api plan 62 mechanical seal supplier

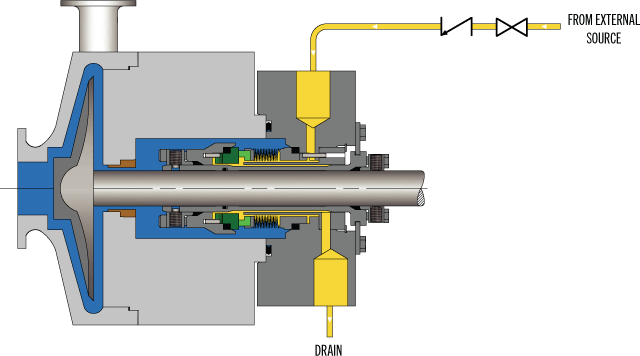

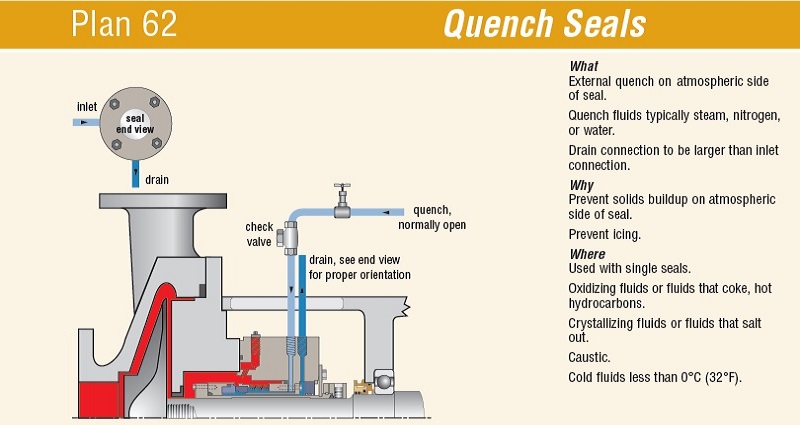

API Plan 62 delivers an external quench fluid to the atmospheric side of the seal. A typical application in a refinery is the prevention of coking on seal faces in hot hydrocarbon service by employing a steam quench. Nitrogen or clean water may also be used to quench or cool and clean the atmospheric side of the seal.

See page 77 of the Mechanical Seal Support Systems Application Guide for additional details and ordering information. Contact your authorized Swagelok sales and service center for information on optional components.

API Plan 62 delivers an external quench fluid to the atmospheric side of the seal. A typical application in a refinery is the prevention of coking on seal faces in hot hydrocarbon service by employing a steam quench. Nitrogen or clean water may also be used to quench or cool and clean the atmospheric side of the seal.

See page 77 of the Mechanical Seal Support Systems Application Guide for additional details and ordering information. Contact your authorized Swagelok sales and service center for information on optional components.

The mechanical seal is the most likely part of the pump to fail. Approximately 70% of the pumps removed from service for maintenance are victims of mechanical seal failure. Mechanical seal parts are highly engineered with very close tolerances and any upset in the pump or associated system can cause seal failure, including:

Mechanical seals are based on positioning two very flat and smooth discs called seal faces, one rotating on the shaft and one stationary in the pump, against each other. The discs are flat and smooth enough to ALMOST prevent the pumped fluid from leaking out between them. However, the faces do rely on a very thin film of fluid between the faces to lubricate that rubbing fit. Without this film of fluid, the seals will overheat and fail. Lack of lubrication is the PRIMARY cause of seal failure. If the fluid is very hot, it can flash to a vapor as the fluid moves across the faces, again resulting in lack of lubrication. Note that gas seals use a gas film between the faces to minimize face contact and heat buildup.

Seal flush plans are intended to keep the area around the seal in the most seal friendly environment practical, usually meaning clean and cool. Dual seal plans also provide backup and leak detection for safety.

Note that seal flush plans use pressure differences at the pump to drive the flush fluids. The pump suction is low pressure, the seal chamber is a medium pressure, and the pump discharge is at high pressure.

As the seal faces faces rub together (with their thin film of lubricating fluid), they generate heat. The heat can build up in the seal chamber and push the fluid towards its boiling point, resulting in premature flashing, lack of lubrication, and failure. This first set of seal plans is intended to create circulation through the seal chamber to dissipate the heat out of the seal chamber and back into the pumped fluid.

Flush fluid flows from high pressure at pump discharge to the medium pressure seal chamber and back into the main flow to remove heat from seal chamber

Can be used to increase seal chamber pressure. Increased chamber pressure may be required to keep chamber fluid from flashing to vapor or to provide enough pressure to push the fluid between the faces for lubrication. (Seal chamber must be 5 psi minimum above external atmospheric pressure).

These seal plans are intended to provide the seal with the friendliest environment possible by cooling and/or cleaning the fluid in the seal chamber. The throat that separates the seal chamber from the main pumped fluid can be further restricted by adding a close clearance bushing in the bottom of the seal chamber, better isolating the cool, clean seal chamber fluid from the hot, abrasive fluid in the pump.

Rather than a Plan 21 single pass system, a Plan 23 is a multi-pass system. Fluid comes FROM THE SEAL CHAMBER instead of the pump discharge, is cooled, and directed back to the seal chamber.

Fluid is driven out of the chamber and through the cooler by “pumping ring” or other “pumping feature” built into the seal. These features provide very little differential pressure. Connecting tubing must have long, sweeping bends, well vented high points, and low point blowouts to ensure fluid flows.

