to 750°F (-40°C ~ 400°C) and gauge pressures up to 600 psi (4 MPa / 40 bar).

Category 3 provides the most rigorously tested and documented seal design. They meet the seal chamber envelope requirements of API 610 (or equal). Their application is limited to seal chamber temperatures from -40°F to 750°F (-40°C ~ 400°C) and gauge pressures up to 600 psi (4 MPa / 40 bar).

Arrangement 2 seals having two seals per cartridge assembly, utilizing the externally supplied buffer fluid at a pressure less than the seal chamber pressure.

Arrangement 3 seals having two seals per cartridge assembly, utilizing the externally supplied barrier fluid at a pressure higher than the seal chamber pressure.

Face-to-back configuration – These seal are Arrangement 2 or 3 seals. In which one stationary face is mounted between two flexible rotary unit or one flexible rotary unit between two stationary face. The inner seal is OD pressurized by process fluid and barrier or buffer fluid is on the ID of the inner seal. The outer seal OD pressurized by barrier or buffer fluid.

Back-to-back configuration – These seal are Arrangement 2 or 3 seals. In which both the rotary faces are mounted between two stationary flexible units. The pumping fluid is on the ID of the inner seal, and the barrier (pressurized) or buffer (un pressurized) fluid is on the OD of the inner and outer seal.

Face-to-face configuration – These seal are Arrangement 2 or 3 seals. In which both the rotary faces are mounted between two flexible stationary units. The pumping fluid is on the ID of the inner seal, and the barrier (pressurized) or buffer (un pressurized) fluid is on the OD of the inner and outer seal.

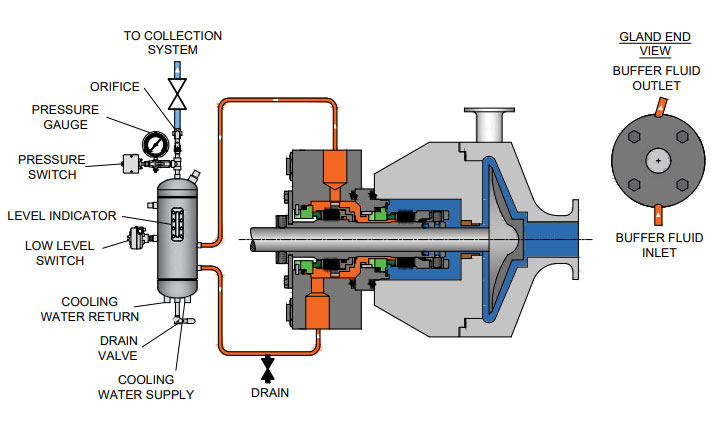

A seal piping plan is designed, manufactured and supplied to improve the environment around the mechanical seal and therefore increase the performance and reliability of the seal. Piping plans range from very simple systems such as fluid recirculation into the seal chamber to complex systems which provide pressurization, cooling and circulation for support fluids and gases. The basic operation of the piping plan and also the requirements for instrumentation are followed as per API Standard 682 guidelines. Major piping plans supplied by Stein Seal® are Plan-21, Plan-23, Plan-32, Plan-52, Plan-53A, Plan-53B & Plan-53C.

Our API 682 seal design features, manufacturing capabilities and test facilities are witnessed and certified by a third party international certification organization. API 682 product offerings and capabilities can be found on our website www.steinseal.in

API Standard 682, titled "Pumps - Shaft Sealing Systems for Centrifugal and Rotary Pumps," is the American Petroleum Institute (API) standard for end-face mechanical seals.centrifugal pumps. It is based on the combined knowledge and experience of seal manufacturers, engineering companies, and end users. API 682 is primarily intended for use in the petroleum, natural gas and chemical industries, but is often referenced for other types of equipment and industries.

By the late 1980s, mechanical seals had been accepted as the preferred method for sealing rotating pumps for many years. However, mechanical seal standards were generally buried in other standards such as DIN 24960, ANSI B73, and API 610. All of these standards were primarily pump standards and any references to seals were directed at how mechanical seals would interact with pumps.

API 610 is the API standard about centrifugal pumps and is primarily intended for use in the petroleum, natural gas and chemical industries. Although the 1st through 7th Editions of API 610 included specifications for mechanical seals, beginning with the 8th Edition, API 610 defers to API 682 for seal specifications.

