ce certification mud agitator quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A3: We has been regard quality as the priority. We always attach great importance to quality controlling from the very beginning to the very end ,so our press can match all the CE and ISO standard also more strict standard .

A4: Generally, it will take 35 working days after receiving your deposit payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have standard machines in stock.

A5: We can supply 1 year warranty for our machines, We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

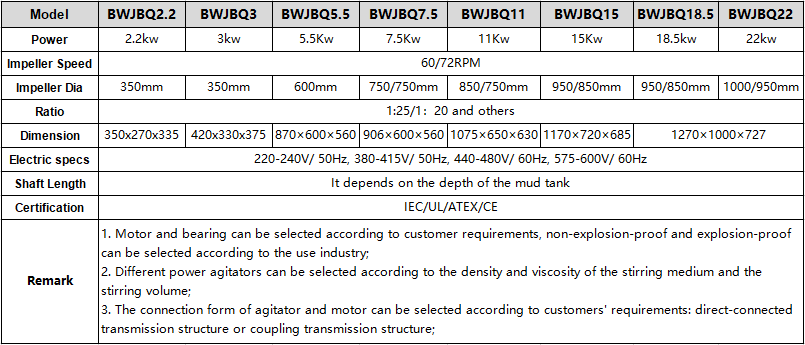

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

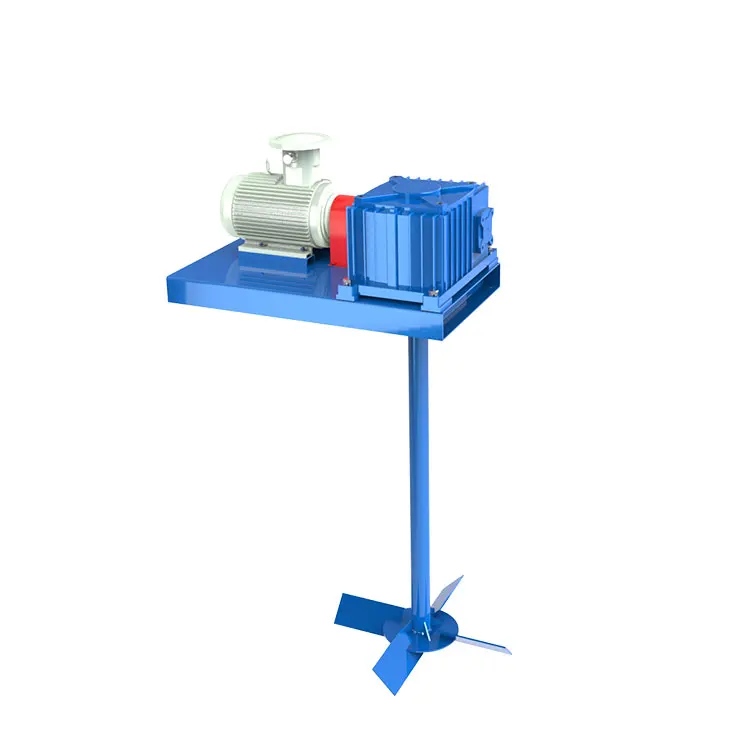

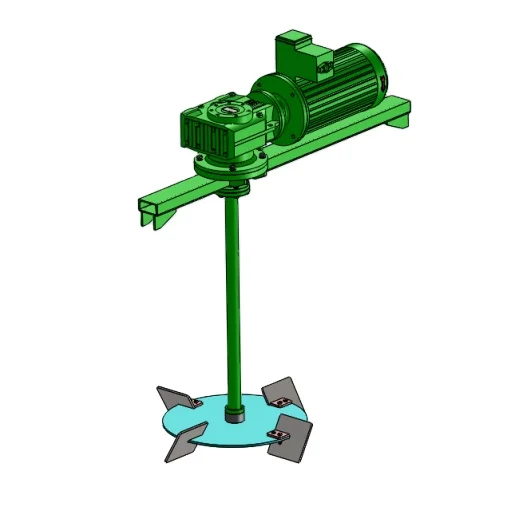

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

Impeller sizes are determined by calculating the TOR (sometimes called the time of rollover) for each compartment. This is the time, in seconds, required to completely move the fluid in a compartment (Table 10.1) and can be calculated by knowing the tank volume and impeller displacement:

For flat and canted impeller applications, TOR should range between 40 and 85 seconds. As the TOR approaches 40 seconds, the chance for vortex formation and possible air entrainment increases. At values greater than 85 seconds, the proper suspension may be jeopardized and solids will begin to settle.

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

For round tanks with dish or cone bottoms, calculations for working fluid volume are based on straight wall height (i.e., this height is measured from the tank top to where the tank joins the cone or dish at the bottom). This leaves adequate free space above the maximum fluid operating level. In all cases, if H<5 feet (1.5 m), a radial flow impeller should be specified.

China Brightway is a famous manufacturer of solid control equipment and solid control system. Brightway has its own factory, processing equipment, workers team, technical team, service team, and has rich experience in design and manufacture of solid control equipment & system. Brightway obtained more than 50 invention patents of solid control equipment and multiple certifications such as API, IADC, CE, ISO.

