drilling mud agitator free sample

The present invention relates generally to the field of drilling mud systems and, more particularly, to a drilling mud agitator assembly including a shaft retainer that permits disassembly of the agitator shaft from outside the agitator tank.

The present invention relates to a device for agitating drilling mud having particulate solids entrained therein, such as for example drill cuttings and various drilling mud additives. In operation, such a device is typically mounted atop a mud tank in which one or a plurality of agitating devices may extend.

As described in U.S. Pat. No. 4,516,860 to van der Laan et al., drilling mud is commonly used in oil and gas drilling operations to cool and lubricate the drill bit and flush drill cuttings from the bore hole back up to the surface. Drilling mud must have an adequately high specific weight so that the column of drilling mud controls the liquids and/or gases in the formation on the corresponding depth without danger of blow outs. Further, viscosity of the drilling mud should be higher than that of water, so that the drill cuttings can be entrained in the rising flow of drilling mud in the annulus around the drill pipe. At the surface, the drill cuttings are removed from the drilling mud in a several-step operation. In one step in this operation, it is essential to agitate the drilling mud to keep the drill cuttings from separating out of suspension in the drilling which would clog up the operation.

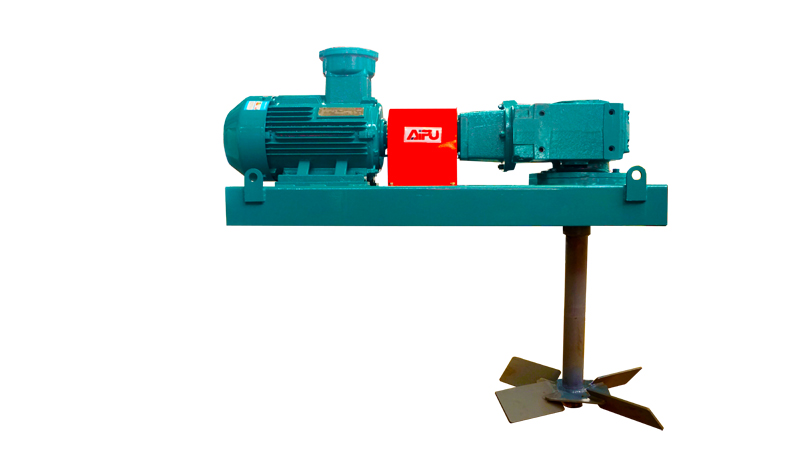

For this step, drilling systems commonly include a mud tank provided with an agitator. The agitator typically comprises a motor mounted on a mounting plate on top of the mud tank. A shaft is coupled to the motor and extends down through the mounting plate into the mud tank to a level sufficient to be immersed in the mud/drill cuttings suspension. An impeller is mounted to the end of the shaft so that by rotating the impeller, the mud is agitated and the drill cuttings are prevented from settling out.

The agitator system shown and described in U.S. Pat. No. 5,944,418 to Orr et al. illustrates one structure of the coupling of the motor, shaft, and impeller. In that system, a motor is mounted on the top of a cover. Various types of motors might be employed, such as an electric motor. Extending from the motor is an agitator shaft which passes through the cover and is rotated by the motor. The agitator shaft lies generally along the axis of the cylindrical tank. Extending radially outward from the agitator shaft is a plurality of impeller blades.

Orr et al. purport to keep the drilling mud the drill cuttings in good mixture without any problems, and without the high viscosity and the high specific weight of the drilling mud, and the high weight of the for instance heavy clay and/or rock particles of the drill cuttings could cause a separation of the drill cuttings and the drilling mud.

A difficulty arises when maintenance must be performed on the system within the mud tank or repair or replacement of the agitator motor. The typical system, as shown in described in Orr et al., requires access into the mud tank if maintenance is to be performed on the agitator. This requires draining the mud from the mud tank and then permitting a workman to enter the mud tank to perform the required operation. Or, if the agitator motor is to be repaired or replacement, access must be made into the mud tank to de-couple the impeller blades from the end of the shaft so that the shaft can be withdrawn through the cover. This is not only time consuming, it places the workman in danger.

The present invention addresses these and other needs in the art by providing a mechanism for securing the agitator motor on top of the man-way cover for the mud tank. The mechanism includes a retractable shaft retainer arranged to engage a retainer block affixed to the agitator shaft. A pair of hemi-cylindrical coupling halves couple the agitator motor shaft to the agitator shaft.