In the late 1980s a group of refinery equipment engineers and managers began to compare sealing solutions in refinery applications. This group, led by V. R. Dodd of Chevron, came up with a general plan and the American Petroleum Institute (API) agreed to establish a standard for mechanical seals: API 682. A Task Force was formed in 1990 and the first meeting was held in January 1991. This Task Force was composed of fourteen members from various refineries, seal and pump manufacturers. API 682, First Edition, was published in October 1994.

One interesting aspect of API 682 is that it includes a strong set of defaults. That is, unless the user indicates otherwise, API 682 makes default choices for specifics such as:

Some statements within API 682 are normative, that is, required, whereas others are informative, that is, descriptive but not required. In particular, many of the illustrations are informative. This distinction has not always been apparent to the reader.

The first edition of API 682 was entirely new although parts of it were extracted from the pump standard API 610 and existing API standard paragraphs.

Although this mission statement no longer appears in the standard, it remains the basic principle driving the work of the API 682 Task Force and its relevance remains the same for the 4th Edition as it did for the 1st.

In addition to providing requirements for mechanical seals, the 1st Edition of API 682 also provided a guide on how to select the correct seal for a number of common refinery applications. In order to provide this seal selection guide, it was necessary to categorize applications into a number of services:

Prior to API 682, 1st Edition, multiple seals were designated as being either “tandem” or “double” seals; however, advances in seal design had rendered these classic terms obsolete. As a result, there was some confusion on how multiple seals were designated. The task force decided to use a more descriptive designation and chose to define dual seal arrangements. A dual seal would be two sets of sealing faces used in the same seal chamber. The fluid between these two sets of sealing faces could be either pressurized or unpressurized. Three standard arrangements were defined:

After having defined the services, seal types, and seal arrangements, a series of flowcharts were created to help in selecting a seal type, special materials or design requirements, and supporting piping plans.

API 682 seals were to have a high probability of three years of reliable service. In order to prove this, seal performance testing on process fluids under representative pressures and temperatures was required. These performance tests are called “Qualification Tests”.

The general idea of the qualification test was to prove that the design was sound. The goal of the qualification test was to simulate a long-term steady state run followed by a process upset. The simulated process upset consisted of pressure changes, temperature changes and included loss of flush. The results of these tests were made available to the purchaser for evaluation. There was no acceptance criteria presented in API 682 1st Edition.

In addition to the qualification test of the design, every API 682 seal, whether new or repaired, is to be pressure tested with air before being shipped to the end user.

One of the major criticisms of API 682 1st Edition was that all the seals were “heavy duty” and therefore expensive with no alternatives for easy services. To some degree, this was intentional and was done in order to reduce inventory, promote familiarity with a limited number of seal types and to increase reliability. Another criticism of API 682 1st Edition was that it considered only API 610 pumps and only refinery applications. The chemical and petrochemical industries routinely use ASME pumps in addition to API 610 pumps. Broadening the scope of pumps covered by API 682 would allow standardized seals to be applied in a greater number of industries.

In 2nd Edition, the organization of API 682 was changed to conform to ISO standards: This reorganization means that there is no simple cross reference guide between 1st edition and 2nd edition paragraph numbers.

The 2nd Edition introduced the concept of seal categories. A seal category describes the type of pump into which the seal will be installed, the operating window, the design features, and the testing and documentation requirements. There are three categories designated as Category 1, 2, or 3.

Category 1 seals are intended for non-API-610 pumps. This category is applicable for temperatures between –40°F and 500°F (-40°C and 260°C) and pressures to 315 PSI (22 bar).

Category 2 seal are intended for API-610 This category is applicable for temperatures between –40°F and 750°F (-40°C and 400°C) and pressures to 615 PSI (42 bar).

Category 3 seals are essentially the original seals of 1st Edition and are also intended for API-610 pumps. Category 3 seals are intended for the most demanding applications. This category is applicable for temperatures between –40°F and 750°F (-40°C and 400°C) and pressures to 615 PSI (42 bar). Design features include a distributed flush and floating throttle bushing for single seals. Additional documentation must be also provided.

Containment seals are the outer seal of Arrangement 2. In the 2nd Edition, containment seals can be used with a liquid buffer fluid, a gas buffer fluid or without a buffer fluid. In the case of a dry running containment seal, the containment seal will be exposed primarily to buffer gas or vaporized process fluid. Such containment seals must therefore be designed for continuous dry running while meeting the reliability goals of the standard. Dry running containment seals may be either contacting or non-contacting.

Non-contacting inner seals are also introduced for Arrangement 2. One of the primary targets for non-contacting inner seals is in flashing hydrocarbon services. In some of these services, it is impossible to obtain adequate vapor margins to prevent flashing of the fluid in the seal chamber. This seal will be used with a dry running containment seal and the leakage past the inner seal will be piped to a vapor recovery system.

