mud agitator manual in stock

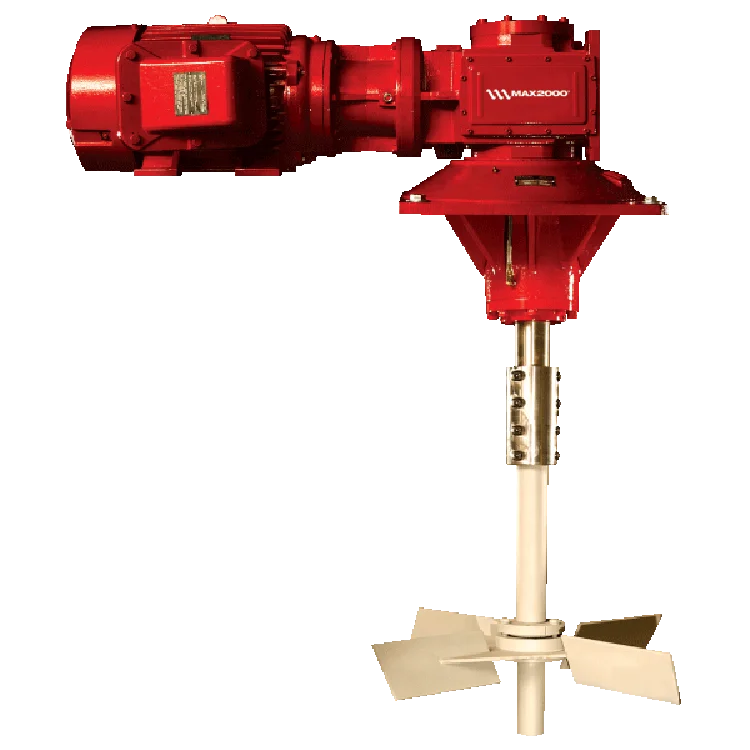

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

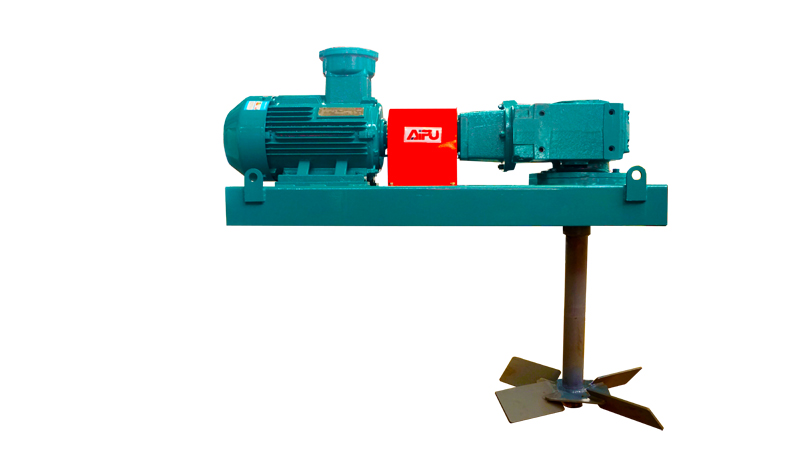

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

Mud agitators are fluid mixing equipment that keeps solids in drilling fluid suspending, no deposit in the mud tank bottom. It uses its impeller to agitate and mix the drilling mud to prevent solid particles from depositing in the tank or mud pit.

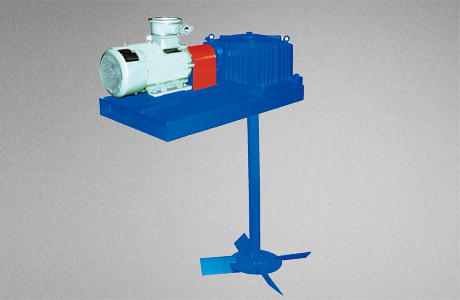

There were many types of mud agitator, depending on purpose demand, gearbox type, and working conditions. But the basic structure of the mud agitator is all the same: Motor, gearbox [Speed reducer], shaft, and impeller.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need a vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different applications and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we’ll help you to get the ideal solution.

For oil and gas drilling, there are different configurations on tanks number, tanks size, so it’s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9 m X 2.2 m X 2.3 m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of the agitator. And the agitators are APM 7.5 driven by 7.5 kw motor.

The most important factor was the power of the mud agitator, 5.5 Kw agitator is cost far lower than 22 KW. There is apparently a different price between the explosion-proof type and Non-proof type. Higher explosion-proof grade means higher cost.

Worm gearbox type mud agitator is a common type, durable, and easy maintenance. But its efficiency lower than the bevel gearbox. so bevel gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. Helical-worm and helical-bevel are advanced generation type of worm and bevel gearbox. They produce less vibration and noise. The planetary gearbox is mainly used in vertical agitator.

THE DOUBLELIFE MUD AGITATORThe Double Life Mud Agitators combine heavy duty design, dependability, low maintenance and easy access to parts for the contractor. This makes the Double Life Agitator the right choice for the customer. High torque combined with service factors well beyond industry standards gives the Double Life Agitator the ability to perform at levels necessary to suspend drill solids throughout the mud system. The Double Life Agitators use explosion proof class 1, group D, electric motors that are directly coupled to Grove heavy duty g~ boxes. Solid machined steel shafts designed to operate well below their first critical speed will easily withstand excessive l tensile and shear stress placedon them in drilling applications. Double Life uses heavy welded steel bases to avoid any deflection or vibration transmission which could cause misalignment or premature failure of couplings or bearings. Double Life 4npellers are designed to give optimum performancein mixing and solid suspension, 60 degree axial design has proven most effective in pits with depth over four feet. Other impellersare availablefor special applications. In all, when contractorscall for an efficient and extremely durable Mud Pit Agitator, call for Double Life.

