mud agitator manual pricelist

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

LIGHTNINΒs unrivaled, patented, Hydrofoil high-flow, high-efficiency style impellers are used to develop the highest flow achievable for solid suspension and blending. LIGHTNIN guarantees the performance of the mixer as well as the mixing result. Equal power is not equal mixing LIGHTNIN֒s axial flow impellers provide more mixing at the same motor power than competitive impellers. LIGHTNIN mud mixers are designed and engineered to provide complete suspension of the mud and cut- tings. This provides a uniform feed to the mud cleaning equipment regardless of the mud weight. This results in...

Exclusive helical gear construction minimizes gear wear that often plagues worm gear designs. Some mud systems require a low profile mixer to accommodate headroom requirements. LIGHTNIN right angle drives have a very low vertical profile. Oversized bearings and shafts increase life and decrease maintenance. > Splash lubrication provides constant, worry-free flow to all critical areas. Integral foot-mounted or flange-mounted configurations. Dry well construction. One piece shafts as standard. Optional couplings with rabbet/spigot fit to assure alignment. No steady bearings. Special paint and...

REV. ECNNO. DATE DRWN. CHK"D. Manual No.: M9215 1 11122 11/17/99 DJC JW Revision: 2 11148 02/03/00 DJC KS 3 11300 11/17/00 LG TM 4 11305 11/27/00 LG KS=J~= 5 11354 03/14/01 LG

-ii -1 IntroductionProduct Description MA-seriesAgitators are heavy-dutymechanicalmixers for viscousfluids. Severalmodelsare availableto meet a variety of mixing applications. The nomenclatureused by Brandt for mesemodels is asfollows:

The MA-series Agitators are very compact. Their low profile reducesheadroom requirementsandprovidesmore layout spaceon top of the tanks. The 1:1height-to-widthratio resultsin a lower centerof gravity providing stability and safetyshould the impeller encountera sudden shock Ion Thiscoupled with the action of the wonn gearbeing more resiStantto shock and vibration givesa morereliableunit than thoseusing helicaland bevelgears. The sliding action of the wonn and gearinsuresquiet smooth,vibration-freeoperation.

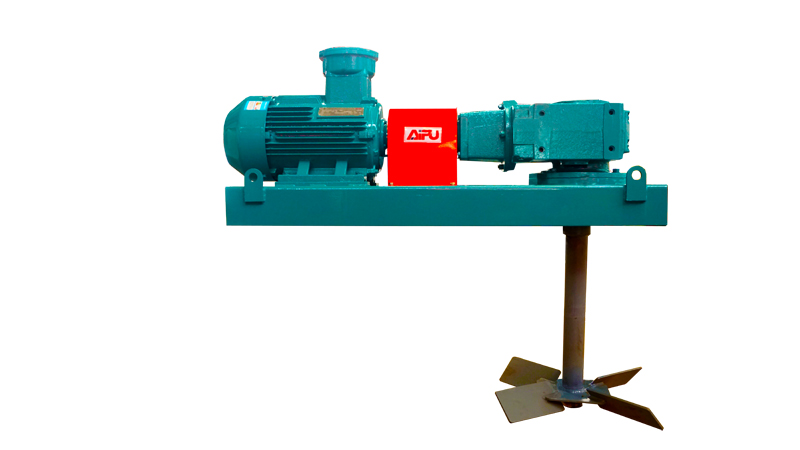

Each MA-series agitatorusesa shaft-mountedimpellerto maintaina homogeneousmixture of liquidsand solids within a tank. Impellers are availablewith cantedblades(axial flow) or flat blades(radialflow), and installedin singleor multiple configurationsto provide the desiredresults.The impellershaftis suspendedfrom, and attachedto the output shaft of the low profile skid mounted gearbox.Thegearboxusesa wonn-wonn geardrive systemto reducethe rotational speed of the explosion-proofmotor to drive the impeller(s).