Quench piping does NOT change conditions inside the seal chamber, at the wet side of the seal faces. Rather, it affects or monitors the environment on the ATMOSHPERIC side of the seal faces.

Pumps that leak when they are filled, even before they are started, often have a flush line intended for a Plan 11 or 13 connected to the QUENCH port, leading to the atmospheric side of the seal. There should be a “Q” or the work “QUENCH” stamped in the gland at this port.

For flush plans Plan 65A, 65B, 66A, and 66B, facility owners may want to know if their seals are leaking excessively without going to the expense of dual seals. These seal plans direct excessive leakage on the outside of the seal to an alarm instrument. Remember that seals leak a little bit. They need to in order to lubricate the faces and function correctly. The plans below handle the nuisance leakage in different ways.

Used in salting services like sodium hydroxide. The leakage across the seal faces will turn to salt when it reaches atmosphere. The salt crystals can wear the faces or build up in the seal, preventing the movement necessary to keep the seal faces in contact. The salt on the outboard of the seal can be washed away with a water quench through the quench and drain ports. Usually a close clearance bushing is installed at the extreme outboard end to the seal assembly to help keep the quench fluid moving from the quench to the drain port (or vice versa) and not just run out along the shaft. Also used for slurry services.

Grease can be introduced into the quench port. This external grease can provide temporary lubrication to the seal in case the pump sees large air or vapor pockets which would normally rob the seal faces of the required lubricating fluid film.

Quench can also be gas. In hot hydrocarbon services, the fluid will turn to solid coke when it reaches the atmospheric side of the seal. The fluid would remain a liquid if the area outside the seal faces is robbed of oxygen with a flood of nitrogen or steam.

An alarm does NOT necessarily mean a failed seal. The collection vessel might be full from years of nuisance leakage. Try emptying the vessel and observing how fast the vessel fills.

Two throttle bushings are used to ensure that the vapor (or fluid) leakage is limited along the shaft and out of the drain. A pressure switch picks up a rise on pressure above nuisance levels on the outboard side of the seal.

Dual seals provide a backup seal in case the primary seal fails. They prevent hazardous fluids from leaking to the surrounding area, desirable for both environmental protection and the safety of nearby personnel. Dual seals also capture and control any leakage of pumpage across the primary seal. The backup seal is kept lubricated by introducing a buffer/barrier fluid (often a mineral or synthetic oil, a water/glycol mix, or diesel) into the space between the primary (inboard) and secondary (outboard or backup) seals. The buffer/barrier fluid is contained in a tank (5 gallons is most common) adjacent to the pump. Instrumentation on the tank indicates what is happening with the seals.

Remember that a lubricating fluid film will flow from high pressure to low pressure. If the pump seal chamber pressure is higher than the pressure on the other side of the seal, the pumpage will be the lubricating film. If the pump’s seal chamber pressure is lower than the external pressure, the external atmosphere will migrate into the pump. Pumps under vacuum cannot use an ordinary single seal, since air from the atmosphere would be drawn between the faces, causing them to run dry and fail. Using a dual seal allows a fluid to be present at the outside of the seal. In a pump under vacuum, the buffer fluid would be pulled into the pump between the seal faces, keeping the inboard seal well lubricated.

If the pump seal chamber pressure is higher than the BUFFER fluid between the primary and backup seal faces, then the pumped fluid will flow from the high seal chamber pressure into the low pressure buffer fluid. This is called a DUAL UNPRESSURIZEDseal (formerly called a tandem seal), and the fluid is called a BUFFER fluid.

If the pump seal chamber pressure is lower than the BARRIER fluid between the primary and backup seal faces, then the barrier fluid will flow across the primary seal from the space between the primary and backup seals into the pump. This is called a DUAL PRESSURIZEDseal (formerly called a double seal), and the fluid is called a BARRIER fluid.

Buffer fluid circulates from the buffer fluid reservoir, through the space between the primary and backup seal, and back to the reservoir. Fluid is circulated by a weak pumping action built into the seal.

It the fluid flashes to vapor at low pressure, the vapor is piped to a flare or vapor recovery system, through an orifice at the top of the tank. If the primary seal is allowing too much leakage, the vapor will build pressure in the reservoir against the orifice and a pressure instrument can alert the operator.

If the fluid remains as a liquid under low pressure, any leakage will cause the fluid level in the buffer tank to rise, where a high level alarm can be tripped. Just because the high level alarm is tripped does not mean that the primary seal is failing; it is the rate of leakage filling the tank which matters. The high level may have been reached after collecting years of nuisance leakage. Often, an oil change to the original level is all that is required. Be sure the fluid is disposed of properly.

Seal face friction or hot pumpage can add heat to the buffer fluid. A cooling water coil is often installed in the reservoir to cool the buffer fluid.

Dual pressurized system (seal barrier fluid is at a higher pressure than the pump seal chamber). Pressurized systems are used to ensure that very dangerous fluids remain in the pump. The difference between 53A, 53B, and 53C is the method of pressurizing the barrier fluid. Pressure in the barrier fluid should be at least 10 psi over the pressure in the pump seal chamber.

Barrier fluid circulates from the barrier fluid reservoir, through the space between the primary and backup seal, and back to the reservoir. Fluid is circulated by a weak pumping action built into the seal.

A low level alarm in the reservoir alerts the operator that a seal may be failing, allowing the barrier fluid to enter the pump through the primary seal or the atmosphere through the backup seal.

