balanced vs unbalanced mechanical seal pricelist

A. A balanced seal is a mechanical seal configuration in which the fluid closing forces on the seal faces have been modified through seal design. Seal balance, or balance ratio of a mechanical seal, is simply the ratio of two geometric areas. These areas are called the closing area (Ac) and the opening area (Ao). The closing area is different when pressure is on the outer diameter of the seal than when the pressure is on the inner diameter. When the pressure is on the outer diameter, the closing area is from the seal face outer diameter down to the lowest point, where the secondary seal rests against the shaft or sleeve. When the pressure is on the inner diameter, the closing area is from the highest point, where the secondary seal rests against the primary ring counter bore, down to the sleeve diameter.

The opening force is always the area of the sealing faces. The balance ratio is then Ac/Ao. A seal with a balance ratio less than 100 percent is called a balanced seal. A seal with a balance ratio greater than 100 percent is called an unbalanced seal. Most balanced seals have a balance ratio between 60 and 90 percent. Most unbalanced seals have a balance ratio between 110 and 160 percent.

Pusher seals normally require a step in the shaft/sleeve or internal hardware to achieve a balanced design. Metal bellows seals do not require this step. The balance diameter, or mean effective diameter (MED), of metal bellows seals is located near the middle of the convolution. When pressure is applied to the outer diameter of the seal, the MED shifts downward, lowering seal balance. The opposite is true when the seal is subject to internal pressure. The rate of change in the balance depends on the face width and the bellows leaflet design.

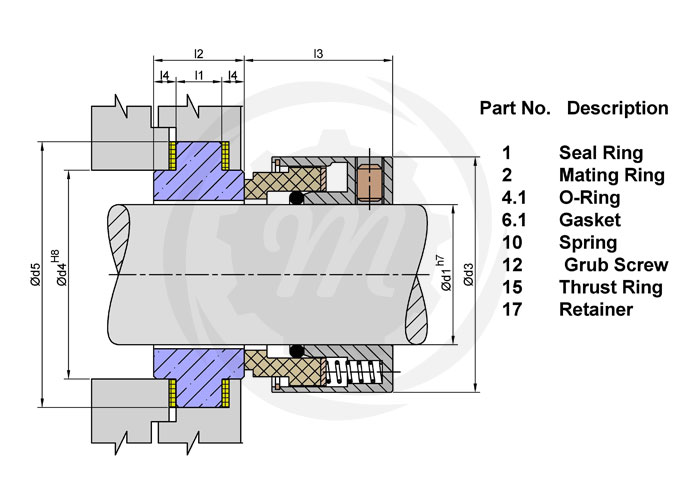

Pusher seals can be designed to withstand pressure from either direction. This is accomplished by trapping the O-ring between two diameters as shown in Figure 4.1. The cavity must be long enough to allow the O-ring to move, allowing pressure to act on the primary ring. These designs allow the seal to withstand system upsets.

Mechanical seals have classified several types. In this article, we will see the basic classification of mechanical seal that is the “Mechanical Seal – Balanced and Unbalanced Type”.

The pressure in any stuffing box acts equally in all directions and forces the primary ring against the mating ring. The force (F) acts only on the diameter (Do) across the seal face, it acts as a closing force on the seal faces.

To relieve the force at the seal faces, the diameter of the shoulder on a sleeve or the seal hardware is decreased. Thereby the seal face pressure can be lowered. This is called seal balancing.

A seal without a shoulder in the design is an unbalanced seal. A balanced seal is designed to operate with a shoulder. Only metal bellows seal is a balanced seal that does not require a shoulder.

Virtually all mechanical seals are available in either unbalanced ( Ref. Figure) or balanced versions. The term “unbalanced” is used when the stuffing box pressure times the area exposed to the pumped fluid (closing force), acting to close the seal faces, is greater than the average pressure between the seal faces (pressure gradient)times the area of contact between the faces. In other words, unbalanced mechanical seal exhibit net hydraulic closing forces which are generated by the actual pressures to be sealed.

For example, if there were a stuffing box pressure of 50 psig (3.4barg), the spring load would have to be added. Hence, the “face load” or closing force on the faces would be even higher than 50 psig times the face area. This, of course, limits the pressure sealing capacity of an unbalanced seal.

Unbalanced seals are often more stable than balanced seals when subjected to vibration, misalignment and cavitation. The disadvantage is their relatively low-pressure limit. If the closing force exerted on the seal faces exceeds the pressure limit, the lubricating film between the faces is squeezed out and the highly loaded dry running seal fails.

