back to back mechanical seal brands

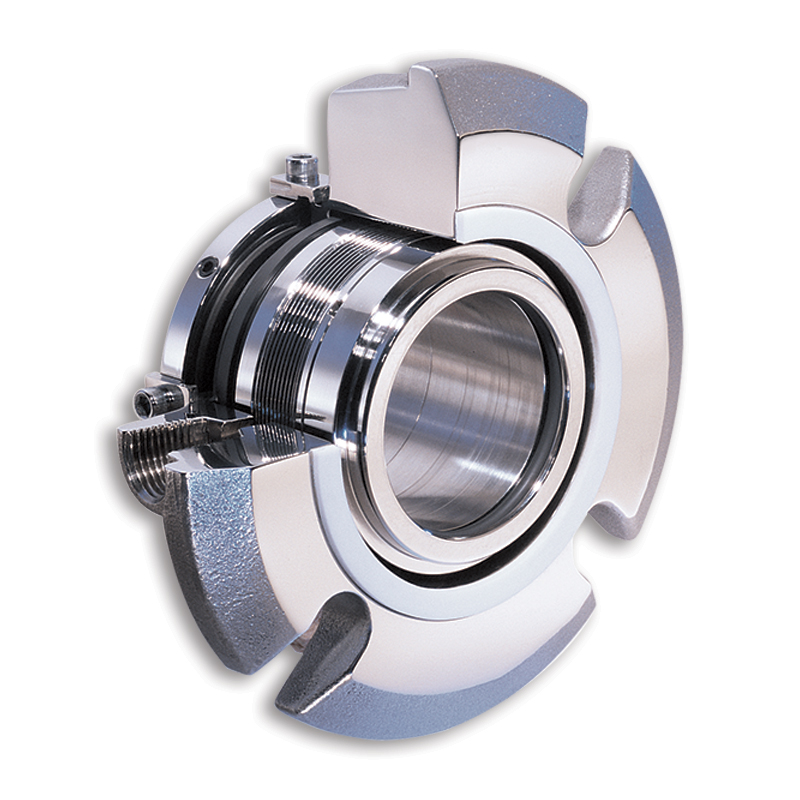

The SEPCO RBD is a stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerated and where positive ...

Dual seal Available for standard (CMS-ASDN) and big bore (CMS-ABDN) seal chambers Balanced Cartridge Double pressure balanced Independent of direction of rotation Integrated pumping device

We manufacture face seals for hydraulic and pneumatic applications in the following designs:- rod seals and piston seals - single-acting - double-acting - rotatory ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

... pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact cartridge that fits ANSI and DIN standard ...

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge easy to ...

• Static grafoil gaskets;• Temperatures up to 425 ºC;• Inconel bellows available;• Cartridge easy to install;• Metal bellows provide better faces alignment;• Does not have dynamic gaskets;• Self-cleaning;• Adapts to API standard pumps;• ...

Burgmann H74-D Mechanical Seal called as PC04 are specialized in mechanical seals products. This device gives double seal and it can be rotated in any ...

The MTM10-11 is a conical spring mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This unbalanced mechanical seal ...

The MTM 25_26, manufactured by MICROTEM, is a conical spring mechanical seal that can compensate positioning errors and withstand stresses created by vibrations. The contact surface can be made with silicon ...

... agitators on sealed tanks will have a mechanical seal of some sort. For many sanitary process vessels, the mixer must have some type of sealing barrier to provide either a dust tight vapor seal, ...

mechanical seal for automotive engine cooling water pump, referred to as water seal, mainly composed of two parts: rotating ring and static ring. Static ring is installed in the pump ...

The 3-D Seal is designed to be the foremost solution for high radial misalignment and high run out applications. By combining Garlock’s proven P/S®-II and expansion joint technologies into ...

Aura™ reduces operational and transactional costs using a patented polymeric sealing device. Aura reduces leakage rates by up to 15 percent, lowering the total cost of operation while protecting the environment. An enhanced rotor design ...

The AESSEAL® API Type A, B and C single-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application ...

Mechnical seal type 5030 / 5031 »with rubber bellowssingle-actingnon-anisotropicAreas of usestandard pumpwaster water pumpsupply engineeringgeneral industrial usemass production seal

When purchasing the units, if left hand rotation, special seal, or a particular position of cartridge (shaft end or cover end) is needed, it should be ...

Cartridge Seals by CinchSeal are customized mechanical seals for rotary air locks in bulk handling equipment. They are designed to replace lip and packing seals in screw ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

