api plan 62 mechanical seal price

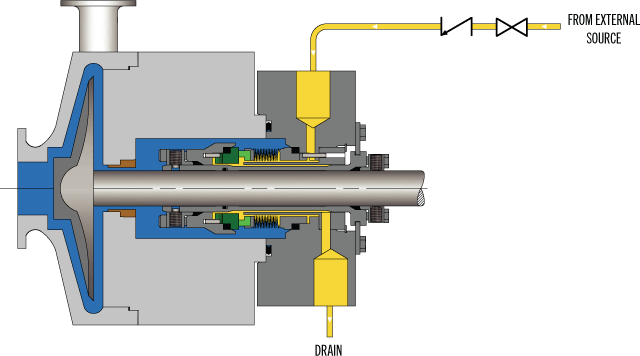

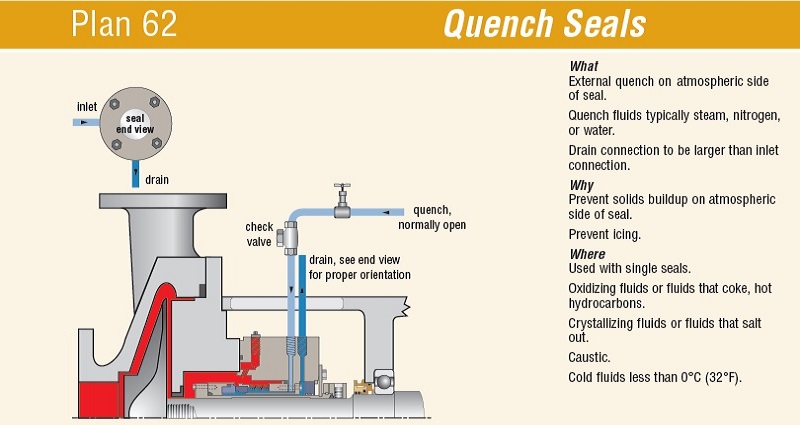

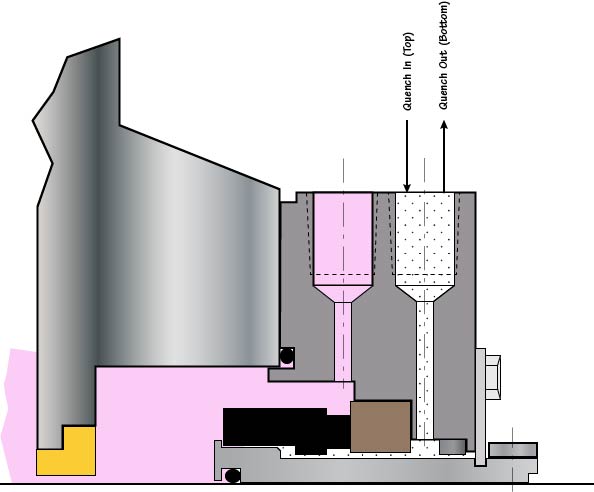

Plan 62 is designed to improve the environment on the atmospheric side of single seals by adding a quench. Typically, this quench is low pressure steam, nitrogen or water to prevent the formation of solids on the atmospheric side of the seal. Plan 62 is typically used with a floating or segmented bushing to limit the leakage of the quench fluid to atmosphere, but can be used with a fixed bushing.

A problem resulting from a steam or water quench is that the bearings (usually immediately near the gland plate) can become contaminated with the quench fluid. This is the reason for providing a close clearance bushing and a drain that is piped away from the seals/bearings.

Advantages:Plan 62 is a low cost alternative to tandem seals. The quench prevents or retards product crystallization or coking. Quenches can also provide some cooling.

General:Typical applications include; steam quenches on hot services to retard coking; nitrogen quenches on cold or cryogenic service to prevent icing; or water quench to prevent crystallization or accumulation of product on the atmospheric side of the seal.

API Plan 62 delivers an external quench fluid to the atmospheric side of the seal. A typical application in a refinery is the prevention of coking on seal faces in hot hydrocarbon service by employing a steam quench. Nitrogen or clean water may also be used to quench or cool and clean the atmospheric side of the seal.

See page 77 of the Mechanical Seal Support Systems Application Guide for additional details and ordering information. Contact your authorized Swagelok sales and service center for information on optional components.

Wet steam is bad for a Plan 62 just as a general rule. The main concern is if you have wet steam injected into the seal, you will usually vaporize the residual water right at the seal faces (due to the face generated heat). This "explosion", so to speak, at the interface will usually pop the faces open and in general cause premature face damage and ultimately leakage will ensue.

The best recipe for a steam quench: hot, dry, and not too much. One way you can ensure you get a nice hot / dry steam supply to the mechanical seal is to wrap the quench tubing around the suction or discharge flange prior to injection into the seal cavity. This creates a mini super-heat coil that should help ensure the steam is dry before it can cause damage at the faces. You also do not want a whole lot of steam injected into the gland since you may leave yourself open to bearing damage due to excessive condensate leakage out of the back of the seal and into the bearing housing (thus condensing in the oil). 1 - 3 psi is best, but for a visual a simple "wisp" out of the back of the gland is what you want. You can also use a small diameter orifice upstream of the seal (.062") to achieve the flow you desire.

One other point to note: make sure you have a good floating or segmented throttle bushing in the seal design to restrict the steam flow to atmosphere. I have have come across seal installs with steam quenches that have a fixed throttle bushing in the gland. This is not optimum as the excessive clearance on the fixed bushing will lend itself to more steam usage and also cool the low pressure side of the seal. This is couterproductive to what you are trying to achieve with the steam quench to begin with. You want this area warm to keep solids from forming in the first place. If you are specifying API 682 requirements for your seal design, then the bushing type should be segmented as a default.

Plan 62 usually refers to a steam quench on the atmospheric side of the seal. What flush plan is used on the primary seal? What is the seal configuration?

If you have replaced the seal, high resolution close up pictures of the seal surfaces and the condition of the components have an important story to tell. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Throttle bushing may be worn and have too much clearance allowing too much fluid pressure into primary seal area from pump casing. Check pump shaft run out should not be more than .002". check pump alignment, seals don"t like misalignment no more than .001". Check shaft o-ring on primary seal for correct material composition for temperature range and fluid. Check stuffing box face runout, should be square to shaft no more than .001" Check shaft diameter and shaft condition in o-ring area of seal. Shaft diameter must be in manufactured spec. for o-ring to seal tight. check manufacture specs on these tolerances as mentioned. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Mechanical seal is a John Crane 604 with a static bellows. Although described as a single mechanical seal, it also has an ECS secondary/backup seal as part of the cartridge (described as dry running), as in the original design a disaster bushing wasn"t considered adequate.

Nature of the failure is external leakage through the outboard ECS (emission control seal). Most recent failure had the ECS seal rings in pieces, but not the only failure observed historically (but I don"t have all the details I"d like).

Plan 62 seal, with N2 as the quench. (There is no flush connection supplied on the gland plate) Also a plan 65A leak detection system on the quench outlet / drain to monitor primary leakage rates.

A problem I"m told we consistently have is blockage of the quench outlet/drain with black oily gunk, such that it can block the quenching flow out the drain. As oil leaks from the primary seal this can backup into the nitrogen feed line (plus leak externally).

Has anybody ever tried using an in-situ cleaning solution to dry and clean up quench outlet lines on a hot oil system??? RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Hot oil pumps I"ve worked on were all fitted with either tandem or double seals, many were modifications of plan 52 ( with pressurised seal fluid reservoir).

