bfp mechanical seal free sample

3. It has strong heavy wind resistance. Impact modifier and stabilizer have been added to its material and structure to guarantee this capacity. Equipped with professional operation system, Lepu seal"s quality is ensured

John crane mechanical seal type 502 is one of the best-performing elastomeric bellows seals available. Working well for general service and provideing excellent performance in a wide range of hot water and mild chemical liquid. It is specifically designed for confined spaces and limited glands lengths.

the Type 502 mechanical seal is widely recognized as the industry"s workhorse., this mechanical seal is ideal for use in pumps, mixers, blenders, agitators, air compressors, blowers, fans and other rotary shaft equipment.

John crane mechanical seal 502 is also a featured seal item in our factory, we do offer high quality with very nice price for our professional mechanical seal clients in the past years.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

A dry gas seal is a revolutionary way of sealing machines and protecting them from dust, moisture and other contaminants. A dry gas seal is a sealing device that uses pressurized gas to keep two surfaces from touching. The most common type of dry gas seal is the O-ring, which is used in many applications, including mechanical seals, piston rings, and gaskets. Dry gas seals are also used in many other industries, such as the food and beverage industry, where they are used to seal containers and prevent contamination. This type of seal not only helps to keep the machine running with maximum efficiency but also significantly reduce downtime, making it cost-effective in the long run. In this article, we"ll explore what a dry gas seal is, how it works and why you should consider using it for your machinery. By understanding the benefits of a dry gas seal and its uses, you can make an informed decision about the best sealing system for your needs. How does a dry gas seal work?Dry gas seals work by using a series of labyrinths to separate the high pressure seal gas from the atmosphere. The labyrinths are formed by a series of grooves and ridges on the surface of the seal ring. The seal ring is rotated at high speed, causing the gas to flow through the labyrinths. The gas is then forced through an aperture in the center of the seal ring, where it escapes into the atmosphere. What is a dry gas seal used for?Dry gas seals are used on rotating equipment to help minimize the leakage of high pressure gases from the inside of the machinery. This helps to reduce maintenance costs and improve safety. Dry gas seals are commonly used in applications such as pumps, compressors, turbines, and blowers. Advantages of a dry gas sealThere are many advantages of a dry gas mechanical seal. One advantage is that they are much simpler in design than other types of seals, making them more reliable and easier to maintain. Additionally, dry gas seals do not require the use of any lubricating fluids, which can leak or evaporate over time. This makes them more environmentally friendly and cost-effective in the long run. Finally, dry gas seals have a much longer lifespan than other types of seals, meaning that they need to be replaced less often.Disadvantages of a dry gas sealThere are several disadvantages of dry gas seals, including: - they can be expensive to purchase and install- they require careful maintenance and regular inspection- they can be susceptible to wear and tear- they can leak if not maintained properlyHow to choose the right dry gas seal for your applicationThere are a few key factors to consider when choosing the right dry gas mechanical seal for your application. The most important factor is the type of fluid being sealed. Gas seals are designed to seal either liquids or gases, but not both. Make sure to choose a gas seal that is compatible with the fluid you are sealing.Another important factor to consider is the pressure of the fluid being sealed. Gas seals are rated for different maximum pressures, so make sure to choose one that can handle the pressure of your application.Finally, take into account the size and shape of the sealing surfaces. Gas seals come in a variety of sizes and shapes to fit different applications, so make sure to choose one that will fit your needs.ConclusionDry gas seals are an extremely important component for many industrial operations, and their ability to prevent leaks has made them invaluable in a variety of applications. Understanding the basics of how dry gas mechanical seal work and how they can be used effectively is helpful when considering the various options available for any specific application. With the right choice, dry gas seals can provide reliable, leak-free performance which will save time, money and resources while ensuring safety and reliability. Lepu dry gas seal manufacturer provides best quality flowserve dry gas seal and dry gas seal. Welcome to contact us!

A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.