Seal faces can be designed to maintain a gas film between them rather than a fluid film. These piping plans are intended to work with theses gas film (dry running) seals. Plan 72 and 74 bring the buffer or barrier gas into the seal; plans 75 and 76 are for the gas exiting the seal.

Secondary seal is ordinarily running with a gas film between the faces. When the primary seal fails, the pumped fluid will fill the space between the primary and backup seal. The backup seal is now working as a liquid seal rather than a gas seal and is designed to run for about 8 hours, allowing the operators time for an orderly pump shutdown.

Plan 72 buffer gas flow keeps the gas in the seal from becoming concentrated from nuisance leakage over time so that any leakage from the gas backup seal is mostly inert flush gas and not toxic pump vapors.

Swagelok’s standard designs can quickly and easily be configured to meet your specific needs whether single-seal, dual-seal, quench or gas seal. Our plans meet API 682 standards that support the use of tubing instead of piping, reducing potential leak points and providing enhanced vibration resistance.

Watch episode 5 of Swaging with Garyas he interviews Technical Advisor JakeJones, a former millwright, and I&E tech and planner, with one of the largest rubber plants on the Gulf Coast about the benefits of Swagelok"s Seal Support Systems.

Kits adhere to API best practices by showing technicians where to bend tubing to eliminate potential leak points through the reduction of elbow fittings and pipe threads.

Plan 11: One of the most widely used flush plans nowadays. Plan 11 takes fluid from the pump discharge or from an intermediate stage and directs it to the seal chamber through a properly designed orifice (the side stream should have a slightly bigger pressure than the prevailing pressure directly behind the pump impeller) for cooling and lubrication of the seal faces. Similar to Plan 01, product contamination is avoided, whereas interconnecting piping is relatively easy to install.

Plan 12 Plan 12 is similar to Plan 11, with the exception that a strainer of filter is added to the flush line for protection of the seal surfaces. A differential pressure indicator or alarm is employed so as to warn the user that the strainer or filter has been clogged.

Plan 21: Plan 21 is a cooled version of Plan 11. A heat exchanger is installed between the pump discharge and the pressure-reducing orifice for lowering the sealing fluid temperature. Cooling provides lubrication and minimises the possibility of vaporisation in the seal chamber. However, due to the big thermal load applied on the heat exchanger, Plan 21 is not frequently used today. It is usually replaced with flushing Plan 23.

Plan 23: Plan 23 is similar to Plan 21. It is generally preferred for hot water services, especially boiler feedwater. It is more efficient to Plan 21

Plan 41: In Plan 41, product from pump discharge passes through a separator and then through a heat exchanger before being introduced to the seal chamber. This is typically used for hot services with solids.

Plan 62: With Plan 62, an external fluid stream is brought to the atmospheric sdide of the seal faces using a quenching gas. Quenching gas can be either steam, nitrogen or water. Typical applications include the following: steam quenching on hot surfaces to delay coking, nitrogen quenching on cold or cryogenic service for prevention of icing, water quenching for prevention of crystallisation. One of the dissadvantages of Plan 62 is the inefficient use of water.

Plan 65: Plan 65 uses a level switch installed at a reservoir for initiating an alarm when excessive leakage is detected. This way, equipment can be shut down in case of excessive seal leakage. This system also includes a loop that allows to bypass the orifice: this way, high pressure on the amtospheric side of the seal is avoided.

Plan 62 usually refers to a steam quench on the atmospheric side of the seal. What flush plan is used on the primary seal? What is the seal configuration?

If you have replaced the seal, high resolution close up pictures of the seal surfaces and the condition of the components have an important story to tell. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Throttle bushing may be worn and have too much clearance allowing too much fluid pressure into primary seal area from pump casing. Check pump shaft run out should not be more than .002". check pump alignment, seals don"t like misalignment no more than .001". Check shaft o-ring on primary seal for correct material composition for temperature range and fluid. Check stuffing box face runout, should be square to shaft no more than .001" Check shaft diameter and shaft condition in o-ring area of seal. Shaft diameter must be in manufactured spec. for o-ring to seal tight. check manufacture specs on these tolerances as mentioned. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Mechanical seal is a John Crane 604 with a static bellows. Although described as a single mechanical seal, it also has an ECS secondary/backup seal as part of the cartridge (described as dry running), as in the original design a disaster bushing wasn"t considered adequate.

Nature of the failure is external leakage through the outboard ECS (emission control seal). Most recent failure had the ECS seal rings in pieces, but not the only failure observed historically (but I don"t have all the details I"d like).

Plan 62 seal, with N2 as the quench. (There is no flush connection supplied on the gland plate) Also a plan 65A leak detection system on the quench outlet / drain to monitor primary leakage rates.

A problem I"m told we consistently have is blockage of the quench outlet/drain with black oily gunk, such that it can block the quenching flow out the drain. As oil leaks from the primary seal this can backup into the nitrogen feed line (plus leak externally).

Has anybody ever tried using an in-situ cleaning solution to dry and clean up quench outlet lines on a hot oil system??? RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Hot oil pumps I"ve worked on were all fitted with either tandem or double seals, many were modifications of plan 52 ( with pressurised seal fluid reservoir).