A dry gas seal is a revolutionary way of sealing machines and protecting them from dust, moisture and other contaminants. A dry gas seal is a sealing device that uses pressurized gas to keep two surfaces from touching. The most common type of dry gas seal is the O-ring, which is used in many applications, including mechanical seals, piston rings, and gaskets. Dry gas seals are also used in many other industries, such as the food and beverage industry, where they are used to seal containers and prevent contamination. This type of seal not only helps to keep the machine running with maximum efficiency but also significantly reduce downtime, making it cost-effective in the long run. In this article, we"ll explore what a dry gas seal is, how it works and why you should consider using it for your machinery. By understanding the benefits of a dry gas seal and its uses, you can make an informed decision about the best sealing system for your needs. How does a dry gas seal work?Dry gas seals work by using a series of labyrinths to separate the high pressure seal gas from the atmosphere. The labyrinths are formed by a series of grooves and ridges on the surface of the seal ring. The seal ring is rotated at high speed, causing the gas to flow through the labyrinths. The gas is then forced through an aperture in the center of the seal ring, where it escapes into the atmosphere. What is a dry gas seal used for?Dry gas seals are used on rotating equipment to help minimize the leakage of high pressure gases from the inside of the machinery. This helps to reduce maintenance costs and improve safety. Dry gas seals are commonly used in applications such as pumps, compressors, turbines, and blowers. Advantages of a dry gas sealThere are many advantages of a dry gas mechanical seal. One advantage is that they are much simpler in design than other types of seals, making them more reliable and easier to maintain. Additionally, dry gas seals do not require the use of any lubricating fluids, which can leak or evaporate over time. This makes them more environmentally friendly and cost-effective in the long run. Finally, dry gas seals have a much longer lifespan than other types of seals, meaning that they need to be replaced less often.Disadvantages of a dry gas sealThere are several disadvantages of dry gas seals, including: - they can be expensive to purchase and install- they require careful maintenance and regular inspection- they can be susceptible to wear and tear- they can leak if not maintained properlyHow to choose the right dry gas seal for your applicationThere are a few key factors to consider when choosing the right dry gas mechanical seal for your application. The most important factor is the type of fluid being sealed. Gas seals are designed to seal either liquids or gases, but not both. Make sure to choose a gas seal that is compatible with the fluid you are sealing.Another important factor to consider is the pressure of the fluid being sealed. Gas seals are rated for different maximum pressures, so make sure to choose one that can handle the pressure of your application.Finally, take into account the size and shape of the sealing surfaces. Gas seals come in a variety of sizes and shapes to fit different applications, so make sure to choose one that will fit your needs.ConclusionDry gas seals are an extremely important component for many industrial operations, and their ability to prevent leaks has made them invaluable in a variety of applications. Understanding the basics of how dry gas mechanical seal work and how they can be used effectively is helpful when considering the various options available for any specific application. With the right choice, dry gas seals can provide reliable, leak-free performance which will save time, money and resources while ensuring safety and reliability. Lepu dry gas seal manufacturer provides best quality flowserve dry gas seal and dry gas seal. Welcome to contact us!

Robco"s Mechanical Seal Division manufactures, distributes and customizes mechanical seals, as well as being a repair facility for virtually any mechanical seal brand, utilizing the latest technology and state-of-the-art manufacturing equipment. Robco’s seal designs are customer driven to provide the best possible solutions to sealing problems.

Robco will repair: Borg-Warner, Chesterton, John Crane, Durametallic, EG&G, Flex-A-seal, Flexibox, Flowserve, Garlock, Pac-Seal, U.S. Seal, and virtually any other brand.

Mechanical seals are used everywhere liquids and gases are transferred through rotating equipment. Robco’s seals and packing are the first step to efficiently control leakage and reduce operation costs.

The ideal seal for alumina applications, specifically designed to operate in this challenging environment, the Robco DRYTEK seal will provide maintenance-free operation at least five to twenty times longer than your average alumina screw conveyor seal.

•Better abrasion resistance •Dry-seal, no lubricant required •Sealing components rotate with the shaft, maintaining an airtight seal •Adapts to axial and radial movements of the shaft •Available in C.E.M.A. and METRIC standard shaft sizes.

Double balanced cartridge seal for pumps, agitators and mixers that prevents the leakage of toxic, hazardous, corrosive and costly fluids to the atmosphere.

The value of repairing instead of replacing whenever possible has always been a source of savings and a way to lower the Total Cost of Ownership of your equipment. At Robco, we believe in supplying you with quick, expert service to make your operations as efficient as possible.

Robco uses specialized equipment to ensure that rebuilt seals operate equal to brand new, with mechanical seal manufacturing and rebuilding experience dating back to 1978, servicing petrochemical, pulp & paper, steel, mining, waste water, utilities, boilers and more...

We rebuild all major brands at competitive prices with premium quality parts that meet all OEM specifications. We offer a free estimate and failure analysis. Rebuild outlay normally varies from a third to half the cost of a new seal, so lower your inventory value and reduce your overall operations cost.

By centralizing your repairs: Robco rebuilds all major brands in one location, simply complete our Seal Repair Form to be enclosed along with your seal shipment and we’ll take care of the rest, returning your seal looking and working like new. Robco tags all rebuilt seals for future rebuild identification, tracking seal life and failure patterns.

Flexaseal offers replacement seals for a full array of compressors, mixers, pumps, and other rotating equipment. Direct replacements are available in standard inch and metric sizes and materials for major brands, including

With four (4) configuration options all incorporating additional engineered features such as reverse pressure capability, non-clogging multi-springs, rugged seal drive operation, and hydraulically balanced faces, the RKCS single and RKCD dual seals successfully contend with the industry’s toughest slurry challenges.

Flexaseal provides component seals for a wide range of challenging applications where cartridge seals are impractical or incompatible with current rotating equipment. This may be due to equipment not having a seal chamber or the seal need to be installed on the wet side of a pump. We offer a sturdy single spring component seals, externally mounted mechanical seals for extremely corrosive applications, and stationary seats (mating rings).