When sealing a centrifugal pump, the challenge is to allow a rotating shaft to enter the ‘wet’ area of the pump, without allowing large volumes of pressurized fluid to escape.

To address this challenge there needs to be a seal between the shaft and the pump housing that can contain the pressure of the process being pumped and withstand the friction caused by the shaft rotating.

Before examining how mechanical seals function it is important to understand other methods of forming this seal. One such method still widely used is Gland Packing.

The stationary part of the seal is fitted to the pump housing with a static seal –this may be sealed with an o-ring or gasket clamped between the stationary part and the pump housing.

The rotary portion of the seal is sealed onto the shaft usually with an O ring. This sealing point can also be regarded as static as this part of the seal rotates with the shaft.

One part of the seal, either to static or rotary portion, is always resiliently mounted and spring loaded to accommodate any small shaft deflections, shaft movement due to bearing tolerances and out-of-perpendicular alignment due to manufacturing tolerances.

The primary seal is essentially a spring loaded vertical bearing - consisting of two extremely flat faces, one fixed, one rotating, running against each other. The seal faces are pushed together using a combination of hydraulic force from the sealed fluid and spring force from the seal design. In this way a seal is formed to prevent process leaking between the rotating (shaft) and stationary areas of the pump.

If the seal faces rotated against each other without some form of lubrication they would wear and quickly fail due to face friction and heat generation. For this reason some form of lubrication is required between the rotary and stationary seal face; this is known as the fluid film

In most mechanical seals the faces are kept lubricated by maintaining a thin film of fluid between the seal faces. This film can either come from the process fluid being pumped or from an external source.

The need for a fluid film between the faces presents a design challenge – allowing sufficient lubricant to flow between the seal faces without the seal leaking an unacceptable amount of process fluid, or allowing contaminants in between the faces that could damage the seal itself.

This is achieved by maintaining a precise gap between the faces that is large enough to allow in a small amounts of clean lubricating liquid but small enough to prevent contaminants from entering the gap between the seal faces.

The gap between the faces on a typical seal is as little as 1 micron – 75 times narrower than a human hair. Because the gap is so tiny, particles that would otherwise damage the seal faces are unable to enter, and the amount of liquid that leaks through this space is so small that it appears as vapor – around ½ a teaspoon a day on a typical application.

This micro-gap is maintained using springs and hydraulic force to push the seal faces together, while the pressure of the liquid between the faces (the fluid film) acts to push them apart.

Without the pressure pushing them apart the two seal faces would be in full contact, this is known as dry running and would lead to rapid seal failure.

Without the process pressure (and the force of the springs) pushing the faces together the seal faces would separate too far, and allow fluid to leak out.

Mechanical seal engineering focuses on increasing the longevity of the primary seal faces by ensuring a high quality of lubricating fluid, and by selecting appropriate seal face materials for the process being pumped.

When we talk about leakage we are referring to visible leakage of the seal. This is because as detailed above, a very thin fluid film holds the two seal faces apart from each other. By maintaining a micro-gap a leak path is created making it impossible for a mechanical seal to be totally leak free. What we can say, however, is that unlike gland packing, the amount of leakage on a mechanical seal should be so low as to be visually undetectable.

Boiler feed pumps (BFPs) consist of feeding to a steam generator (e.g. boiler) a quantity of feedwater corresponding to the quantity of steam generated. Operating parameters (flow, head, temperature) of boiler feed water are calculated by a boiler designer.

Today, almost all BFPs are centrifugal pumps. The construction of BFPs in respect to shaft power, material, pump types and drive are governed by the developments which have taken place in power technology. The trend in fossil fuel power stations is continuously towards larger power block units.

