ce certification mud agitator brands

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

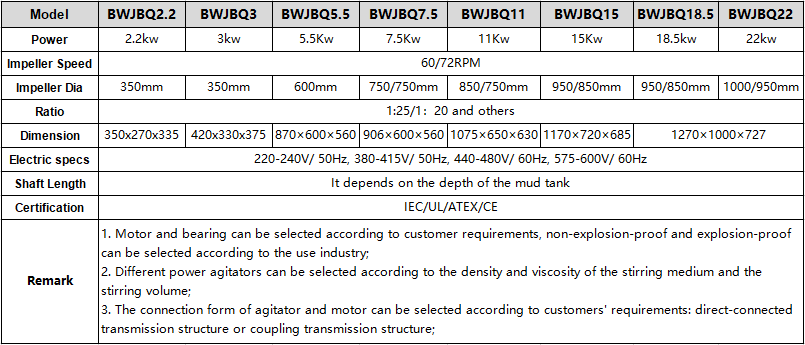

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

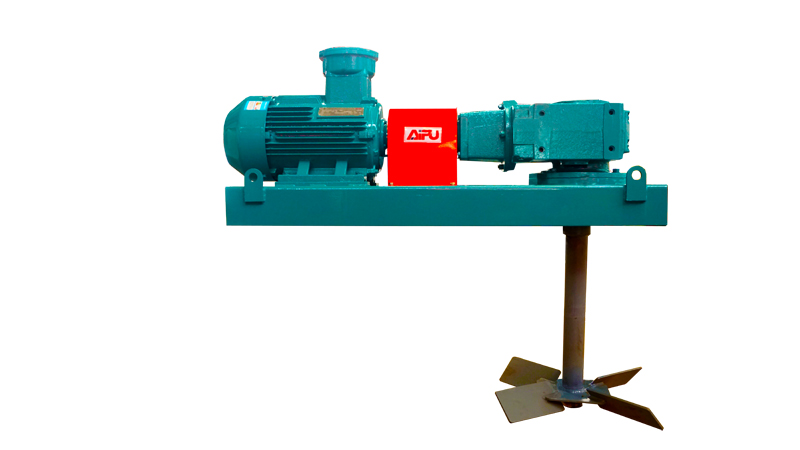

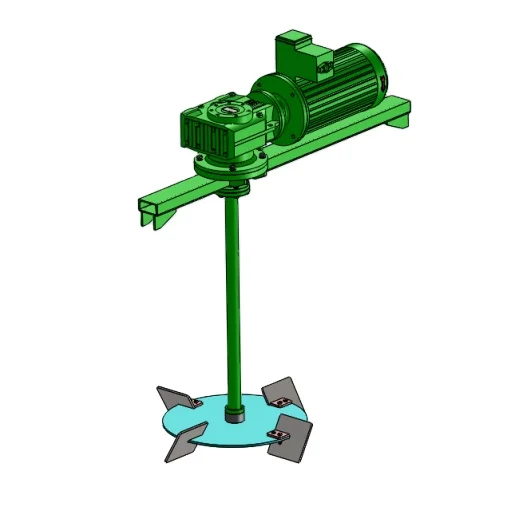

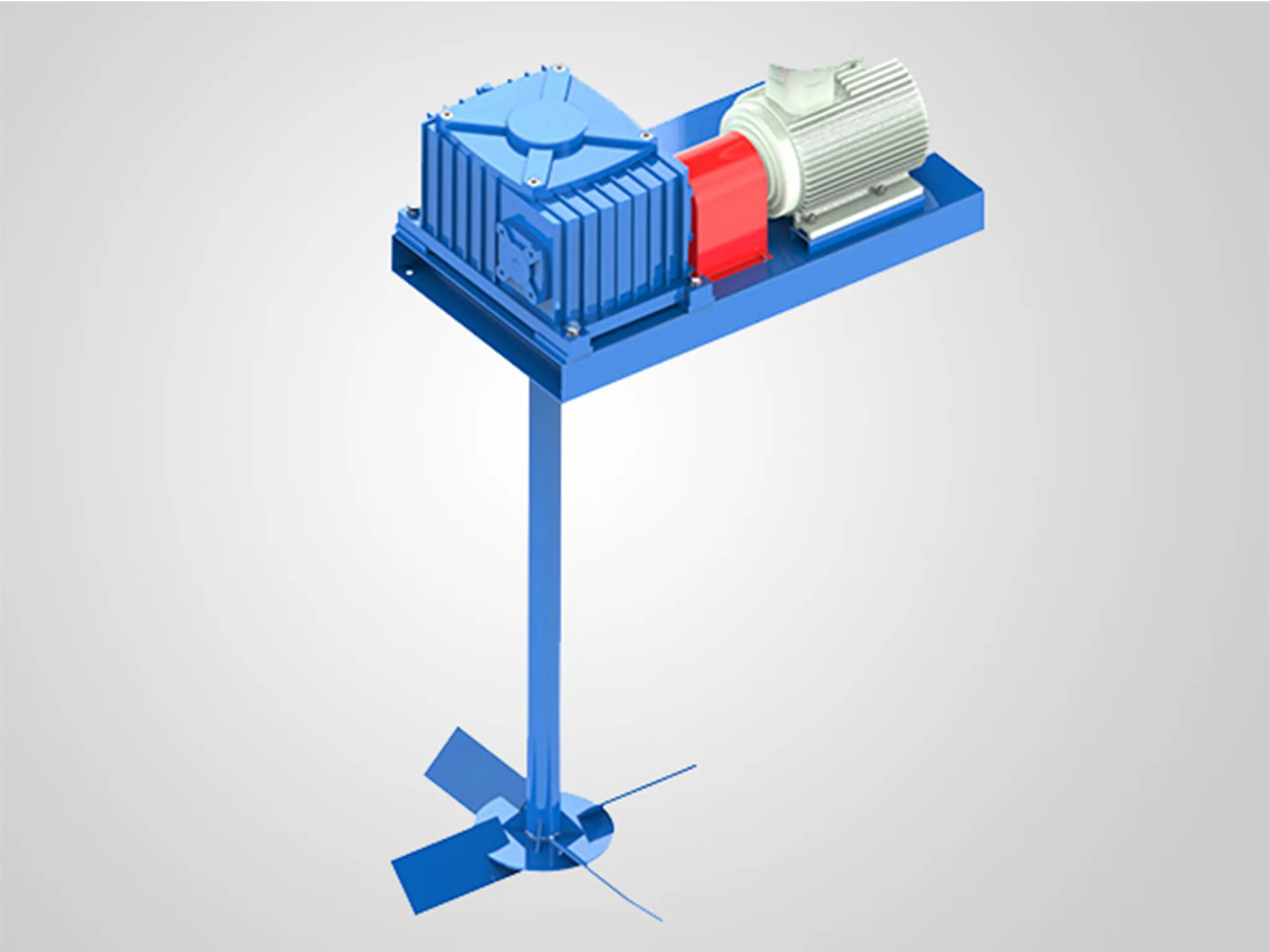

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole.

The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used. Horsepower, mechanical configuration, impeller diameter, number of impeller and shaft length are customized to tank dimensions and maximum mud weights. Here is a list of our recommended configuration.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

GN Solids Control is API & ISO Certified,and our Solids Control equipments and systems have passed the inspection by Tangshan Quality Technology Surveillance and was identified as "100% Assured Quality."We have got all the certificates required to export to counties around the world.

Drill-Quest Engineering is a family-owned business founded in 2002 in Zug Switzerland by the late William (Bill) Schluneger. Bill was first introduced to the oilfield business early in life by his grandfather while growing up in Oklahoma and began to buy and sell drilling equipment as a young adult.

Dragon pump accessories are constructed to handle the harsh oilfield environment. Dragon stands ready to support our drilling and oilfield customers with the highest quality equipment in the industry. And, as always, Dragon backs every product it manufactures with the support you need.

That support includes 24/7 access to our skilled service teams and vast parts inventory. We are always here for you, because we know you do not want downtime. You want quality, dependability and the support of a long-standing oilfield equipment expert backing you up.

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

After years of development, Brightway Solids Control Co., Ltd. has been recognized by many authoritative organizations in the industry and won many awards, including: the honor of drilling solids control equipment technology center; the honor of high-tech enterprise; the honor of AAA credit company; independent innovation enterprise; independent research and development company; quality service integrity company; police equipment alliance companies; CCTV recommended brand company; Alibaba gold supplier,etc.