There is no one universal seal for all mixer applications. Every mixer, agitator, and reactor model is distinctive and engineered for a specific application. Many of these applications require seals to perform in environments that would destroy common seals due to extreme drag and shear forces, abrasive materials, or other challenges. That means successful sealing requires clearly defining the type of equipment, the product, and the sealing conditions. Flexaseal’s design and engineer team are capable of providing innovative solutions for your toughest challenges.

The mechanical seal style GFR/GFL offers a number of benefits over liquid lubricated dual seal for API plans 53 and 54. These include lower maintenance costs for the seal and support system since there is no barrier fluid to fill and the ability to retain 100% product purity through the use of nitrogen as a lubricant.

The resultant gas film pressure provides an opening force slightly greater than the net closing forces, which cause the faces to separate and not contact.

Simple support system – utilizes API 682 Plan 74 instead of more complex Plans 53 or 54, lowering the cost of operation and maintenance of the seal support system

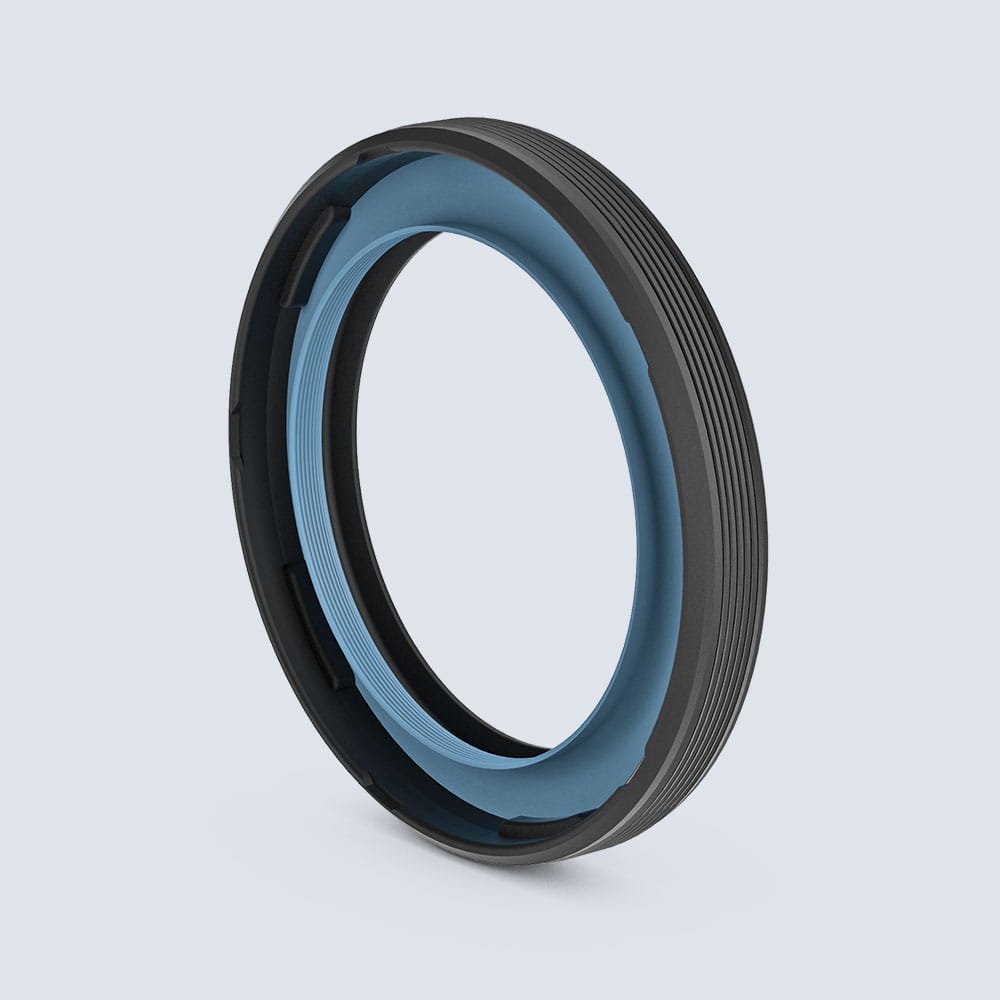

Viscous substances such as syrups, tars, thick oils, resins, and glues prove to be challenging for most mechanical seals. Lip seal designs have been the go-to option for these processes that have centipoise values well above the normal range for seal face operation. The MLC3 cartridge seal achieves optimum pumping rates at lower speeds with fewer sealing issues than products currently in the field and requires virtually no seal support system.

Machined lip seals with deflected lip geometry ensures reliable sealing while producing a smaller footprint compared to competitor designs. This smaller footprint reduces parasitic torque and heat generation.

Single Lip Seal with anti-rotation ring and integrated back up ring: Energized front lip prevents leakage when transitioning between high viscosity and high fluidity processes. Anti-rotation rings statically seal even under normal temperature cycling. The integral back up ring provides added lip support under higher pressures and potential pressure spikes.

Double Lip Seal with anti-rotation ring: The PTFE-ML compound is formulated with a lower coefficient of friction, which coupled with the enhanced heat dissipation leads to lower under-lip temperatures. Lower temps = lower seal and sleeve surface wear.