Sounds like your hot oil is badly fouled up, and you have excluded high tubeskin temps in the WHRU or the fired heater as a cause in this report. Another reason may be reverse flow of process fluids into hot oil at one or more of the process HXs", most likely at the tube - tubesheet joints- this requires hot oil pressures to be less than process side pressure. Ideally, you"d want hot oil pressure to be higher than process side pressure, else use seal welded tube-tubesheet joints. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

You are totally right!!!,both seals are failed single seal leak through leak detection and ECS leak into external.(Excess leakage flow backs up at orifice and fills leak detector tank,External Leakage = both seals failed) see attached picture.

primary single seal are equipped with quench fluid N2 on atmospheric side plan62 and external drain with leakage detection system plan65A to monitor oil leaking.

"A problem I"m told we consistently have is blockage of the quench outlet/drain with black oily gunk, such that it can block the quenching flow out the drain. As oil leaks from the primary seal this can backup into the nitrogen feed line (plus leak externally)."what we should do to stop and fix this issue???

With a single mechanical the hot oil will go through the seal. Solids in the hot oil will detorioate the seal surfaces and increase the leakage rate. Only real solution there is a pressurized dual seal.

With the single seal you get oil on the other side of the seal. This will have to be removed. I doubt whether Nitrogen is able to do this. Hot steam is to my opinion much better to remove the oil on the outside. You might even have a similar appliance at home for cleaning.

If there is Oxygen in the Nitrogen oxidation processes can be expected causing clogging etc. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Will using solvent before starting up this Hot Oil Pump, help? We are considering the use of solvent, with specified residence time, before starting up the hot Oil Pump, in order to dislodge the coking debris trapped in the below and loading springs, as well as between the seal faces. We are not intending to use any aggressive solvent, just one which can do some cleaning before starting the pump. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

It is possible that the hot oil is creating Coke at your high temperatures. These Coke particles coat the mechanical seal working parts. The coke particles restrict the movement of the sliding and flexing parts of the seal causing the lapped seal faces to open and leak. The oil must be cooled to stop coking. Sometimes the hot oil will damage bearings in the bearing housing due to the heat from the pump shaft conducted to the bearings and lubricating oil. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

A cool clean oil flush into the seal chamber of the pump with a carbon throat bushing that restricts hot oil dirty oil from entering the seal chamber may help. Maintain the cool seal flushing pressure higher than the stuffing box pressure. RE: Hot oil circulation pumps Mechanical seal failures API plan 62

Seal Support Systems operate to control the fluid in between and around the seal faces whether cleaning, cooling or heating the seal media or providing a separate fluid to the mechanical seal.

Some applications are simply not suitable for mechanical seals e. g applications which are corrosive, abrasive, crystallizing or precipitative. In order for a mechanical seal to operate under these applications with reasonable mean time between failure (MTBF), either the seal fluid requires treatment before coming into contact with the seal faces or an external fluid is required which is compatible with the process. Also double mechanical seals will require some sort of fluid to act as a buffer or barrier fluid andthe system which provides this buffer or barrier fluid are Seal Support Systems.

A seal plan is used in conjunction with the API 682 Standard and it is a way to formalise the different seal support systems into a standard. It consists of seal flush plans, buffer & barrier fluid plans, quench plans and gas supply plans.

The API Plan 53A is a dual seal plan where a barrier fluid is supplied to a double mechanical seal between the 2 sets of faces of the mechanical seal.

Plan 62 is a quench seal plan where a fluid is supplied to the space between the atmospheric side of the mechanical seal and the throttle bushing on the shaft.

Flowserve provides Seal Support Systems for in accordance with API 682 but can also provide systems outside of this standard, if the application dictates.

Our Mechanical Seal specialists can advise you on the appropriate selection of a seal support system which will deliver years of reliable service and operating cost savings in the longer term.

This discussion opens a three-part series covering mechanical seal piping plans that provide guidelines for various seal arrangements, fluids and control equipment to help you determine what support system requirements will maximize the performance reliability of your application.

The American Petroleum Institute (API) created a numbering system for a variety of seal flush plans. The API flush plans are now located in API Standard 682 and the corresponding ISO standard, ISO 21049. The American National Standard Institute (ANSI) adopted a slightly different designation system.

These plans are utilized to provide the seal with the proper environment, depending upon the type of equipment used and the application the seal is exposed to. This series of articles discusses the basic flush plans, providing some general guidelines to be used along with the advantages/disadvantages of the plans, and, where appropriate, information on sizing and proper control of the system.

The internal and recirculation systems have the advantage that the flush source comes from the pumpage and goes back to the pumpage, so no product contamination occurs. In addition, these flush plans, unlike an external injection, do not require any reprocessing of the product.

These same flush plans share the disadvantage that if the product pumped is not a good face lubricant, then the seal can become damaged. For some of the plans noted circulation from the pump discharge back to pump suction or vice versa will decrease pump efficiency and increase power required for the application. The volume of flush is usually very small compared to the capacity of the pump and, therefore, the decrease in efficiency is very small.

Generally, the flush rate must be calculated based on fluid properties, system pressure, shaft speed, and seal size. See the "Flush Rates" section for more details.

With few exceptions, any flush system works hand-in-hand with the hardware and seal components. If the seal is set up with a distributed or single point flush, and/or an enlarged bore seal chamber, the effectiveness of the system will be better and the seal will run cooler no matter how much or little the flush flow rate is.

Flush requirements for seals should be given in terms of a minimum and a recommended flow rate. Some seals can actually operate satisfactorily without a flush. Such applications usually involve non-volatile fluids at low pressures and low speeds. Heat transfers from the faces, through the liquid and into the metal surrounding the seal chamber. Analysis of these cases is beyond the scope of this article.

The minimum flush rate is necessary to obtain the performance rating given by the product technical bulletin; it is determined by an energy balance computation. The assumption is that heat generated by the seal faces is absorbed by the flush through ideal mixing. This raises the temperature of the flush. Typically, an increase of 15-deg F for water and low vapor pressure hydrocarbons, 30-deg F for lube oils, and 5-deg F for high vapor pressure hydrocarbons is allowed. Frequently, the minimum flush rate is relatively low, often less than 1-gpm.

Field experience indicates, and laboratory tests confirm, that seal performance generally improves when the flush rate is greater than the minimum. In particular, heat transfer usually improves and the average temperature around the seal decreases with increased flush rate; as a result, the face temperature and wear rate decreases. The recommended flush rate promotes these benefits.

The recommended flush rate should be based on experience with similar applications. Some considerations include performance goals and fluid properties as well as the design and interaction of the seal chamber, gland, flush plan and seal. In the absence of specific experience, a simple rule of thumb is: the recommended flush rate is the larger of 1-gpm per inch of seal size or the minimum flush rate.

Questions are sometimes asked about the maximum flush rate. Although increasing the flush rate beyond the recommended value may produce further improvements, by definition this effect is rapidly diminishing beyond that point. At very high flush rates and close clearances, erosion can occur.As an example, when sealing water at 250-psig using a balanced 2-in seal at 3600-rpm, the minimum flush rate might be computed as 0.4-gpm based on an allowable temperature rise of 15-deg F. The rule of thumb yields 2-gpm for a 2-in seal. Therefore, the recommended flush rate would be 2-gpm.

On the other hand, when sealing propane under the same conditions, the minimum flush rate is computed as 2.5-gpm based on an allowable temperature rise of 5-deg F. Thus, for propane the recommended flush rate would be 2.5-gpm.