Sounds like your hot oil is badly fouled up, and you have excluded high tubeskin temps in the WHRU or the fired heater as a cause in this report. Another reason may be reverse flow of process fluids into hot oil at one or more of the process HXs", most likely at the tube - tubesheet joints- this requires hot oil pressures to be less than process side pressure. Ideally, you"d want hot oil pressure to be higher than process side pressure, else use seal welded tube-tubesheet joints. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

You are totally right!!!,both seals are failed single seal leak through leak detection and ECS leak into external.(Excess leakage flow backs up at orifice and fills leak detector tank,External Leakage = both seals failed) see attached picture.

primary single seal are equipped with quench fluid N2 on atmospheric side plan62 and external drain with leakage detection system plan65A to monitor oil leaking.

"A problem I"m told we consistently have is blockage of the quench outlet/drain with black oily gunk, such that it can block the quenching flow out the drain. As oil leaks from the primary seal this can backup into the nitrogen feed line (plus leak externally)."what we should do to stop and fix this issue???

With a single mechanical the hot oil will go through the seal. Solids in the hot oil will detorioate the seal surfaces and increase the leakage rate. Only real solution there is a pressurized dual seal.

With the single seal you get oil on the other side of the seal. This will have to be removed. I doubt whether Nitrogen is able to do this. Hot steam is to my opinion much better to remove the oil on the outside. You might even have a similar appliance at home for cleaning.

If there is Oxygen in the Nitrogen oxidation processes can be expected causing clogging etc. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Will using solvent before starting up this Hot Oil Pump, help? We are considering the use of solvent, with specified residence time, before starting up the hot Oil Pump, in order to dislodge the coking debris trapped in the below and loading springs, as well as between the seal faces. We are not intending to use any aggressive solvent, just one which can do some cleaning before starting the pump. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

It is possible that the hot oil is creating Coke at your high temperatures. These Coke particles coat the mechanical seal working parts. The coke particles restrict the movement of the sliding and flexing parts of the seal causing the lapped seal faces to open and leak. The oil must be cooled to stop coking. Sometimes the hot oil will damage bearings in the bearing housing due to the heat from the pump shaft conducted to the bearings and lubricating oil. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

A cool clean oil flush into the seal chamber of the pump with a carbon throat bushing that restricts hot oil dirty oil from entering the seal chamber may help. Maintain the cool seal flushing pressure higher than the stuffing box pressure. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

After more than five years of planning, the American Petroleum Institute (API) is preparing to release the 4th edition of API Standard 682 (ISO 21049:2011). The API 682 standard, which dates back to 1994 and is formally known as Shaft Sealing Systems for Centrifugal and Rotary Pumps, offers specifications and best practices for mechanical seals and systems to pump end users.

The standard’s latest edition began to take shape in 2006, when API formed a 4th edition task force to respond to end users’ questions and comments about previous editions. The task force soon realized that major changes, including reorganization and editing, would be necessary. While addressing every aspect of the resulting 4th edition (which is more than 250 pages long) would be impossible, this article summarizes the standard’s main points.

Those who use API 682 should understand the standard’s scope and remember that the standard does not include specifications for equipment outside that scope, such as engineered seals or mixers. Another important but often misunderstood point is that API 682’s figures are illustrative and not normative in their entirety.

For example, one of API 682’s figures shows a fixed throttle bushing combined with a rotating Type A seal, but seal manufacturers do not always have to combine these two components. The standard provides normative details in clauses and tables to help purchasers distinguish between requirements and suggestions.

The 4th edition continues to divide seals into three categories, three types and three arrangements. For all practical purposes, seal manufacturers can combine a seal’s component parts into nearly any orientation or configuration. Each orientation and configuration has advantages and disadvantages with respect to certain applications, performance and system disturbances.

Before the 4th edition, API 682 did not specify a minimum clearance between the inside diameter of a stationary seal part and the outside diameter of a rotating seal part. The 4th edition specifies this minimum clearance—typically the clearance between the sleeve and the mating ring. The specified clearances are representative of standard clearances that end users have used for decades. End users should not consider seal components to be “shaft catchers” to restrict shaft movement. The minimum clearance specified in API 682 also applies only to equipment within the standard’s scope. Equipment outside that scope, such as non-cartridge seals, older pumps, non-API 610 pumps and certain severe services, might benefit from larger clearances.

The new standard also updates the default bushings for the gland plate for the three seal categories. Fixed throttle bushings are now the default for Category 1 only, while floating bushings are the default for Categories 2 and 3.

While the 4th edition features the recommended seal selection procedure from the standard’s first three editions, it adds an alternative selection method in Annex A. Proposed by task force member Michael Goodrich, this alternative method recommends using material data sheet information to select a sealing arrangement.

Plan 65 is now subdivided into 65A and 65B. End users can use Plan 65A to detect an excessive leakage flow rate and Plan 65B to detect a certain amount of cumulative leakage.

Plans 66A and 66B are new to the standard, although end users have used them previously in pipeline applications. These plans detect and restrict excessive leakage rates in case of an Arrangement 1 seal failure.

The 4th edition now requires Plan 52, 53A, 53B and 53C systems to have a sufficient working volume of buffer or barrier fluid for at least 28 days of operation without refilling. As a point of reference, the default reservoir for Plans 52 and 53A has a three-gallon capacity, or pot, for pump shafts smaller than 2.5 inches and a five-gallon pot for larger shaft sizes. Plan 53C must have the same working volume of fluid as Plan 53A. For Plan 53B, the default bladder and accumulator sizes are five gallons and nine gallons, respectively. The design of Plan 53B systems can be complex, especially when ambient temperatures vary widely, and purchasers should become familiar with the calculations and procedures in the 4th edition’s Annex F tutorial. The new edition also discusses the option of adding a pressure gauge and isolation valve to check the accumulator or bladder’s integrity in a Plan 53B system.