Lantern Ring: Multifunctional PTFE ring provides additional bearing support as well as even dispersion of lubricant or barrier/buffer fluid around the lip seals.

Energized O-ring front lip tolerates lower speeds and higher shaft runout. This design increases sealing viability with certain emulsifiers and fluid viscosity transitioning such as CIP applications.

Sleeve: Sintered Silicon Carbide sleeve for durable wear and sealing surface. Inboard and outboard sleeve O-rings dampen vibration and aid in easy removal and repair.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A.W. Chesterton® is a manufacturer of industrial fluid sealing and maintenance products including hydraulic seals, pneumatic seals, mechanical seals and packing, oil seals, o-ring seals, metric seals, lip seals and many other products. We are ISO 9001/14001 and MRP II Class A certified.

AccroSeal® is committed to manufacturing high quality seals to your design at competitive prices. The AccroSeal® technical sales team works directly with your engineering department to solve the most difficult sealing applications. Our sealing product portfolio includes wipers, lip seals, o-rings, piston rings, v-rings, and more produced from our exclusive Accrolon® engineered compounds.

American High Performance Seals Inc. designs and manufactures hydraulic seals, rotary shaft seals, oil seals, gaskets and other high performance rubber and plastic parts. AHP Seals designs and manufactures the most durable seals available and delivers them within 1-4 days.

Since 1981, American Seal Supply Co. has been distributing top-quality fluid seals and packing to its varied customer base. Among our product offerings are oil seals, rubber seals, o-ring seals, metric seals, Teflon® seals and lip seals. We also supply hard-to-find and custom-made seals.

American Seal & Packing is a leading manufacturer & distributor of mechanical seals, Grafoil, gasket material, cut gaskets and quality o-rings. We are constantly working to provide innovative solutions to mechanical seal problems. With our wide selection of products we"re finding better ways to serve our customers all the time. Contact our expert staff for a quote to meet your needs.

Appleton Packing and Gasket was born out of the need for better service. Among the many products we offer are mechanical seals, oil seals, gaskets, mechanical packings and o-rings. We attribute our success to the trust placed in us by our customers. Our continuing goal is to offer outstanding quality products at competitive pricing, in a manner which will best satisfy customer needs.

Beacon Gasket & Seals Co. is fully tooled to cut your requirements from compressed non-asbestos, gylon, gore-tex, flexible graphite, teflon, silicone, red rubber and neoprene rotary seals and other hydraulic sealing systems. Specializing in MTBF Solutions and representing the best manufacturers in the industry, we are excited about our expanding product offerings and the opportunity to serve you.

CoorsTek provides custom engineering, materials expertise, operational excellence and rapid execution to make our world measurably better! Technical ceramic, engineering plastic and specialized metal components help us build tomorrow’s technology. CoorsTek hydraulic seals offer extreme-temperature, high-pressure, chemically inert, static and dynamic seals for the most demanding applications.

CW Marsh offers you the best of both worlds: the toughest, most versatile natural material available for sealings and the benefits of a century of technological advancements and product innovation. CW Marsh produces leather vee packings, cups, u-packings, flanges, and back-up washers, all manufactured and backed with the same old-world dedication to quality, service and dependability.

At D&D Engineered Products Inc. we manufacture top of the line hydraulic seals, gaskets, various o-rings, high temperature tapes, compression packings, and much more. We promise to cater our product to any needs you may have, such to ensure your satisfaction. If you would like more information please give us a call.

East Texas Seals, Inc. is a distributor of O"Rings and Gaskets for Parker Seal. If you need an O"Ring, Seal or Gasket, we can fulfill your needs. We have supplied the Oil Field industry with O"Rings to adequately keep their oil rigs up and running. East Texas Seals, Inc. works closely with the U.S. Government and Defense departments, shipping and storage companies and all commercial sectors.

EPM, Inc. is your one stop shop for seals, with billions of styles including rod seals, piston seals, symmetrical seals, V-Rings, wipers, rotary shaft seals, wear rings, static seals, back-up rings, o-rings, buffer rings, u-cups, oil & grease seals, cast iron piston rings and gaskets. Whether you need one or one million, EPM offers fast turnaround and great prices on seals up to 21inches or 600mm.

With an extensive customer service center for catering to customer needs, Freudenberg-NOK manufactures a number of different seals. These offerings include hydraulic seals, pneumatic seals, o-ring seals, rod seals, piston seals and pump seals.

Garlock Sealing Technologies is the global leader in high-performance fluid sealing products for the world’s processing industries. Their 12 manufacturing facilities in the U.S., Canada, Europe, Asia and Latin America collectively produce the broadest range of fluid sealing products designed specifically for industrial applications. Some products include metal gaskets, o-rings and oil seals.

Here at Gasket & Seal Fabricators, we supply die cut, lathe cut, extruded, molded and spliced gaskets of all types, sizes and shapes. We specialize in both commercial and military spec materials, including many UL, FDA and NSF recognized materials. Our in-house capabilities include various types of die cutting equipment such as punch presses, both manual and automatic roll feed, clicker presses, and beam presses. Contact us for more information!

We manufacturer high quality hydraulic seals that are ideal for a wide range of industries. Here at Global O-Ring and Seal, LLC we are a trustworthy manufacturer who is known for our ability to adhere to all of your special requests. These seals come in a number of different materials including Buna, Viton, Silicone, Teflon, Aflas and more. Please give us a call today to learn more!