The other new seal type introduced in 2nd Edition was the dry running gas seal used in Arrangement 3. This seal is designed to run on a gas barrier fluid such as nitrogen.

Several new piping plans were introduced in the 2nd Edition. These included additional options for dual pressurized liquid seals as well as new piping plans to support containment seals and dual pressurized gas seals.

One of the strengths of the 1st Edition was to provide qualification tests in which seal vendors would be required to prove the suitability of their seals for a given service. The 2nd Edition expanded on these requirements by adding new tests for containment seals and dual gas seals as well as defining acceptance criteria for all tests.

For all practical purposes, API 682 3rd Edition is the same as 2nd Edition. The completed 2nd Edition was submitted to the ISO Organization for approval as their ISO 21049. At the time, API and ISO had an agreement to jointly issue standards. The ISO Organization made slight editorial changes to 2nd Edition, including correcting typographical errors and unit conversions. Therefore, API had to re-issue a corrected 2nd edition but choose to label it as 3rd edition. API 682 3rd Edition was published in September 2004.

API and ISO no longer have the agreement to jointly issue standards. The 2004 issue of ISO 21049 is the only issue and plans to update it are unknown.

Seal Configuration refers to the orientation of the seal components in an assembly. In previous editions, orientations were defined as face-to-back, back-to-back, and face-to-face and these terms are carried over into the 4th Edition. In 4th Edition, any orientation (face to back, back to back, face to face) can be used in a dual seal provided that the design features are appropriate to the functionality of that particular arrangement.

Fourth Edition added additional specifications for clearances, placed these requirements in the form of tables and noted that seal components are not to be considered as “shaft catchers” to restrict shaft movement. The minimum clearances specified apply only to equipment within the scope of the standard. Equipment outside that scope, such as non-cartridge seals, older pumps, non-API 610 pumps and certain severe services, might benefit from larger clearances.

Before API 682, API 610 (the pump standard) used a simple seal code to specify seals. API 682 attempted to use a more comprehensive seal code; however, that code changed with every edition of API 682. The 4th Edition code, described in Annex D, is probably the best to date and includes some concepts and codes from the historical API 610 seal code.

API standards are reviewed every five years and re-issued every ten years. A new Taskforce for API 682 was formed in 2017 and preparations for 5th Edition are underway.

Buck, G. S., Huebner, M. B, Thorp, J. M., and Fernandez, C. L. “Advances in Mechanical Sealing – An Introduction to API-682 Second Edition”, Texas A&M Turbomachinery Symposium, 2003.

API Standard 682, Second Edition, 2001, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” American Petroleum Institute, Washington, D.C.

API Standard 682, Third Edition, 2004, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” American Petroleum Institute, Washington, D.C.

API Standard 682, Fourth Edition, 2014, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” American Petroleum Institute, Washington, D.C.

Many users do not like the strong handed approach used by API 682. However, with a little study of API 682, the user can easily learn to specify his preferences in detail using the seal data sheet.

Some statements within API 682 are normative, that is, required, whereas others are informative, that is, descriptive but not required. In particular, many of the illustrations are informative. This distinction has not always been apparent to the reader.

In spite of its strong handed approach, API 682 encourages innovative or developing technology. However, non-standard alternatives should be carefully discussed between the purchaser and seal company.

It is important to realize that API 682 is a users’ standard; it was written by and for the end users of mechanical seals and these users wanted to force changes. The result was an entirely new standard written around a limited set of seal types, arrangements and materials that were favored by the end users in refineries. These new seals were also required to be proven through a series of rigidly prescribed tests. Although everyone agreed that API 682 seals were robust and well suited to the best practices of the refining industry, cost quickly became a limiting factor to the specification. Consequently, API 682 1stEdition was not applied as extensively as had been anticipated. Subsequent editions have had an increase in the scope and also are more flexible with respect to defaults and options.

It is important to know the background and development of API 682 in order to fully understand and apply the standard. The story of API 682 begins in the late 1980’s.

By the late 1980’s, mechanical seals had been accepted as the preferred method for sealing rotating pumps for many years. However, prior to API 682, mechanical seal standards were generally buried in other standards such as DIN 24960, ANSI B73 and API 610. All of these standards were primarily pump standards and any references to seals were directed at how mechanical seals would interact with pumps.