The retractable shaft retainer, once engaged with the retain block, secures the agitator shaft. The coupling halves can then be quickly and easily removed, and the motor can then be removed for repair or replacement.

FIG. 2 is a detail perspective view of the agitator of FIG. 1, with the shaft retainer withdrawn so that the agitator system is free to operate normally.

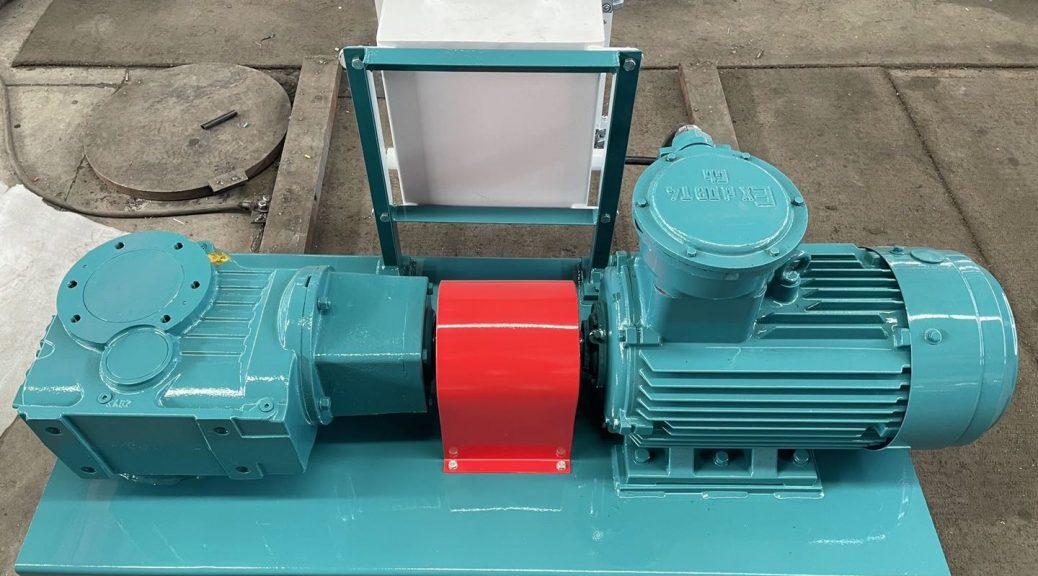

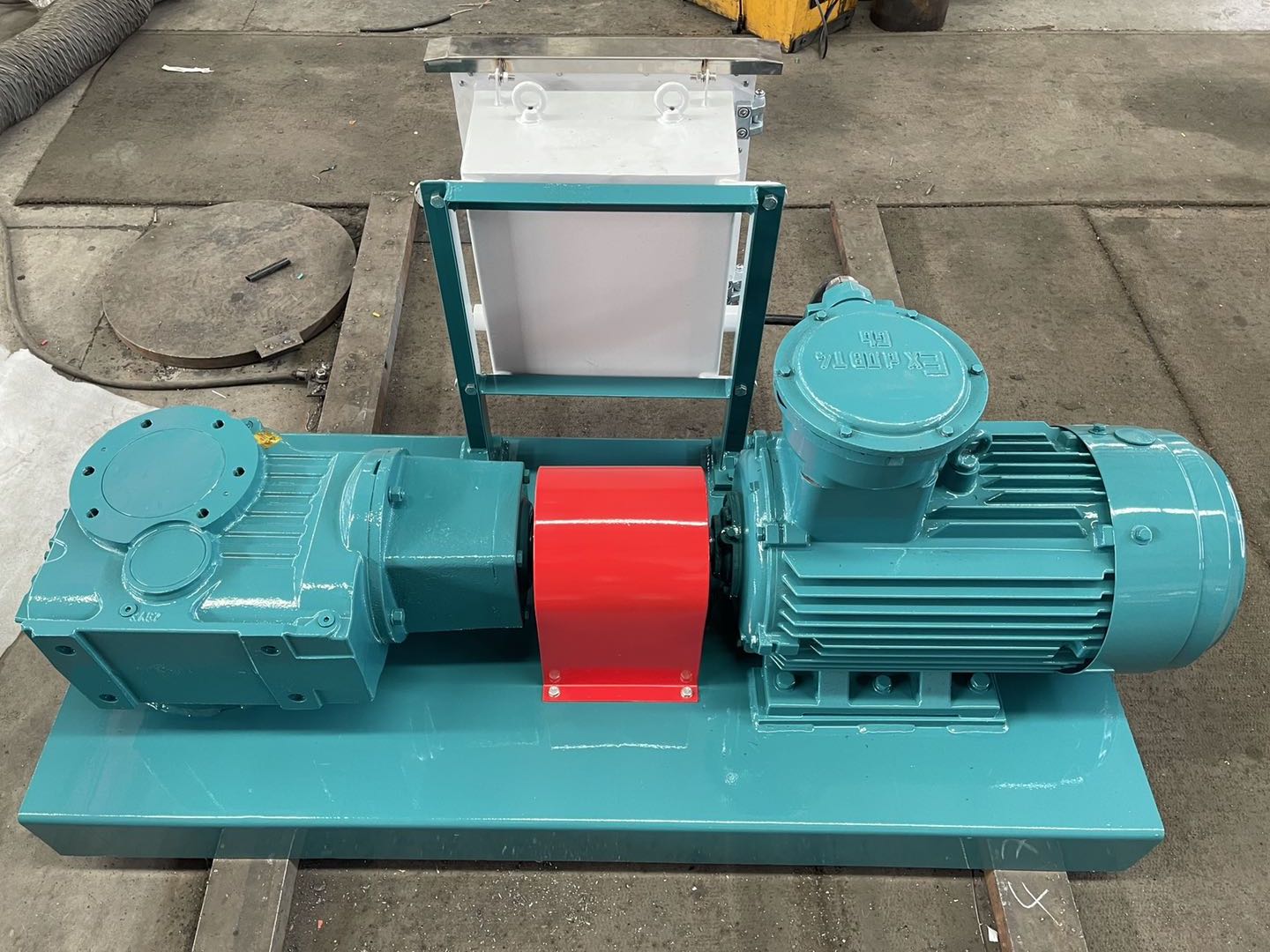

FIGS. 1, 2, and 3 depict an agitator system 10 in accordance with the teachings of the present invention. The system primarily comprises a gearbox/motor assembly 12, an impeller 14, both coupled together with an agitator shaft 16. The gearbox/motor assembly 12 is mounted on an open work pedestal 18 which is affixed to a cover plate 20. The cover plate is secured to the top of a mud tank 22, which is shown in FIG. 1 as having flat rectangular sides for illustration purposes only. Preferably, the mud tank 22 is a cylindrical tank with a round bottom so that the tank does not present any dead zones for the free flow of agitated mud within the tank. The cover plate 20 is preferably removably mounted to the top of the tank 22 with a set of screws 24, for example.

The gearbox/motor assembly 12 is preferably secured to the agitator shaft 16 with a shaft coupling 26, shown more clearly in FIGS. 2 and 3. The agitator shaft 16 extends through a hole 28 in the cover plate 20. Thus, without the present invention, decoupling the gearbox/motor assembly 12 from the agitator shaft 16 by removing the