The 4th edition has revised the data sheets in Annex C extensively to make them the same for all seal categories. Only two data sheets are included in the 4th edition—one in metric units and one in U.S. customary units. The new edition also folds Annex J into Annex E.

Previous editions of API 682 required metal plugs and anaerobic sealants when shipping new or repaired cartridges. After much debate, the task force decided that threaded connection points should be protected with plastic plugs for shipment. These plastic plugs should be red and have center tabs that operators can pull easily to distinguish the plugs from metal plugs. Shippers should also attach yellow warning tags to the plugs to indicate that end users need to remove the plugs before operation.

Although tutorial notes are scattered throughout API 682, this edition expands the tutorial section, Annex F, from seven pages to 42 pages. The expanded annex includes illustrative calculations. In particular, users interested in systems such as Plan 53B will find Annex F to be useful.

The 4th edition of API 682 is the product of more than 20 years of discussion, debate, usage and peer review. It includes a strong set of defaults and is by far the best and most logical starting point for mechanical seal and systems use. Equipment operators should take the time to familiarize themselves with API 682 to get the most out of this comprehensive standard.

The API plans presented in this section are developed in accordance with the API 682, 3 revision / API 610, 10 revision standard. This is the standard scheme of the drilling pipes, which are widely used in industry. It is possible to customize these plans to meet the needs of customers.

The flushing of the seal from the outlet to the seal chamber via the aperture and flushing the seals from the seal chamber to the inlet through the diaphragm

Diagram of the system for ensuring the operation of a single seal with an impeller that creates fluid circulation through the stuffing box along an Autonomous circuit.

If the pressure in the oil seal chamber of the pump is less than the design pressure of the tank (4mpa), the installation of a safety valve on the tank pipelines is not required.

"Tandem" type mechanical seals can be used both with a refrigerator at the pump"s working medium temperature up to 400 °C, and without it at the working medium temperature up to 150 °C.

Diagram of the system for ensuring the operability of a double seal with a tank. The system operates at constant maintenance of the pressure of the shut-off fluid (pressure in the tank) within:

At pump working medium temperatures up to 150°C seals are used without a refrigerator, at the temperature of the pumped medium 150...400°C-with a refrigerator.

For servicing seals of a group of pumps that perform the same task and are located close to each other, it is possible to use the system diagram shown below.

The most commonly used scheme is a system with the supply of shut-off fluid from a separate pipeline with an overpressure m through the seal of the threads.

At pump working medium temperatures up to 150°C seals are used without a refrigerator, at the temperature of the pumped medium 150...400°C-with a refrigerator.

For condensate pumps, where dry operation of the mechanical seals is not excluded, the guaranteed supply of the shut-off fluid can be carried out according to the following scheme.

At pump working medium temperatures up to 150°C seals are used without a refrigerator, at the temperature of the pumped medium 150...400°C-with a refrigerator.

API plan 65 allows you to determine the volume of leaks through the mechanical seal. If the friction pair breaks through, the external strapping tank is equipped with an upper-level alarm that will trigger as soon as the liquid level in the tank increases.

This discussion opens a three-part series covering mechanical seal piping plans that provide guidelines for various seal arrangements, fluids and control equipment to help you determine what support system requirements will maximize the performance reliability of your application.

The American Petroleum Institute (API) created a numbering system for a variety of seal flush plans. The API flush plans are now located in API Standard 682 and the corresponding ISO standard, ISO 21049. The American National Standard Institute (ANSI) adopted a slightly different designation system.

These plans are utilized to provide the seal with the proper environment, depending upon the type of equipment used and the application the seal is exposed to. This series of articles discusses the basic flush plans, providing some general guidelines to be used along with the advantages/disadvantages of the plans, and, where appropriate, information on sizing and proper control of the system.

The internal and recirculation systems have the advantage that the flush source comes from the pumpage and goes back to the pumpage, so no product contamination occurs. In addition, these flush plans, unlike an external injection, do not require any reprocessing of the product.

These same flush plans share the disadvantage that if the product pumped is not a good face lubricant, then the seal can become damaged. For some of the plans noted circulation from the pump discharge back to pump suction or vice versa will decrease pump efficiency and increase power required for the application. The volume of flush is usually very small compared to the capacity of the pump and, therefore, the decrease in efficiency is very small.

Generally, the flush rate must be calculated based on fluid properties, system pressure, shaft speed, and seal size. See the "Flush Rates" section for more details.

With few exceptions, any flush system works hand-in-hand with the hardware and seal components. If the seal is set up with a distributed or single point flush, and/or an enlarged bore seal chamber, the effectiveness of the system will be better and the seal will run cooler no matter how much or little the flush flow rate is.

Flush requirements for seals should be given in terms of a minimum and a recommended flow rate. Some seals can actually operate satisfactorily without a flush. Such applications usually involve non-volatile fluids at low pressures and low speeds. Heat transfers from the faces, through the liquid and into the metal surrounding the seal chamber. Analysis of these cases is beyond the scope of this article.

