carbon vs silicon carbide mechanical seal factory

![]()

You must consider the “environment” the seal will be exposed to when selecting the design, and importantly, the material of your mechanical seal. The saying “pay me now, or pay me later” very much applies to seals as not selecting the right material will cost more in the long run.

For all environments the material used for the seal face must be stable, be able to conduct heat, be chemically resistant and deliver good wear resistance. However, certain environments will need these properties to be stronger than in others.

Abrasive and harsh environments mean that the material selected must be able to withstand this, which can be more expensive. However the cost will be returned to you over time as poor material grade selection will only result in costly shut downs, repairs, refurbishments or replacements of the seals once again.

Various materials can be used for seals depending on the requirements and environment they will be used for. By looking at material properties such as hardness, stiffness, thermal expansion, wear and chemical resistance, you are able to find the ideal material for your seal.

When mechanical seals first arrived, seal faces were often made from metals such as hardened steels, copper and bronze. Over the years, more exotic materials have been utilised for their property advantages, including ceramics and various grades of mechanical carbons.

Selection of the proper seal face materials is essential for the successful operation of the mechanical seal. In fact, it could be argued that selection of materials is the most important decision to be made by the seal designer.

In evaluating materials for seal faces both the properties of the individual materials and the combination of the tribological pair must be considered. In general, dissimilar materials are used for seal faces. These materials are frequently thought of as the “soft face” and the “hard face” although sometimes two “hard faces” are used.

Mechanical seal design would be considerably simplified if the “perfect” seal face material could be found. With such a material, the designer would not be concerned about balance ratio, face widths, heat generation, flushing, corrosion, etc. Therefore there is a tremendous incentive to develop improved seal face materials.

Even though a perfect seal face material is not likely, the ideal face seal material can be described based on our experiences and problems with existing materials. This ideal material would have the following characteristics:

Leakage is probably more a result of the seal design rather than a property of the material but good face materials can certainly promote low leakage seal designs. In most seals, the actual face separation is strongly related to the surface finish of the materials. Therefore, materials which have and maintain smooth surfaces generally leak less than those with rough surfaces.

Leakage is also related to the compliance, or ability of the seal faces to conform to each other. Compliance is generally thought of as a function of the seal shape; however, it is strongly influenced by the modulus of elasticity. Materials with a low modulus, such as carbon, are more easily made into compliant shapes than materials such as tungsten carbide.

Mechanical seal calculations are considerably simplified through the use of a coefficient of friction. Unfortunately, this coefficient of friction is not a constant and ranges from around .03 to .3. Naturally, the coefficient of friction is a function of the tribological material pair but it also depends on the fluid being sealed. To make matters worse, it turns out that the coefficient of friction also depends on the seal face load and is reduced when the seal leaks.

In spite of these limitations, the coefficient of friction is a useful means of comparing seal face materials, especially when tests are done under similar conditions. Table II shows coefficients of friction for various face combinations.

As shown in Table II, there is a considerable variation in coefficient of friction for various materials. Even when specific material formulations are tested, the coefficient of friction depends on the fluid being sealed, the seal load and aspects of the seal design such as face distortion.

A good mechanical seal material must not only be strong enough to resist the stresses of normal operation, it must also be strong enough to survive the manufacturing process, storage and the rigors of installation.

The strength, hardness and rigidity of carbon graphite based materials is generally an order of magnitude less than that of metals and ceramics such as steel, tungsten carbide or silicon carbide. This means that more design effort is normally directed toward the component which is manufactured from carbon graphite. The primary reason for the use of carbon graphite in mechanical seals is it self lubricating qualities — not its strength.

Tungsten carbide is at the other extreme from carbon graphite. Tungsten carbide has a very high compressive and tensile strength, is very hard and has a high modulus of elasticity.

Silicon carbides are even harder than tungsten carbides but are much more brittle and greater care must be taken during installation and removal. These difficulties in handling have caused many users to prefer tungsten carbide in spite of the low frictional characteristics of silicon carbide.