In the late 1980’s a group of refinery equipment engineers and managers began to compare sealing solutions in refinery applications. This group, led by V. R. Dodd of Chevron, came up with a general plan and the American Petroleum Institute (API) agreed to establish a standard for mechanical seals: API 682. A Task Force was formed in 1990 and the first meeting was held in January 1991. This Task Force was comprised of fourteen members from various refineries, seal and pump manufacturers. API 682, First Edition, was published in October 1994.

After more than five years of planning, the American Petroleum Institute (API) is preparing to release the 4th edition of API Standard 682 (ISO 21049:2011). The API 682 standard, which dates back to 1994 and is formally known as Shaft Sealing Systems for Centrifugal and Rotary Pumps, offers specifications and best practices for mechanical seals and systems to pump end users.

The standard’s latest edition began to take shape in 2006, when API formed a 4th edition task force to respond to end users’ questions and comments about previous editions. The task force soon realized that major changes, including reorganization and editing, would be necessary. While addressing every aspect of the resulting 4th edition (which is more than 250 pages long) would be impossible, this article summarizes the standard’s main points.

Those who use API 682 should understand the standard’s scope and remember that the standard does not include specifications for equipment outside that scope, such as engineered seals or mixers. Another important but often misunderstood point is that API 682’s figures are illustrative and not normative in their entirety.

For example, one of API 682’s figures shows a fixed throttle bushing combined with a rotating Type A seal, but seal manufacturers do not always have to combine these two components. The standard provides normative details in clauses and tables to help purchasers distinguish between requirements and suggestions.

The 4th edition continues to divide seals into three categories, three types and three arrangements. For all practical purposes, seal manufacturers can combine a seal’s component parts into nearly any orientation or configuration. Each orientation and configuration has advantages and disadvantages with respect to certain applications, performance and system disturbances.

Before the 4th edition, API 682 did not specify a minimum clearance between the inside diameter of a stationary seal part and the outside diameter of a rotating seal part. The 4th edition specifies this minimum clearance—typically the clearance between the sleeve and the mating ring. The specified clearances are representative of standard clearances that end users have used for decades. End users should not consider seal components to be “shaft catchers” to restrict shaft movement. The minimum clearance specified in API 682 also applies only to equipment within the standard’s scope. Equipment outside that scope, such as non-cartridge seals, older pumps, non-API 610 pumps and certain severe services, might benefit from larger clearances.

The new standard also updates the default bushings for the gland plate for the three seal categories. Fixed throttle bushings are now the default for Category 1 only, while floating bushings are the default for Categories 2 and 3.

While the 4th edition features the recommended seal selection procedure from the standard’s first three editions, it adds an alternative selection method in Annex A. Proposed by task force member Michael Goodrich, this alternative method recommends using material data sheet information to select a sealing arrangement.

Plans 66A and 66B are new to the standard, although end users have used them previously in pipeline applications. These plans detect and restrict excessive leakage rates in case of an Arrangement 1 seal failure.

The 4th edition has revised the data sheets in Annex C extensively to make them the same for all seal categories. Only two data sheets are included in the 4th edition—one in metric units and one in U.S. customary units. The new edition also folds Annex J into Annex E.

Previous editions of API 682 required metal plugs and anaerobic sealants when shipping new or repaired cartridges. After much debate, the task force decided that threaded connection points should be protected with plastic plugs for shipment. These plastic plugs should be red and have center tabs that operators can pull easily to distinguish the plugs from metal plugs. Shippers should also attach yellow warning tags to the plugs to indicate that end users need to remove the plugs before operation.

Although tutorial notes are scattered throughout API 682, this edition expands the tutorial section, Annex F, from seven pages to 42 pages. The expanded annex includes illustrative calculations. In particular, users interested in systems such as Plan 53B will find Annex F to be useful.

The 4th edition of API 682 is the product of more than 20 years of discussion, debate, usage and peer review. It includes a strong set of defaults and is by far the best and most logical starting point for mechanical seal and systems use. Equipment operators should take the time to familiarize themselves with API 682 to get the most out of this comprehensive standard.

A brand new mechanical seal provides a specific level of protection against pump leakage, but by itself, it can’t necessarily ensure the level of leak protection you need in your Northern California refinery. Here’s why: The API 682 Integrity Test is designed to identify mechanical seal manufacturing defects and assembly errors. This mechanical seal leak test procedure isn’t designed to simulate the seal’s actual performance under operating conditions, and the test certainly has its limitations.