The balanced seal has the same opening (face) area as the unbalanced seal, but the closing area has been reduced about the face area. Because force equals pressure times area, reducing the closing area reduces the closing force. Consequently, less heat is generated and the seal generally has a longer life.

To simplify the explanation, balancing mechanical seal involves a small design change which reduces the hydraulic forces acting to close the seal faces. Balanced seals have higher pressure limits, lower seal face loading, and generate less heat. They are better able to handle liquids with low lubricity and high vapour pressures. This would include light hydrocarbons. Because seal designs vary from manufacturer to manufacturer and from application to application, it is not possible to standardize on either configurations or materials that cover all conceivable services. Available basic designs have variations that were often developed to meet specific applications. Each seal design has its own strengths and weaknesses.

Nowadays most of the seal manufactures are used only balanced mechanical seal. In some special mechanical seals (ie., engineered seals) are designed with unbalanced mechanical seal.

Balanced mechanical seals are more preferred than unbalanced mechanical seals. Seal balance can range from 0.65 to 1.35, depending on operating conditions.

Optimal performance is attained by selecting from three standard seal face balances; the BXQ seal is high balanced for flashing hydrocarbon applications

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• ...

Cartridge seals for critical, toxic and emission control applications, where single seals are notaccepted;• Built-in pumping device improves barrier fl uid cooling;• Springs locations prevents contact ...

... corrosion;• Monolithic rotating unit virtually eliminates clogging in the seal area;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge ...

Single mechanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The MTM180 Series represents the mechanical seal ...

Single mechanical seal, balanced, external, independent of the direction of rotation with multi-spring configuration. The MTM190 Series represents the mechanical seal ...

Single echanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The springs are never in contact with the fluid. The MTM190 Series represents the mechanical ...

... dual unpressurized arrangement, without outboard seals also incorporating the same non-pusher technology, the seal can be configured to suit both the operator and pipeline needs.

Flexible seal, suitable for the narrower seal housing and suitingcommon European seal housing standards. STK A1 has a longworking length and is fitted with a seal head ...

The balance of a seal refers to the distribution of load across the seal faces. If there is too much load on the seal faces, it can lead to a leakage of fluids from within the seal which essentially renders the seal useless. Moreover, the liquid film in between the seal rings runs the risk of vaporising.

This can result in higher wear and tear off the seal, shortening its life span. Seal balancing is therefore necessary to avoid disasters and to also elongate the life of a seal.

A balanced seal has a higher pressure limit. This means that they have a larger capacity for pressure and they also produce less heat. They can handle liquids that have a low lubricity better than unbalanced seals.

On the other hand, unbalanced seals are typically much more stable than their balanced counterparts as far as vibration, cavitation and misalignment are concerned.

The only major drawback that an unbalanced seal presents is a low pressure limit. If they are put under even slightly more pressure than they can take, the liquid film will quickly vaporise and will cause the running seal to run dry and thus fail.

Robco"s Mechanical Seal Division manufactures, distributes and customizes mechanical seals, as well as being a repair facility for virtually any mechanical seal brand, utilizing the latest technology and state-of-the-art manufacturing equipment. Robco’s seal designs are customer driven to provide the best possible solutions to sealing problems.

Robco will repair: Borg-Warner, Chesterton, John Crane, Durametallic, EG&G, Flex-A-seal, Flexibox, Flowserve, Garlock, Pac-Seal, U.S. Seal, and virtually any other brand.

Mechanical seals are used everywhere liquids and gases are transferred through rotating equipment. Robco’s seals and packing are the first step to efficiently control leakage and reduce operation costs.

The ideal seal for alumina applications, specifically designed to operate in this challenging environment, the Robco DRYTEK seal will provide maintenance-free operation at least five to twenty times longer than your average alumina screw conveyor seal.

•Better abrasion resistance •Dry-seal, no lubricant required •Sealing components rotate with the shaft, maintaining an airtight seal •Adapts to axial and radial movements of the shaft •Available in C.E.M.A. and METRIC standard shaft sizes.

Double balanced cartridge seal for pumps, agitators and mixers that prevents the leakage of toxic, hazardous, corrosive and costly fluids to the atmosphere.

Robco uses specialized equipment to ensure that rebuilt seals operate equal to brand new, with mechanical seal manufacturing and rebuilding experience dating back to 1978, servicing petrochemical, pulp & paper, steel, mining, waste water, utilities, boilers and more...