Greenville Industrial Rubber & Gasket is your source for industrial rubber products and accessories. For over 35 years, we have been providing the industry with top-quality rubber products including: gaskets, conveyor belts, packing, hoses, industrial hose fittings and hydraulics. In addition to industrial rubber products, we also stock a wide selection of safety products, adhesives, and other accessories.

We are a preferred supplier to most of the leading global manufacturers of hydraulic equipment, air compressors, transmissions, hydraulic clutches, valves and shock absorbers. We manufacture hydraulic seals and pneumatic seals among other products. Let us work together to enhance your applications.

Over 100 years, Hallite Seals International has been at the cutting edge of fluid power technology, manufacturing a wide range of rod / gland, piston, and static seals, as well as support and bearing components, for technically challenging applications, from a wide range of materials which include Polytetrafluoroethylene (PTFE), Polyurethane (AU), nitrile rubbers (NBR) and Fluoro-elastomers (FKM).

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

Hi-Tech Seals is capable of either creating parts with our in-house machining department or utilizing our relationships with industry leading seal manufactures. Our sales staff works with customers to find the best solution to replicate existing or design new parts. Different manufacturing options include machining, molding and extrusion.

At HydraPak, we make replacing your hydraulic seals easy, so you can get your seal repair jobs completed quickly, saving you time money. Even the most difficult seal repair challenges can be handled by our knowledgeable staff to get your equipment. We offer expertise in products for high-tech applications, as well as the ability to source everything from o-rings to sheet goods to sealing devices.

Being a seal manufacturer and distributor, JEM Seal Co. offers mechanical seals, hydraulic seals, oil seals, rubber seals, and more. Our mining equipment industry seals are used exclusively by Hallite Mining. Our stock of piston seals, rod seals, and wipers are in stock for your specific needs.

Encapsulated O-ring manufacturer and Precision extruder M-Cor Inc. is a leading U.S. producer of high performance sealing products for extreme environments. Extruded profiles are converted into o-rings, Teflon® encapsulated o-rings, camlock gaskets, chemical transport tubing and other sealing products. With in house tooling capabilities, we are able to immediately respond to customer requests.

Martin Fluid Power distributes on a worldwide basis, hydraulic seal repair kits, o-ring seal repair kits, metric seals, Teflon® seals and a lot of other types of seals, plus gaskets and packing. Our products come in many different shapes, sizes, materials and colors to suit your specifications.

Speed is of the essence at Michael-Stephens Co. Within 24 hours of your request, we can customize nitrile oil seals for you in a variety of profiles and materials. We work with a wide range of Teflon®-filled items. We also supply hydraulic seal kits; our website lists the wide range of manufacturers we carry.

Pacific International Bearing is capable of providing solutions for all types of applications with an educated and committed staff here to service your needs. PIB offers quality seals from Chu Hung Oil Seals Industrial Company (manufactured in Taiwan). They hold ISO 9001 Quality Certificates to provide top quality oil seals. Seals come in a variety of sizes and lip designs to suit your need.

With over 175 years of accumulative sealing experience, this team has helped pioneer the development of high performance seals around the world. Our core people excel at innovative seal design, high performance materials utilization, and efficient production techniques with a Certified ISO 9001: 2000 and AS9100 Rev. Some products of ours include, rotary shaft, rod and piston seals.

We are not only technically knowledgeable about hydraulic seals, but we also have the hands-on experience to back it up. We have over 30 years of industry experience, and we can use that experience to benefit you. We have faced nearly every problem and know the right solution for most problems. We can offer both stock and custom seals to benefit you. We will always put the customer first, so contact us today!

R&B Plastics is a supplier of custom machining serving a variety of industries including electronic connectors, plastics, filters, bearings, hydraulics and valve seals. With 34 years experience, R&B Plastics provides quality products to both the U.S. Government and major aerospace companies such as Boeing Corporation.

R.T. Dygert International is one of the largest distributors located in Minneapolis, MN and an office/warehouse in Niles, IL. RT/Dygert International prides itself on its responsive, service-driven culture and its reputation for its core values of quality, honesty and integrity and committed to a process of continuous improvement. Some of the products include piston and rod seals and o-rings.

Seal Master® specializes in manufacturing custom-built inflatable seals. These products include metric seals and rubber seals available in different sizes and shapes. Our seals are used in a wide variety of applications, including valves, robotics, conveyors, gates, brake devices and actuating devices.

Established in 1979, Southwest Seal and Supply has grown to become one of the most predominant distributors of sealing, hydraulic hoses, fittings, couplings/connectors, gasketing and fluid control products in the Southwest. We offer a wide range of products including the best in selection, quality, and value-added services.

System Seals offers a complete range of industrial hydraulic seals: small or large diameter, low or high pressure, reciprocating or rotary motion, dynamic or static sealing. We carry in-stock standard sizes plus are flexible enough to cater to all sizes. Rod Seals, Piston Seals, wipers & guide elements.

The T-Bird Group is a collection of distributors and manufacturers of seals, bearings, v-packings, unified pistons, wear rings, wipers, wear strips, u-cups, and machined plastic components.

