mud agitator design pricelist

Mud Agitator Price is composed of two parts, one is the Mud Agitator Power you will use, and the other is the material of the impeller and length of the impeller. So if you want the details of Mud Agitator Price, you need to provide your use and requirements. How much power is needed and your deepth of mud tanks.

Brightway is the famous mud agitator manufacturer and mud agitator supplier in China. and have more types mud agitators used in the mud tank of drilling mud system or other industry. such as 5.5KW 7.5kw 11kw 15kw mud agitators, or Horizontal Mud Agitator and Vertical Mud Agitator for Mud tank. Gear driven, Advanced impeller designs, Good Packed and delivered quickly. At present, Brightway BWJBQ series mud agitator had been exported to 40+ countries and service for many coustomers. Competitive Prices of Mud Agitator and good sevice is the importent factor.

If you want kown the Mud Agitator Price, please send your request to Brightway Email ( brightway@bwwell.com ) and our sales engineer will give you an Competitive Prices offer as soon as possible.

Mud agitators are fluid mixing equipment that keeps solids in drilling fluid suspending, no deposit in the mud tank bottom. It uses its impeller to agitate and mix the drilling mud to prevent solid particles from depositing in the tank or mud pit.

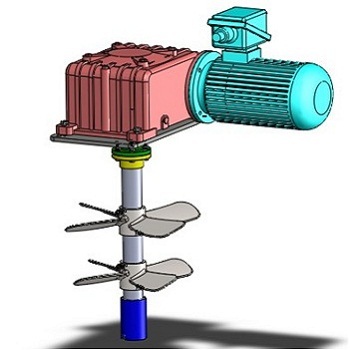

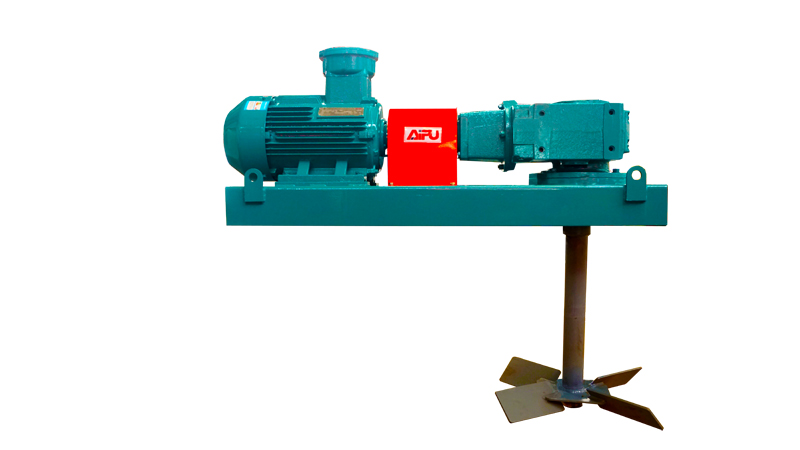

There were many types of mud agitator, depending on purpose demand, gearbox type, and working conditions. But the basic structure of the mud agitator is all the same: Motor, gearbox [Speed reducer], shaft, and impeller.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need a vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different applications and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we’ll help you to get the ideal solution.

For oil and gas drilling, there are different configurations on tanks number, tanks size, so it’s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9 m X 2.2 m X 2.3 m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of the agitator. And the agitators are APM 7.5 driven by 7.5 kw motor.

The most important factor was the power of the mud agitator, 5.5 Kw agitator is cost far lower than 22 KW. There is apparently a different price between the explosion-proof type and Non-proof type. Higher explosion-proof grade means higher cost.

Worm gearbox type mud agitator is a common type, durable, and easy maintenance. But its efficiency lower than the bevel gearbox. so bevel gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. Helical-worm and helical-bevel are advanced generation type of worm and bevel gearbox. They produce less vibration and noise. The planetary gearbox is mainly used in vertical agitator.