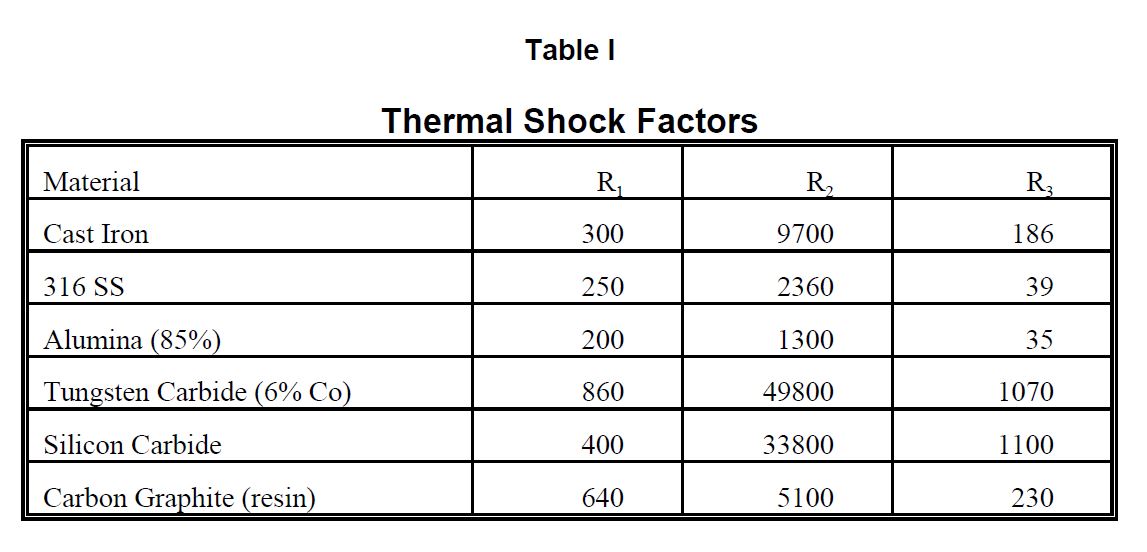

The thermal aspects of mechanical seals are a major factor in seal performance and reliability. Two of the major material properties are thermal conductivity and thermal expansion.

The thermal shock characteristics of materials have already been discussed. Although thermal conductivity enters into the thermal shock parameters R2 and R3 directly, its effect on seal face temperature is probably more important.

Carbon graphite materials generally have a thermal conductivity of around 5 to 8 Btu/hr ft F; metal filled carbons are somewhat higher. In contrast, tungsten carbides and silicon carbides have thermal conductivities ranging from 40 to 100 Btu/hr ft F. This means that, in a typical seal with carbon versus tungsten carbide or silicon carbide faces, the major of the heat transfer takes place through the non-carbon element.

Stainless steels, Stellite and alumina have much lower thermal conductivities than tungsten carbide and seals using these materials will run considerably hotter than one using tungsten carbide or silicon carbide.

The thermal expansion of seal face materials is related to both the seal face temperature and the coefficient of expansion of the material. In order to minimize the effects of face temperature on distortion, a low coefficient of expansion is desired.

The coefficient of expansion of carbon graphites, tungsten carbides and silicon carbides is similar. This is fortunate and allows for some degree of substitution in seal face materials within the same design family. Alumina is higher and stainless steels still higher.

Any differences in coefficient of expansion become especially important when a seal is manufactured by shrink fitting components made from different materials. In this case, if the operating temperature is sufficiently different from the manufacturing temperature, the seal faces may become distorted. In an extreme case, the components may become loose.

Corrosion of carbon graphites is usually more related to the binder than the carbon graphite. Metal filled carbon are especially subject to corrosion but a suitable resin filled carbon can usually be found for most services. Carbon graphites are not recommended for aqua regia, oleum or perchloric acid. Resins in common use are attacked by lithium hydroxide, potassium hydroxide, sodium metophosphate, anhydrous ammonia, sodium diphosphate and sodium cyanide.

Alumina has good corrosion resistance and high purity alumina is very good. Before the introduction of silicon carbide, alumina was the preferred corrosion resistant material in many mechanical seal services.

The two most common variations of tungsten carbide are cobalt bound and nickel bound. Nickel bound tungsten carbide is the more corrosion resistant although the cobalt bound tungsten carbide is more than adequate for most services. Neither is as good as alumina.