Texacone Company, Inc is a manufacturer of fabric-reinforced elastomer and urethane molded products. Texacone specializes in molded seals up to 65" diameter in solid or split from a wide variety of fabric-reinforced elastomers. High temperature materials also available. Some of our products are: v-rings, flared u cup, piston cups and flanges.

Direct replacement mechanical seals suitable for BURGMANN® BT-AR, AESSEAL® B01, JOHN-CRANE® Type-6A, FLEXIBOX® PR-DR, VULCAN® Type-18 and other usual manufacturers.

Rubber bellow mechanical seal, unbalanced, single spring, independent rotation and short length. AT metallic parts are AISI-304 and AT2 metallic parts are AISI-316. (*)

We have available seal materials to suit chlorinated water pools and seawater pool (with salts). Sealing materials, metallurgy & elastomers are not compatible for both media. (*)

Direct replacement mechanical seals suitable for BURGMANN® BT-PN, and other manufacturers. Rubber bellow mechanical seal, single-spring, and short design. Suitable for pool pumps. (*)

Direct replacement mechanical seals suitable for JOHN CRANE® type-2100, AESSEAL® B05 or B052, VULCAN® type-14 or type-142 and other usual manufacturers.

Direct replacement mechanical seals suitable for JOHN-CRANE® type-1A, BURGMANN® MG910-D1, AESSEAL® P01, VULCAN® type-10 and other usual manufacturers.

Direct replacement mechanical seals suitable for JOHN-CRANE® & SEALOL® type-675, FLEXASEAL® Style 40/42/60, AESSEAL® BSAI and other usual manufacturers.

Double mono-block mechanical seal back-to-back execution, multi-spring, and bi-directional. To avoid atmospheric emissions by pressurized barrier fluid. (API PLAN 53A), suitable for toxic, corrosive and dangerous liquids. (*)

(**) COSGRA Company don’t have any relation with the brands: JOHN-CRANE®, BURGMANN®, SEALOL®, FLEXASEAL®, AESSEAL®, FLUITEN®, VULCAN® & FLEXIBOX®. Which are mentioned for orientation only, according the right of citation.

If you are in need of an ASI©seal replacement, Gaddis Mechanical Seals is here to help. We offer replacement mechanical seals for a variety of applications, and our team is highly experienced in mechanical seal repair and installation. We understand the importance of keeping your machinery running smoothly, and we will work diligently to get your mechanical seals repaired or replaced as quickly as possible. With ASI© Mechanical Seals, you can rest assured that your mechanical seal repair needs will be handled promptly and professionally. Contact us today to learn more about our mechanical seal repair services.

In Part 2, we’re taking a closer look at the various rotary and stationary double seal arrangement options (configurations), and how to maximize their success.

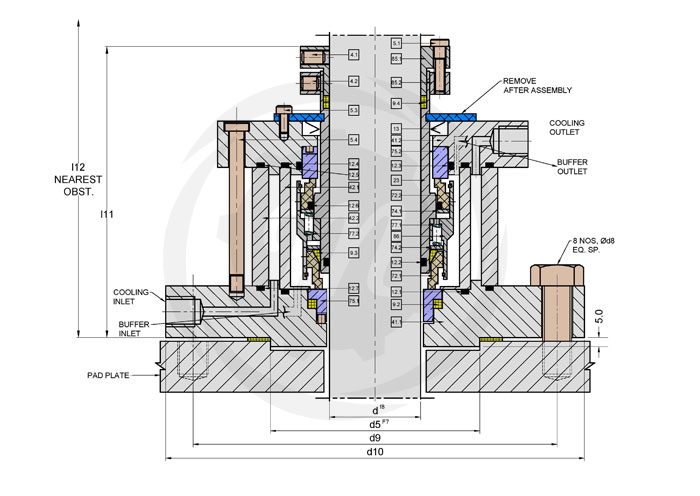

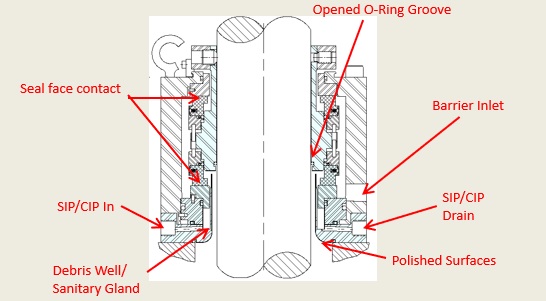

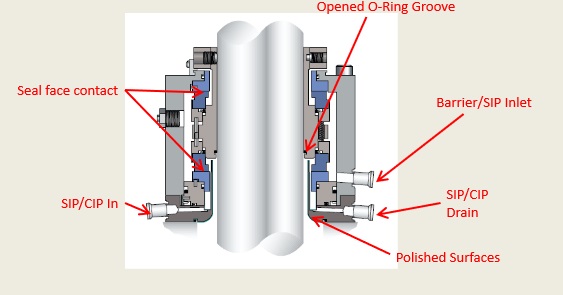

A double seal is designed with two primary seals. These seals often use two rotating seal faces and two stationary seal faces. A fluid is provided between these two seals at a lower pressure than the sealed fluid (known as buffer fluid) or at a pressure higher than the sealed fluid (known as barrier fluid). The fluid provided to the dual seal allows the seal to survive in lethal, explosive, carcinogenic, hazardous, adhesive, or extremely viscous fluids.

