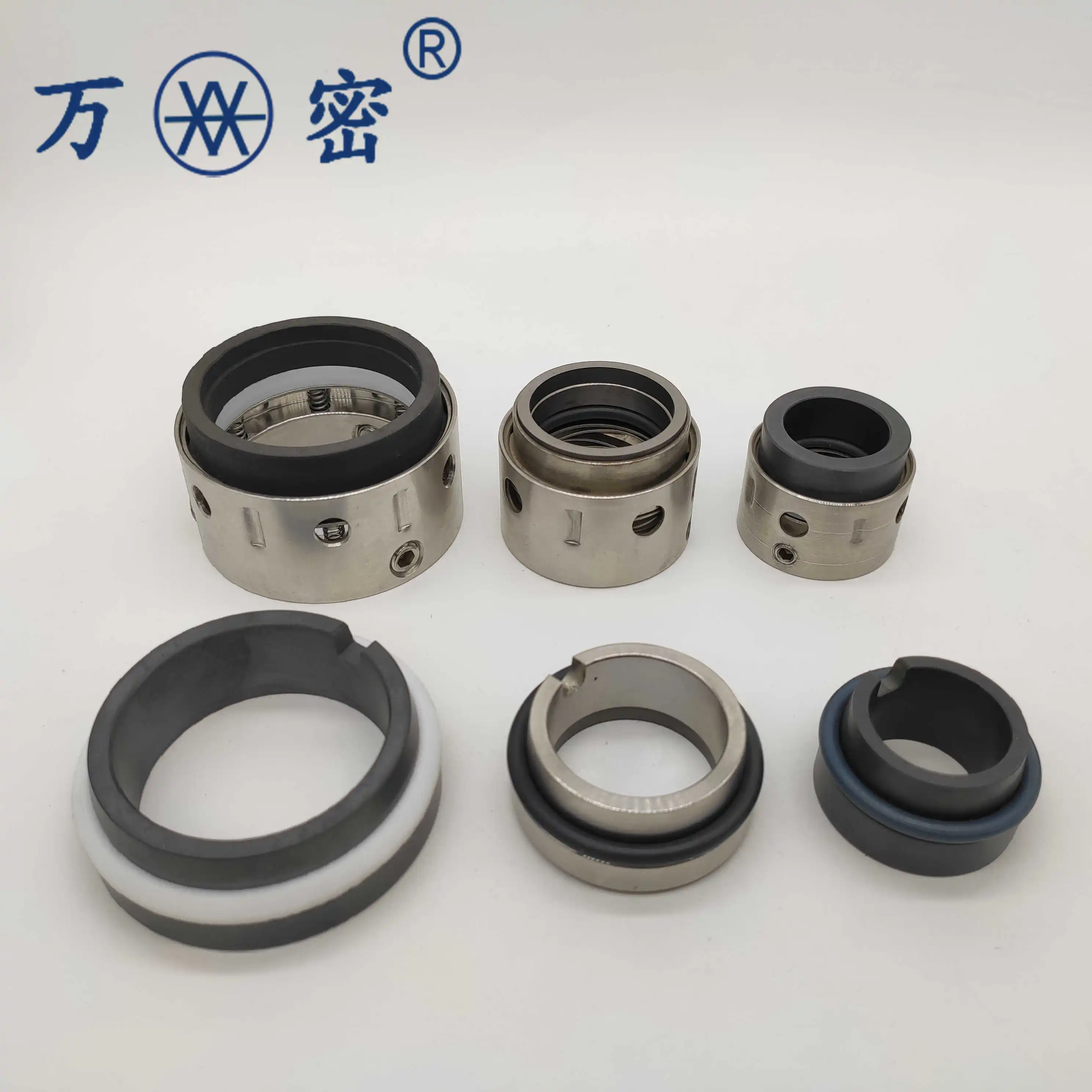

buy mechanical seal in stock

We specialize in hard-to-find seals and demanding applications. Our extensive network of resources enables us to locate the right manufacturer and part, every time.

At All Seals we know down time is not an option. We specialize in hard-to-find seals and demanding applications. With over 40 years of experience in supplying quality replacement mechanical seals, we can help you identify the seal you need and solve your sealing problem. Our technical staff is available to help you – just give us a call. Our comprehensive stock of components ensures that we can build almost any seal combination for same day shipment. Whether you need a new seal or you have a seal to be repaired, we welcome the opportunity to help you with your rotary sealing needs.

We carry a comprehensive inventory of mechanical seal components, which allows us to build the right seal for your application. We’ll even design custom seals for one-of-a-kind applications.

Need hard faces or specialty elastomers? Give us a call. We can quickly build a repair kit to withstand any medium being pumped. You’ll find All Seals’ pump repair kits an invaluable part of your operation.

Our experienced mechanical seal staff is committed to helping you with all of your mechanical seal sales, repair, design, and correct application questions.