The chemical resistance of silicon carbide is excellent. The two most common variations of silicon carbide are reaction bonded and alpha sintered. Of the two, the alpha sintered is the more corrosion resistant but even reaction bonded silicon carbide is very resistant to chemical attack. Both are generally better in corrosion resistance than nickel bonded tungsten carbide. The “free silicon” in reaction bonded silicon carbide can be attacked by strong oxidizing chemicals. Alpha sintered silicon carbide has no free silicon; it is considered to be the most corrosion resistant of all the seal face materials.

Many of the desirable material qualities for a seal face are not so desirable during the manufacturing process of that component. In particular, the hardness and high strength of many materials make manufacturing very difficult. A common approach is to mold the “green” material into a near finished shape before completing the manufacturing process.

Carbon graphites are typically molded to a rough shape before being impregnated with resin or metal binder. Some simple shapes with small cross sections may be machined from cylindrical stock. The final shape is machined. Faces are always lapped.

Seal components made of very hard materials such as tungsten carbide and silicon carbide are frequently repairable. The repair process consists of chemical and mechanical cleaning and relapping. Caution must be used to assure that dimensional tolerances are maintained.

Softer materials, such as carbon graphites, frequently are not reused, especially if they have been in service for an extended period of time. These softer components generally have more extensive face damage than the hard component and are also less expensive to replace. In the case of carbon graphites, there may also be a concern about chemical attack of the binder.

The cost of seal components is generally related to the hardness and chemical resistance of the material. This cost is normally considered to be a small fraction of the total cost of removing the pump from service and the labor involved in changing out the seal parts. For this reason, most seal users prefer to use the best available materials in their mechanical seals. Currently, the most popular material combination is a premium resin filled carbon graphite versus silicon carbide.

The additional cost of tungsten carbides and silicon carbides is somewhat offset by the fact that components made from them can frequently be repaired – meaning cleaned and re-lapped.

For typical HVAC applications, carbon-ceramic have stainless steel metals, BUNA elastomers, a 99.5% pure aluminum oxide ceramic stationary seal face, and a carbon rotating face. These seals work well with the temperatures mentioned above and a pH neutral range of 7.0-9.0. They can handle up to 400 ppm of dissolved solids and 20 ppm of undissolved solids which satisfied most system requirements.

In most applications carbon-ceramic seals work fine but there are certain circumstances when a different type of material for the mechanical seal should be specified. These include:

Systems with high pH levels. Most HVAC applications maintain a pH from 7.0 to 9.0. Once in a while the pH is too high for the carbon-ceramic seal material. The main issue may be located in the chemical treatment portion of your specification. There are specifications that call for the pH to be maintained at levels in the 9.0-11.0 range. If your specification calls for this range, the pump seal material specification should be changed to EPR/Carbon/Tungsten Carbide (TC) or EPR/Silicon Carbide (SiC) /Silicon Carbide (SiC). We recommend the EPR/SiC/SiC material since that seal can handle pH up to 12.5 which gives some “wiggle room.”

Higher solids levels. Solids, otherwise known as dirt, are another area of concern for mechanical seals. If the system is dirty or has silica in the water, you may find, once again, that you need the EPR/SiC/SiC seal. The standard Buna/Carbon/Ceramic seal in HVAC systems cannot handle any silica and the solids handling capability was mentioned earlier in this article. The silicon carbide seal can handle 60 times the dissolved solids content and double the undissolved solids content with 20 ppm silica content thrown in for good measure.

So, why not just always specify EPR/SiC/SiC seals? There are two reasons: cost and lead-time. This seal will cost three times as much as the standard seal. In addition, since the carbon-ceramic seal is standard, there may be additional lead-time to get a pump with a special seal.

Improperly mixed glycols. The term glycol is a bit of a misnomer when it comes to heat transfer solutions in HVAC systems. Glycol is used in many applications from shaving lotions to whipping cream to automotive antifreeze. In HVAC systems you want a properly mixed glycol-based heat transfer fluid that has the correct inhibitors for the application. If you use automotive antifreeze in HVAC systems, the silica based inhibitors will create a gel in the coils that blocks heat transfer and flow. That is, if the seals don’t leak first!

We commonly see Dowtherm® SR-1 and Dowfrost™ HD heat transfer fluids used for these type of applications. These products are made for use in our industry but should be mixed according to the manufacturer’s instructions. Dow recommends they be pre-mixed with deionized water before filling the system. If you simply mix these product with city or well water the calcium and magnesium in water will mix with inhibitors and cause a particulate that exceeds the ppm of normal seals.