Until 1950, the average discharge pressure of BFPs was in the 200 bar region. By 1955, it had risen to 400 bar. Mass flows were in the region of 350 tons per hour (t/h) in 1950 and have risen to 2,500 t/h (4,000 t/h) in conventional power plants. BFPs operate at temperatures of 160 C to 180 C, and in exceptional cases,

BFPs were constructed of unalloyed steels through the 1950s. Since then, 13% to 14% have pivoted to chrome steel (A743 Gr. CA6NM). This change in materials was made necessary by the introduction of new feedwater treatment processes. The development of high strength, corrosion-resistant chrome steels with emergency running characteristics paved the way for the current BFP with speeds of 5,000 to 6,000 rotations per minute (rpm). The flow rate of BFPs rose with the rise of power block outputs. Today’s full-load BFPs for traditional 750 megawatt (MW) power trains are constructed with four to five stages, with stage pressure up to 80 bar.

Electric motors (asynchronous motors) are used to drive the feed pumps. Speed adjustment of an electrically driven BFP is possible to achieve by several means, including using fluid coupling, variable frequency drive (VFD) into motor and gearboxes. If a plant has abundant steam available, a steam turbine can also be used for the driver unit. In several cases, condensing turbines running at 5,000 to 6,000 rpm are used. However, using condensate-type steam turbine increases the requirement of equipment into the train. It is essential to use a heat exchanger, condensate extraction pump or the like for effective use of the unit.

If a BFP is needed for high pressure and high rpm, a booster pump is required. In such a case, adequate net positive suction head available (NPSHa) is difficult to achieve and the booster pump fulfills the requirement. For reducing the net positive suction head required (NPSHr), it is possible to select the pumps making first stage (suction) as a double suction. NPSH is most significant at the suction stage only.

There are two types of construction mostly used for BFP application. One is a multistage barrel type pump, which is defined as a between bearings (BB) 5 type pump per American Petroleum Institute (API) 610. The other is a ring section multistage pump which is defined as a BB4 type pump. However, a ring section pump does not meet the criteria of

The pump casings of BFPs must be considered from two points of view: the wall thickness must be sustainable on one side to satisfy the pressure loading requirement and the other side needs to adapt itself to the temporary temperature variation which arises.

Barrel casings are usually made of ductile forged steel, and all surfaces in contact with the feed water are coated with the austenitic material by cladding process. To weld the pump casing into the pipeline, an intermediate piece made compatible for welding into the pipeline and the pump casing is welded onto the pump suction and discharge branches. The cover on barrel pumps are sealed by flattening a cellular metal spiral-wound gasket (sealing).

The casings of ring section pumps are constructed from cast or forged carbon steel—sometimes cast iron—depending on the application and requirement defined by the user. The sealing of each casing (stages) against one another is by metal-to-metal contact—the individual casings being clamped together axially by tie bolts between the suction and discharge pump casings. Metal-to-metal contact is one of the drawbacks of the ring section pump, as it restricts the use of the pumps in high temperature applications. Temperature shocks are absorbed by additional stresses on the tie bolts and sealing faces of the stage casings.

Water injection at a pressure situated between the suction and discharge pressures of the pump is a frequent service requirement. This is taken care of by tapping water from one of the pump stages—both in the case of barrel pumps and ring section pumps. These pressure zones are sealed off from one another by flexible spiral-wound gaskets and the flexibility and thermal shock behavior are suitably matched to one another.

BFPs are fitted with pump shafts, which have an appropriate distance between bearings and are combined with a large shaft diameter. The impellers are usually shrunk on the shaft, and consequently the static shaft sag is small. The shaft is insensitive to vibrations, and in normal running conditions, is smooth without any undesirable radial contact with the casing. The hub diameter is increased at the back of the impeller, and the impeller entry geometry is designed to keep the diameter as small as possible to reduce the axial forces which must be absorbed by the balancing device.