MA-series Agitators are available in models ranging from 3 to 30 horsepower. hnpellers range from 20incl1es(508 mm) diameter to 52 incl1es(1321 mm) diameter. Flat blade impellers are recommended fortanks less than five feet (1.5 m) in depth. Canted blades are used in tanks deeper than five feet (1.5 m).A combination of both types is often mounted on a single shaft in tanks greater than 15 feet (4.5 m).

Installation: This section contains instructions on how to prepare, transport, locate, and mol.U1tthe equipment described in this manual. It also includes electricalinstallation information.

Notes, Cautions and WarningsThroughout this manual, you will see Waming; Caution and Notes signs to call attention to specificinfonnation neededto prevent damageor injury.

Reaching BrandtIf you needadditionalinfonnaUon,pleasecall your local Brandtrepresentative.H you cannotlocatealocalrepresentative, pleasecallus atthe nmnberlisted on the coverof this manual.

-2-2 SafetyThank you for purchasingBrandt equipment. All Brandt products are designedfor manyyears ofdependableperformance with proper maintenanceand care. This manual contains detailedinformation on the proper installation,operation, maintenance,and repali" for the Brandt MASeriesAgitators.

I.3 Unit DescriptionGeneral DescriptionMA-seriesAgitators are heavy-dutymechanicalmixers for viscousfluids and are availablein modelsranging from 3 to 30 horsepower. Each MA-series Agitator consistsof a shaft-mountedimpeller,motor, gearbox,andmounting base. Electricalcontrols,specialcoatings,sealedbases,and other optionsareavailable.

The motors used on Brandt mud agitators are explosion proof, T-frame, three-phase electric motorsdirecrJycoupled to the gearbox using a flexible coupling with a solid steel guard Motors are available formost voltage/frequent}" requirements. Other electrical code styles and temperature ratings are alsoavailable.

NominalRatings: 230V/460V 60Hz - 1800rpm 190V/380V 50Hz - 1500rpmGearboxThe gearboxis a single reduction wonn-wonn geardrive, reducingthe motor speed (1800 rpm @60 Hz / 1500 rpm @ 50 Hz) to the agitator speed(60 rpm / 50 rpm respectively)in a single30:1reduction. The gearboxcontains an output shaft, two seals,and four to six bearingsin addition tothe wonn-wonn gear. The bearings are generously spaced to minimize shaft vibration anddeflection, and seals are readily obtainable standard sizes. Unlike many competing agitators,Brandt"s gearboxrequires no manual lubrication of the bottom output bearing.

When an agitatoris used in an extremelydeeptank, over 15 feet (4.5 m) deep,multiple impellerscan be mounted on one shaft. Usuallythe upper impeller(s)will be cantedblade,and the bottom impeller will be a flat blade. ContactBrandt engineeringfor properimpeller smng and stabilizerrequirements.

-9-Impeller ShaftBrandt MA-series agitatorimpeller shafts are manufacturedof solid, mild steel. The impeller shaft iscoupledto the gearboxwith a rigid coupling. All shaftsarekeyedto adjustthe height of the impeller.

Shaft length is determined by tank depth. When ordering impeller shafts, always specify theactual tank depth. Tank depth is defined as the distance from the bottom surface of the tank tothe top of the agitator support beams.

Bottom shaft stabilizerA bottom shaft stabilizeris requiredin deeptanksto reducesideloading on the gearboxbearings.Thestabilizeralsoprotectsthe agitatorshaft and impeller when auXl1iary equipmentis canied insidethe mudtank during rig moves. MA-3 Agitators requirea bottom stabilizerin all tanks 6 feet (1.8 m) or deeper;all otherMA-seriesagitatorsrequirea bottom stabilizerin tanks8 feet (2.4m) or deeper.

OptionsThere are severaloptions availablefor Brandt MA-series Agitators. Popular options include specialpaint fmishesor other coatings,remote startersand other elecrricalcontrols, and specialduty motors.Contactyour Brandtsalesrepresentative to disCUss which optionsmaybe right for your application.