Occasionally contractors will put the glycol based fluid in the system, filled it with water and then turn on the pump to “mix” the solution in the piping system. This subjects the pump seals to shots of up to 100% ethylene or propylene glycol which is well beyond the maximum recommended amounts for even silicon carbide seals.

Our experience is that the standard carbon ceramic seal work fine with properly mixed glycol products designed for our industry. However, brands vary in their quality and make-up so we cannot say that carbon-ceramic seals are appropriate for all glycol mixtures. These fluids do carry a higher pH than water, so we recommend specifying a glycol seal if there is any question.

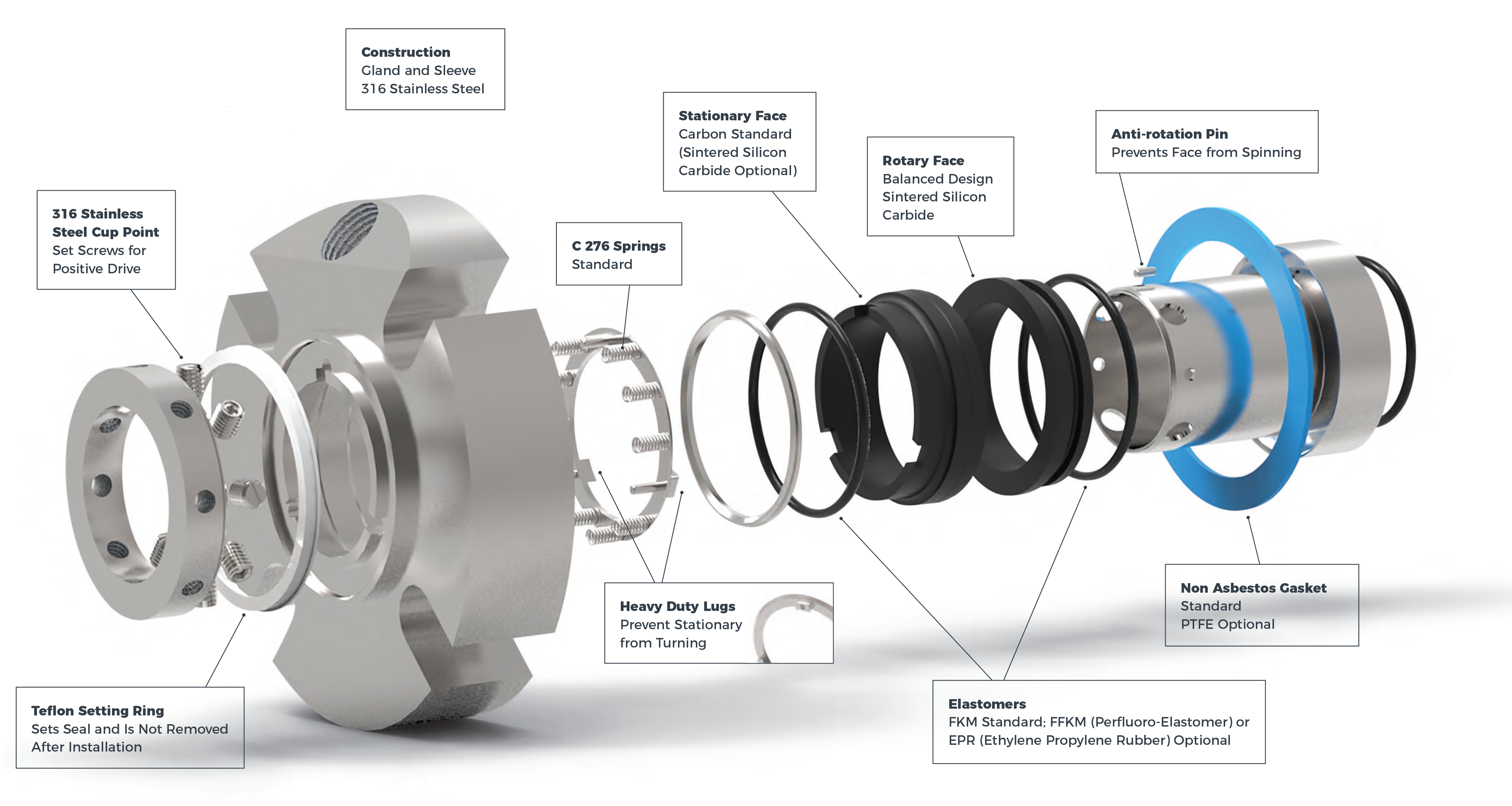

Mechanical face seals are a complex combination of materials and design that form a system whose prime objective is maintaining the integrity of the pumping system, keeping what is inside where it belongs and preventing contamination from the outside.