Pumping rings are used in closed loop sealing systems such as Plans 23, 52, and 53A-C to produce flow through coolers and reservoirs. There are two basic pumping ring designs: radial flow and axial flow. Either design can be effective. Just as the performance of a centrifugal pump is a function of the impeller and volute, the performance of the pumping ring depends on the design of the seal chamber. In particular, the design, size and placement of the inlet and outlet ports are crucial to the performance of the pumping ring.

The circulation rate in a seal system is a function of the fluid properties and system piping as well as the pumping ring. Small piping, numerous directional changes, and viscous liquids result in low flow rates. The procedure for estimating the circulation rate is to first construct a piping system (resistance) curve and then superimpose the pumping ring performance curve. The intersection of these curves defines the circulation rate.

When both the pumping ring and the system are properly designed, circulation rates of about ½-gpm to 1-1/2-gpm per inch of seal size are easily attainable.

Thermosyphons can provide cooling for liquid sealing systems; however, great care must be taken because thermosyphon flow rates are small and easily stopped by bubbles from vaporization or dissolved gases. A single bubble that is about the same diameter as the piping can stop flow; this is called vapor-locking. To prevent vapor locking and maximize flow, large diameter piping, connections, and drill-throughs should be used. The cooler or reservoir should be 2-ft to 5-ft above the seal chamber. If thermosyphoning is not a concern a cooler or reservoir height of 1-ft to 2-ft can be used as this will reduce the system resistance slightly. Liquid should flow "in the bottom and out the top" of the seal chamber. The system must be periodically, or continuously, vented. To assist in the thermosyphon effect, the return or hot piping leg should be insulated so that no cooling occurs in this line.

Because of the quirky and sensitive nature of thermosyphons, most specifications require a positive circulation using some type of pumping ring. Even so, the effects of thermosyphoning should always be considered when designing seal circulation systems. That is, the system should always be designed to promote thermosyphoning.

A quench, as defined by API 682, is "a neutral fluid, usually water or steam, introduced on the atmospheric side of the seal to retard formation of solids that may interfere with seal movement." Nitrogen is another quench medium.

Nitrogen quenches, based upon general observations, are not as effective as steam for quenching high temperature seals. Product decomposition ("coking") is related to temperature. Not only does coke form more quickly in hot pumps, but it also forms more quickly around seals that run hot because of heavy load or inadequate flushing.

Steam quenches can be used with either rotating seal heads or stationary designs. Quenches on rotating seals, sometimes called a "steam blanket", is not particularly effective because very little steam is circulated within the quench area. Depending upon the type of bushing used, the steam can even be directed towards the pump bearings. A steam quench used with a stationary design, such as the Type 1604 (metal bellows seal), is more effective. The steam must enter underneath the bellows assembly, between the bellows and the anti-coking baffle, and is guided around the seal to wash away the leakage from the seal faces.

If a quench is to be applied, then the minimum quench rate can be thought of as a purge.In that case, the minimum rate is a function of the volume being purged and the leakage being diluted. For typical seal gland plates and a contingency plan for high leakage rates, dilution of leakage usually governs.

Steam is usually readily available in plants and the flow rates are typically not regulated very closely due to the availability. This is also due, in part, to the cost versus other quench media. The relative cost of quench media is:

The cooling effect of gases such as steam and nitrogen on the face temperature of hot seals is small. The order of magnitude is less than 500-btu/hr removed from the seal faces. If the quench rate is too small, the temperature of the quench will heat up to nearly the pump temperature and allow decomposition and coking to occur. To prevent this, the average temperature in the quench volume can be estimated from an energy balance using the seal leakage rate, quench flow rate and heat soak from the surrounding metal. By constraining this average temperature to be less than some critical "coking" temperature, the quench rate can be computed.

After all the above considerations, the recommended quench rate is the largest of the values. For most pump seals the recommendation can be simplified in the following table.

Water is typically used as a quench medium when the fluid being sealed has solids in solution or will crystallize upon exposure to atmosphere. The flow rate for water does not have to be very large. In some cases it can just be enough to keep a volume of fluid on the atmospheric side of the seal, while in other cases a slight flow rate of 1/8-gpm to ¼-gpm is sufficient to prevent build up of product underneath the seal faces. This is one case where the containment device may be a lip seal.

Plans 71, 72, 75, and 76 are new plans for dry running secondary containment seals used in conjunction with a liquid lubricated primary seal. The process, or inner seal, of the dual unpressurized arrangement usually has its own flush plan. For example, the flush plans for a dual unpressurized seal arrangement with a dry running secondary containment seal might be written as Plan 11/71, 11/71/75, 11/71/76, or as noted below 11/72/75 or 11/72/76. The Plan 11 for the inboard seal can be any of the plans normally associated with a single mechanical seal.

A secondary containment device is a means of containing and controlling the primary seal leakage from a mechanical seal. In contrast to a dual liquid lubricated mechanical seal, which operates in a buffer or barrier fluid, a secondary containment device operates primarily in the leakage from the process seal, although purges may be added.

There are many different types of secondary containment devices from simple bushings to mechanical seals. Leakage rates for the various secondary sealing devices can vary by several orders of magnitude. Selection of the secondary containment device and system will depend on the level of leakage to atmosphere that is considered acceptable as well as performance requirements for normal operation, upsets, and in the event of process seal failure.

By definition, the secondary containment device does not necessarily have the performance or rating of the primary seal; however, it may be able to temporarily tolerate seal cavity pressure and fluid in the event of a failure of the primary seal.

Large clearance devices like fixed bushings have the highest leakage rates; floating bushings with reduced clearance are much better. Floating segmented bushings have still lower leakage rates. Dry running mechanical seals, both contacting and non-contacting, may also be used as secondary containment devices and can approach the level of performance of a dual unpressurized liquid lubricated seal arrangement.

API Plan 72 is designed to have an inert gas purge through the containment seal area with the intent to reduce emission levels to the atmosphere. The purge gas mixes with leakage from the primary seal, thereby reducing the concentration of the hazardous fluid (liquid or gas). Leakage rates from the various types of containment devices will vary from high rates with bushings to low leakage rates with contacting face seals.

Leakage to atmosphere will also have a wide variation depending upon operating conditions, length of time in service and equipment conditions, as well as a myriad of other lesser considerations. When deciding on the purge rate, consideration should be given to the type of containment device, the flow rate past the orifice, the fact that excessive purge rates can dry out the sealing cavity and possibly decrease the life of contacting face seals, and that excessive containment seal cavity pressures can decrease the life of the containment sealing device with the possible exception of non-contacting containment seals.

A simple rule of thumb is to have a flow rate on the order of ½ SCFM to the containment seal cavity. This relates to the rough flow rate for a 5-psi differential pressure across a 1/16-in orifice. This rate can be adjusted upwards or downwards depending upon the specific application.

Even though leakage from dual gas seals is normally very low, the following issues related to pump design and installation may require attention, depending upon the seal duty:

Some exceptional horizontal installations also suffer the same circumstance when suction pipework originates from below the shaft centerline. Not all vertical pumps are vulnerable, as the sensitivity is dependent on the relative positions of the impeller and the suction inlet. Some in-line units using a Plan 13 flush (in conjunction with a Plan 74 for the dual gas seals) have the ability to naturally vent through the suction valve, if the piping orientation permits.

To accommodate these issues in vertical pump installations or horizontal pumps with non-venting suction lines, a provision for manual or continuous automatic venting of seal chambers must be incorporated within the total pump installation.

If for operational or hazard reduction reasons it is required to shut both the suction and the discharge valves and isolate a standby pump, it can be expected (as with any dual pressurized seal) that the pump casing stands the risk of becoming pressurized to the same pressure as the gas barrier source. Depending upon the effectiveness of the valve seats, the casing pressure could also rise to that of the pump discharge manifold, which might be in excess of the barrier gas pressure.