We rebuild all major brands at competitive prices with premium quality parts that meet all OEM specifications. We offer a free estimate and failure analysis. Rebuild outlay normally varies from a third to half the cost of a new seal, so lower your inventory value and reduce your overall operations cost.

By centralizing your repairs: Robco rebuilds all major brands in one location, simply complete our Seal Repair Form to be enclosed along with your seal shipment and we’ll take care of the rest, returning your seal looking and working like new. Robco tags all rebuilt seals for future rebuild identification, tracking seal life and failure patterns.

The mechanical seals markers are defined as a leak control device, which is found in circulating materials such as pumps and mixtures to prevent leakage of liquids and gases. Mechanical signals help to mark the rotating part of the shaft against the vertical part of the pump housing. Mechanical markers are widely used by various industries such as oil and gas, the chemical industry, and others.

The mechanical seal market is segmented on the basis of type, product type, industry, and region. As types of mechanical seal market arecartridge seals, unbalanced and balanced seals, non-pusher and pusher, conventional seals and others. Based on industry, it is categorized into metals & mining, oil & gas, aerospace, energy and power, food & beverage, marine, manufacturing & construction and others. The oil and gas industry became the largest market share in the mechanical seals industry and is expected to see significant growth during the coming years. In addition, the segment of the wastewater and water sector is believed to be growing rapidly by the coming years. On the basis of Product type, it is divided as Cartridge Seals, Split seals, Dry Gas Seal, Cassette Seals, Slurry Seals, Bellows Seals, Component Seals, Mixer Seals, Others. Based on segment region it is divided as North America, Asia-Pacific, LAMEA, Europe. The Asia-Pacific region is expected to continue its dominance over the forecast period. The region is a lucrative market worldwide due to emerging economies such as India and China.

COVID-19 Impact analysisCOVID-19 virus has closed the manufacturing of many products in the Mechanical Seals market accolade to the lockdown in worldwide. This has hampered the growth of Mechanical Seals market from the last few months and is likely to continue during 2021.

COVID-19 has so far impacted the sales of Mechanical Seals Market in the first 4 month of 2021 and is expected to create a negative effect on the growth of market all over the year.

By 2020, COVID-19 impact negatively on the Mechanical Seals Market, leading to a decline in shipping of Mechanical Seals products as well as revenue received from them. Due to which, the decline in market growth showed in the first half of 2020.

Industrial Seals companies rely heavily on the supply of raw materials, components and materials from different countries around the world. With so many governments limiting exports, manufacturers had to stop production due to a shortage of raw materials.

The CORONA epidemic has had a devastating effect on Mechanical Seals Market prices. India, US, China, and Japan have been hit hard by the epidemic, are playing a key role in the production of the Mechanical Seals Products that are being promoted worldwide. The agricultural, industrial, printing presses, conveyors, automobiles, motorcycles, telephone and bicycles which is expected to continue for a brief period due to land recession.

The dominant factors in the steady development of the mechanical seal market is the growing need for heat-resistant, strong, and thermal signals that allow for rapid power development between the two circular moving elements. Temperature is a key factor in this process which will cause heat-resistant seals during the weather. Factors such as increased productivity and providing full performance are reason of increasing demand in the production sector will also boost industrial seal market growth in the off-season. In addition, the growing trend in custom-made industrial brands going to open new opportunities for earning money during the monsoon season.

The mechanical seal market has shown significant growth over the time and is hoped to develop over time. The growth of development in industries in the emerging economy are hoped to trigger additional development and investment policies. The several types of seals available on the market offer cartoon markers, balanced and non-proportional markers, non-pusher and pusher markers, and common symbols that contribute to the growth of the marking market in developing countries.

The growth of the machinery industry is draining the entire market share, due to the use of power tools in compressors for sealing, centrifugal pumps and separating liquids in rotating barrels. Therefore, the increase in market need for mechanical seals in various industries are expected to drive market development soon. In addition, high market development is expected to be confirmed in Asia-Pacific, and after that North America.

Market TrendsIn May 2021, AESSEAL plc., They goes beyond Absolute Zero. AESSEAL seeks independent confirmation of its indirect release of Scope 3, as well as the measuring effect of the unauthorized release of the use of company products in the major industry. A separate test was performed on the Scope 3 release, which included indirect deductions from the company’s value chain such as business trips, as well as avoidances that were included in one of the company’s leading environmental programs.