-10- Available models Brandt MA-seriesAgitators are availablein severalmodels,from 3ill to 30 ill. The following table liStSthe physicalspecificationsfor theseunitS.

Routine Maintenance Checklist Your BrandtMA-seriesagitatoris designedfor yearsof dependableservicewith routine inspectionand maintenance. Pleaserefer to the Routine MaintenancedIecklist locatedin the Addendum sectionfor routine maintenanceinstructions. Additional copiesof this checklistshould be placedcloseto the unit for qW~ reference.

The MA -series agitator should be kept in a cool city place. The gear box should be filled with oil and the gear box input shaft should be rotated 30 times once a month. When taken out of storagethe gear box oil should be changed.

ISYMPTON I POSSIBLE CAUSE lff?9LUTION Agitatorwon"t run No Power d1eck Power

Tripped breaker 01~ Voltage,ch~ that agitatorshaft not dragging on bottomstabilizer

Agitator makes grinding High speednoise Replaceworn bearings noIse Low speednoise Replace drop bearing or thrustbearing

Agitatorvibrating coupling Ali~ mot?r coupling. See repaIrseCtIon

0 1.) Check oil level with agitator OFF: Oil should be level with the bottom of 2 7 the "oil level" hole. DO NOT OVERFill! 2.) Impeller rotation: The impeller " should rotate clockwise when viewed from top. 3.) Oil FillNent Plug: Vent plug must be clear of any obstruction to prevent pressure build-up and possible seal ,d damaQe. 4.) Agitator should operate with no 5 vibration. 5.) Check rubber insert on input shaft coupling for wear and cracks. 6.) Change oil** after first four days of ~... operation. DAILY OJ 7.) Inspect oil seals for leaks. Seals are self-lubricating and a slight seepaoe is normal. 8.) Keep motors clean and ventilation -! opening clear of mud blJild-up or 6 other debris. 9 9.) Check impeller shaft coupling for prODer make-UD. 6 PERIODIC ~ 10.) Check oil level. 11.) Lubricate the top bearing with one shot of approved bearing grease* every four days of running time. DO NOT OVER LUBRICATE! 12.) Change oil every three months Lubricate* motors every three f==[

U"Ii NOTES; ,. TANK DEPTH IS DEFINEDAS THE DISTANCEFROM THE TANK BOnOM TO THE TOP OF THE AGITATOR SUPPORT BEAMS. 2. REOUIRED.IF THE TANK DEPTH IS EOUALTO OR GREATERTHAN B FT. 3. SECUREMUD AGITATORBASE BY WELDING TO TANK. & 4. SEE PI9B09 FOR IMPELLERMOUNTINGLOCATIONS

REV. ECN NO. DATE OWN. CHK"D. TITLESHAFTAND IMPELLER ASSEMBLY BUSINESS PROPRIETARYTHIS INFORMATION IS THEPROPERTY OF TUBOSCOPE vrn:o INTERNATIONAl M A -3 MUD A G I TAT 0 R1Nt. AND IS NOT TO BE COPIED.DISClOSEDOR USEDFOR ANY PURPOSEOTHERTfM THE PURPOSEFOR WHCH IT HAS BEEN SUBlimED w~ OWN. DC DATE11.10.92 DRAWING NO. REV.PRORWRmENPER~ISSION BYTUBOSCOPE vrn:o INTERNATIONAl INC. CHK"O. DATE APP.O.TCA DATE 1,. , 2.92 PI 50 79 1 BILL OF MATERIAL ITEM QTY. DESCRIPTION PART NO. n- 1 2 WORM & BEARING WORM GEAR 30: 1 20:1 INPUT i 45MLi~H gAG 2 BEARING OUTPUT gAP 1 OIL SEAL INPUT 10AH oJ 2 OIL SEAL OUTPUT lOAF 1 OIL PLUG VENTED 42AF 1 OIL LEVEL PLUG 42Z 8 1 OIL DRAI~Pl~G- 42AD I 1 (lS"F TO 50"F) 46J 46A lOlL 5 46L 468I 46M_46Z