Even though the dual gas seal may have a reverse pressure design feature on horizontal units, it is possible that a small quantity of process fluid may contaminate the gas barrier chamber. This is not detrimental to the seal (unless the process crystallizes or hardens), but when restarting the pump there is a risk that this small volume of process fluid will be pumped through the outer seal to the atmosphere.

Barrier gas leakage across the inner seal face during dynamic operation will eventually mix with the process flow. Depending on the seal size, operating conditions, pump size, pump design, and operation this leakage can affect the seal"s performance. This may be an increase in the NPSHR, a reduction in differential head, and in extreme cases a loss of prime.

At normal leakage levels this may not be an issue, but when leakage levels approach a condition when failure is deemed imminent, the effect on pump operation should be minimized. The seal size, shaft speed, barrier gas pressure, pump flow capacity, impeller design, and level of operational flow compared to the pump"s design BEP (best efficiency point) are all factors that determine the affect on normal pump operation.

To prevent the likelihood of dual gas seal leakage in dynamic operation affecting the design pump performance, screening by consultants is advised on pumps operating between 40-gpm and 90-gpm, when operating at less than 50 percent of its BEP.

At high vacuum suction conditions the effect of dual gas seal leakage into the process fluid is exaggerated because the gas expands at the low pressure. This is not a normal pump operating condition, but on pump NPSHR proof testing it may occur. The normal measurement criteria of a loss of 3 percent in the head generated can be created by gas entrainment. In an NPSHR proof test with a low capacity pump design and dual gas seals, a conservative and inaccurate value may be indicated.

It is advised that if NPSHR proof tests are applied to pumps with a BEP capacity less than 40-gpm, the influence of gas seal leakage must be evaluated and if necessary use an alternate seal design.

Plan 01 is an integral (internal) recirculation from the pump discharge to the seal chamber, which is typically at a pressure slightly above pump suction pressure. It is similar to Plan 11 in that it uses the pressure differential between pump discharge and pump suction to develop flow, but is different in that there are no external lines (piping or tubing) on the pump. It is recommended for clean pumpage only and is typically limited to pumps with a Total Discharge Head of less than 125-ft.

Useful arrangement on fluids that are highly viscous at normal ambient pumping temperatures so as to minimize the risk of freezing if exposed to low temperatures in external piping plans, such as a Plan 11.

There is no external way to control flow. Unlike Plan 11, which can have an externally replaceable orifice to control flow, the internal design of a Plan 01 eliminates this possibility.

The flow rate is dependent upon the pressure differential in the pump and the design of the line running internal to the pump casing. Changing the impeller design can affect the pressure differential and thus the flush rate. The pump OEM should be contacted to ensure that the flow rate is adequate to maintain a stable condition at the seal faces.

This flush system can perform its function well when used properly. Changes in pump impellers, or changing seal designs that can move the seal faces away from the flush hole can cause problems that result in seal failures. This system is not recommended on vertical pumps.

Plan 02 is a non-circulating flush plan. In Plan 02 the process is not directed into or out of the seal chamber. Seal generated heat is removed by convection and conduction to the process fluid, pump components, and the surrounding environment. Also, some seal chamber designs promote cooling, by mixing of process fluid between the pump cavity and seal chamber. Often, this plan is used in conjunction with API Plan 62 and/or the optional use of a cooling jacket, which will provide some additional cooling. This plan should only be used for services where adequate vapor suppression can be assured, so that vaporization of the process in the seal chamber or at the seal interface does not occur. Plan 02 is often used with a self venting, open seal chamber, i.e. no throat bushing.

Low duty, chemical service pumps are often a prime candidate for Plan 02. In these services, it is also advantageous to apply Plan 02 in conjunction with a large (open bore) or taper bore seal chamber. Often, in these services, suspended solids may be included in the process stream. In these cases, devices which encourage seal chamber circulation, while excluding solids from the seal chamber, are available and offered by many OEM and after market suppliers. Applications where these devices have been applied often work well with Plan 02.

Hot, refinery and petrochemical heavy oil services can be successfully sealed with Plan 02. Often, these services congeal or become highly viscous at ambient conditions. This can result in fouling and plugging of the recirculation plans, such as Plan 11, 13, 23 and their derivatives, unless effective temperature control schemes are employed. In these services, Plan 02 offers a relatively simple, cost effective way to obtain reasonable seal life. Only Plans 32 or 54 may be found to provide superior seal life. Use of Plan 02 in hot oil applications normally requires the use of Plan 62, using steam or nitrogen. In most cases, use of a seal chamber cooling jacket is helpful.

Successful use of Plan 02, as with other plans, is dependent on maintaining a lubricating film between the seal faces. This can be accomplished only if vapor formation in the seal chamber can be adequately suppressed. Plan 02, with no forced circulation through the seal chamber, requires thorough venting. This can be accomplished before startup (after pump inventory) or on a continuous basis by means of a self venting seal chamber design. Further, this Plan should be used with caution if the process has entrained gas or other components, which may vaporize easily. This plan is not recommended for vertical pumps.

Plan 11 is the most common flush plan in use today. This flush plan simply takes an appropriate amount of fluid from the discharge of the pump (or the discharge of one of the intermediate stages if applicable) and puts it into the seal chamber to provide cooling and lubrication to the seal faces.

Generally the flush rate must be calculated based on service conditions, pump speed and seal size. The rule of thumb is for not less than 1-gpm per inch (0.16-l/m per mm) of seal size, but the flush requirement may be greater if the pressure or speed is high. For application above 3600-rpm or box pressures above 500-psig (35- barg) the flush rate should be calculated to avoid excessive heat at the seal.

An interesting challenge arises when the differential pressure is high and a 1/8-in orifice allows for more flow than is desired. This can be addressed two ways. One option is to use two or more orifices in series. The number is dependent on the differential pressure. The other way is to use a "choke tube". This is a piece of tubing generally ¼-in heavy wall. The length of the tubing is calculated using a piping pressure drop calculation such that the pressure drop across the tubing is equal to the difference between the discharge pressure and the seal chamber pressure at the flow rate desired.

Any flush system works hand in hand with the hardware and seal parts. If the seal is set up with a distributed or extended flush, the effectiveness of the system will be better and the seal will run cooler no matter how much or little the flush flow rate.

FLUSH PLANS FOR MECHANICAL SEALS – INTRODUCTIONPumps and seals are being installed into increasingly difficult services. Forsuccessful operation of mechanical seals, the environment and care of the sealsrequire more sophisticated seal chambers and flushing arrangements. This sectionof the Dean Pump Price Book is designed to allow the application and pricing offlush plans suitable to meet the requirements for the mechanical seal.The American Petroleum Institute (API) has defined certain seal flusharrangements known by their plan numbers. Later, the flush plans developed forthe ANSI standard followed suit and placed the digits "73" in front of the API plannumber to achieve some standardization within the process industry. Thus, APIplan 11 becomes and ANSI Plan 7311.Dean Pump has worked with many engineering houses and customers over theyears and has developed a great deal of experience with sealing systems. WhileDean will quote any flush system requirement as requested by a particularcustomer, it has been found that the API/ANSI systems generally meet or exceedmost customer requirements. In addition, Dean Pump developed the Seal GuardEnvironment systems that provide the ultimate mechanical seal flush plan. Forsystems that do not require ANSI/API flush plans, Dean Pump has also includedthe P1200 loop, which is a basic low cost flush plan to satisfy the economyminded customer.The experience of Dean Pump is contained in these price pages. Many of theflush plans are divided into "Toxic/Flammable" and "Non-Toxic/Non-Flammable“services. The information on these plans along with the details described in the"Special Notes" section can be used as a guide in quoting and discussing optionswith customers. The "fine print" in the Special Notes section provides a multitude ofdetails about each flush system. For example, a customer requesting all socketwelded connections can not have every connection welded. Some accommodationmust be made for disconnecting the system. Being aware of the requirements ofthe customer and the manufacturing limitations of the product is extremely helpful.API flush plans are based on the 7 th Edition of API610. Newer versions of the APIspecifications has limited the cooling and flushing options available.Finally, if there are any doubts, questions, or comments, please feel free to call theFactory and the seal vendor.Effective: FEBRUARY 2011 • Replaces: NEWPage 1