The quality management system certifications obtained by Brightway Solids Control Co., Ltd. include: API certification, ISO9001-2015 quality management system certification; environmental management system certification; environmental occupational health and safety management system certification, etc.; industry qualification certifications obtained include: IADC drilling contractor qualification certification; product qualification certifications are: mud shaker CE certification by EU; mud cleaner CE certification by EU; drill cuttings dryer CE certification by EU; drilling fluid centrifuge CE certification by EU, etc.; mud agitator CE certification by EU; drilling fluid sand pump CE certification by EU, etc.

The CE mark is a symbol that a manufacturer (see definition below) affixes to a product so that it can be sold in Europe. The mark is mandatory for products which fall under one of 24 European directives. The CE mark means that the manufacturer takes responsibility for the compliance of a product with all applicable European health, safety, performance and environmental requirements. CE stands for “Conformité Européenne", the French for European conformity.

The mark is required in all 27 member states of the EU, as well as Iceland, Norway, and Liechtenstein. Switzerland accepts the CE mark for some products and Turkey actually requires that many products be CE marked.

The natural or legal person with responsibility for the design, manufacture, packaging and labelling of a device before it is placed on the market under its own name.

The Canadian Standards Association (CSA) or the Underwriters’ Laboratories (UL) marks, for example, can only be used when those organizations have determined that a product meets applicable standards. European organizations do not grant authorization to use the CE mark as it is not owned by any particular body. The manufacturer is responsible for its proper use.

The manufacturer, whether established inside or outside the EU, is ultimately responsible for affixing the CE mark and is also responsible for its proper use. The manufacturer established outside the EU may appoint an authorized representative established in the EU to act on his behalf. CE marking is about more than affixing a symbol to a product.

How do you know if your product requires a CE mark? The first step is to see if your product is covered under one or more of the 24 CE directives below. If your product falls under any of these directives, it needs to be CE marked.24 CE directivesDirective NumberProduct Category2006/95/ECLow Voltage

For example, the EU directive for products which fall under theThe EMC directive first limits electromagnetic emissions of equipment in order to ensure that, when used as intended, such equipment does not disturb radio and telecommunication as well as other equipment. The directive also governs the immunity of such equipment to interference and seeks to ensure that this equipment is not disturbed by radio emissions when used as intended.- European Commission

Determining whether your product falls under one or more directives can be difficult. For example, if you manufacture electronic packaging machines with a conveyer belt, several directives will impact you. If you want to know which directives apply, you will have to go through each of the 24 directives (product coverage is sometimes found in an annex). There is no reference tool or database that lists which directives might be applicable to certain products. A trade commissioner can help you navigate these complexities.

Once you have figured out if your product falls under one or more directives, it’s time to assess if your product conforms to the applicable directive(s) and, if not, how you will achieve conformity.

The European Commission often provides mandates to European organizations (CEN, CENELEC and ETSI) to develop standards which are harmonized with the essential requirements of the directives.

In many cases, manufacturers may rely on standards other than harmonized standards in order to demonstrate compliance with the essential requirements in the directives. One notable exception to this rule is the Construction Products Regulation which makes the use of harmonized standards mandatory.

The European Commission often provides detailed guidelines on the application of specific directives, including details on the interpretation of the essential requirements of the directive. While these guidelines do not have legal value (only the official text of the directive does), they are often written in consultation with Member State authorities that enforce the directives.

Below is an excerpt of a table of harmonized standards for construction products, though not all tables have the same format:Harmonized standards for construction productsESOReference and title of the harmonised standard

(and reference document)Reference of superseded standardDate of applicability of the standard as a harmonised European standardDate of the end of the co-existence period Note 4CENEN 1:1998

EN 40-4:2005/AC:200601/01/200701/01/2Column 1: ESO, or the European Standards Organization, is the group responsible for the adoption and publication of EU standards. For the construction products above, the European Committee for Standardization (CEN) is the author.

Once you have identified the essential requirements in the directives and harmonized standards applicable to your product, you need to determine whether your product meets the applicable requirements, and whether you need to have a conformity assessment body test and certify your product to ensure that this is the case.

Some directives require that products be tested and certified by a third-party organization in order to ensure their conformity with applicable essential requirements. Whereas these organizations are known worldwide as conformity assessment bodies, they are also known in Europe as notified bodies (NB). If applicable directives do not require the use of an NB, manufacturers may rely on their own in-house facilities to assess their product’s conformity.