If you’re looking for high quality and personal service, you’ve come to the right place. At WSC Mechanical Seals we’ll give you the attention and personal service you’ll come to expect and enjoy. Contact us with any mechanical seal sizing or classification questions you may have. We are here to help you.

WSC Mechanical Seals stocks a large selection of mechanical seals & offers same day shipping for all in stock mechanical seals. Our mechanical seal inventory includes Goulds Centrifugal Pump Mechanical Seals, Ro-Flo/Alis Chalmers Gas Compressor Mechanical Seals, Durco Mechanical Seals, Flygt Mechanical Seals, and Screw Compressor Mechanical Seals just to list a small selection of our extensive in-house mechanical seal inventory.

We are a proud SEPCO distributor of their quality brand of mechanical seals. We offer a full line of cartridge, component, and air seals, as well as seal accessories at our mechanical seal store. We’re your premier mechanical seal supplier, and we have an expert staff that can guide you in your purchase! Contact us today!

All design companies that develop or have previously developed sealing systems for liquid and gas unify their products and adopt a certain standard for the use of certain types of mechanical seals, oil seals for liquid and gas, which are used in pumps, pumping and compressor systems and seals.

World-famous brands of pumping equipment Waukesha, Pedrollo, Zenit, Fristam, Johnson, APV, KOLMEKS, LFP LESZNO , PACKO, PENTAX, SPERONI, Saer Grundfos, Alfa Laval, Ebara, Allweiler, Andritz, ABS, Calpeda, Caprari,GEA Tuchenhagen, DAB, KSB, INOXPA, CSF Inox, Wilo EMU, Varisco, Lowara, Flygt, Grindex, Godwin, Gormann Rupp, Hidrostal, Hilge, Homa, Mody Pump, Sarlin, Seepex, Sterling Sihi , Viking pump, manufacturers of general industrial pumps ,as well as special ,chemical pumps ,develop and apply the pump seal system as precisely as possible and apply certain materials that are most suitable for the conditions and operating mode ,thus ensuring the reliability and durability of pumps and compressors . Many OEM manufacturers, without inventing "bicycles" , are already following the path of analogues of Burgmann, AESSEAL, Roten, Vulcan, John Crane, Anga, Flowserve, Latty, Roplan, Fluiten, and the manufacturers themselves work on the principle of cooperation with other companies, thereby reducing the cost of their product by placing parts of housings, processing friction pairs or manufacturing spring elements in markets where raw materials and labor are cheaper. Production in the same China is carried out on machines and equipment that give precision processing, the use of materials of correspondingly high quality .

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

The right seal support system is critical for promoting seal reliability. John Crane customizes support systems to meet a variety of seal specifications, contributing to safe, cost-effective, reliable operation and reducing harmful environmental effects. Our support systems comply with constantly changing design codes and standards, and meet the increasingly stringent demands on end users.

Our comprehensive suite of seal face technologies are designed to overcome rigorous sealing challenges, including limited seal face lubrication and severe-service duties that adversely affect reliability, operational costs and seal life. Designed by our engineering experts, John Crane’s face treatment options help your equipment power through low-lubricity and dry-running conditions by using advanced micromachined patterns and features to improve seal face lubrication to optimize the performance of rotating equipment in all process industries

Isomag’s advanced magnetic face technology delivers unparalleled performance. The lapped flat faces create a positive liquid tight seal preventing lubricant leakage and the ingress of contaminants in both static and dynamic conditions on horizontal and vertical equipment alike. By optimizing the magnetic energy loading, Isomag’s are capable of running at shaft speeds well above average (up to 15,000 feet per minute) providing the ability to effectively seal the bearing housings on a wide variety of applications

Do you want to minimize leakage from your pumps in an effective manner? This is a challenge operators and maintenance managers face on a daily basis, which can prove costly. John Crane offers a wide selection of packing materials in compression packing, automatic packing, floating packing, and injectable packing. Learn more about our variety of packing equipped to handle the vast majority of sealing solutions and available for nearly all applications.

PumpWorks is the go-to company for all your pump sealing needs. The Sealing Technology Division of PumpWorks offers over 30 years of hands-on experience in the application, selection, troubleshooting, and repair of mechanical seals. We repair all manufactures of seals for a wide variety of applications from general industrial to process industries such as chemical, petroleum refining, and marine.

PumpWorks offers trained seal specialists and extensive in-house repair capabilities to service and repair all brands and types of seals including (but not limited to):

Before PumpWorks conducts a seal repair, we conduct a review of your equipment to isolate problem areas and to determine how to achieve long-term reliability with your seals. Our review consists of:

Once a seal is selected, our trained technicians can modify stuffing boxes, substitute component materials, re-install the seal and pressure test the entire pump. The mechanical seal can also be field installed to assure a positive fit and true alignment.

8613371530291

8613371530291