SEAL GUARD SYSTEMS – PRODUCT DESCRIPTIONSeal Guard systems are designed to provide a clean liquid for seal flushing thatprovides protection for the mechanical seal in the pump seal chamber. Dean Pumpoffers two basic systems to guard against mechanical seal failure. These systemswill also help to prolong the life of the seal. Both systems are filtration systemsinstalled into the seal flush lines to remove stray abrasive particles which causeseal face wear.Seal Guard A - is designed for filtration only. Particles larger than 10 microns arefiltered from the system using clean-able or replaceable 316SS woven filterelements.Seal Guard B - is designed for high temperature applications and includes a heatexchanger installed ahead of the replaceable filter elements for both filtration andtemperature control.Seal Guard systems are most often used with MIN-FLO Bushings in the pump sealchamber. These bushings restrict the flow from the seal chamber back into thepump during operation and increases the effectiveness of the Seal Guard system.Seal Guards can be used on any pump product line. Their sale is not limited toDean Pump products. Seal Guards are hydrostatically tested but do not meet anyindustrial standard and are not for application to API610 series pumps. Seal Guardapplications must be limited to iron or steel pumps and are not suitable forapplications that require alloy materials.The Seal Guard system is fully described in Bulletin A2000.Effective: FEBRUARY 2011 • Replaces: NEWPage 2

SEAL GUARD SYSTEMS – (See Note #1)Model A Series – Filtration Only (See Note #2)Mounted on Pump BaseplateModel Description List PriceA500T A Series Seal Guard - Filtration - Threaded Connections $4,483A500F A Series Seal Guard - Filtration - Flanged Connections C/FA700T A Series Seal Guard - Filtration - Threaded Connections C/FBD500TB500TModel B Series – Filtration and Cooling (See Notes #2 & #3)Mounted on Separate BaseplateModel Description List PriceBD200T B Series Seal Guard - Cooling & Filtration - $5,248Threaded Connections & Duplex FilterB400T B Series Seal Guard - Cooling & Filtration - $5,248Threaded Connections & Simplex FilterB400F B Series Seal Guard - Cooling & Filtration - C/FFlanged Connections & Simplex FilterB500T B Series Seal Guard - Cooling & Filtration - $6,226Threaded Connections & Simplex FilterBD500T B Series Seal Guard - Cooling & Filtration - $8,240Threaded Connections & Duplex FilterNotes:1. Seal Guard systems are not rated for API application and are suitable for pumps in steel or iron construction only. Do notuse for 316SS or other alloy applications.2. The product description letters and numbers are as follows:First Letter - Seal Guard Series A - Filtration Only; B - Cooling and Filtration. (The letter D following in the second positionindicates a Duplex arrangement.); 3 Digit Number indicates the pressure rating of the Seal Guard system in psi.;Final Letter: T - Threaded Construction; F - Flanged Construction3. The heat exchangers provided for Seal Guard B are furnished with a steel shell and 316SS tube as standard.Effective: FEBRUARY 2011 • Replaces: NEWPage 3

DEAN P1200 ECONOMY FLUSH PLAN FOR PROCESS PUMPSPlan Description:Dean Plan P1200 systems include piping (or tubing) from the pumpdischarge gauge connection to the seal flush connection on the pumpbackhead or seal gland. These plans include all piping and/or tubing.List Prices (Notes 1 & 3)Carbon SteelCarbon SteelFitted 316SS Pipe 316SS PipeSystem Description (Note #2) Tubing Threaded ThreadedRecirculation of Pumpage from Pump Case toP1200 Seal Without Orifice (Similar to API Plan 11 orANSI Plan 7311) VALVE NOT INCLUDED$216 $329 $456 $692Valve Valve for Recirculation Line $205 $762 $205 $762General Notes:1. For all other flush plans, refer to API/ANSI Flush Plans shown elsewhere for your particular requirements.2. The plan with carbon steel tubing uses carbon steel fittings with 316SS tubing.3. Connections on the casing require a price adder for discharge gauge connections and may require an additional price adderif the seal chamber requires back drilling.Effective: FEBRUARY 2011 • Replaces: NEWPage 4

SOME COMMENTS AND RECOMMENDATIONSABOUT API/ANSI FLUSH PLANSThere are two organizations in the United States which have taken the lead in developingacceptable standards for the pump industry. The American Petroleum Institute (API) and AmericanNational Standards Institute (ANSI) have outlined a number of flush plans which encompass themajority of applications. API610 is mainly recognized as a standard which defines the qualityrequirements of a pump and/or system. ANSI-B73.1 is viewed as more of a dimensional and featurestandard. ANSI plans are designated the same as API plans except for the addition of a "73" prefixon the plan number. For example, an API Plan 21 is designated as an ANSI Plan 7321.API and ANSI flush plans are similar and upon initial examination look nearly identical. However,there are definite differences in their construction. Often, API flush plans, which are historicallylocated in refinery environments, are piped and welded. ANSI plans, on the other hand, can utilizetubing. Another notable difference is in the API plan 52/53 and the ANSI plan 7352/7353. APIspecifies Schedule 40 minimum thickness vessels. ANSI allows for the use Schedule 10 vessels. Allof the plans are offered in steel and stainless steel construction. They also have differingconstructions for Toxic/Flammable or Nontoxic/Nonflammable applications.Meeting the customer"s specific requirements is the most important consideration in applying theseplans. Many customers modify their individual requirements from the API and ANSI specifications.Sometimes these are more stringent rules than the API and ANSI specifications. These must takeprecedence over the standard flush plans. There are some limitations as to what the flush plans canor cannot accomplish. The Special Application Notes section on each sheet identifies the particularlimitations of each of the flush plans. For example, a flush loop which requires socket welded jointscan not have all the connections welded some provision must be made to allow for disassembly andrepair.When applying a particular flush plan to a specific job, great care should be taken to insure theneeds of the customer are met. Do not select a plan based solely upon pricing. In general, most APIplans require piping and many require welded joints. Note that these are the most expensive plans.A few API services permit the less expensive plans but, the customer"s requirements takeprecedence. ANSI, on the other hand, is much less specific but still requires close analysis of thecustomer"s specifications and requirements for guidance. However, API plans are often seen onANSI type pumps. Oil companies are very likely to request the more expensive plan and will pay forit. Do not make errors in this area. If there is any doubt, or questions regarding plan selection, sendthe specification/ requirements to the factory for review. The factory will provide any comments,limitations, and pricing that is required.Effective: FEBRUARY 2011 • Replaces: NEWPage 5