One test is used regardless of seal design. It doesn’t differ according to seal arrangement, materials, face technology, size, or mating ring proportions. These and several other factors affect seal performance. Even though most mechanical seals effectively seal both air and liquids at low pressure, not all do. For example, high-pressure seals with low balance ratios satisfactorily seal liquids but leak air. Mechanical seals with polished faces have less air leakage in comparison to special (matte) face finishes. Contacting seals have less leakage than non-contacting seals. So one test doesn’t cover all bases.

The API 682 Integrity Test permits a maximum pressure drop of 0.14 bar (2 psig) over a five minute period from a maximum 28 liter (1cu ft) reservoir pressurized to 1.7 barg (25 psig). This represents a leakage rate of 56.9 g/hr of air, based on the ideal gas laws.

For a Bay Area refinery concerned with fugitive emissions and possible sanctions from Cal/OSHA or BAAQMD, that leakage rate is unacceptable. So, even though the API 682 Integrity Test can catch manufacturing defects, you’re not guaranteed leak-free performance. That’s where mechanical seal support systems bridge the gap between the mechanical seal leak test procedure limitations and a refinery’s stringent requirements.

A seal support system properly configured for your mechanical seal and pumping process helps minimize the chance of pump leakage. There are near-infinite combinations of pumping conditions, mechanical seals, and seal support systems. To help navigate this complexity of options, I recommend seeking the guidance of an experienced seal support system supplier. They’ll work with you to assess the specific requirements of each pump, mechanical seal, and process conditions. Based on the assessment, they’ll recommend the mechanical seal support system plan and configuration to help ensure you comply with Cal/OSHA and BAAQMD regulations and extend the mechanical seal’s life.

Proper configuration tailors the seal support system to the specific temperature, pressure, and process fluid conditions of the pumping process. Components are selected to help ensure the optimum operating environment for each mechanical seal.

Coolers or heat exchangers rated to maintain process or flush fluid at a temperature to sufficiently remove heat from seal faces and prevent thermal distortion of seal faces that inevitably result in leakage

Barrier fluids pressurize by nitrogen, bladder accumulator, piston accumulator, or an external pump to maintain the correct between-seal pressure for dual/tandem seal arrangement

Valves, pressure gauges, and pressure transmitters to monitor pressure and alert to variations that could lead to unacceptable leakage across inboard and outboard seal faces

A well-configured echanical seal support system begins with matching the proper seal support plan to the mechanical seal type and then refines the plan with components tailored to the specific pumping conditions.

A properly configured mechanical seal support system will incorporate the components and function to maximize pump reliability. That configuration should also provide easy accessibility by operations and maintenance personnel.

For more than 50 years Swagelok has been working with refineries in Northern California. Our expert Field Engineers are available to consult on-site to assess your requirements and recommend solutions tailored to your specific pumping needs. Swagelok’s petroleum industry experience, highest-quality components, and assembly services enable us to design, fabricate, and test (following ISO 9001 quality standards) mechanical seal support systems to help minimize mechanical seal leaks and meet stringent California environmental standards.

To find out more about how Swagelok Northern California can help you select the right API plan for dry gas seals for your specific process needs, contact our team today by calling

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization focused within the pneumatic and hydraulic industry where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

The mechanical seal is the most likely part of the pump to fail. Approximately 70% of the pumps removed from service for maintenance are victims of mechanical seal failure. Mechanical seal parts are highly engineered with very close tolerances and any upset in the pump or associated system can cause seal failure, including:

Mechanical seals are based on positioning two very flat and smooth discs called seal faces, one rotating on the shaft and one stationary in the pump, against each other. The discs are flat and smooth enough to ALMOST prevent the pumped fluid from leaking out between them. However, the faces do rely on a very thin film of fluid between the faces to lubricate that rubbing fit. Without this film of fluid, the seals will overheat and fail. Lack of lubrication is the PRIMARY cause of seal failure. If the fluid is very hot, it can flash to a vapor as the fluid moves across the faces, again resulting in lack of lubrication. Note that gas seals use a gas film between the faces to minimize face contact and heat buildup.

Seal flush plans are intended to keep the area around the seal in the most seal friendly environment practical, usually meaning clean and cool. Dual seal plans also provide backup and leak detection for safety.

Note that seal flush plans use pressure differences at the pump to drive the flush fluids. The pump suction is low pressure, the seal chamber is a medium pressure, and the pump discharge is at high pressure.

As the seal faces faces rub together (with their thin film of lubricating fluid), they generate heat. The heat can build up in the seal chamber and push the fluid towards its boiling point, resulting in premature flashing, lack of lubrication, and failure. This first set of seal plans is intended to create circulation through the seal chamber to dissipate the heat out of the seal chamber and back into the pumped fluid.