Additional disturbing forces can arise if pumps are operating in abnormal conditions. For example, if the pump starts to cavitate, it means the NPSH is not sufficient to run the pump smoothly. On the larger BFPs, the balancing of the axial thrust on the pump rotor is affected by means of a balancing device through which the pumped fluid flows, combined with an oil-lubricated thrust bearing. The hydraulic balancing device may comprise a balance disc with balance disc seat, or a balance piston or double piston with the associated throttling bushes. Pistons and double pistons can also be combined with a balance disc. It is important to note API 610 does not allow the use of a balancing disc, so a drum should be used. However, API 610 strictly pertains to petrochemical, oil and gas applications. In several cases, plants have prohibited the use of a balancing disc for the BFPs in typical power plants.

Radial forces arise from the weight of the rotor, mechanical out-of-balance and radial thrust. The balancing of the radial forces is affected by two oil-lubricated radial bearings and by throttling gaps by which fluid flows axially. These throttling gaps through which the fluid flows axially are located at the impeller neck, or in the case of multistage BFPs, in conventional power stations in the throttling bushes of the diffuser plates and on the balance piston. If the rotor is slightly eccentric, a centering restoring force will be generated in these gaps, and this force will be dependent on the pressure differential and on-the-gap geometry. This restoring action is usually called the Lomakin effect. It is reduced when the headwater in the gap flow is not in a purely liquid phase. The hydrostatic action of the throttling gaps in respect of mechanical stiffness can exceed the shaft stiffness. The system is tuned in a way that the critical speed of rotation always remains away from the operating speed. Hydraulic exciting forces, particularly under part load operation, can be absorbed in addition.

Soft-packed stuffing boxes, mechanical seals, floating seals and labyrinth seals can be used on BFPs for sealing purposes. The application limit of soft-packed stuffing boxes is governed by the existing possibilities for the removal of frictional heat. In the case of high duty, soft-packed stuffing boxes, there is usually a precooling of the leakage water and an ambient of the stuffing housing, shaft protection sleeve and gland. The packing material usually consists of braided Teflon twine. This shaft seal is used with success on full load feed pumps up to 150 MW power train capacity.

The small leakage of mechanical seals is emitted into the atmosphere in the vapor form at the exit. The frictional heat generated is less than in the case of soft-packed stuffing boxes. A closed-circuit cooling system is generally adopted—which is driven by a circulator device on the rotating seal ring when the pump is running and by thermosiphon action when the pump is stopped.

A floating seal can be used for high circumferential velocities and high sealing pressures. The floating seal consists of a series of short throttling rings which can be displaced radially. A stream of cold sealing water is injected into the seal to ensure that no hot water can leak out of the pump. This sealing water feed must be kept going while the pump is running under pressure. The control of the sealing condensate injection into a floating seal can be affected by differential pressure, regulation or by differential temperature regulation of the sealing condensate.

In case of high temperature application, more than 80 C, use a single acting mechanical seal with the cooler which is classified as Plan-23 as per API 682.

If BFP is switched on and off frequently, it is desirable to avoid thermal shock and warping of the casing after the pump has stopped to prevent premature internal wear at the sealing gap. In principle, the construction materials are selected in such a way that the BFP can be started up from any thermal condition. However, a physical contact between rotor and casing at locations with a close clearance cannot be avoided under certain circumstances of abnormal operation—e.g., when cavitation occurs, or during a semi-warm start, when the BFP is warped. The affected locations are the throttling gaps at the impeller inlet, the throttling bush in the diffuser and the balancing device. The matching of appropriate construction materials at these locations, consisting of corrosion-resistant chrome steels with special alloy additions ensures good emergency running conditions even at high circumferential velocities. Any high wear at close clearance gaps is always linked with a drop in efficiency.

A so-called minimum flow valve (e.g., an automatic leak-off valve, valves, and fittings), is arranged downstream of the outlet pipe if the BFP ensures that a minimum flow is always present and prevents any damage that might arise during low load operation, as a result of excessive overheating and evaporation of the contents of the pump, or as a result of cavitation at part load operation.