API PLAN 11 - FLUSH PLAN FOR PROCESS PUMPS (Note #1)ANSI PLAN 7311 – FLUSH PLAN FOR CHEMICAL PUMPSPlan Description:API Plan 11 (ANSI Plan 7311) systems include piping (ortubing) from the pump discharge gauge connection throughan orifice to the seal flush connection on the pumpbackhead or seal gland. These plans include all piping,tubing, and the orifice. Refer to Note #B for additionalpump drilling.SYSTEMS FOR NON-TOXIC AND NON-FLAMMABLE APPLICATIONSSystem DescriptionDescription Special Notes Max. Press. Max. Temp. List PriceAASteel Threaded Pipe and Fittings with 316SS Tubingand Tube Connectors2, 3, 7, 19 500psi 800º F. $ 413AB Steel Threaded Pipe and Fittings 2, 5, 8 500psi 800º F. $ 627AC316SS Threaded Pipe and Fittings with 316SS Tubing andTube Connectors2, 3, 7, 19 500psi 850º F. $ 483AD All 316SS Threaded Pipe and Fittings 2, 5, 8, 500psi 850º F. $1,496SYSTEMS FOR TOXIC AND/OR FLAMMABLE APPLICATIONSSystem Description Special Notes Max. Press. Max. Temp. List PriceAESocket Welded Steel Pipe and Fittings with 316SS Tubingand Tube Connectors1, 4, 7, 19 500psi 300º F. $ 890AF Socket Welded Steel Pipe and Fittings 1, 6, 8 500psi 800º F. $1,124AGSocket Welded 316SS Pipe and Fittings with 316SS Tubingand Tube Connectors2, 3, 7, 19 500psi 300º F. $ 982AH All Socket Welded 316SS Pipe and Pipe Fittings 2, 5, 8 500psi 850º F. $1,577General Notes:A. ALL PUMPS - The plans are similar to but may not comply with API610, 5 th Ed. Review customer requirements as plansmay not comply with later editions or specific customer requirements.B. ALL PUMPS - Flush plans require one or more pump taps. Add the price of the discharge and suction gauge connections ifrequired. For clamped seat applications, consult factory.Special Application Notes:1. Pipe connections at the pump are threaded and are not backwelded.2. All pipe joints are threaded.3. Pipe nipples, threaded pipe fittings, stainless steel tubing, and compression type stainless steel tube connectors.4. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, stainless steel tubing and compression typestainless steel tube connectors with threaded pipe connections that are not backwelded.5. Pipe nipples, threaded pipe fittings, and threaded pipe unions.6. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, socket weld pipe unions.Effective: FEBRUARY 2011 • Replaces: NEWPage 7

API PLAN 12 - FLUSH PLAN FOR PROCESS PUMPS (General Note #A)ANSI PLAN 7312 – FLUSH PLAN FOR CHEMICAL PUMPSPlan Description:API Plan 12 (ANSI Plan 7312) systems include piping (ortubing) from the pump discharge gauge connection througha Y-strainer, and orifice to the seal flush connection on thepump backhead or seal gland. These plans include allpiping, tubing, and the orifice. Refer to Note #B foradditional pump drilling.SYSTEMS FOR NON-TOXIC AND NON-FLAMMABLE APPLICATIONSSystem DescriptionDescription Special Notes Max. Press. Max. Temp. List PriceBASteel Threaded Pipe and Fittings with 316SS Tubing andTube Connectors and Y-Strainer2, 3, 7, 9, 19 500psi 800º F. $ 638BB Steel Threaded Pipe and Fittings 2, 5, 8, 9 500psi 800º F. $1,123BC316SS Threaded Pipe and Fittings with 316SS Tubing andTube Connectors and Y-Strainer2, 3, 7, 9, 19 500psi 850º F. $ 939BD All 316SS Threaded Pipe and Fittings and Y-Strainer 2, 5, 8, 9 500psi 850º F. $1,736SYSTEMS FOR TOXIC AND/OR FLAMMABLE APPLICATIONSSystem Description Special Notes Max. Press. Max. Temp. List PriceBESocket Welded Steel Pipe and Fittings with 316SS Tubingand Tube Connectors and Y-Strainer1, 4, 7, 10, 19 500psi 300º F. $1,298BF Socket Welded Steel Pipe and Fittings and Y-Strainer 1, 6, 8, 10 500psi 800º F. $1,602BGSocket Welded 316SS Pipe and Fittings with 316SS Tubingand Tube Connectors and Y-Strainer2, 3, 7, 9, 19 500psi 300º F. $1,270BHAll Socket Welded 316SS Pipe and Pipe Fittings andY-Strainer2, 5, 8, 9 500psi 850º F. $1,817General Notes:A. ALL PUMPS - The plans are similar to but may not comply with API610, 5 th Ed. Review customer requirements as plansmay not comply with later editions or specific customer requirements.B. ALL PUMPS - Flush plans require one or more pump taps. Add the price of the discharge and suction gauge connections ifrequired. For clamped seat applications, consult factory.Special Application Notes:1. Pipe connections at the pump are threaded and are not backwelded.2. All pipe joints are threaded.3. Pipe nipples, threaded pipe fittings, stainless steel tubing, and compression type stainless steel tube connectors.4. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, stainless steel tubing and compression type stainless steeltube connectors with threaded pipe connections that are not backwelded.5. Pipe nipples, threaded pipe fittings, and threaded pipe unions.6. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, socket weld pipe unions.7. Stainless steel orifice plate in tube connector.8. Stainless steel orifice plate in pipe union.9. Y-strainer has stainless steel screen and 1/4" NPT (plugged) blow-off connection.10. Y-strainer has stainless steel screen and bolted cap without blow-off connection.19. This loop has stainless steel tubing and should not be used where chlorides are present.Effective: FEBRUARY 2011 • Replaces: NEWPage 8

API PLAN 21 - FLUSH PLAN FOR PROCESS PUMPS (General Note #A)ANSI PLAN 7321 – FLUSH PLAN FOR CHEMICAL PUMPSWHEN SPECIFIEDPlan Description:API Plan 21 (ANSI Plan 7321) systems include piping (ortubing) from the pump discharge gauge connection throughthe heat exchanger to the seal flush connection on thepump backhead or seal gland. These plans include allpiping, tubing, heat exchanger, and the orifice. The heatexchanger includes a steel shell and 316SS tubing. Ref.Note #B.SYSTEMS FOR NON-TOXIC AND NON-FLAMMABLE APPLICATIONSMAWP 500psi @System Description Special Notes 300º F 650º F 750º FCACBCCCDSteel Threaded Pipe and Fittings with 316SS Tubing andSteel Threaded Pipe and Fittings and Heat Exchanger316SS Threaded Pipe and Fittings with 316SS Tubing andAll 316SS Threaded Pipe and Fittings and Heat Exchanger2, 3, 7, 11, 13,2, 5, 8, 11, 13,2, 3, 7, 11, 13,2, 5, 8, 11, 13,Heat Exchanger (Steel Sheel & 316SS Tubing)(Steel Sheel & 316SS Tubing)Heat Exchanger (Steel Sheel & 316SS Tubing)(Steel Sheel & 316SS Tubing)19, 212119, 2121$3,301$3,663$5,016$5,229$3,301$3,663.$5,489$5,701$4,864$5,227$6,700$6,913ADD Temperature Indicator 13 C/F C/F C/FSYSTEMS FOR TOXIC AND/OR FLAMMABLE APPLICATIONSSystem Description Special Notes 300º FMAWP 500psi @650º F 750º FCESocket Welded Steel Pipe and Fittings and Heat Exchanger 1, 6, 8, 11, 12,(Steel Sheel & 316SS Tubing) 14, 21$4,286 $4,286 $5,849CFAll 316SS 316SS Pipe and Fittings and Heat Exchanger 2, 5, 8, 11, 13, C/F C/F C/F(Steel Sheel & 316SS Tubing) 21ADD Temperature Indicator with Thermowell 14 C/F C/F C/FGeneral Notes:A. ALL PUMPS - The plans are similar to but may not comply with API610, 5 th Ed. Review customer requirements as plans may not comply withlater editions or specific customer requirements.B. ALL PUMPS - Flush plans require one or more pump taps. Add the price of the discharge and suction gauge connections if required. Forclamped seat applications, consult factory.Special Application Notes:1. Pipe connections at the pump are threaded and are not backwelded.2. All pipe joints are threaded.3. Pipe nipples, threaded pipe fittings, stainless steel tubing, and compression type stainless steel tube connectors.4. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, stainless steel tubing and compression type stainless steeltube connectors with threaded pipe connections that are not backwelded.5. Pipe nipples, threaded pipe fittings, and threaded pipe unions.6. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, socket weld pipe unions.7. Stainless steel orifice plate in tube connector.8. Stainless steel orifice plate in pipe union.11. Heat exchanger has 1/4" diameter, 18 gauge, stainless steel tubes good for the maximum operating temperature and pressure of the pump.12. Heat exchanger connections are threaded and are not backwelded to allow replacement of the tube coil.13. Dial thermometer is 3" diameter, bi-metal, and screwed into pipe TEE and is furnished only when specified.14. Dial thermometer is 3" diameter, bi-metal, and screwed into a thermometer socket which is welded into pipe TEE and is furnished onlywhen specified.19. This loop has stainless steel tubing and should not be used where chlorides are present.Effective: FEBRUARY 2011 • Replaces: NEWPage 9