These systems enable relative motion between stationary and rotating components while simultaneously accommodating some level of axial or radial movement. The technology that has been developed and implemented in these systems has become so reliable that mechanical seals are often taken for granted. The vast majority of failures of mechanical seals can be attributed to the system in which the seal is installed, not the seal itself.

One of the materials used in many mechanical seal systems is based on the fourth most common element and the basis of all life—carbon. This article will explore how this common element plays such a critical role in these complex systems.

Because mechanical sealing systems must maintain tightly controlled contact between one rotating and one stationary face, interface stability must be maintained across a potentially wide spectrum of conditions. Face flatness is critical and is measured in millionths of an inch; unexpected distortion will change the interface dynamics significantly. With the proximity of the two face materials, contact is inevitable and the materials must be able to operate with some level of self-lubricity so they do not damage each other, which would create a path across that interface that enables system leakage.

There are eight allotropes of the carbon element (see Figure 1), based on how the carbon molecules align in the lattice, that result in a range of properties from the softest version, graphite (often used in pencil “lead”) through amorphous carbon to diamond, the hardest material known to man.

Each company creates a unique recipe intended to address specific conditions that maintain the interface stability; from low temperatures (cryogenic), to water, to methane, to oil, to higher temperatures and beyond, materials exist to provide the needed capability. These materials are designed for specific conditions. One recipe cannot perform in every condition, and seal companies work with material manufacturers to provide the optimum candidate for the application.

Figure 3 shows the variation in physical properties, thermal conductivity and chemical resistance of the part according to the relative amount of carbon and graphite in the finished product.

The attributes of the allotropes, or the various forms of carbon, can be combined in specific ratios and leveraged to achieve desired responses in a system where there is relative motion between two components in terms of friction and wear, (a.k.a. tribology), along with a large temperature range and the need for corrosion resistance. Carbon is an ideal seal face material for the range of conditions within a mechanical sealing system, and is widely used.

In the same way a pencil transfers graphite to a piece of paper, mechanical carbon can transfer material to the mating face—the level of that transfer is where the technology comes into play.

Manufacturers of carbon-based materials for mechanical seal faces achieve specific tribology through formulation of different elemental forms of the carbon atom and the use of other proprietary elements. Processing these recipes results in a structure that is literally held together by atomic carbon bonds.

A mechanical seal’s mating pair is the heart of the system and the two components are designed to work together. There exist optimum pairs for specific conditions.

The components of the recipe enable the proper tribology—too much or too little film transfer would result in shortened life or performance of the mechanical seal.

Carbon is also a critical component in some of the hard face materials used in mechanical seals because it combines with metals at high temperatures to form metallic carbides. These materials include tungsten carbide and silicon carbide.

These carbides provide superior hardness and stiffness. They are not self-lubricating and therefore cannot run “dry,” but they run well against mechanical carbons.

We invite your suggestions for article topics as well as questions on sealing issues so we can better respond to the needs of the industry. Please direct your suggestions and questions to sealingsensequestions@fluidsealing.com.

One approach to improving mechanical seal performance is to upgrade to a sintered silicon carbide composite material. Silicon carbide based materials have been increasing the limits of mechanical seals for more than 25 years, starting with Chemical Vapor Reacted (CVR) silicon carbide whose cross section resembles that of a piece of M&M"S® candy. The porous outer surface is a combination of silicon carbide and graphite. This surface coating encapsulates a carbon-graphite core. This material provided a hardened surface with a unique topography for increased interfacial lubrication.

However, it needed an impregnation to make it impervious for sealing applications. The graphite core also limited desirable physical characteristics such as high elastic modulus. This material did demonstrate that a hard, non-self-lubricating material could be run against itself and improve performance to a primary seal pair.