A five-year partnership with Shell done by Flowserve Corporation, with the aim of providing standard services for their FLNG facility. A business partnership with Al-Ahed Trading and Contracting Co by John Crane with the aim of aiding service providers to achieve the first set of dry gas seals.

Key Benefits of the ReportThis study presents the analytical depiction of the Mechanical Seals Market along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the Mechanical Seals Market share.

The report provides a detailed Mechanical Seals Market analysis based on competitive intensity and how the competition will take shape in coming years.

Key Market Players A.W. Chesterton Company, EagleBurgmann, AESSEAL plc., Flowserve Corporation, Flex-A-Seal, Inc., John Crane, Avon Seals Private Limited, TREM Engineering SC, PPC Mechanical Seals, Meccanotecnica Umbra S.p.A.

... a dual pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact ...

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge easy to ...

The product is constructed with the combination of materials such as graphite, silicon carbide, tungsten carbide and aluminum oxide. Then, a secondary sealing of materials are acrylonitrile rubber, fluorine and silicon ...

... carbide, tungsten carbide and Aluminum oxide, with the secondary sealing. The secondary sealings consist of Acrylonitrile rubber, Fluorine rubber, Ethylene propylene rubber, PTFE, metal component and ...

This seal withstands -45℃-200℃ temperature, over 2.0Mpa pressure, in 15m/s speed or over. The series V1,Q1,Q2,U2,U1 are stationary, A,B,Q1,Q2,U2 are rotary and V,P and E are secondary seal. It has a standard ...

The MTM10-11 is a conical spring mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This unbalanced mechanical seal ...

... manufactured by MICROTEM, is a conical spring mechanical seal that can compensate positioning errors and withstand stresses created by vibrations. The contact surface can be made with silicon carbide, ...

Single mechanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The MTM180 Series represents the mechanical seal with the ...

Aura™ reduces operational and transactional costs using a patented polymeric sealing device. Aura reduces leakage rates by up to 15 percent, lowering the total cost of operation while protecting the environment. An enhanced rotor design ...

The AESSEAL® API Type A, B and C single-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application ...

Cartridge Seals by CinchSeal are customized mechanical seals for rotary air locks in bulk handling equipment. They are designed to replace lip and packing seals in screw ...

Our Mechanical seal model CR is widely used for GRUNDFOS-PUMP . The normal material combination include SIC/SIC/viton/machined ss304,TC/TC/VITON/machined ss304 and SIC/ SIC/VITON/SS304. ...

Mechanical seals with area ratio B≥1 are called unbalanced mechanical seals; mechanical seals with area ratio B<1 are called balanced mechanical seals.

The area ratio is equal to the ratio of the effective area of the sealing fluid A2 (internal type) or A1 (external type) to the sealing surface area Af, namely

For non-balanced mechanical seals with a sealing fluid area larger than the sealing surface area, the force on the sealing end surface increases as the pressure of the sealing fluid increases, so it is only suitable for low pressure.

In the balanced mechanical seal, the force on the sealing end changes little with the pressure of the sealing fluid, so it is suitable for high pressure.

Hot Tags: fs 35 flygt pump cartridge seal, China, suppliers, manufacturers, factory, customized, buy, quality, pricelist, quotation, low price, made in China, Flygt pump seals types, 58U 59U Mechanical Seal, ffkm kalrez, metal bellows seals, S32D Cartridge Seals, Type 2 Mechanical Seal

Pump SealOur range of products include johnson pump seal, boiler feed pump seal, water pump seal, stork pump open and close type seals, mechanical pump seal and grundfos pump seal.

Being amongst the leading names of the industry, we are highly occupied in offering a superb quality array of Stork Pump Open And Close Type Seals. The provided products are procured from some of the genuine and reliable vendors of the industry who are widely reckoned for their quality.

Many early mechanical seal designs placed the spring inside the process fluid. Most products (process fluids) that are sealed are not very clean. When the spring mechanism of the mechanical seal is immersed in this unclean fluid, dirt collects between the springs. This situation eventually impacts the spring’s ability to respond to movements and vibrations, and the ability to keep the seal faces closed. Over time, clogging of the springs will cause premature seal failure.

The ideal design offers springs on the atmospheric side of the mechanical seals. The springs will be protected from the process fluid and their ability to work will not be impeded.

The pressure from both the seal springs (Ps) and the hydraulic pressure of the liquid in the pump (Pp) provide a compression force that keeps the seal faces closed. Balanced seals reduce the seal ring area (Ah) on which the hydraulic pressure of the liquid in the pump (Pp) acts.