A conventional double seal can be designed to seal the buffer or barrier fluid on the inside or outside diameter of the seal faces. Typically, the seal designer will place a softer, narrow face against a harder, wide seal face. The design intention is to enable the softer seal face to wear, while keeping the wider hard face from wearing in service. Once the narrow seal face has been worn away, the seal has reached the end of its suitable life.

Each configuration has its own strengths which are addressed below. Ultimately, it’s best to speak with a sealing specialist who can draw on a wealth of direct experience and implement according to your organizations’ expectations for reliability and environmental compliance.

In this double seal configuration, two narrow seal faces are mounted back-to-back (opposing) to one another. This is the original concept of a dual seal —taking two component mechanical seals and placing them ‘back-to-back’ within the stuffing box. This configuration is used in most general applications.

The unbalanced back-to-back mechanical seal requires a barrier fluid pressure of 15 psig higher than the seal chamber pressure. The barrier fluid is being pressurized above the seal chamber pressure, so the outboard seal faces are carrying the greater load and should wear out or fail first. When this happens, the barrier pressure will be lost, causing the inboard faces to open. In other words – if the seal works correctly, both seals will fail at the same time. This is not very good back-up protection.

If this seal is a double balanced design, the fluid between the inboard and outboard seal faces can be higher (barrier) or lower (buffer) pressure than the seal chamber pressure. This means that if the barrier/buffer fluid is lost, both seals will remain closed and operate reliably.

In back-to-back arrangement (both unbalanced and balanced seal designs), the outboard seal faces almost always are rated for a lower pressure than the inboard seal faces. This is because the outboard seal faces are an outside seal configuration and the faces are exposed to tensile force. Ceramics are generally weaker in tension than compression, so their pressure limit is lower.

If the inboard seal fails first, the barrier fluid will leak into the process which will cause product dilution. This product dilution sometimes is not desirable for products that can not tolerate it.

This configuration occurs when two sets of seal rings are identically orientated and mounted in-series. This configuration is often referred to as the “in-series seal face arrangement” or “face-to-back.” It is commonly used in dual seals.

In this arrangement, the seals position the barrier or buffer pressure on the outside diameter of the outboard face. The pressure acts to compress the outboard seal faces. This allows a higher barrier fluid pressure.

Face-to-face seals can be used when the equipment is space constrained to accommodate a back-to-back or tandem seal arrangements. In this configuration a portion of the seal is mounted in the seal chamber and the remainder is mounted outside of the seal chamber.

For successful seal life and reliability it is very important to have the right seal arrangement along with the right barrier/buffer fluid system. In upcoming blogs, we will discuss various seal environmental control plans available for double seals and how to select the best barrier / buffer fluid for good seal life to achieve maximum reliability.

Antim Parikh is a Special OEM Projects & Applications Support Manager at A.W.CHESTERTON for mechanical seal product line. He manages the group of mechanical seal applications engineers and OEM platform products/projects.

Antim has worked for the A.W. Chesterton Company for the last six years in the Mechanical Seal product line as Lead Applications Engineer. He has provided support to all field salespeople and customers on product recommendation and troubleshooting. He has also conducted numerous mechanical seal training classes for customers and distributor’s specialists to provide assistance to training group.

Antim holds degrees in Master of Science in Mechanical Engineering (Fluid Power) from CT, USA and Bachelor of Science in Mechanical Engineering from India.

Pumping processes involving toxic or hazardous fluids that can’t risk leakage because of stringent environmental regulations require a double mechanical seal. Compared to a single mechanical seal, a double seal gives you significantly greater protection against leaks. With a double mechanical seal, you have an arrangement of two mechanical seals (a primary or inboard seal and a secondary or outboard seal) in series—back-to-back, tandem, or face-to-face. Each seal has a rotating (R) surface and a stationary (S) seal surface. These seals can be arranged in one of three patterns.

In a back-to-back arrangement, the stationary seal faces are positioned back-to-back with the rotating seal faces on the outside. The back-to-back arrangement is easy to install and used for many general pumping applications.

The tandem arrangement has the two pairs of seals mounted with the same orientation. This arrangement is preferred for toxic or hazardous applications because the outboard seal provides full pressure back-up, allowing the outboard seal to back up in the event of an inboard seal failure.

In the face-to-face arrangement, the rotating seal faces share a common stationary seal face. This arrangement is useful when equipment space is too constrained to permit back-to-back or tandem seal arrangements.

The American Petroleum Institute (API) Standard 682 classifies double mechanical seals into two configurations—pressurized and unpressurized. The pressurized arrangement has a barrier fluid delivered to the double mechanical seal by a seal support system. The barrier fluid is delivered at a higher pressure than the process fluid and must be chemically compatible with the process fluid as it will lubricate the inboard seal faces and mix with the process fluid. The unpressurized arrangement has a buffer fluid delivered to the double mechanical seal by a seal support system. The buffer fluid is delivered at a lower pressure than the process fluid.

The barrier and buffer fluids you use can be liquid or gas. They provide lubrication and help maintain the required operating temperature of the seal faces. The typical choices are water and water/glycol mixtures, low-viscosity petroleum or synthetic oils, kerosene, diesel, and nitrogen.