Homogeneous materials such as reaction bonded silicon carbide provided the advantages of lower porosity, higher elastic modulus (stiffness) and improved thermal conductivity and tribological behavior. Initially, the costs associated with the processing of this family of materials somewhat limited their use to high duty applications with less aggressive chemicals. These materials required extensive grinding and the free silicon in the structure was susceptible to highly caustic or acidic environments.

This family of materials quickly gained acceptance in a variety of applications as contact pressures could be increased with less face deflection than that of metallic materials. Normal protocol was to run a high duty, hard, mechanical carbon-graphite against the reaction bonded silicon carbide.

The need for greater abrasion and chemical resistance drove the development of sintered silicon carbide. Because of the chemical resistance in virtually all corrosive environments sintered (aka, self-sintered, direct sintered or pressure less sintered) silicon carbide began to enter the market. This material could be formed into specific shapes and then sintered to, or nearly to, the finished size, limiting the amount of expensive grinding for the finished item.

This reduction in production cost, coupled with the homogeneous nature of the material, enabled its use in highly corrosive environments and higher volume applications. It began to displace other materials such as alumina where higher pressure-velocity (P-V) capabilities were required. (The P-V parameter is an index of the severity of the application. It is a relative measure of the material pair and is affected by other variables such as the fluid being sealed.)

Unfortunately, this virtually impervious material does not have all the tribological characteristics of a reaction bonded silicon carbide, nor can it run at the higher duties of that material.

The marriage of silicon carbide and graphite was a normal progression. Graphite initially was added to reaction-bonded silicon carbide and quickly exhibited an increase in the performance capabilities of hard face combinations. While strength is reduced somewhat and the ability to handle abrasives is not as good as that of pure silicon carbide, tribological behavior is improved significantly. Using this type of material in at least one of the two hard faces extended the seal life cycle in some cases from minutes (i.e., unacceptable) to hundreds of hours.

Graphite-loaded sintered silicon carbide was more recently applied in hard face combinations. This unique family of composite materials has the benefits of sintered silicon carbide while incorporating a second, abradable phase that provides pockets or reservoirs for the "storage" of fluid.

These composite silicon carbide hard face combinations enable higher contact pressures and speeds by improving interfacial lubrication in the same way a matte lap finish does. As shown in Figure 2, both graphite-loaded silicon carbide composites running against themselves have the highest relative P-V values of any of the hard-face pairs. When they are combined with a carbon-graphite mating material, P-V is further enhanced.

The reservoir"s configuration is critical so as to not create other issues during operation. Specifically, edge breakdown around the reservoir can create debris that then damages the interface. A graphite-loaded sintered silicon carbide composite with properly configured reservoirs can provide for a smooth transition between the reservoir and the silicon carbide matrix.

Silicon carbide primary seal pairs do not perform well in the absence of a lubricant. Fortunately, only a small amount of lubricant is needed to significantly improve tribological characteristics. The abradable graphite phase creates reservoirs that provide dry run survivability, increasing the amount of time a mating pair can operate in the absence of the fluid. In addition, the composite creates a material that is even more resistant to thermal shock than the silicon carbide itself, providing enhanced resistance to those upset conditions that are difficult to predict and control.

These graphite-loaded silicon carbide materials have been around for several years, and new applications are regularly identified. Initially, they were developed to address the highest P-V applications, with a focus on the highest pressures. Now they are being applied to lower pressure and speed applications because they can offer total cost savings to the user through reduction in warranty claims and improved tribological consistency.

It is always best to consult the mechanical seal manufacturer for proper selection and application, since a wide range of primary ring materials are available. The manufacturer can provide further information on their strengths and weaknesses.

We invite your questions on sealing issues and will provide best efforts answers based on FSA publications. Please direct your questions to:sealingquestions@fluidsealing.com.

Selecting the proper mechanical seal face material combination is crucial in providing every mechanical seal a prolonged seal life & eliminating any chances of a premature seal failure. WSC Mechanical Seals offers an extensive variety of mechanical seal face materials and gladly offers experienced advice of which mechanical seal face materials are best suited for your exact operating conditions.

Tungsten Carbide is a versatile seal face material. It is a hard material & heavy to the touch, making it easy to distinguish from other materials. Tungsten Carbide is ideal for high pressure applications with little face distortion. It is also applied into extreme debris mechanical seal enviroments. With its dense construction characteristics, Tungsten Carbide will not break or crack under these severe conditions.