Flush fluid flows from high pressure at pump discharge to the medium pressure seal chamber and back into the main flow to remove heat from seal chamber

Can be used to increase seal chamber pressure. Increased chamber pressure may be required to keep chamber fluid from flashing to vapor or to provide enough pressure to push the fluid between the faces for lubrication. (Seal chamber must be 5 psi minimum above external atmospheric pressure).

These seal plans are intended to provide the seal with the friendliest environment possible by cooling and/or cleaning the fluid in the seal chamber. The throat that separates the seal chamber from the main pumped fluid can be further restricted by adding a close clearance bushing in the bottom of the seal chamber, better isolating the cool, clean seal chamber fluid from the hot, abrasive fluid in the pump.

Rather than a Plan 21 single pass system, a Plan 23 is a multi-pass system. Fluid comes FROM THE SEAL CHAMBER instead of the pump discharge, is cooled, and directed back to the seal chamber.

Fluid is driven out of the chamber and through the cooler by “pumping ring” or other “pumping feature” built into the seal. These features provide very little differential pressure. Connecting tubing must have long, sweeping bends, well vented high points, and low point blowouts to ensure fluid flows.

Quench piping does NOT change conditions inside the seal chamber, at the wet side of the seal faces. Rather, it affects or monitors the environment on the ATMOSHPERIC side of the seal faces.

Pumps that leak when they are filled, even before they are started, often have a flush line intended for a Plan 11 or 13 connected to the QUENCH port, leading to the atmospheric side of the seal. There should be a “Q” or the work “QUENCH” stamped in the gland at this port.

For flush plans Plan 65A, 65B, 66A, and 66B, facility owners may want to know if their seals are leaking excessively without going to the expense of dual seals. These seal plans direct excessive leakage on the outside of the seal to an alarm instrument. Remember that seals leak a little bit. They need to in order to lubricate the faces and function correctly. The plans below handle the nuisance leakage in different ways.

Used in salting services like sodium hydroxide. The leakage across the seal faces will turn to salt when it reaches atmosphere. The salt crystals can wear the faces or build up in the seal, preventing the movement necessary to keep the seal faces in contact. The salt on the outboard of the seal can be washed away with a water quench through the quench and drain ports. Usually a close clearance bushing is installed at the extreme outboard end to the seal assembly to help keep the quench fluid moving from the quench to the drain port (or vice versa) and not just run out along the shaft. Also used for slurry services.

Grease can be introduced into the quench port. This external grease can provide temporary lubrication to the seal in case the pump sees large air or vapor pockets which would normally rob the seal faces of the required lubricating fluid film.

Quench can also be gas. In hot hydrocarbon services, the fluid will turn to solid coke when it reaches the atmospheric side of the seal. The fluid would remain a liquid if the area outside the seal faces is robbed of oxygen with a flood of nitrogen or steam.

An alarm does NOT necessarily mean a failed seal. The collection vessel might be full from years of nuisance leakage. Try emptying the vessel and observing how fast the vessel fills.

Two throttle bushings are used to ensure that the vapor (or fluid) leakage is limited along the shaft and out of the drain. A pressure switch picks up a rise on pressure above nuisance levels on the outboard side of the seal.

Dual seals provide a backup seal in case the primary seal fails. They prevent hazardous fluids from leaking to the surrounding area, desirable for both environmental protection and the safety of nearby personnel. Dual seals also capture and control any leakage of pumpage across the primary seal. The backup seal is kept lubricated by introducing a buffer/barrier fluid (often a mineral or synthetic oil, a water/glycol mix, or diesel) into the space between the primary (inboard) and secondary (outboard or backup) seals. The buffer/barrier fluid is contained in a tank (5 gallons is most common) adjacent to the pump. Instrumentation on the tank indicates what is happening with the seals.

Remember that a lubricating fluid film will flow from high pressure to low pressure. If the pump seal chamber pressure is higher than the pressure on the other side of the seal, the pumpage will be the lubricating film. If the pump’s seal chamber pressure is lower than the external pressure, the external atmosphere will migrate into the pump. Pumps under vacuum cannot use an ordinary single seal, since air from the atmosphere would be drawn between the faces, causing them to run dry and fail. Using a dual seal allows a fluid to be present at the outside of the seal. In a pump under vacuum, the buffer fluid would be pulled into the pump between the seal faces, keeping the inboard seal well lubricated.

If the pump seal chamber pressure is higher than the BUFFER fluid between the primary and backup seal faces, then the pumped fluid will flow from the high seal chamber pressure into the low pressure buffer fluid. This is called a DUAL UNPRESSURIZEDseal (formerly called a tandem seal), and the fluid is called a BUFFER fluid.