API PLAN 22 - FLUSH PLAN FOR PROCESS PUMPS (General Note #A)ANSI PLAN 7322 – FLUSH PLAN FOR CHEMICAL PUMPSWHEN SPECIFIEDPlan Description:API Plan 22 (ANSI Plan 7322) systems include piping (ortubing) from the pump discharge gauge connection througha Y-strainer, through the heat exchanger to the seal flushconnection on the pump backhead or seal gland. Theseplans include all piping, tubing, heat exchanger, and theorifice. The heat exchanger includes a steel shell and316SS tubing. Ref. Note #19.SYSTEMS FOR NON-TOXIC AND NON-FLAMMABLE APPLICATIONSMAWP 500psi @System Description Special Notes 300º F 650º F 750º FDADBDCDDSteel Threaded Pipe and Fittings with 316SS Tubing andSteel Threaded Pipe and Fittings and Heat Exchanger316SS Threaded Pipe and Fittings with 316SS Tubing andAll 316SS Threaded Pipe and Fittings and Heat Exchanger2, 3, 7, 9, 11, 13,2, 5, 8, 9, 11, 13,2, 3, 7, 9, 11, 13,2, 5, 8, 9, 11, 13,Heat Exchanger (Steel Sheel & 316SS Tubing) and Y-Strainer(Steel Sheel & 316SS Tubing) and Y-StrainerHeat Exchanger (Steel Sheel & 316SS Tubing) and Y-Strainer(Steel Sheel & 316SS Tubing) and Y-Strainer19, 212119, 2121$3,549$3,912$5,454$5,460$3,549$3,912$5,928$5,955$5,112$5,475$7,138$7,145ADD Temperature Indicator with Thermowell 14 C/F C/F C/FSYSTEMS FOR TOXIC AND/OR FLAMMABLE APPLICATIONSMAWP 500psi @System Description Special Notes 300º F 650º F 750º FDEDFSocket Welded Steel Pipe and Fittings and Heat ExchangerAll 316SS 316SS Pipe and Fittings and Heat Exchanger1, 6, 8, 10, 11,2, 5, 8, 9, 11, 13,(Steel Sheel & 316SS Tubing) and Y-Strainer(Steel Sheel & 316SS Tubing) and Y-Strainer12, 14, 2121$4,534C/F$4,534C/F$6,097C/FADD Temperature Indicator with Thermowell 14 C/F C/F C/FGeneral Notes:A. ALL PUMPS - The plans are similar to but may not comply with API610, 5 th Ed. Review customer requirements as plans may not comply withlater editions or specific customer requirements.B. ALL PUMPS - Flush plans require one or more pump taps. Add the price of the discharge and suction gauge connections if required. Forclamped seat applications, consult factory.Special Application Notes:1. Pipe connections at the pump are threaded and are not backwelded.2. All pipe joints are threaded.3. Pipe nipples, threaded pipe fittings, stainless steel tubing, and compression type stainless steel tube connectors.4. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, stainless steel tubing and compression type stainless steeltube connectors with threaded pipe connections that are not backwelded.5. Pipe nipples, threaded pipe fittings, and threaded pipe unions.6. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, socket weld pipe unions.7. Stainless steel orifice plate in tube connector.8. Stainless steel orifice plate in pipe union.9. Y-strainer has stainless steel screen and 1/4" NPT (plugged) blow-off connection.10. Y-strainer has stainless steel screen and bolted cap without blow-off connection.11. Heat exchanger has 1/4" diameter, 18 gauge, stainless steel tubes good for the maximum operating temperature and pressure of the pump.12. Heat exchanger connections are threaded and are not backwelded to allow replacement of the tube coil.13. Dial thermometer is 3" diameter, bi-metal, and screwed into pipe TEE and is furnished only when specified.14. Dial thermometer is 3" diameter, bi-metal, and screwed into a thermometer socket which is welded into pipe TEE and is furnished onlywhen specified.19. This loop has stainless steel tubing and should not be used where chlorides are present.21. Heat exchanger size may vary from standard offering due to service conditions of liquid being pumped.Effective: FEBRUARY 2011 • Replaces: NEWPage 10