The minimum flush rate is necessary to obtain the performance rating given by the product technical bulletin; it is determined by an energy balance computation. The assumption is that heat generated by the seal faces is absorbed by the flush through ideal mixing. This raises the temperature of the flush. Typically, an increase of 15-deg F for water and low vapor pressure hydrocarbons, 30-deg F for lube oils, and 5-deg F for high vapor pressure hydrocarbons is allowed. Frequently, the minimum flush rate is relatively low, often less than 1-gpm.

Field experience indicates, and laboratory tests confirm, that seal performance generally improves when the flush rate is greater than the minimum. In particular, heat transfer usually improves and the average temperature around the seal decreases with increased flush rate; as a result, the face temperature and wear rate decreases. The recommended flush rate promotes these benefits.

The recommended flush rate should be based on experience with similar applications. Some considerations include performance goals and fluid properties as well as the design and interaction of the seal chamber, gland, flush plan and seal. In the absence of specific experience, a simple rule of thumb is: the recommended flush rate is the larger of 1-gpm per inch of seal size or the minimum flush rate.

Questions are sometimes asked about the maximum flush rate. Although increasing the flush rate beyond the recommended value may produce further improvements, by definition this effect is rapidly diminishing beyond that point. At very high flush rates and close clearances, erosion can occur.As an example, when sealing water at 250-psig using a balanced 2-in seal at 3600-rpm, the minimum flush rate might be computed as 0.4-gpm based on an allowable temperature rise of 15-deg F. The rule of thumb yields 2-gpm for a 2-in seal. Therefore, the recommended flush rate would be 2-gpm.

On the other hand, when sealing propane under the same conditions, the minimum flush rate is computed as 2.5-gpm based on an allowable temperature rise of 5-deg F. Thus, for propane the recommended flush rate would be 2.5-gpm.

Pumping rings are used in closed loop sealing systems such as Plans 23, 52, and 53A-C to produce flow through coolers and reservoirs. There are two basic pumping ring designs: radial flow and axial flow. Either design can be effective. Just as the performance of a centrifugal pump is a function of the impeller and volute, the performance of the pumping ring depends on the design of the seal chamber. In particular, the design, size and placement of the inlet and outlet ports are crucial to the performance of the pumping ring.

The circulation rate in a seal system is a function of the fluid properties and system piping as well as the pumping ring. Small piping, numerous directional changes, and viscous liquids result in low flow rates. The procedure for estimating the circulation rate is to first construct a piping system (resistance) curve and then superimpose the pumping ring performance curve. The intersection of these curves defines the circulation rate.

When both the pumping ring and the system are properly designed, circulation rates of about ½-gpm to 1-1/2-gpm per inch of seal size are easily attainable.

Thermosyphons can provide cooling for liquid sealing systems; however, great care must be taken because thermosyphon flow rates are small and easily stopped by bubbles from vaporization or dissolved gases. A single bubble that is about the same diameter as the piping can stop flow; this is called vapor-locking. To prevent vapor locking and maximize flow, large diameter piping, connections, and drill-throughs should be used. The cooler or reservoir should be 2-ft to 5-ft above the seal chamber. If thermosyphoning is not a concern a cooler or reservoir height of 1-ft to 2-ft can be used as this will reduce the system resistance slightly. Liquid should flow "in the bottom and out the top" of the seal chamber. The system must be periodically, or continuously, vented. To assist in the thermosyphon effect, the return or hot piping leg should be insulated so that no cooling occurs in this line.

Because of the quirky and sensitive nature of thermosyphons, most specifications require a positive circulation using some type of pumping ring. Even so, the effects of thermosyphoning should always be considered when designing seal circulation systems. That is, the system should always be designed to promote thermosyphoning.

A quench, as defined by API 682, is "a neutral fluid, usually water or steam, introduced on the atmospheric side of the seal to retard formation of solids that may interfere with seal movement." Nitrogen is another quench medium.

Nitrogen quenches, based upon general observations, are not as effective as steam for quenching high temperature seals. Product decomposition ("coking") is related to temperature. Not only does coke form more quickly in hot pumps, but it also forms more quickly around seals that run hot because of heavy load or inadequate flushing.

Steam quenches can be used with either rotating seal heads or stationary designs. Quenches on rotating seals, sometimes called a "steam blanket", is not particularly effective because very little steam is circulated within the quench area. Depending upon the type of bushing used, the steam can even be directed towards the pump bearings. A steam quench used with a stationary design, such as the Type 1604 (metal bellows seal), is more effective. The steam must enter underneath the bellows assembly, between the bellows and the anti-coking baffle, and is guided around the seal to wash away the leakage from the seal faces.

If a quench is to be applied, then the minimum quench rate can be thought of as a purge.In that case, the minimum rate is a function of the volume being purged and the leakage being diluted. For typical seal gland plates and a contingency plan for high leakage rates, dilution of leakage usually governs.

Steam is usually readily available in plants and the flow rates are typically not regulated very closely due to the availability. This is also due, in part, to the cost versus other quench media. The relative cost of quench media is:

The cooling effect of gases such as steam and nitrogen on the face temperature of hot seals is small. The order of magnitude is less than 500-btu/hr removed from the seal faces. If the quench rate is too small, the temperature of the quench will heat up to nearly the pump temperature and allow decomposition and coking to occur. To prevent this, the average temperature in the quench volume can be estimated from an energy balance using the seal leakage rate, quench flow rate and heat soak from the surrounding metal. By constraining this average temperature to be less than some critical "coking" temperature, the quench rate can be computed.