Mud agitator is one of the most popular equipment for drilling mud systems. It is mainly used to keep both the mud uniformity and the suspension of solids. The mud agitator is used to agitate the mud consecutively and reliably. This agitator agitates the mud to make the cuttings silt and sand pass the solids control system without being precipitated onto the tank bottom.

The worn and gear reducer mud agitator is an economic standard mud agitator. The mud agitator is equipped with explosion proof motor, worn and gear reducer. The worn and gear reducer is working stable and cost effective. It is also easy for maintenance.

The mud agitator is equipped with heavy duty helical bevel gearbox. Compared with traditional worn and gear gearbox, the helical bevel agitator is with a bigger torque. It is more powerful for heavy mud. The heavy duty helical bevel mud agitator save also power, for the same motor power, the helical bevel mud agitator is with a big torque compared with worn gearbox. So a smaller power helical bevel mud agitator can reach the performance of a bigger power worn gearbox agitator.

2) Impeller: There are double layer and single layer impeller for mud agitators. The impeller size is also designed to suit for the tank depth and width for a better agitating performance.

3) Tank bottom stabilizer to fix the shaft. For mud tank depth over 1800mm. GN will recommend Tank bottom stabilizer to fix the shaft and avoid is swaying during rotating.

HJBL series vertical mud agitator is mainly used for deep mixing and mixing in the mixing tank. The mixing shaft is longer than 1 meter and equipped with a stainless steel base to ensure that the mixer runs stably and does not shake during the mixing process.

Vertical mud agitator can be widely used in chemical industry (fine chemicals, pharmaceutical chemicals and daily chemicals), environmental protection (sewage treatment), pharmaceuticals, cosmetics, metallurgy, food, heat treatment cooling, leather processing and other industries.

2. Reliable: the steel frame is equipped with a high-quality brand geared motor with excellent performance, and the specific anti-corrosion material or anti-corrosion surface treatment is designed and used according to the actual working conditions;

GAURAV ASSOCIATES manufacture the GAMA range of Mud Agitators. These Mud Agitators are used for agitating mud slurry for obtaining consistency through proper blending in flow controlled applications.

Mud agitator, also called drilling mud agitator, used for drilling fluid agitation mix, prevent drilling fluid solid particles in the tank circulation system deposit, cycle drilling fluid performance stability, mixed evenly. Mud agitator composed by explosion-proof motor, reducer, engine base and impeller components four parts.read more...

Used for rapid and uniform incorporation of dry and liquid ingredients.Creates a deep vortex, exposing dry ingredients directly into the agitator blades. This is a standard agitator for bakery applications.Ideal for soluble, dry ingredients that want to float on the surface.

The Technostrength Mud Agitator combines compact design with high torque performance levels necessary for a uniformly suspended flow of drilled solids throughout the mud systems.

Powered by 1500RPM (4 pole) explosion proof motor and connected through heavy duty gear reducer, this agitator transfers high torque at RPM toread more...

Mud agitator, also called drilling mud agitator, used for drilling fluid agitation mix, prevent drilling fluid solid particles in the tank circulation system deposit, cycle drilling fluid performance stability, mixed evenly. Mud agitator composed by explosion-proof motor, reducer, engine base and impeller components four parts.read more...

We are providing to our clients superior quality Mud Agitators. Our offered Mud Agitators are widely appreciated by our clients which are situated all round the nation. These Mud Agitators are used for agitating mud slurry for obtaining consistency through proper blending in flow controlled applications.

- Lightweight, but sturdy construction with the highest torque rating in the industry. Example: 15 hp KOE Agitator weighs 246.4 kg compared to industry averageread more...

LIGHTNINΒs unrivaled, patented, Hydrofoil high-flow, high-efficiency style impellers are used to develop the highest flow achievable for solid suspension and blending. LIGHTNIN guarantees the performance of the mixer as well as the mixing result. Equal power is not equal mixing LIGHTNIN֒s axial flow impellers provide more mixing at the same motor power than competitive impellers. LIGHTNIN mud mixers are designed and engineered to provide complete suspension of the mud and cut- tings. This provides a uniform feed to the mud cleaning equipment regardless of the mud weight. This results in...