If the pump seal chamber pressure is lower than the BARRIER fluid between the primary and backup seal faces, then the barrier fluid will flow across the primary seal from the space between the primary and backup seals into the pump. This is called a DUAL PRESSURIZEDseal (formerly called a double seal), and the fluid is called a BARRIER fluid.

Buffer fluid circulates from the buffer fluid reservoir, through the space between the primary and backup seal, and back to the reservoir. Fluid is circulated by a weak pumping action built into the seal.

It the fluid flashes to vapor at low pressure, the vapor is piped to a flare or vapor recovery system, through an orifice at the top of the tank. If the primary seal is allowing too much leakage, the vapor will build pressure in the reservoir against the orifice and a pressure instrument can alert the operator.

If the fluid remains as a liquid under low pressure, any leakage will cause the fluid level in the buffer tank to rise, where a high level alarm can be tripped. Just because the high level alarm is tripped does not mean that the primary seal is failing; it is the rate of leakage filling the tank which matters. The high level may have been reached after collecting years of nuisance leakage. Often, an oil change to the original level is all that is required. Be sure the fluid is disposed of properly.

Seal face friction or hot pumpage can add heat to the buffer fluid. A cooling water coil is often installed in the reservoir to cool the buffer fluid.

Dual pressurized system (seal barrier fluid is at a higher pressure than the pump seal chamber). Pressurized systems are used to ensure that very dangerous fluids remain in the pump. The difference between 53A, 53B, and 53C is the method of pressurizing the barrier fluid. Pressure in the barrier fluid should be at least 10 psi over the pressure in the pump seal chamber.

Barrier fluid circulates from the barrier fluid reservoir, through the space between the primary and backup seal, and back to the reservoir. Fluid is circulated by a weak pumping action built into the seal.

A low level alarm in the reservoir alerts the operator that a seal may be failing, allowing the barrier fluid to enter the pump through the primary seal or the atmosphere through the backup seal.

Seal faces can be designed to maintain a gas film between them rather than a fluid film. These piping plans are intended to work with theses gas film (dry running) seals. Plan 72 and 74 bring the buffer or barrier gas into the seal; plans 75 and 76 are for the gas exiting the seal.

Secondary seal is ordinarily running with a gas film between the faces. When the primary seal fails, the pumped fluid will fill the space between the primary and backup seal. The backup seal is now working as a liquid seal rather than a gas seal and is designed to run for about 8 hours, allowing the operators time for an orderly pump shutdown.

Plan 72 buffer gas flow keeps the gas in the seal from becoming concentrated from nuisance leakage over time so that any leakage from the gas backup seal is mostly inert flush gas and not toxic pump vapors.

Mechanical seal failure due to unfavorable operating conditions is an issue in every industry. Double mechanical seals especially require proper sealing accessories to create suitable operating environments which are key to increasing MTBF. Reservoir systems are one of the most common and effective options to supply cooling fluid crucial to successful seal operation.

A double -or dual – cartridge seal is defined as an arrangement of two mechanical seals in a series. These seals may be configured in various orientations within the cartridge. The seals themselves are referred to as the “primary” (or inboard) seal and the “secondary” (or outboard) seal. A double seal arrangement is the superior option to a single cartridge when it is imperative the product being pumped does not leak into the atmosphere. The API (American Petroleum Institute) Standard 682 classifies dual seals into two configurations. These configurations also apply to ASME (American Society of Engineers) B73.1 and ASME B73.2 pump designs.

Arrangement 2 (Unpressurized) Designs: the buffer fluid is the operating environment for the secondary seal and forms a “buffer” between the process fluid and the atmosphere.

Arrangement 3 (Pressurized) Designs: the barrier fluid is the operating environment for both the inboard and outboard seal, preventing process leakage to the atmosphere.

Buffer and barrier fluids may be either liquid or gas. These fluids lubricate seal faces during operation as well as regulate operating temperatures by moving heat—both generated and absorbed—away from the faces.

Seal support systems are necessary for the smooth operation of a dual mechanical seal. Here are two of the most common piping plans for these systems.

This is an unpressurized system consisting of a reservoir, supply and return lines, and an internal circulation device within the outer seal (commonly referred to as a pumping ring). The buffer fluid circulation rate is dependent on how this circulation device functions during seal operation.