To gain a better understanding of the differences between the uses of barrier and buffer fluids, let’s look at two common API plans for double mechanical seals—API Plan 52 Buffer Fluid Seal Pot and API Plan 53A Barrier Fluid Seal Pot Pressurized by Nitrogen.

API Plan 52 takes buffer (unpressurized) fluid from a reservoir (seal pot), delivers it to the seal chamber, circulates it between the inboard and outboard seals using a pumping ring located driven by shaft rotation, then returns the fluid to the reservoir. In the event of an inboard seal failure, process fluid leaks into the seal chamber. When that occurs an increase in buffer fluid pressure and/or level alerts operators to the problem. The outboard seal, however, contains leakage until maintenance can replace the damaged seal.

This plan can include cooling coils in the reservoir to maintain the required buffer fluid temperature, visual or mechanical fluid level indicators, pressure and level transmitters, and connection to a collection system and buffer fluid replenishment source.

The overall design of this API plan for a double mechanical seal is relatively simple in comparison to other plans. Design decisions involving tubing size, length, geometry, type (carbon vs stainless steel), buffer fluid type, and volume of the buffer fluid reservoir are critical in maintaining the proper operating environment for the double seal. If you don’t have this expertise in-house, work with an experienced, local seal support system vendor to ensure the API Plan 52 is designed to meet your specific pumping requirements.

API Plan 53A is conceptually similar to API Plan 52 with the difference that the fluid being circulated between the double mechanical seals is under pressure. A pumping ring is used to circulate the fluid. The reservoir that contains the barrier fluid is pressurized by plant nitrogen. Reservoir pressure should be set a minimum of 20 to 25 psi (1.4 to 1.73 bar) above the maximum seal chamber pressure, allowing the barrier fluid to leak (and lubricate) across the inboard seal faces into the process fluid. For this reason, the barrier fluid must be chemically compatible with the process fluid.

Because barrier fluid is depleted as it moves across the inboard seal faces, it needs to be replenished. This can be done manually or automatically by way of a system that serves multiple pumps. API Plan 53A design options include reservoir type and volume, cooling coils, fluid level and pressure indicators, and transmitters to alert to level or pressure changes that indicate seal failure.

When you choose an API plan for a double mechanical seal, your primary decision is between a buffer or barrier plan. I’ve highlighted two of the API plans for double mechanical seals above to show the basic differences. There are multiple API plans for double mechanical seals to choose from—pressurization from bladder or piston accumulators, plant nitrogen delivered directly to the seal chamber, and custom-engineered external systems. Your choice will be determined by the process fluid and pumping conditions and the type of double mechanical seal your vendor recommends.

With this information in hand, it’s best to work with an experienced local seal support system vendor. They’ll be able to meet with you on-site to review the specifications for the pumping process, the pump, and the double mechanical seal. They’ll evaluate your existing infrastructure and its influence on seal support system design. Based on this information, they’ll then design the seal support system to meet the specific pumping requirements.

If you work with a global vendor like Swagelok, based on the design, we can quickly assemble and thoroughly test the API plan at our local facilities prior to delivery. We’re also conveniently available for follow-up consultations, on-site, remotely, or by way of a quick phone call.

For well over 50 years, Swagelok has worked closely with Northern California process industries to confidently choose the right API plans for pumping needs. Our locally based Field Engineers and certified technicians provide field verification of your seal support requirements, designs based on best practices gained from global experience.

To find out more about howSwagelok Northern California can help you choose the right API plan for double mechanical seals, as well as process and atmospheric side seals,contact our team today by calling

Morgan holds a B.S. in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682). He is also well-versed in B31.3 Process Piping Code. Before joining Swagelok Northern California, he was a Manufacturing Engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

ISO 9001:2015 certified. Custom manufacturer of abrasion, acid, alcohol, alkali, oxidation, ozone, radiation, sunlight and water resistant rubber and plastic O-ring seals. Made from EPDM, butyl, fluoroelastomer, fluorosilicone, natural rubber, neoprene, nitrile, NBR, HNBR, SBR, silicone, high tear strength silicone, TPR, TPU, TPE, thermoplastics and polyurethane. Capabilities include injection molding, die cutting and prototyping. Assembly and PTFE coating additional services are also provided. Serves the aerospace, automotive, commercial, construction, dental, electrical, food handling, laboratory, marine, mining, municipal, oil and gas, recreational, retail, transportation and wastewater industries. Meets ASTM and SAE standards. Six Sigma certified. JIT delivery. Overseas sourcing options also offered.

The PS-SEAL® product line stands for reliable sealing of rotating shafts at high circumferential speed, high pressure and extreme temperatures. Abrasive media is sealed as well as aggressive media. Radial shaft seals typically do not perform well under these conditions as their seal lips are made of elastomeric materials. PS-SEALs are used in many different applications and can also be an alternative to mechanical seals and braided packings. The product line PS-SEAL® offers cost-effective and practical solutions to a wide range of applications. The portfolio of Garlock shaft seals offers standardized as well as special customized seals. The high performance seals PS-SEAL® work with a sealing lip made of GYLON® or other modified PTFEs. Garlock produces GYLON® in a process that has been specially developed.

8613371530291

8613371530291