Exclusive helical gear construction minimizes gear wear that often plagues worm gear designs. Some mud systems require a low profile mixer to accommodate headroom requirements. LIGHTNIN right angle drives have a very low vertical profile. Oversized bearings and shafts increase life and decrease maintenance. > Splash lubrication provides constant, worry-free flow to all critical areas. Integral foot-mounted or flange-mounted configurations. Dry well construction. One piece shafts as standard. Optional couplings with rabbet/spigot fit to assure alignment. No steady bearings. Special paint and...

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

An Agitator is a equipment used in a tank for mixing various process media together. Media include all liquid types, gases & solids (such as salts, powders, granules etc). In summary, it works by rotating an impeller to impart energy to the media which interact and mix. The components of an agitator in general are the motor & gearbox, shaft & impellers selected for the duty.

An Agitator is used for mixing different process media – liquids, gases and solids in chemical addition or Pharmaceutical Ingredients. The agitator imparts energy through mechanical mean by rotating a shaft on which there is an impeller designed specifically for the duty. This could be axial pumping, gas induction, flocculating, high viscosity products, high & low shear mixing etc. An agitator is also used in the Water Industry for adding various chemicals to bring the source water up to drinking water standards

An Agitator is generally made up of a three main components – a shaft with impellers, a mechanical seal and motor with option of gearbox for lower RPM duties.

The agitator is mounted onto the vessel or via a supporting bridge in the water industry. The mechanical seal has a number of options depending on the duty – single/double mechanical seal, dry or wet mechanical seal, gas lift off mechanical seal that is related to the duty involved.

An agitator shaft is connected to the drive unit (motor & gearbox) and where the impellers used for the mixing are welded or bolted onto. There are options for magnetic driven units where there is a hermetic seal as opposed to mechanical.

Agitators can be simplified into Bottom Entry Agitator, Side Entry Agitator and Top entry Agitator Mud Agitator, depending on the duty & scale of the application to be mixed.

90% of Agitators are a Top Entry Agitatorin API / Chemical / Water industries. The main advantages of a Top Entry Agitator is that it can handle a larger variance in viscosities and specific gravities and also the fact that the mechanical seal is not in the liquid.

The remaining 10% include Bottom Entry Agitator, Side Entry Agitator and Bottom Entry Mag Drive Agitator. Milk silos & very large holding tanks use side entry agitators not necessarily for mixing but to keep the process media moving and keep the milk cool while bottom entry agitators are more common in the Biotechnology sector, where it is a magnetic driven unit (see below).

A slurry agitator is often used to keep the solids in suspension to prevent settling out and forming on the base of the vessel or bulk tank before being transferred to the next stage of processing.

Standard Hydrofoils: these impellers are axial flow high efficiency general purpose – they are designed to offer mixing with low Power requirements. They are also low shear and will not damage sensitive process media.

Wide Blade Hydrofoils: these impellers are axial flow high efficiency – general purpose – they are designed with higher pumping in mind in comparison to the Standard Hydrofoils impellers. They are low shear and they use more power however they would still use less power in comparison to the Pitched or Straight Blade Turbines.

RCI (Retreat Curve Impellers): can be used on Glass Lined Tank/Agitators, they offer lower shear than the Straight Blade Turbines with lower power requirements. They are usually used as a Bottom Impeller because they can be positioned very close to the curve of the bottom dish of the Tank, the blades curve upwards and they are also curved towards the end of the blades.

A wide variety of agitator price options are available to you, such as sus304, sus316l and sus316.You can also choose from new, used agitator price,as well as from manufacturing plant, food & beverage factory, and food & beverage shops agitator price, and whether agitator price is 1000, 500, or 100.

8613371530291

8613371530291