Reservoirs may be fitted with a variety of measurement devices such as a liquid level indicator and pressure gauges as well as valves and switches to aid in various operation and maintenance functions. For instance, a typical support system configuration for natural gas liquids (NGL) would issue an alarm (visual, audible, or both) when the inner seal fails. In addition, the outer seal would take over the primary seal function until maintenance is performed.

This system forces gas from an external pressurized source into the reservoir to pressurize the barrier fluid. This means the reservoir pressure will be above seal chamber pressure; a guideline is a minimum of 20 to 25 psig (1.4 to 1.73 bar) above the maximum process pressure.

The Plan 53A is also used to maintain a specific operating temperature range to ensure optimum lubrication at the seal faces. The reservoir houses a cooling coil which actively cools the barrier fluid as necessary.

As with the Plan 52, a circulation device is used to move the barrier fluid. Replenishing a Plan 53A system with fresh barrier fluid can be as simple as a using a hand pump or a more complex arrangement which satisfies multiple seals.

Liquid-lubricated dual mechanical seals require an external source of clean, cool lubricating fluid. The following fluid reservoir systems create this enhanced sealing environment, enabling longer operational life for dual seals.

In the oil and gas industry, reliable seal operation is critical to running efficient, safe processes. In conjunction with API 682 Piping Plans 52 and 53A, seal support systems aid in smooth seal operation.

If you require an engineered seal support system or are interested in additional options to Flexaseal’s ANSI PLUS and ANSI LITE support systems, please contact our applications engineering team.

The Flexaseal Style 59A is designed specifically to conform to API 682 Category 2 Applications for Midstream and Downstream Oil and Gas Applications. Standard design features include:

The 59A is also available with contacting and noncontacting secondary sealing. The Flexaseal FC seal (Available as 59A/FC) provides decades of proven operational reliability as a contacting secondary seal. The Flexaseal FGSA (Available as 59A/FGSA) is our newest lift-off design for API applications that require a noncontacting secondary seal.

Prominent & Leading Manufacturer from Palanpur, we offer API 682 Mechanical Seals, Dry Gas Seal, Split Seal Series LPH 5050, API Plan 52 Thermosyphon Vessel Series LPTS 07, Rotary Joints and Segmental Carbon Rings.

Series LPA90S Multi-spring pusher seals are designed and qualification tested according to the stringent testing norms specified by API 682 standard. These dependable, engineered mechanical seals are developed to attain extremely low emmissions, typically to less than 150ppm. These seals are offered in single, dual unpressurized and dual pressurized arrangements for awide range of petroleum and light hydrocarbon Services in refinery and petrochemical industries.

These special engineered seals provide the following advantagesTo extend seal life beyond 25000 hours of operation.To reduce emission levels.To ensure plant and personal safety in hazardous environments.To standardise the seals and sealing systems.

Dry Gas seals are part of our manufacturing range which are used on high speed compressors in Gas and Oil Industries. We refurbish dry gas seals of any brand.

Series LPH 5050 is a unique design with minimum components for assembling the seal and allow user to install the seal in minimum time. The multi spring design keep the faces uniformely in contact. The split seal face is balanced covered with split O-Ring as a sealing member. Slots provided in the housing facilitates fitting the seal on various equipmentswith different PCDs.

Series LPTSO7 is used as a storage & unpressurising unit. Used for double mechanical seals in tandem seal arrangement. This is equipped with cooling coil inside the shell to bring down the temperature of buffer fluid coming from seal to Thermosyphon Vessel. Higher capacity upto 20 ltr. can also be offered.

Rotor connection options : BSP, NPT, UNF, UNC, METRIC THREAD are available. Built in Flange connection and quick change Flange connection are also available.No External support required : Self supporting on two precision Ball Bearings far enough to reduce vibration & wobbling.Balanced Mechanical Seal : Minimises operating torque & enhances life. Seal faces are self lubricating. Carbon (Resin impregnated) and Silicon Carbide with suitable elastomeric secondary sealing. 0r as per the requirement.

Series LPM 900 is a cartridge construction multiple spring heavy duty balanced seal specially developed for equipments handling slurries, sludges, syrups and other fluids that polymerizes or solidify with the changes in temperature. The springs are isolated from the fluid being sealed by dynamic O-ring, which enhances the seal life. Seal requires tightening of studs, nuts and detaching of location plates before starting the equipment. No dimensionalmeasurement to be done at site. Even non – skilled person can install the seal.

Series LPKS 918 seals are designed for Agitated nutsche filters (ANF). These seals are used for ANF filters & dryers, Rotary vacuum paddle dryers and Horizontal reactors with expanding shafts.

8613371530291

8613371530291