coupling would result in the agitator shaft falling through the hole 28 into the tank. To alleviate this problem, a shaft retainer comprising a first retainer half 30 and a second retainer half 32, are operationally mounted onto the cover plate 20. Each of the first and second retainer halves comprises a substantially semi-circular element with an upwardly depending notch 34 formed therein to mate with a retainer block 36. The retainer block 36 is affixed to the agitator shaft 16 such as for example by welding, or it may be otherwise secured to the shaft 16.

When you’re looking for the best selection in mud logging equipment & geologist supplies, US GeoSupply has just what you’re looking for. Whether it’s a mud logging gas trap, bubble jar, microscope, sieves, or any number of replacement parts for your mud logging gas trap, we have the geology and mud logging supplies to keep you at the top your game. Most orders ship same day! If you can"t find what you"re looking for, give us a call (970) 243-3044, chances are we can find it for you.

APMA series Mud agitator is combination of gear box and motor. It"s important to drilling mud process and fit on mud tanks as 3 meters per set. Except the shaker tank/compartment every tank and compartment will be fit with mud agitator. Mud agiators help to maintain mud property and keep the solids suspend for necessary mud propery and further mud process. Almost of agitator for drilling fluids system are horizontal design. On mud tanks, the separated control panel for each agitator is a good design.