The EU has reduced the number of products that require NB assessment. The Low Voltage directive, for example, does not require the use of an NB. European authorities are increasingly putting the onus on manufacturers to prove their products are compliant.

Be prepared:To find the notified bodies appointed by European authorities to carry out conformity assessment, use NANDO - the New Approach Notified and Designated Organisationsdatabase. Manufacturers can search for a notified body by country and by directive. While the vast majority of notified bodies are located in Europe, a number of them have subsidiaries or contractual relations with certification bodies or testing laboratories located in Canada or in the United States to service North American clients.

How do you know that your product complies with the essential requirements in the applicable directives? You will have to test and document that your product actually conforms. Each directive outlines which conformity assessment procedures - also referred to as modules - a manufacturer can undertake. There are 8 conformity assessment modules. The applicable directives outline which module(s) apply for a particular product category.Module A: Internal production control

Notified body:ascertains, by performing or having performed examinations and tests, that the specimen(s) meet(s) the applicable provisions and is manufactured in accordance with the technical documentation

The manufacturer can hire a service provider for their access to test facilities but will pay simply for testing or other elements of conformity assessment, not consulting and certification, which is also what an NB is hired to do. A company can assess conformity of products by itself if it has the required facilities to test its product. This method is much less expensive.

The manufacturer is required to use an NB to assess conformity and certify its products, but it ultimately remains responsible for their conformity with EU essential requirements.

Conformity assessment to the European directives for CE marking may consist of different activities, including product testing, visual inspection, risk analysis as well as a review of product labels and instructions.

Many directives allow the manufacturer to choose among different conformity assessment procedures for the same product. Knowing all your options can yield significant savings in time and money.

All CE marking directives impose an obligation for the manufacturer to create and make available technical documentation (or a technical file) containing information that demonstrates that the product conforms to the requirements of the directive.

Technical documentation relevant to a CE-marked product must be kept for at least 10 years from the last date the product was manufactured, unless the directive provides for a later date. The technical documentation must be provided on demand to enforcement authorities, often within short timelines. The technical documentation needs to be kept up-to-date, especially when the product is modified or is subject to updated conformity assessment procedures.

Although several of the CE marking directives and European national laws impose that user information (e.g., user manuals) be translated into the official languages of the countries where they are sold, the rest of the technical documentation can be maintained in any EU language (including English or French).

EU law does not require that the technical documentation be located in Europe. The situation is different for the Declaration of Conformity (See step 6). However, EU importers must ensure that the exporter provides that file to EU enforcement authorities. Furthermore, EU importers or distributors marketing products under their own names are required to have a copy of the complete technical documentation.

If European harmonized standards have been applied then evidence of compliance is required. At a minimum this will be a dated list of the European harmonized standards applied and the results obtained on their application;

The document certifying compliance with CE marking directives is the Declaration of Conformity. The Declaration of Conformity is an acknowledgement by the manufacturer that they are responsible for the compliance of its products with the applicable directives.

The declaration should be available to authorities at the EU point of entry. Contrary to the complete technical documentation (which does not necessarily need to be shared with importers and distributors in some cases – see step 5), the Declaration of Conformity should be made available to EU distributors, who may be required to provide it to national authorities immediately upon request.

The CE mark must be affixed to all new products, whether manufactured in the Member States or in third countries; to used and second-hand products imported from third countries; and to substantially modified products that are subject to directives as new products.

Directives may exclude the application of the CE mark on certain products (specified below), even if the directive otherwise applies to the product. These specific exceptions vary from directive to directive.

The CE mark may not, in principle, be affixed until the conformity assessment procedure has been completed to ensure that the product complies with all the provisions of the relevant directives. This will usually be at the end of the production phase. However, if the CE mark forms an inseparable part of the product, or of a component, for example by stamping or casting, the mark can be affixed at any other stage of the production phase, provided that the conformity of the product is verified as appropriate throughout the production phase.

The CE marking shall, as a rule, be affixed to the product or to its data plate. However, it may instead be affixed to the packaging or to the accompanying documents if:affixing the mark is impossible

The CE mark consists of the letters ‘CE’, sometimes followed by the identification number of a notified body, as below. The identification number of the NB is added only when that NB has been involved in the production phase of the product.