Mud Mixer Selection(Refer to chart on page 3) 1. Dete11IWIe the heaviest mud to be suspended. 2. - Determine tank sizes using equal dimensions for length and width. Depth and width should not exceed length. Example 1: 10" x 30" Tank. .

MUD AGITATOR INSTALLATION: (1) MAKE CERTAIN THE MOUNTS IN WHICH THE AGITATOR WILL REST UPON ARE HEAVY AND SECURE ENOUGH TO SUPPORT THE WEIGHT AND TORQUEOF THE AGITATOR. (2) THE AGITATOR BASE IS MOUN:rED AND SECURED WITH FOUR BOLTS,NUTS, AND LOCKWASHERS. THE IMPELLER SHAFT SHOULD NOW BE COUPLEDTO THE GEARBOXSHAFT. (3) CHECK THE ELECTRIC MOTOR FOR PROPER VOLTAGE WIRING. THE DOUBLE LIFE AGITATORS ARE WIRED 460 VOLTS UNLESS SPECIFIED OTHERWISE. (4) THE IMPELLER SHOULD ROTATE CLOCKWISE WHEN VIEWED FROM THE TOP. IF THE ROTATION IS INCORRECT, SWITCH ANY TWO LEAD WIRES AT THE STARTERTO REVERSETHE ROTATION. (5) CHECK THE OIL LEVEL. OIL SHOULDBE FILLED TO THE BOTTOMEDGE OF OIL LEVELPLUG USING THE LUBRICANTSPECIFIED. GEAR DRIVE MAINTENANCE (1) A WORM GEAR RUNS HOT DURING THE FIRST FEW DAYS OF OPERATION. THERE IS NO CAUSE FOR ALARM UNLESS THE TEMPERATURE OF THE GEAR DRIVE EXCEEDS 200 DEGREES FAHRENHEIT(93 DEGREESCELSIUS). (2) THE FIRST "OILCHANGE SHOULD BE MADE AFTER 100 HOURS RUNNING TIME. AFTER THE FIRST OIL CHANGE, WE RECOMMEND THE OIL BE CHANGEDEVERY 1,800HOURS OF RUNNINGTIME. (3) GREASETHE TOP BEARINGEVERY 100OF RUNNINGTIME WITH A GOOD HIGH TEMPERATURELITHIUMBASED GREASE.. (4) THE GEAR BOX HAS BEEN TESTED AND ADJUSTED AT THE FACTORY. DO NOT DISMANTLE OR REPLACE COMPONENTS WHILE THE UNIT IS STILL UNDERWARRANTY. (5) CHECK OIL LEVER OF GEAR DRIVE ON A DAILY BASIS. lOlL LEVEL IS LOW, ADD LUBRICATIONTHROUGHTHE FILLER PLUG UNTIL IT COMES OUT THE OIL LEVELPLUG. (6) IF UNIT HAS BEEN SPECIAL ORDERED WITH SYNTHETIC OIL, DO NOT MIX COMPOUNDEDOIL AND SYNTHETICOIL IN REDUCER. (7) INSPECTVENT PLUG OFTEN TO INSUREIT IS CLEAN AND OPERATING."

DESCRIPTIONBASE XX HP 1800 RPM MOTOR COUPLING GUARD COUPLING COMPLETE MOTOR TO GEARBOX BUSHING, MOTOR SIDE BUSHING, GEAR BOX SIDE FLEXIBLE COUPLING INSERT GEARBOX WITH OIL FE-XXXX-20-1 COUPLING COMPLETE GEARBOX TO SHAFT COUPLING, TOP HALF, MALE COUPLING BOTTOM HALF, FEMALE BUSHING, SHAFT, GEARBOX SIDE BUSHING, SHAFT, IMEPLLER SIDE SHAFT FOR MUD AGITATOR IMPELLER FOR MUD AGITATOR BUSHING, IMPELLER TO SHAFT WELD-IN FLANGE FOR IMPELLER MUD AGITATORXXHP. 20-1 GEAR RATIO BEARING, GEARBOX INPUT MOTOR BEARING, GEARBOX LOWER OUTPUT OILSEAL, INPUT GEARBOX OILSEAL, OUTPUT GEARBOX OIL, GEARBOX (ARTIC CLIMATE) OIL, GEARBOX (COLD CLIMATE) OIL, GEARBOX (HOT CLIMATE) BEARING, GEARBOX INPUT FAN END BEARING, GEARBOX UPPER HOUSING

5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators 5W 7.5W 15W motor / gear-box Drilling Mud Mixing Industrial mud tank mud Agitators

As an SPX FLOW brand, Lightnin serves the challenging waste and water treatment sector, as well as the processing of solvents, fertilizers, food/beverages, pharmaceuticals and biofuels. The mixers and agitators, that are custom designed and fabricated, are used for equalization, neutralization, flocculation, aeration, sludge mixing, flash mixing and general blending purposes. The Lightnin industrial mixer portfolio covers both portable and larger fixed-mount units. All Lightnin equipment is designed to provide prolonged trouble-free operation regardless of the specific application demands. Through the proprietary gearbox and impeller technologies developed in recent times, we can offer the market advanced mixing solutions that are far more compact and power-efficient than ever before. They also have significantly greater operational lifespans, thanks to anti-fouling mechanisms and other state-of-the-art features. Consequently, customers are able to raise their productivity levels and avoid costly downtime issues, while also keeping the energy consumption involved to an absolute minimum.

8613371530291

8613371530291