Silicon Carbide is a versatile seal face material like Tungsten Carbide. It is a hard material & light to the touch, with a bluish color. Silicon Carbide has much better lubrication qualities than most mechanical seal face materials. Alpha Sintered Silicon Carbide is most common & suited for chemical applications, as well as higher temperature sealing enviroments. Silicon Carbide is a hard material, but unlike Tungsten Carbide, it will shatter/crack if contacted with force or dropped.

Ceramic is a versatile seal face material, that is generally inexpensive. It is a hard material & light to the touch, with a white color. Ceramic offers excellent wear characteristics & chemical compatibility. Unlike other mechanical seal face materials though, it cannot handle thermal shocks. Ceramic retains heat when equipment is not operating, and general startup procedures can easily crack this seal face material. Ceramic, like Silicon Carbide, will shatter/crack if contacted with force or dropped.

Carbon Graphite is a self-lubricating mechanical seal face material, generally used as a mechanical seal rotating face. Our standard grade of carbon used is CNFJ. It has superior wear characteristics with a broad chemical resistance. For severe applications, Antimony Filled Carbon can be applied to assist with any mechanical seal face issues. Carbon is light to the touch & black in color.

Ni-Resist is a form of cast iron with a high nickel content to lower the friction generated by the mechanical seal"s rotating face. It is typically an inexpensive mechanical seal face material that can substitute for Tungsten Carbide. Ni-Resist shows signs of wear earlier than Carbide seal faces, but is ideal for Rotary Vane/Screw Gas Compressors or Oil applications. If installed into a water application, Ni-Resist will show signs of corrision.

Silicon carbide faces in mechanical seal assemblies result in improved performance, increased seal life, lower maintenance costs, and lower running costs for rotating equipment such as turbines, compressors, and centrifugal pumps. CoorsTek seal faces help reduce the possibility of leakage and catastrophic failure to safeguard the environment from the risk of fugitive emissions. They also lower energy consumption with reduced friction on startup and shutdown, as well as reduced wear and erosion during operation.CoorsTekseal faces are exceptionally durable and help increase the mean time between failures,resulting in greater productivity and lower total cost of ownership for processing equipment.

Carrying on with our series on sanitary mechanical seals, the following will provide a good overview of the mechanical seal face materials we see in sanitary pump applications.

Note that we are only discussing seals and seal material for sanitary pumps. Sanitary pumps have unique characteristics in that they have to be hygienic or cleanable. Because of that, many commercial mechanical seals and packing type seals that do an excellent job from a sealing standpoint, are not suitable for sanitary pumps. So, we are keeping our comparisons to sanitary mechanical seals only.

First, it’s important to think about what makes a good seal face material. Few materials, in fact, are suitable for use in seals. As discussed in our previous blog post, to keep leakage to a minimum, the seal gap must be very small. As a result, the lubricating film is very thin. Consequently, the seal faces need to be able to withstand rubbing together at high speeds. And what also comes when things rub together at high speeds? Friction. Heat. So we also need to select materials that are able to withstand this heat. In sum, the best seal face materials have low friction, high hardness, good corrosion resistance, and high heat conductivity.

Carbon seals. The old standby. Carbon seals offer the greatest economy and lubricity for sealing non-abrasive products. It’s good for clean, abrasive free materials. It self-lubricates to reduce heat and extend service life. It works great with all other seal materials.

Ceramic is much more resistive to abrasive materials than carbon. It’s a great all around seal material. It has good hardness and stiffness. It’s wear resistant, corrosion resistant, and cheap. Despite the material’s stiffness, it struggles in applications with thermal shock. It is most commonly paired with carbon and is Waukesha’s standard seal material in its sanitary positive displacement pumps. It’s the “can do” seal material in the “can do” sanitary pump.

Silicon carbide, specifically reaction bonded and self-sintered silicon carbide, offers superior strength, abrasion resistance, and thermal conductivity to alumina ceramic.

Reaction bonded silicon carbide is made by infiltrating compacts made of mixtures of SiC and carbon with liquid silicon. The silicon reacts with the carbon forming silicon carbide. The reaction product bonds the silicon carbide particles. Any excess silicon fills the remaining pores in the body and produces a dense SiC-Si composite.