Sometimes several notified bodies are involved in the production phase, where more than one directive is applicable. In these situations, several identification numbers follow the CE mark.

Be prepared:The CE mark must be easily seen and accessible for all parties. It could, for instance, be affixed on the back or underside of a product. A minimum height of 5 mm is required to ensure that it is legible. It shall also be indelible so that it cannot be removed under normal circumstances without leaving noticeable traces. (For example, some product standards use a rub test with water and petroleum spirits). However, this does not mean that the CE mark must form an integral part of the product.

sanitary stainless steel mixing tank with scraper(CE certificate)1.mostly together with other mixing forms, 2.efficient mixing - details see: //www.machineto.com/sanitary-stainless-steel-mixing-tank-with-scraper-ce-certificate-10298285

Additional Capabilities:storingPlace of Origin:Zhejiang China (Mainland)Brand Name:HS(sanitary stainless steel blender tank with scraper(CE certificate))Model Number:OEM

The S/S mixing tank is widely applied in beverage, food, dairy, pharmaceutical, chemical and process industries .Our mixing tank can make according to customer"s requirement for the structure, single-layer ,double-layer(jacket) and three-layer(insulation layer) or make limpet coil (inside or external ) to heat and cold.

1. Mainly consisting of canister body, honeycomb jacket and outer wrap layer, between the outer wrap layer and jacket is adiabatic material, with lateral agitator.

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

we are offering mud mixer and mud agitator.colin jet mud mixer is used to concoct the drilling fluids and to change its density and viscosity. This device can satisfy the fluid weighting & mixing of solids control system used for 1500m-9000m drilling. Jet mud mixer is special equipment to prepare and increase the drilling fluids weight by adding and mixing bentonite, change the fluid density, change the mud density, viscosity, and dehydration. The effect is more prominent matching with shear pump. Jet mud mixer is a unit used together with the solids control system for petroleum drilling and horizontal directional drilling (hdd). The unit includes one sand pump, one jet mixing hopper and one jet mixer that are installed in a base with pipe valves. It is safe and stable and can be moved conveniently. At the same time�we can make twin-jet mud mixer according to the user requirements. Jet mud mixer features & benefits: 1. Mud mixer is a single jet mixer combined with 45 kw (or 55 kw) sand pump and a jet mud hopper or a double jet mixer of two pumps and two hoppers. 2. The weighting hopper can be combined with a pump or be used independently with pump connected together by manifold valve. 3. Put the drilling fluids materials (bentonites, barite powder) and the corresponding chemical additives (polymer) into circulation tank for increasing the total.

China The company was founded in December 2010, register capital have 5 million. The company is a modern solid control equipment manufacturer that collection of R&D, production, sales and technical services, the products are widely used in petroleum, oil and gas drilling and exploration industry, the excavation engineering, geotechnical engineering, mining, metallurgy, coal, water and electricity, etc. The company mainly produces drilling fluid vibrating shale shaker and vacuum degasser, the desander and desilter, mud gas separater, mud agitator, centrifugal pump, shear pumps, centrifuge, flare ignition devices, mixed funnel, jet mud mixer, tanks of oil drilling solid control equipment and complete sets of mud purification system, the excavation mud recycling system, gas layer exploration mud recycling system, shield mud recycling system, and the river purification system.

China Various castings used for heat treatment furnaces, like Trays, Grids , Baskets , Holders, Jigs, Rails, Fans, etc., Centrifugal casting tubes for petrochemical&metallurgical industries, like reformer tubes, radiant tubes , furnace rollers, etc.,

China Hebei Jinquanhong Electromechanical Equipment Sales Co., Ltd supplies power saving centrifugal fans. We use advanced Japanese technology, design, manufacture and sell a variety of power saving centrifugal fan and spare parts.With advanced technology from Japan, we offer customized-made fan according tocustomer’s specific needs. Our fan can be used in cement, steel, chemical, metallurgical, power plants and so on. Especially for cement plant, we offer fans of preheater exhaust, raw mill exhaust, coal mill exhaust, cooler exhaust, final exhaust, cooling fan for cooler clinker etc. We also design and manufacture fan for other industries, such as steel, chemical, coke plants etc. Special working conditions in the plants will be seriously considered when design and each of our design is fully tested. It is professional knowledge and rich experience that make Jinquanhong a leading supplier of industrial customized fan in China.Our power saving fans achieve maximum efficiency of 88.9%; saving