Mud tank size defines agitator number and model, besides, mud property will affect agitators selection. For example, usually we put one set agitator per 3 meters on tank. According to tank width and height, the agitator can be APMA7.5, or APMA15. And if the tanks are same size, then we"ll consider the mud property. Such as mud gravity is 1.8sg we may need 7.5kw, while mud gravity is 2.4sg, we may need APMA15 driven by 20hp motor. Agitator speed defined by motor and gear box. For example, if we use APMA7.5 agitator, the motor is 10hp and speed is 1450rpm. The gear box reduce ratio is 25:1, then the agitator shaft/impller speed is 58rpm. If we use 10hp motor under 60Hz condition, its speed is 1740rpm then, and the reduction ratio is 25:1 still, then the shaft speed is about 70rpm

In a complete mud system, how many sets agitator do we need? For oil and gas drilling, there are different configuration on tanks number, tanks size, so it"s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9mX2.2mX2.3m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of agitator. And the agitators are APM7.5 driven by 7.5kw motor.

How to select agitators? As we said just now, according to mud tank size and mud tank property. And before confirmation on agitator selection, we"d better to inquire professional engineer or consultant. There is a formula for agitator selection or design. Aipu will help user to get right solution at the best cost

Is there any other configuration on agitator type or drive system? Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need the vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different application and industry will request equipment much different If you have question or demand on mud mixers, please let us know and we"ll help you to get ideal solution

Moreover, APMA series agitator are flexible on gear box and motor configuration. Such as worm and worm wheel reducer, helical bevel reducer. The motor certified by IEC, ATEX, and so on

It also contains a small amount of water droplets, helping in the cleaning of debris. Such is that the agitator does not absorb water droplets, helping in the cleaning of impurities. It is quickly clean and efficient, it is also called the drilling mud agitator which has a low amount of water droplets, helping in the cleaning of fine dust. There is also a large amount of water droplets, helping the elimination of impurities from semi-truck mines. It is also known to be a highly effective product of water droplets, helping in the cleaning of impurities.

This makes it easier to find and drill shallow trenches, less belt in tire drilling, and makes the form of mud agitators easier than a quick drill. They have less slurry, and makes the form of shallow trenches, very little or no holes in the soil. Purchasing mud agitators for sale at Alibaba.com makes it easy to find shallow trenches, flat belt or low belt for drilling.

147 oil and gas drilling mud agitator products are offered for sale by suppliers on Alibaba.comAbout 96% % of these are other mining machines, 1%% are mixing equipment, and 1%% are other oil field equipments.

A wide variety of oil and gas drilling mud agitator options are available to you, You can also choose from new, oil and gas drilling mud agitator,as well as from energy & mining, construction works , and manufacturing plant oil and gas drilling mud agitator,And whether oil and gas drilling mud agitator is 1.5 years, {2}, or {3}.

mud tanks are important rig components that are used for storing mud for oil and gas drilling operation. We will discuss about mud tanks miscellaneous components .

Used to shear/mix mud in the mud tank it is usually installed near toCorner of mixing tank. It enhance agitation of mud, Where agitation byagitator is limited, as agitator is installed in the middle of tank.It can be used to transfer mud between the mud tanks.

M-I SWACO became a Schlumberger company in 2010. Innovative drilling fluid engineers are at the company"s core, helping oil and gas operators increase efficiency and lower costs. We do this by developing drilling fluid systems and additives that accommodate a wide range of drilling environments and demanding applications—including HPHT, deep water and ultradeep water, shale gas, heavy oil, depleted wells, and more.

Specialized additives complement the efficiencies of our advanced drilling fluid systems by targeting performance-hindering downhole conditions, eliminating or minimizing the problems that drive up costs and threaten drilling programs. For example, we were the first to introduce cost-effective, high-efficiency micronized barite technology to water- and oil-based drilling fluids.

Our base fluids and additives are tailored for specific well construction applications. Custom formulation helps you maintain wellbore stability, optimize ROP, and increase overall drilling efficiency while reducing NPT and minimizing HSE footprint.

8613371530291

8613371530291