After all the above considerations, the recommended quench rate is the largest of the values. For most pump seals the recommendation can be simplified in the following table.

Water is typically used as a quench medium when the fluid being sealed has solids in solution or will crystallize upon exposure to atmosphere. The flow rate for water does not have to be very large. In some cases it can just be enough to keep a volume of fluid on the atmospheric side of the seal, while in other cases a slight flow rate of 1/8-gpm to ¼-gpm is sufficient to prevent build up of product underneath the seal faces. This is one case where the containment device may be a lip seal.

Plans 71, 72, 75, and 76 are new plans for dry running secondary containment seals used in conjunction with a liquid lubricated primary seal. The process, or inner seal, of the dual unpressurized arrangement usually has its own flush plan. For example, the flush plans for a dual unpressurized seal arrangement with a dry running secondary containment seal might be written as Plan 11/71, 11/71/75, 11/71/76, or as noted below 11/72/75 or 11/72/76. The Plan 11 for the inboard seal can be any of the plans normally associated with a single mechanical seal.

A secondary containment device is a means of containing and controlling the primary seal leakage from a mechanical seal. In contrast to a dual liquid lubricated mechanical seal, which operates in a buffer or barrier fluid, a secondary containment device operates primarily in the leakage from the process seal, although purges may be added.

There are many different types of secondary containment devices from simple bushings to mechanical seals. Leakage rates for the various secondary sealing devices can vary by several orders of magnitude. Selection of the secondary containment device and system will depend on the level of leakage to atmosphere that is considered acceptable as well as performance requirements for normal operation, upsets, and in the event of process seal failure.

By definition, the secondary containment device does not necessarily have the performance or rating of the primary seal; however, it may be able to temporarily tolerate seal cavity pressure and fluid in the event of a failure of the primary seal.

Large clearance devices like fixed bushings have the highest leakage rates; floating bushings with reduced clearance are much better. Floating segmented bushings have still lower leakage rates. Dry running mechanical seals, both contacting and non-contacting, may also be used as secondary containment devices and can approach the level of performance of a dual unpressurized liquid lubricated seal arrangement.

API Plan 72 is designed to have an inert gas purge through the containment seal area with the intent to reduce emission levels to the atmosphere. The purge gas mixes with leakage from the primary seal, thereby reducing the concentration of the hazardous fluid (liquid or gas). Leakage rates from the various types of containment devices will vary from high rates with bushings to low leakage rates with contacting face seals.

Leakage to atmosphere will also have a wide variation depending upon operating conditions, length of time in service and equipment conditions, as well as a myriad of other lesser considerations. When deciding on the purge rate, consideration should be given to the type of containment device, the flow rate past the orifice, the fact that excessive purge rates can dry out the sealing cavity and possibly decrease the life of contacting face seals, and that excessive containment seal cavity pressures can decrease the life of the containment sealing device with the possible exception of non-contacting containment seals.

A simple rule of thumb is to have a flow rate on the order of ½ SCFM to the containment seal cavity. This relates to the rough flow rate for a 5-psi differential pressure across a 1/16-in orifice. This rate can be adjusted upwards or downwards depending upon the specific application.

Even though leakage from dual gas seals is normally very low, the following issues related to pump design and installation may require attention, depending upon the seal duty:

Some exceptional horizontal installations also suffer the same circumstance when suction pipework originates from below the shaft centerline. Not all vertical pumps are vulnerable, as the sensitivity is dependent on the relative positions of the impeller and the suction inlet. Some in-line units using a Plan 13 flush (in conjunction with a Plan 74 for the dual gas seals) have the ability to naturally vent through the suction valve, if the piping orientation permits.

To accommodate these issues in vertical pump installations or horizontal pumps with non-venting suction lines, a provision for manual or continuous automatic venting of seal chambers must be incorporated within the total pump installation.

If for operational or hazard reduction reasons it is required to shut both the suction and the discharge valves and isolate a standby pump, it can be expected (as with any dual pressurized seal) that the pump casing stands the risk of becoming pressurized to the same pressure as the gas barrier source. Depending upon the effectiveness of the valve seats, the casing pressure could also rise to that of the pump discharge manifold, which might be in excess of the barrier gas pressure.

Even though the dual gas seal may have a reverse pressure design feature on horizontal units, it is possible that a small quantity of process fluid may contaminate the gas barrier chamber. This is not detrimental to the seal (unless the process crystallizes or hardens), but when restarting the pump there is a risk that this small volume of process fluid will be pumped through the outer seal to the atmosphere.

Barrier gas leakage across the inner seal face during dynamic operation will eventually mix with the process flow. Depending on the seal size, operating conditions, pump size, pump design, and operation this leakage can affect the seal"s performance. This may be an increase in the NPSHR, a reduction in differential head, and in extreme cases a loss of prime.

At normal leakage levels this may not be an issue, but when leakage levels approach a condition when failure is deemed imminent, the effect on pump operation should be minimized. The seal size, shaft speed, barrier gas pressure, pump flow capacity, impeller design, and level of operational flow compared to the pump"s design BEP (best efficiency point) are all factors that determine the affect on normal pump operation.

To prevent the likelihood of dual gas seal leakage in dynamic operation affecting the design pump performance, screening by consultants is advised on pumps operating between 40-gpm and 90-gpm, when operating at less than 50 percent of its BEP.