China KOSUN is capable of providing customers with such three series as oil & gas drilling solids control equipment, centrifuges and drilling waste treatment equipment, including 25 categories of products, which are extensively used in oil & gas drilling and workover, coalbed methane drilling, shale gas drilling, water well, geothermal well drilling, trenchless horizontal directional crossing projects, mine gravel staged treatment, tailings treatment, rive dredging works, industrial wastewater treatment, environmentally friendly sewage treatment, waste oil recovery and purification treatment, etc.Nowadays, KOSUN possesses three factories: two factories in Xi’an China, one specializing in producing solids control equipment and centrifuges, the other manufacturing all kinds of drilling fluid tanks, water tanks, oil tanks and pressure containers, and the third factory producing various drilling fluid tanks, oil tanks, water tanks and camps in Aktobe Kazakhstan.

China Located in Xi’an- a famous historical city and founded in 2000, Shaanxi Green Environmental Protection Technology Co., Ltd. Our main oilfield chemicals include drilling fluid additives, cement paste additives, oilfield production additives, oil & gas gathering and transportation additives, water treatment additives, etc. Green owns a R&D laboratory with several advanced technologies that can complete the research & development, compatibility study and quality test of products, and also cooperates with Xi’an Shiyou University in scientific research projects. Main oilfield environmental protection equipment includes decanter centrifuge, vertical centrifuge (cuttings dryer), centrifugal pump, screw pump, disc centrifuge (used in such industries as fruit juice, beer, dairy products, chemical industry, medicine, etc.). Green has its own research & development and production base, and its products are mainly applied in oilfield, chemical industry, municipal sewage treatment, etc.

China Zhejiang Redbud Pump Industry Co., Ltd is a professional manufacturer and designer specializing in various electrical submersible pumps.We focus on the product rang including submersible water pumps, deep well pumps, sewage pumps, self priming pumps, and centrifugal pumps.

China Top-rank Japanese technology as the core, we offer industrial fans for customers’ specific needs, such as, multi-blade centrifugal fan, vane centrifugal fan, high pressure centrifugal fan etc. Our products are used in such industries as cement, lime, ceramics; steel, iron, chemical, petrochemical, petroleum refining, pulp, fiber, building materials, semiconductors etc.Our fan efficiancy can reach 85% -90%; saving energy of 10% to 30%; , low noise, small vibration and long service life.Enterprise Culture: Company culture: Core value: double win and mutual benefit.Management philosophy: closely related to the market, persue high-efficiency; Corporation spirits: unity, innovation, integrity, dedication.

China Main products and applications: OIL & GAS Drilling----Mud Solids Control & Waste ManagementHDD & CBM Drilling ----Mud Recycling SystemMining & Industrial----Slurry Separation PlantComplete Line ProductsGN Main Equipment: Shale Shaker, Mud Cleaner , Desander , Desilter, Centrifuge, Cutting Dryer , Agitator, Mixing Hopper, Flare Igniter, Various Tanks, Pumps, Degassers etc.GN Manufacture all types of shale shaker screens in Asia largest wiremesh center city

China KOSUN is a leader in China’s solids control industry and expert in drilling waste management. It is capable of providing customers with professional oil & gas drilling solids control equipment, such as shale shaker, mud desander, oilfield desilter and decanter centrifuge, as well as waste management equipment and drilling security equipment. In total, KOSUN has 25 categories of products, and can also customize packaged design and matching products of oil & gas drilling rigs.

China hangjiagang W-Prosperity International trade Company is a professional hotel and hospital laundry washer and chemical centrifugal extractor provider; we have our own manufacturer workshop which covers 500 square meters, Our main products are: Hotel/restaurant/hospital Commercial Washer & extractor (front door type) (steaming heating and electric heating) Industry washer (front door type): cloth/textile wash Hydro extractor (used in pharmacy/chemical/textile/hospital/food producing /slurry separator etc) Pharmacy centrifugal machine: special design to make sure it is satisfy the special area Flat ironer (single roller and double roller are used in textile/hospital/hotel) We are glad to cooperate with the customers all over the world by providing the good solution to the project.

8613371530291

8613371530291