Brightway can provide users with solid control equipment including: Shale Shaker, Vacuum Degasser, Desander Desilter, Decanter Centrifuge, Cuttings Dryer, Vacuum Pump, Mud Agitator, Mud Tanks, Mud Mixing Hopper, Oil Tanks, Liquid Gas Separator, Centrifugal Pump etc. and complete set of Solid Control System for 1000HP-4000HP(ZJ20-90) drilling rig. Brightway Solid control equipment and system can be applied to oil drilling, natural gas drilling, coalbed methane drilling, shale gas drilling and other HDD drilling industries.

Shaker Equipment: Linear Motion Shale Shaker, Balanced Elliptical Shale Shaker, Double-deck Shaker, Triple-deck Shaker, Dual Tandem Shaker, Triple Tandem Shaker; Desander Equipment: Mud Cleaner, Desander, Desilter; Degassing Equipment: Vacuum Degasser, Liquid Gas Separator; Centrifugal Equipment: Decanter Centrifuge, Cuttings Dryer; Mud Mixing Equipment: Mud Agitator, Mud Mixing Hopper, Mud Mixing Tanks, Mud Gun; Tanks: Oil Tank, Elevated Oil Tank, Water Tank, Mud Tank, Mixing Tank, Barite Bulk Silo, Offshore Tank; Mud Equipment Parts:Shaker Screen, Shaker Motor, Shaker Spring, Cyclone, Agitator Reducer, Mud Tank Suction Valves;

Brightway Solid control system can be designed and manufacture according to the customer drilling rig conditions and requirements, provide the scheme diagram and a complete set of solutions of drilling mud system. Brightway can provide types mud System for 1000hp-4000hp (ZJ20-ZJ90) oil & gas drilling rig, XJ350-750 Workover Rig, coalbed methane drilling rig, hdd drilling rig. Brightway can design and construct 3000-20000 bbl liquid Mud Plant for drilling project.

In order to avoid the customer worry,Brightway provides parts for solid control equipment,such as: Shaker Screen, Shaker Motor, Shaker Spring, Desander Cyclone, Desilter Cyclone, Agitator Reducer, Tank Valves etc.

Manufacturer of standard and custom vacuum high shear and vacuum homogenizing mixers for the pharmaceutical and cosmetic industries. Consists of counter rotating turbine and high speed rotors or stators. Vacuum homogenizing mixers are available in 10 to 4,000 L capacity. Features vary depending upon model including batch and inline design, vigorous radial and axial flow patterns, variable speed controls, color touch screen controls and displays, electronic pushbutton lifts, stainless steel wetted parts, safety limit switches and more. Bending, milling, drilling and turning services offered. Additional services such as rental, rebuild, preventative maintenance, equipment restoration and field services are also provided. Serves the aerospace, aviation, chemical, coatings, animal health and pharmaceutical industries.

The Rig Safe 900 CFM air compressors are ideal for use in hazardous areas with adjustable pressure rating to 150PSI. All units are containerized and stackable uniquely designed to provide operating personnel with the ability to access and operate upper level units when stacked from within the unit through internal access hatches. This fully internal design provides enhanced safety for operating personnel whilst eliminating requirements for scaffolding which further reduces precious foot print space Features: All Containerized (DNV 2.7-1) Compressors • Heavy duty, fully bunded DNV2.7-1 offshore container • Designed for stacking in use - ISO Blocks for locked-on safety • Internal personnel access way between units when stacked • All-pneumatic starting and shutdown systems • Compact footprint - transport three in a 40ft shipping container • High capacity on-board fuel tanks • Direct drive fan (No fan belts to wear out) Options: • Air treatment - aftercooling, filtration and drying

The system consists of 2-5 or even more mud tanks. Most tanks are connected with mud pipelines, such as mud pump suction lines, mud mixing suction and discharge lines, water lines, and gun lines. A number of equipment will be installed onto the mud tank flow lines according to the drilling requirement. The necessary equipment includes:

GMA500‐1000E cement grout mixer and agitator in one same station, int this case, could continuous cement mixing and grouting in ground/underground engineering. It can fast mix water, cement and additive, then the mixed slurry can be stored into a 1000 liters agitator, thus the mixing work and grouting work can be donecontinuously.

Many thanks for visiting our web, we can supply grout mixer and agitator for you. Before we send quotation, please let me know the following question:

The Duplex differs from the standard Multipurpose Batch mixers in having two work heads facing in opposite directions; the upper head pulls materials down from the surface of the mix, while the lower head draws material ...

... inline mixer installations in place for tomato paste standardization, salad dressing and mayonnaise processing, pet food production, flavor emulsions, pharmaceutical preps and API blending, polymer blends, ...

... robust, compact and elegant blender housing with integrated plexiglas protection hood, safeguarding by means of a contactless proximity switch, i.e. the blending process can only be started when the hood ...

The Mud Mixer by kosun is mainly applicated in concoct the drilling fluids and to change its density and viscosity.The characteristics of Mud Mixer by kosun:1. Mud Mixer is a single ...

Most chemical process industry plants for high viscosity mixing applications: polymer industries Food industry plants for high viscosity mixing applications: ...

... close clearances between the paddles as well as between the paddles and the barrel walls, uniform mixing is performed in less time than with conventional mixers. These same tight tolerances also provide ...

SK500 series mixers are agitators with high performance for extended lifetime, reduced maintenance and operating costs.This kind of mixer is specially designed for the application ...

... nyton and polyester fibres, cellulose fibres, extruded PVC-C polymer, PE, PP and PES, static mixers are used in heat exchangers for reducing temperature gradients and for the homogenous mixing ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291