Sintered silicon carbide is a premium version of silicon carbide. It contains no free graphite or silicon. Sintered silicon carbide is Waukesha’s hardest seal face for sanitary pumps. It contains no silicon that can leach into the process, is excellent in an oxidizing environment, and has good thermal shock resistance due to low thermal expansion coefficient and high thermal conductivity.

In summary, silicon carbide’s combination of hardness, strength, and temperature resistance gives it excellent capabilities for services in a wide range of applications where high speeds, high pressures, and chemical and abrasion resistance are required.

Commonly known as Purebide, siliconized graphite is technically a silicon carbide. It is made from specially formulated graphite whose surface has been converted to silicon carbide. This provides surface characteristics similar to silicon carbide but is less costly to produce than solid silicon carbide. Free graphite in the silicon carbide layer serves a dry lubricant, reducing friction and improving performance. Purebide is used exclusively in the Waukesha 200 series sanitary pumps.

There is nothing pure about this material. It is a composite. In order to hold the tungsten carbide particles together, a binder is required. Nickel is common in food applications due to its corrosion resistance and compatibility with food products. The metallic binder provides “toughness” to the seal material, making it perfect for heavy-duty applications where high starting torques or shock loading is present. It’s ideal for products that are sticky or set up, high temperature applications, and high loads. It is not inexpensive and should only be specified when absolutely necessary. Tungsten carbide mates with carbon, silicon carbide or itself.

Chrome oxide is an interesting material because most of the seal is actually machined from stainless steel. The base part’s seal face is then coated with chrome oxide. The stainless steel provides a strong base that resists high starting torques, impact loading, and rough handling. The chrome oxide coating provides a hard, wear resistant face that provides performance similar to solid ceramic.

To close, we hope is that this gives you a good idea of what seal face materials are available for sanitary pumps and when to consider them. A future post will expound on seal face combinations, focusing on specific applications when they should be applied, but for now, hopefully this table serves as a good recap:

![]()

Some knowledge of the different materials that are common within mechanical seals is important to determine the correct seal when it comes to seal faces combinations and the material of the o-rings.

With the mechanical seal we are dealing with two seals, primary and secondary. The primary seal is the seal created by the hydrodynamic film between the two (very flat) seal faces. The secondary seal is the seal between the stator part and the housing and the rotor part on the shaft. The secondary seal is (almost always) achieved by using o-rings or gaskets (elastomers). Below you will find a brief overview of the most commonly used materials and combinations. Contact Qseals directly for advice.

![]()

GRAPHITAR carbon is an ideal material for use as a sliding face within a mechanical seal configuration, operating successfully against counterfaces in materials such as Silicon Carbide , Tungsten Carbide and other ceramics. GRAPHITAR is a very hard material and extremely resistant to wear. It is lubricated by most fluids so that the medium being sealed can serve as the seal lubricant. GRAPHITAR’s permeability can be controlled to allow the lubricating medium to be metered to the sealing surface or to be impervious and fully “Leak Tight” to 6 BAR pressure of nitrogen.

Seal faces can be manufactured as fully machined components, lapped to 3 light bands, as semi finished parts or as finished parts pressed to size parts.

Materials used for the manufacture of mechanical seal faces. These materials must meet the tribological demands unique to mechanical seals. Industry has evolved primarily to the use of mechanical carbons and ceramics for these components. A mechanical seal (Fig. 1) is by its very nature a collection of components that are designed to control leakage of a fluid through a sealing interface. These components serve a wide variety of functions and correspondingly require a wide range of material properties. Many of these properties, such as mechanical strength, thermal conductivity, or corrosion resistance, are similar to considerations made for many other devices. Some properties, however, are unique to mechanical seals, such as coefficient of...

S. Chinowsky, Friction and wear of carbon-graphite materials, in ASM Handbook, Friction, Lubrication, and Wear Technology, vol. 18, ed. by P. Blau (1992)

M.B. Huebner, Material selection for mechanical seals, in Proceedings of the 21st International Pump User’s Symposium, Turbomachinery Laboratory, Texas A&M University, College Station, Texas (2005)

Editors and AffiliationsDepartment of Mechanical Engineering and Center for Surface Engineering and Tribology, Northwestern University, Evanston, IL, USA

8613371530291

8613371530291