Essential fundamentals to emphasize for BFPs are proper pump warmup, standby warming and shaft (fixed bushing) seal drain temperature control. These characteristics have become more critical as central station plants are cycled and large feed pumps are operated with varying loads and in standby modes. Prewarming of the pump and maintaining warmup flow to an idle pump to assure dimensional thermal uniformity is essential to maintenance of internal clearances, pump efficiency and long life. This process is critical for multistage pumps to minimize thermal distortion. The distortion will cause the following potential failure modes: flashing, internal rubbing, increased wear ring clearances, pump seizure, worn seal bushing clearance and excessive leakage, loss of pump performance and efficiency, high pump vibration and worn bearings/bearing clearances.

Booster Pump Model - FA1B75 Speed – 1495 RPM Capacity – 990m3/hr. Head – 205 mtr. Direction of rotation - MDBFP set - clockwise (Viewed from driven end) TDBFP set – counter clockwise (Viewed from driven end)

Horizontal, Single Stage, Double Suction, Axial Split Casing, Radial Flow. Double Suction Impeller for minimum NPSHR. Shaft sealing by Mechanical Seals.Boiler feed pump• Model – FK 4E36• Discharge capacity – 990 m3/hr.• Head – 2050 mlc• Speed - 5465 RPM.• Operating temp. – 161.6 deg.C• Installed quantity – 3 nos. 1 no. driven by MOTOR of 10,000 Kw capacity. 2 nos. driven by 16 stage Steam turbine.• Direction of rotation - counter clockwise (Viewed from driven end)• Inters tage tap off flow – 55m3/hr.• Kicker stage flow – 150 m3/hr.Sectional View of BFPConstructional Details of BFP• Boiler Feed Pump is a four + one stage horizontal centrifugal pump of barrel design casing.• The pump internals are designed as a cartridge which can be easily removed for maintenance without disturbing the suction and discharge pipe work, or the alignment of the pump and the turbo coupling.• The rotating assembly is supported by plain white metal lined journal bearings and axially located by a double titling pad thrust bearing.• The dynamically balanced rotating assembly consists of the shaft, impellers, seal sleeves, shaft nuts, balance drum, thrust collar and the pump half coupling.• 04 nos. Inter stage tapping after 2nd stage impeller has been made for attemperation for super heater panel.• O1 no. tapping from 5th stage (called kicker stage) impeller has been made for attemperation for reheater panel.• The pump shaft is sealed at the drive end and non-drive end by Mechanical SealsBFP BARREL & CARTRIDGE

DVC GET 2013 8Thrust acting on BFPThe pressures generated by the pump exert forces on both its stationary androtating parts. The design of these parts balances some of these forces, butseparate means may be required to counterbalance other’s.

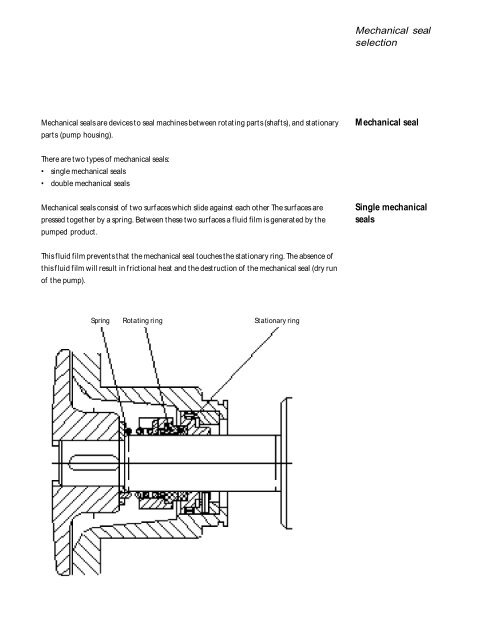

To minimize the cost of pump maintenance, Boiler feedpump is equipped with Wearing rings. These arereplaceable rings that are attached to the impeller or thepump casing to allow a small running clearance betweenthe impeller and the pump casing without causing wear ofthe actual impeller or pump casing material. Thesewearing rings are designed to be replaced periodicallyduring the life of the pump and prevent the more costlyreplacement of the impeller or the casing.Mechanical seal - make - Eagle Burgmann • It consists of two highly polished surfaces, one surface connected to the Shaft – rotating assembly and the other to the stationary part of the Pump. SW in SW out • Both the surfaces are of dissimilar materials held in continuous contact by a spring. • These wearing surfaces are perpendicular to the axis of Shaft. Pumping ring • A thin film of working fluid between these faces provides cooling & lubrication.