At high vacuum suction conditions the effect of dual gas seal leakage into the process fluid is exaggerated because the gas expands at the low pressure. This is not a normal pump operating condition, but on pump NPSHR proof testing it may occur. The normal measurement criteria of a loss of 3 percent in the head generated can be created by gas entrainment. In an NPSHR proof test with a low capacity pump design and dual gas seals, a conservative and inaccurate value may be indicated.

It is advised that if NPSHR proof tests are applied to pumps with a BEP capacity less than 40-gpm, the influence of gas seal leakage must be evaluated and if necessary use an alternate seal design.

Plan 01 is an integral (internal) recirculation from the pump discharge to the seal chamber, which is typically at a pressure slightly above pump suction pressure. It is similar to Plan 11 in that it uses the pressure differential between pump discharge and pump suction to develop flow, but is different in that there are no external lines (piping or tubing) on the pump. It is recommended for clean pumpage only and is typically limited to pumps with a Total Discharge Head of less than 125-ft.

Useful arrangement on fluids that are highly viscous at normal ambient pumping temperatures so as to minimize the risk of freezing if exposed to low temperatures in external piping plans, such as a Plan 11.

There is no external way to control flow. Unlike Plan 11, which can have an externally replaceable orifice to control flow, the internal design of a Plan 01 eliminates this possibility.

The flow rate is dependent upon the pressure differential in the pump and the design of the line running internal to the pump casing. Changing the impeller design can affect the pressure differential and thus the flush rate. The pump OEM should be contacted to ensure that the flow rate is adequate to maintain a stable condition at the seal faces.

This flush system can perform its function well when used properly. Changes in pump impellers, or changing seal designs that can move the seal faces away from the flush hole can cause problems that result in seal failures. This system is not recommended on vertical pumps.

Plan 02 is a non-circulating flush plan. In Plan 02 the process is not directed into or out of the seal chamber. Seal generated heat is removed by convection and conduction to the process fluid, pump components, and the surrounding environment. Also, some seal chamber designs promote cooling, by mixing of process fluid between the pump cavity and seal chamber. Often, this plan is used in conjunction with API Plan 62 and/or the optional use of a cooling jacket, which will provide some additional cooling. This plan should only be used for services where adequate vapor suppression can be assured, so that vaporization of the process in the seal chamber or at the seal interface does not occur. Plan 02 is often used with a self venting, open seal chamber, i.e. no throat bushing.

Low duty, chemical service pumps are often a prime candidate for Plan 02. In these services, it is also advantageous to apply Plan 02 in conjunction with a large (open bore) or taper bore seal chamber. Often, in these services, suspended solids may be included in the process stream. In these cases, devices which encourage seal chamber circulation, while excluding solids from the seal chamber, are available and offered by many OEM and after market suppliers. Applications where these devices have been applied often work well with Plan 02.

Hot, refinery and petrochemical heavy oil services can be successfully sealed with Plan 02. Often, these services congeal or become highly viscous at ambient conditions. This can result in fouling and plugging of the recirculation plans, such as Plan 11, 13, 23 and their derivatives, unless effective temperature control schemes are employed. In these services, Plan 02 offers a relatively simple, cost effective way to obtain reasonable seal life. Only Plans 32 or 54 may be found to provide superior seal life. Use of Plan 02 in hot oil applications normally requires the use of Plan 62, using steam or nitrogen. In most cases, use of a seal chamber cooling jacket is helpful.

Successful use of Plan 02, as with other plans, is dependent on maintaining a lubricating film between the seal faces. This can be accomplished only if vapor formation in the seal chamber can be adequately suppressed. Plan 02, with no forced circulation through the seal chamber, requires thorough venting. This can be accomplished before startup (after pump inventory) or on a continuous basis by means of a self venting seal chamber design. Further, this Plan should be used with caution if the process has entrained gas or other components, which may vaporize easily. This plan is not recommended for vertical pumps.

Plan 11 is the most common flush plan in use today. This flush plan simply takes an appropriate amount of fluid from the discharge of the pump (or the discharge of one of the intermediate stages if applicable) and puts it into the seal chamber to provide cooling and lubrication to the seal faces.

Generally the flush rate must be calculated based on service conditions, pump speed and seal size. The rule of thumb is for not less than 1-gpm per inch (0.16-l/m per mm) of seal size, but the flush requirement may be greater if the pressure or speed is high. For application above 3600-rpm or box pressures above 500-psig (35- barg) the flush rate should be calculated to avoid excessive heat at the seal.

An interesting challenge arises when the differential pressure is high and a 1/8-in orifice allows for more flow than is desired. This can be addressed two ways. One option is to use two or more orifices in series. The number is dependent on the differential pressure. The other way is to use a "choke tube". This is a piece of tubing generally ¼-in heavy wall. The length of the tubing is calculated using a piping pressure drop calculation such that the pressure drop across the tubing is equal to the difference between the discharge pressure and the seal chamber pressure at the flow rate desired.

Any flush system works hand in hand with the hardware and seal parts. If the seal is set up with a distributed or extended flush, the effectiveness of the system will be better and the seal will run cooler no matter how much or little the flush flow rate.

In LIDERING we have an extensive range of mechanical seals for all types of pumps: from seals for domestic pumps to seals for process pumps, specific in complex applications in the chemical and petrochemical industry. In addition, we offer a wide range of spare parts compatible with the originals of the main manufacturers of pumps (RMS). Our catalog also includes cartridge seals for more demanding industrial processes, and our extensive range of products is ever-growing in order to adapt to the requirements of our customers.

8613371530291

8613371530291