boiler feed pump mechanical seal quotation

We recognize and understand the vital role of boiler feed water pump mechanical seal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale boiler feed water pump mechanical seal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider boiler feed water pump mechanical seal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

HST offers Boiler Feed pumps for high pressure multistage pump mechanical seals Suitable for KSB, Sulzer & KBL Make Pumps, these seals are used in power plants, steel Industries, pharma, oil and gas and sugar industries.

We are a highly acclaimed company for offering boiler feed pump"s mechanical seal to the clients. This mechanical seals are available for any kind of high pressure application, like chemical, water, steam, petrol, diesel, oil & gas etc. Offered product is designed and developed by a team of expert professionals so that they can be easily used in heavy industries. In addition, customers can avail custom-made mechanical seals from us.

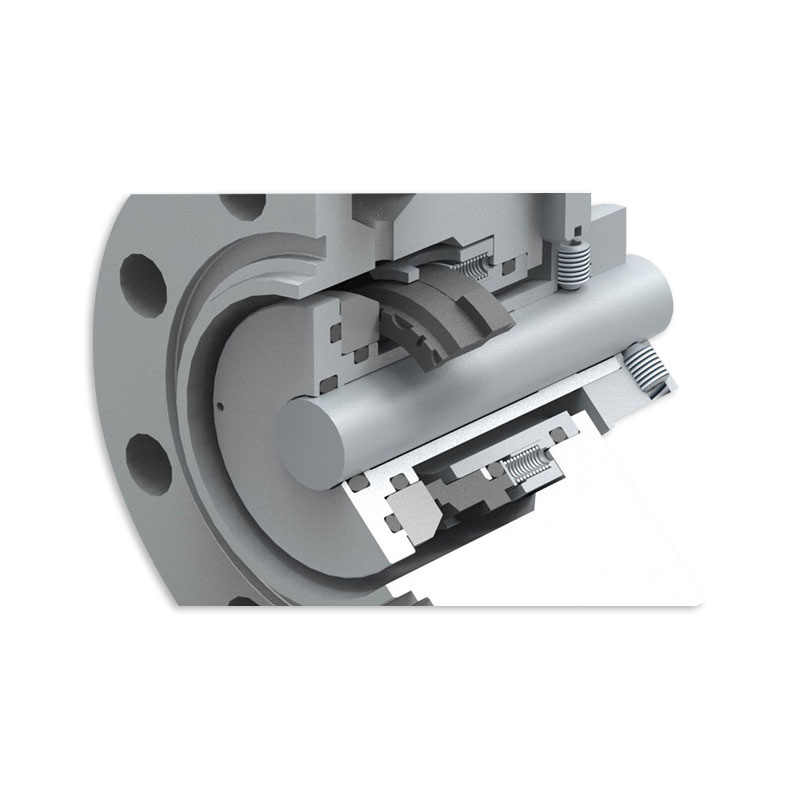

Structural Features: single end and multiple springs, balanced, independent rotary direction and coil driven. The coil driven structure is simple and reliable. This seal component is easy to install and the sealing performance is stable and reliable and has a longer life time.

Scopes of Application: widely used in boiler feed pumps deployed in power plants, booster pumps and other medium pressure and high speed applications. It is specifically designed for boiler feed pumps, booster pumps, clean water pumps, chemical pumps and other rotary devices.

Zigong Ke Yu Seal Science and Technology Co.,LTD located in hightech industry of zigong city in sichuan province. We are large manufacturer and exporter of high pressure,high temperature, high speed mechanical seal. Our products widely used in KSB pumps, Grundfos pumps, Flowserve pumps, etc. And our mechanical seal can exactly replace original mechanical seal in sharpe agitator, ekato agitator, lightnin agitator, sardik agitator, mut agitator, mixpro agitator etc. We design and manufacture mechanical seal up to 60 bar, 3000rpm, 300C°in different material of constructions like ss316/316L,ss304, Sillicon Carbide, Tungsten Carbide, Carbon, Viton, NBR, EPDM ,PTFE, etc. From pumps to reactor for various application. We can also provide ODM and OEM precision machined parts according to your drawings or design requirements. For exmple,customized shaft, shaft sleeve, as well as a variety of high-precision, high request products. Materials that can be produced include stainless steel, titanium and any other metal material of different grade.