• For safe operation of the mechanical seal a circulation circuit is required, from the seal through a heat exchanger back to the seal. When the shaft rotates the liquid is circulated by a pumping ring in the mechanical seal.

• The cooling jacket, which provides a heat soak barrier between the pump casing and the mechanical seal, is continuously flushed with cooling water from an external source.

Jacket cooling• For Safe operation observing the following seal circuit temperatures, measured at seal outlet : • warning temperature : 55° C • shut-off temperature : 65° C • standstill temperature : 75° C• A mechanical seal is a dynamic seal that cannot be free of leakage due to physical and technical reasons. Seal design, manufacture tolerance, operating conditions, running quality of the machine etc. mainly define the leakage value. As compared to other sealing systems (e.g. Gland packing"s) there is few leakages.• Small seal leakage is desirable and admissible, because of longer operating life of mechanical seal. If however, leakage exceeds a value of 8 liters per hour, the seal is damaged . It has to be replaced.Cooler for mechanical seal – MECHANICAL SEAL SKID Magnetic filters –1 working , 1 standby for each end 1 working , 1 standby for each end CW out CW in

After cleaning, the magnetic discs need to be mounted in such a way that spacers they attract each others in pairs but repel adjacent pairs from which they are separated by spacers. strainer Seal water inSimplex basket filter in BP suction Simplex basket filter in BFP suctionFiltration rate – 315 micron Filtration rate – 195 micronMax. allowable pr. Drop – Max. allowable pr. Drop – clean – 0.1 ksc clean – 0.1 ksc clogged – 0,15 ksc clogged – 0.15 kscPumps performance - MDBFP vs TDBFP MDBFP TDBFP Reference DESIGN BEP DESIGN BEP Flow (m3/hr) 990 855 990 855 Head (mlc) 2050 1985 2050 2002 Efficiency 81 80 81 80 Power (kw) 6177 5240 6178 5285 Speed (rpm) 5465 5260 5465 5260

Best Efficiency Point (BEP) is the point at which a pump is least prone to failure and its lifeexpectancy is greatest i.e the minimum flow a pump should produce in order to operate withoutany issues such as high temperature rise, low flow cavitation or low bearing and seal life. Major TroubleshootingSYMPTOMS POSSIBLE CAUSE ACTIONPump performance low Incorrect rotation of pump in case of Check motor electrical connections.(Pump Discharge pressure low) MDBFP Excessive wear of Dismantle pump and inspect pump internals components. Low Speed Check Speed Regulation System. Strainer Chocked Clean strainerBearings overheating Defect in lubricating oil system. Check lubricating oil system. Oil flow to bearing. Bearings worn of misaligned. Examine bearings. Misalignment of pump. Check alignment.Mechanical Seal Temperature high Insufficient cooling Water to cooler. Check Heat Exchanger for blockages and clean. Mechanical seal damaged Check the rotating and stationary part of sealExcessive noise/vibration Misalignment of pump set Check alignment Bearing misalignment Examine bearing Holding down bolts loose Tighten holding down bolts Excessive clearance of pump Check clearances overhaul as internals necessary Rotating assembly out of balance Check dynamic balance Excessive load of interconnecting Check hot and cold values of piping pipings acting on pump supports and float Hydraulic flow disturbances Increase flow through pump. Avoid long running on low flow

8613371530291

8613371530291