API PLAN 23 - FLUSH PLAN FOR PROCESS PUMPS (General Note #A)ANSI PLAN 7323 – FLUSH PLAN FOR CHEMICAL PUMPSWHEN SPECIFIEDPlan Description:API Plan 23 (ANSI Plan 7323) systems include piping (ortubing) from the seal flush connection on the backhead orseal gland, through the heat exchanger, and back to theseal gland. These plans include all piping, tubing, heatexchanger, and the orifice. The heat exchanger includes asteel shell and 316SS tuning. Ref. Note #B. – Similar toPlan 21 (7321) with addition of Pumping Ring in sealchamber and may require additional pump changes.SYSTEMS FOR NON-TOXIC AND NON-FLAMMABLE APPLICATIONSMAWP 500psi @System Description Special Notes 300º F 650º F 750º FEASteel Threaded Pipe and Fittings with 316SS Tubing and 2, 3, 11, 13, 19,Heat Exchanger (Steel Sheel & 316SS Tubing) and Y-Strainer 21C/F C/F C/FEBSteel Threaded Pipe and Fittings and Heat Exchanger(Steel Sheel & 316SS Tubing) and Y-Strainer2, 5, 11, 13, 21 C/F C/F C/FEC316SS Threaded Pipe and Fittings with 316SS Tubing and 2, 3, 11, 13, 19,Heat Exchanger (Steel Sheel & 316SS Tubing) and Y-Strainer 21C/F C/F C/FEDAll 316SS Threaded Pipe and Fittings and Heat Exchanger(Steel Sheel & 316SS Tubing) and Y-Strainer2, 5, 11, 13, 21 C/F C/F C/FADD Temperature Indicator 13 C/F C/F C/FSYSTEMS FOR TOXIC AND/OR FLAMMABLE APPLICATIONSMAWP 500psi @System Description Special Notes 300º F 650º F 750º FSocket Welded Steel Pipe and Fittings and Heat Exchanger 1, 6, 11, 12, 14,EEC/F C/F C/F(Steel Sheel & 316SS Tubing) and Y-Strainer 21All 316SS 316SS Pipe and Fittings and Heat ExchangerC/FEF2, 5, 11, 13, 21 C/FC/F(Steel Sheel & 316SS Tubing) and Y-StrainerADD Temperature Indicator with Thermowell 14 C/F C/F C/FGeneral Notes:A. ALL PUMPS - The plans are similar to but may not comply with API610, 5 th Ed. Review customer requirements as plans may not comply withlater editions or specific customer requirements.B. ALL PUMPS - Flush plans require one or more pump taps. Add the price of the discharge and suction gauge connections if required. Forclamped seat applications, consult factory.Special Application Notes:1. Pipe connections at the pump are threaded and are not backwelded.2. All pipe joints are threaded.3. Pipe nipples, threaded pipe fittings, stainless steel tubing, and compression type stainless steel tube connectors.5. Pipe nipples, threaded pipe fittings, and threaded pipe unions.6. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, socket weld pipe unions.11. Heat exchanger has 1/4" diameter, 18 gauge, stainless steel tubes good for the maximum operating temperature and pressure of the pump.13. Dial thermometer is 3" diameter, bi-metal, and screwed into pipe TEE and is furnished only when specified.14. Dial thermometer is 3" diameter, bi-metal, and screwed into a thermometer socket which is welded into pipe TEE and is furnished onlywhen specified.19. This loop has stainless steel tubing and should not be used where chlorides are present.21. Heat exchanger size may vary from standard offering due to service conditions of liquid being pumped.All Requests for Plan 23/73223 Must Be Made to the Application EngineersEffective: FEBRUARY 2011 • Replaces: NEWPage 11

API PLAN 31 - FLUSH PLAN FOR PROCESS PUMPS (Note #1)ANSI PLAN 7331 – FLUSH PLAN FOR CHEMICAL PUMPSPlan Description:API Plan 31 (ANSI Plan 7331) systems include piping (ortubing) from the pump discharge gauge connection througha cyclone separator to the seal flush connection on thepump backhead or seal gland and fluid with solids back topump suction gauge connection. These plans include allpiping, tubing, and the cyclone separator. Refer to Note #Band #C for preparation. See note #D for performance.SYSTEMS FOR NON-TOXIC AND NON-FLAMMABLE APPLICATIONSSystem DescriptionDescription Special Notes Max. Press. Max. Temp. List PriceFASteel Threaded Pipe and Fittings with 316SS Tubing andTube Connectors2, 3, 7, 19 500psi 800º F. C/FFB Steel Threaded Pipe and Fittings 2, 5, 8 500psi 800º F. C/FFC316SS Threaded Pipe and Fittings with 316SS Tubing andTube Connectors2, 3, 7, 19 500psi 850º F. C/FFD All 316SS Threaded Pipe and Fittings 2, 5, 8, 500psi 850º F. C/FSYSTEMS FOR TOXIC AND/OR FLAMMABLE APPLICATIONSSystem Description Special Notes Max. Press. Max. Temp. List PriceFESocket Welded Steel Pipe and Fittings with 316SS Tubingand Tube Connectors1, 4, 7, 19 500psi 300º F. C/FFF Socket Welded Steel Pipe and Fittings 1, 6, 8 500psi 800º F. C/FFGSocket Welded 316SS Pipe and Fittings with 316SS Tubingand Tube Connectors2, 3, 7, 19 500psi 300º F. C/FFH All Socket Welded 316SS Pipe and Pipe Fittings 2, 5, 8 500psi 850º F. $4,518General Notes:A. ALL PUMPS - The plans are similar to but may not comply with API610, 5 th Ed. Review customer requirements as plansmay not comply with later editions or specific customer requirements.B. All items contain steel or stainless steel tubing and should not be used where chlorides are present. Consult factory forspecial pricing.C. ALL PUMPS - Flush plans require one or more pump taps. Add the price of the discharge and suction gauge connectionsif required.For clamped seat applications, consult factory.D. This plan may cause flow disruption in the suction and will decrease total head and efficiency and increase NPSHR.Special Application Notes:1. Pipe connections at the pump are threaded and are not backwelded.2. All pipe joints are threaded.3. Pipe nipples, threaded pipe fittings, stainless steel tubing, and compression type stainless steel tube connectors.4. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, stainless steel tubing and compression typestainless steel tube connectors with threaded pipe connections that are not backwelded.5. Pipe nipples, threaded pipe fittings, and threaded pipe unions.6. Pipe, pipe nipples, socket weld pipe fittings, backwelded threaded pipe fittings, socket weld pipe unions.Effective: FEBRUARY 2011 • Replaces: NEWPage 12

API PLAN 32 - FLUSH PLAN FOR PROCESS PUMPS (Note #1)ANSI PLAN 7332 – FLUSH PLAN FOR CHEMICAL PUMPSPlan Description:API Plan 32 (ANSI Plan 7332) systems provide injection tothe seal from an external clean source provided by thecustomer. These plans include all piping, tubing, Y-strainer,pressure gauge, temperature indicator, and flow regulatingvalve. Refer to Note #A and #B for preparation.SYSTEMS FOR NON-TOXIC AND NON-FLAMMABLE APPLICATIONSSystem Description Special Notes Max. Press. Max. Temp. List PriceGAGBGCGDSteel Threaded Pipe and Fittings with 316SS Tubing and TubeConnectors with Y-Strainer, Pressure Gauge, Temperature Gauge,and Flow Regulating ValveSteel Threaded Pipe and Fittings with Y-Strainer, Pressure Gauge,Temperature Indicator, and Flow Regulating Valve316SS Threaded Pipe and Fittings with 316SS Tubing and TubeConnectors with Y-Strainer, Pressure Gauge, TemperatureIndicator, and Flow Regulating ValveAll 316SS Threaded Pipe and Fittings with Y-Strainer, Pressure,Gauge, Temperature Indicator, and Flow Regulating Valve2, 3, 9,13,19,252, 5, 9, 13, 252, 3, 9,13,19,25800º F.850º F.2, 5, 9, 13, 25 500psi 850º F.SYSTEMS FOR TOXIC AND/OR FLAMMABLE APPLICATIONSSystem Description Special Notes Max. Press. Max. Temp. List PriceGEGFGGSocket Welded Steel Pipe and Fittings with 316SS Tubing and1, 4, 10, 14, 18,Tube Connectors with Y-Strainer, Pressure Gauge, Temperature19,25Indicator, and Flow Regulating ValveSocket Welded 316SS Pipe and Fittings with 316SS Tubing and2, 3, 9, 13,Tube Connectors with Y-Strainer, Pressure Gauge, Temperature19, 25Indicator, and Flow Regulating ValveSocket Welded Steel Pipe and Fittings with Y-Strainer, Pressure 1, 6, 10, 14,Gauge, Temperature Indicator, and Flow Regulating Valve18, 25500psi500psi500psi300º F.800º F.300º F.$2,088$2,381$2,785GHAll Socket Welded 316SS Pipe and Pipe Fittings with Y-Strainer,Pressure Gauge, Temperature Indicator, and Flow Regulating Valve2, 5, 9, 13, 25 500psi 850º F. $3,151500psi500psi 800º F.500psi$1,521$1,664$2,221$2,614General Notes:A. ALL PUMPS - The plans are simila

8613371530291

8613371530291