Engineered Mechanical SealsPioneers in the industry, we offer boiler feed pump mechanical seal, boiler feed pump seal, high pressure mechanical seal, vacuum processing unit mechanical seal, tunnel drill machine mechanical seal and extruder mechanical seal from India.

We are a highly acclaimed company for offering boiler feed pump"s mechanical seal to the clients. This mechanical seals are available for any kind of high pressure application, like chemical, water, steam, petrol, diesel, oil & gas etc. Offered product is designed and developed by a team of expert professionals so that they can be easily used in heavy industries. In addition, customers can avail custom-made mechanical seals from us.

We are a highly acclaimed company for offering boiler feed pump"s mechanical seal to the clients. This mechanical seals are available for any kind of high pressure application, like chemical, water, steam, petrol, diesel, oil & gas etc. Offered product is designed and developed by a team of expert professionals so that they can be easily used in heavy industries. In addition, customers can avail custom-made mechanical seals from us.

We are a highly acclaimed company for offering Boiler feed pump"s mechanical seal to the clients. This mechanical seals are available for any kind of high pressure application, like Chemical, Water, Steam, Petrol, Diesel, Oil & Gas etc. Offered product is designed and developed by a team of expert professionals so that they can be easily used in heavy industries. In addition, customers can avail custom-made mechanical seals from us.

ApplicationBoiler Feed Water Pumps, Oil Pipeline Pumps, HSD Pumps, Booster Pumps, Drip Pumps, Condensate Pumps, Fuel Oil Pumps & High Pressure Pumps Etc.

Incorporated in 2012, Gipfel Engineering is a widely accomplished manufacturer, exporter and service providerof Chemical Process Pumps & Mechanical Seals. Our product line includes Component Mechanical Seal, Bellow Mechanical Seal, and Cartridge Mechanical Seal. Owing to the qualitative fabrication, our range is widely known among the clients for its attributes such as dimensional accuracy, robustness, high tolerance capacity, leakage proofing and longer shelf life. We serve in various process industries including refineries, petrochemicals, food processing, beverage industries, paint industries & pharmaceuticals. Our products with high technology and excellent quality are in all over India with prompt services. We have partnered with the industry"s best vendors, to obtain the machinery used in our production units. Our installation and repairing services are provided by assiduous professionals. All these products are made under the expert guidance to deliver maximum quality to our esteemed client base. We have made a recognizable growth in our domain in by supplying our Chemical Process Pumps & Mechanical Seals all over India.

Incorporated in 2012, Gipfel Engineering is a widely accomplished manufacturer, exporter and service providerof Chemical Process Pumps & Mechanical Seals. Our product line includes Component Mechanical Seal, Bellow Mechanical Seal, and Cartridge Mechanical Seal. Owing to the qualitative fabrication, our range is widely known among the clients for its attributes such as dimensional accuracy, robustness, high tolerance capacity, leakage proofing and longer shelf life. We serve in various process industries including refineries, petrochemicals, food processing, beverage industries, paint industries & pharmaceuticals. Our products with high technology and excellent quality are in all over India with prompt services. We have partnered with the industry"s best vendors, to obtain the machinery used in our production units. Our installation and repairing services are provided by assiduous professionals. All these products are made under the expert guidance to deliver maximum quality to our esteemed client base. We have made a recognizable growth in our domain in by supplying our Chemical Process Pumps & Mechanical Seals all over India.

Incorporated in 2012, Gipfel Engineering is a widely accomplished manufacturer, exporter and service providerof Chemical Process Pumps & Mechanical Seals. Our product line includes Component Mechanical Seal, Bellow Mechanical Seal, and Cartridge Mechanical Seal. Owing to the qualitative fabrication, our range is widely known among the clients for its attributes such as dimensional accuracy, robustness, high tolerance capacity, leakage proofing and longer shelf life. We serve in various process industries including refineries, petrochemicals, food processing, beverage industries, paint industries & pharmaceuticals. Our products with high technology and excellent quality are in all over India with prompt services. We have partnered with the industry"s best vendors, to obtain the machinery used in our production units. Our installation and repairing services are provided by assiduous professionals. All these products are made under the expert guidance to deliver maximum quality to our esteemed client base. We have made a recognizable growth in our domain in by supplying our Chemical Process Pumps & Mechanical Seals all over India.