By reducing the area, the net closing force is reduced. This allows for better lubrication that results in lower heat generation, face wear, and power consumption. Balanced seals typically have higher pressure ratings than unbalanced seals.

Mechanical seals can be designed with inserted seal faces or with monolithic seal faces. In both cases, the sacrificial seal face is often made from carbon/graphite. This material offers good running properties but is relatively weaker from a mechanical standpoint than other options. Inserted face designs use a metal rotary holder to transmit the shaft torque to the seal face.

The disadvantage of this inserted face design is that the face and holder material have different coefficients of thermal expansion. This changes the net interference force between both parts when they are exposed to heat from the process fluid or face friction. The seal face deforms, which results in leakage and accelerated wear.

More modern seals are equipped with monolithic seal faces that are made out of only the seal face material itself. The torque transmission is applied directly to the seal face. This is possible if the geometry of the seal face is designed in a particular shape to give it the strength to handle the torque through its geometric design. These monolithic seal face designs have been made possible through the use of Finite Element Analysis (computer modeling).

Monolithic seal faces provide a more stable fluid film between the faces, and they do not deform in operation compared to inserted faces (or to a much lesser degree). Therefore, they are more commonly used nowadays when reliability and low emissions are vital.

All mechanical seal designs have at least one secondary seal that interacts with the dynamic movement of theflexible mounted face. This secondary seal moves with the springs to keep the seal faces closed and is defined as thedynamic secondary seal. During operation of a rotary design, springs will keep the seal faces closed. They adjust with each rotation for any misalignment from installation and parts tolerances. As the springs compensate, the dynamic secondary seal moves back and forth, twice per revolution. This rapid movement prevents the protective chrome oxide layer (the layer that protects the metal) from forming. Erosion of this unprotected area under the dynamic secondary seal will cause a groove to develop. Eventually this groove becomes so deep that O-Ring compression is lost and the seal leaks. In most cases, fretted shafts must be replaced to achieve an effective seal.

With rotary mechanical seals, it is important that the stuffing box face is perpendicular to the shaft for the faces to stay closed. There will always be some resulting misalignment from installation and parts tolerances. The springs must adjust with each rotation to keep the seal faces closed. This adjustment becomes more difficult at higher speeds.

In contrast, a stationary seal is a mechanical seal designed in such a way that the springs do not rotate with the pump shaft; they remain stationary. Because the springs do not rotate, they are unaffected by rotational speed. The springs do not need to correct or adjust with each rotation; they adjust for misalignment only once when installed.

Rotary seals are simple in design which makes them inexpensive. They are suitable for lower speeds only. Stationary seals are more complicated to design but are suitable for all speed ranges. Because of design complexity, stationary seals are more commonly configured as cartridge seals rather than component seals.

Marco Hanzon is Vice President of Global Marketing for A.W. Chesterton Company. He has been an active member and past chairman of the Mechanical Seal Committee of the European Sealing Association. Marco"s experience includes working as an In-Field Support Engineer for mechanical seals.

The balance ratio of a mechanical seal is an area ratio and is related to the seal face load. Balance ratio is defined as the ratio of the closing area to the opening area. Seals with a balance ratio > 1 are "unbalanced"; ratios of < 1 are considered "balanced". Seals are balanced to decrease friction and wear, so you will usually move to a balanced seal at pressures of 250 psid and above (although you can use them at lower pressures as well). Unbalanced seals will be used up to 250 psid. The theory becomes more complex when you talk about metal bellows style mechanical seals; in those designs the balance ratio will increase at higher pressures primarily due to the bellows plate geometry. Visually if you were to look at the primary face of an unbalanced pusher style seal vs. a balanced pusher style seal you would notice a "step" in the face geometry (reducing the closing area and changing the balance ratio).

In theory, the lower the balance ratio, the lower the fluid film temperature, the longer the seal life. In practice, leakage control can sometimes be sacrificed and the faces may become unstable depending on if the fluid is volatile (vaporizing), or if any other face distortions occur. In general, review of the application with your seal vendor is always recommended. If you are adhering to API 682; then balanced seals are your only options due to the nature of the services. The attached is a very rough representation of what I just said. It depicts a single set of seal faces pressurized from the OD: the balance ratio calculations will become more complicated when you discuss OD vs. ID pressurizations particularly in dual pressurized seals. Hope this helps.

8613371530291

8613371530291