Incorporated in 2012, Gipfel Engineering is a widely accomplished manufacturer, exporter and service providerof Chemical Process Pumps & Mechanical Seals. Our product line includes Component Mechanical Seal, Bellow Mechanical Seal, and Cartridge Mechanical Seal. Owing to the qualitative fabrication, our range is widely known among the clients for its attributes such as dimensional accuracy, robustness, high tolerance capacity, leakage proofing and longer shelf life. We serve in various process industries including refineries, petrochemicals, food processing, beverage industries, paint industries & pharmaceuticals. Our products with high technology and excellent quality are in all over India with prompt services. We have partnered with the industry"s best vendors, to obtain the machinery used in our production units. Our installation and repairing services are provided by assiduous professionals. All these products are made under the expert guidance to deliver maximum quality to our esteemed client base. We have made a recognizable growth in our domain in by supplying our Chemical Process Pumps & Mechanical Seals all over India.

Incorporated in 2012, Gipfel Engineering is a widely accomplished manufacturer, exporter and service providerof Chemical Process Pumps & Mechanical Seals. Our product line includes Component Mechanical Seal, Bellow Mechanical Seal, and Cartridge Mechanical Seal. Owing to the qualitative fabrication, our range is widely known among the clients for its attributes such as dimensional accuracy, robustness, high tolerance capacity, leakage proofing and longer shelf life. We serve in various process industries including refineries, petrochemicals, food processing, beverage industries, paint industries & pharmaceuticals. Our products with high technology and excellent quality are in all over India with prompt services. We have partnered with the industry"s best vendors, to obtain the machinery used in our production units. Our installation and repairing services are provided by assiduous professionals. All these products are made under the expert guidance to deliver maximum quality to our esteemed client base. We have made a recognizable growth in our domain in by supplying our Chemical Process Pumps & Mechanical Seals all over India.

Since 2007, the hot-filament Chemical Vapor Deposition (CVD) technology for crystalline diamond thin-film coatings has found its way into the mechanical seal market to combat the problems of dry running, corrosion and abrasion. This new technology has proved successful in hundreds of pumping applications in a wide range of services and duties. The reliability and lifetime of mechanical seals are improved by using diamond-coated faces. One such application involved the sealing of large boiler feed and steam generator pumps in power plants. The duty conditions for the pump’s seals can be as high as pressures up to 580 psig (40 bar), shaft RPMs up to 6,500 and temperatures up to 400˚F (200˚C). Consequently, the mechanical seal faces are highly loaded in a fluid with far less than ideal lubricating qualities. It is evident, therefore, that these applications are technologically challenging for mechanical seal manufacturers not only from a tribological perspective, but also from a corrosion viewpoint when the feed water has a low electrical conductivity or is free of impurities. This paper discusses a new seal-face treatment using hotfilament CVD manufacturing technology tested in a lab for 16,000 hours and currently used in feed pump operations in several power stations in the USA and Europe.

Structural Features:single end and multiple springs, balanced, dependent rotary direction and coil driven. The coil driven structure is simple and reliable. This seal component is easy to install and the sealing performance is stable and reliable and has a longer life time. Pumping screw/ring arrangement enhances the flow of media.

Scopes of Application:widely used in boiler feed pumps deployed in power plants, booster pumps and other medium pressure and high speed applications. It is specifically designed for boiler feed pumps, booster pumps, clean water pumps, chemical pumps and other rotary devices.

Flowway Teknik design and manufactures seals and associated products mainly for the oil and gas, chemical, pharmaceutical, pulp and paper, power, mining and many more industrial applications. Today, it provides the most complete selection of engineered mechanical seals and sealing support systems. Our products are recognized as a trusted brand in a process industry.

Since 2007, the hot-filament Chemical Vapor Deposition (CVD) technology for crystalline diamond thin-film coatings has found its way into the mechanical seal market to combat the problems of dry running, corrosion and abrasion. This new technology has proved successful in hundreds of pumping applications in a wide range of services and duties. The reliability and lifetime of mechanical seals are improved by using diamond-coated faces. One such application involved the sealing of large boiler…Expand

Mechanical seal designed is a unique seal developed to meet stringent technical requirements of Boiler feed water pumps. Rotating stationary ring design makes it suitable for high speed application & avoids critical requirement of stuffing box face squareness. Both the faces are having strong positive drive & locking arrangement which make seal very strong and sturdy. Thermodynamic circulation grooves inscribed on the rotating faces boost the cooling of the sliding faces by reducing the coefficient of friction and protecting the seal against thermal over loading. Increased coolant flow effected by the pumping screw & the fluid guiding channel combine to force the cold water into the gap between dynamic ring & stationary ring, blowing out gas bubbles and dirt particles & picking up frictional heat. In view of risk dynamic distortion because of high sliding velocity of over 25 m/sec the springs are located in the stationary part.

DG type boiler feed water pump device, the mechanical seal of the mobile equipment accounts for about 80%-85% of the total dynamic seal. In the mechanical pump failure, the mechanical seal failure accounts for about half of the total maintenance workload. It can be seen the position occupied by the mechanical seal in the maintenance of the pump. Since the media conveyed by the pumps are very different and the process conditions are different, it is important to understand these conditions for the selection and maintenance of the mechanical seal.

DG type multi-stage boiler feed water pump mechanical seals will fail due to overheating, which is thermal damage failure. Common thermal damage failures include end face thermal deformation, thermal cracking, blister scars, carbonization, loss of elastic components, rubber parts Aging, deformation, cracking, etc. Many small hot spots and isolated discoloration areas are sometimes found on the sealing end surface, which indicates that the seal is locally deformed and distorted under the influence of high pressure and heat, and sometimes symmetrical and discontinuous bright bands are found on the sealing end surface. This is mainly It is because of irregular cooling that causes local thermal deformation of the end face. Why is the mechanical seal of the boiler feed water pump thermally damaged? The following editor will analyze it for you:

In the mechanical seal under high temperature environment, pits and scars are often found on the surface of the graphite ring. This is because when the resin-impregnated graphite ring exceeds its allowable temperature, the resin will be carbonized and decomposed to form hard particles and precipitate volatiles, forming scars, thereby greatly increasing friction and causing high leakage of surface damage.

The environment may reduce the elasticity of the elastic element, thereby making the closing force of the sealing end face insufficient and causing serious leakage of the sealing end face. The high temperature loss of metal bellows is a common and typical failure mode of this type of mechanical seal. The effective way to avoid this is to select a reasonable corrugated pipe material and conduct proper heat treatment.

High temperature is an important reason for the aging, cracking and deformation of rubber seals. Rubber aging is manifested by the hardening of the rubber, the decrease in strength and elasticity, and cracking in severe cases, resulting in loss of sealing performance. Overheating can also decompose the rubber components and even carbonize. In high-temperature fluids, the rubber ring may continue to vulcanize, and the ui will eventually lose its elasticity and leak. The deformation of rafter seals is usually more serious than other materials. The sealing ring will become the same shape as the groove when it is exposed to high temperature for a long time. When the temperature remains the same, it can also play a sealing role; but when the temperature drops, the sealing ring will quickly shrink, forming a leakage channel and causing leakage. Therefore, attention should be paid to the use temperature of various glue types, and long-term use at extreme temperatures should be avoided.

Failure caused by overheating is thermal damage failure. Common thermal damage failures include end face thermal deformation, thermal cracking, blistering, carbonization, elastic element loss, and rubber aging, deformation, and cracking. The thermal deformation of the sealing end face of the boiler feed water pump includes local thermal deformation and overall thermal deformation. Many small hot spots and isolated discoloration areas are sometimes found on the sealing end surface, which indicates that the seal is locally deformed and distorted under the influence of high pressure and heat; sometimes it is found that there are symmetrical and discontinuous bright bands on the sealing end surface. It is because of irregular cooling that causes local thermal deformation of the end face. Sometimes it is found that the seal end face wears very seriously on the inside, the larger the radius, the shallower the contact marks, until they are indistinguishable. The inner edge of the sealing ring may show chipping and edge jumping. When the shaft rotates, the seal continues to leak, but does not leak when the shaft is stationary. This is because when the seal is in operation, the outer side is cooled sufficiently, and the inner side frictional heat is serious, so the inner thermal deformation is greater than the outer thermal deformation, forming an inner contact type (positive cone angle) end surface caused by thermal deformation.

Sealing rings of brittle materials such as cemented carbide, engineering ceramics, carbon graphite, etc., sometimes radial cracks appear on the end faces, so that the leakage of the sealing surface increases rapidly, and the mating parts wear sharply. This is mostly due to the dry friction of the sealing surface and the sudden interruption of cooling. A kind of thermal damage failure caused by the rapid accumulation of friction heat on the end face and other reasons.

8613371530291

8613371530291