ECN NO DATE OWN. CHK"D. TITlE GEAR REDUCER PROPRIETARY RIGHTS ARE INCLUDED IN THE INFOR~TlON DISCLOSED HEREIN. NEITHER THIS DOCU~EHT NOR THE INFOR~A1K)N DISCLOSED REPLAC EM ENT P ARTS HEREIN SHALL BE REPRODUCED OR TRANSFERRED TO 01HER DOCU~ENTS ~ ~~ 1 ~ ~~ I "CAW""" "",., gn, OR DISCLOSED TO OTHERS FOR MANUF~RING OR FOR ANY PURPOSE I OWN. DC !OAT[ 11-9-92 ,DRAWING NO"1 REV. EXCEPl AS SPEClnCALlY ALITHORIZED IN WRITING BY THE BRANDT CO~PANY.lCHK"D. A OtVlSK>N OF DREXEL OIlfiElD SERVICES. INC. I APP"O. -;-~ IDAT[ P 15 0 8 0 I 0J_9J~! NOTES: 1. TANK DEPTHIS DEFINEDAS THE DISTANCEFROM THE TANK BOnOM TO THE TOP OF THE AGITATOR SUPPORT BEAMS. 2. REQUIRED.IF THE TANK DEPTHIS EQUALTO OR GREATERTHAN8 FT. 3. SECUREMUD AGITATORBASE BY WELDING TO TANK. &"4. SEE PI9B10 FOR IMPELLERMOUNTINGLOCATIONS

1 10835 09.16.98 KA A TUBOSCOPE COMPANY REV. ECN NO. DATE OWN. CHK"D. TITLESHAFTAND IMPELLER ASSEMBLY BUSINESS PROPRlnARYTHISINFORMAOONIS THE PROPERTY Of" TUBOSCOPE vrn:o INT£RNA~ MA-5 MUD AGITATOR1Nt. AND 5 NOT TO BE COPIED. D5CLOSEDOR USED FOR ANY PURPOSEOTHERTHAN THE PURPOSEFOR WHICHIT ~ BEEN SUBUmED WI~UT I OWN. :C DATE 11.10.92 iDRAWING NO. REV.PRK)RWRITTENPERMISSIONBY TUBOSCOPE VETCt) INTER~TlO~ INC. ICHK"D. APp.D. TCA 1DATE DATE 11.12.92 PI 508 1 1 BILL OF MATERIAL

t< -~~~ (\Ir--.. i: ~~~m ..-0 , ~ 5 ~~~~~~,~c~ ;.eo. "~,""UCZ- .."~i~~ r; ~~~~:~ i 1 , mill iI"I NOTES: 1. TANK DEPTH IS DEFINED AS THE DISTANCE FROM THE TANK BDnOM TO THE TOP OF THE AGITATOR SUPPORTBEAMS. 2. REQUIRED. IF THE TANK DEPTH IS EQUAL TO OR GREATER THAN 8 FT. 3. SECURE MUD AGITATOR BASE BY WELDING TO TANK.

1 10835 09.16.98 KA A TUBOSCOPE COMPANY REV. ECN NO. DATE OWN. CHK"D. ,TrTLESHAFTAND IMPELLER ASSEMBLY BUSINESSPROPRIETARY THISINrOR~TK)NIS THEPROPERlY OF"TU~PE V£TCOINTER~~ M A -7.5 MUD A G I TAT 0 R INC. AND5 NOTTO BE COPIED.DISClOSEDOR USEDFORANYPURPOSE OTHERT~ THEPURPOSE rOR WHICHIT HASBEENSUBMITTEDWIn«>UT OWN. DC DATE1 1.10.92 DRAWING NO. REV. PRORWRITTENPERMISSIONBY TUBOSCCPE VETCO INTER~TlONAl INC. ICHK"D. DATE IAPP"D. TCA DATE 11.12.92 PI 5083 1-c"==[ BILL OF MATERIAL PART NO.1 :"_45P/458- 90 9U I

NOTES: - r- -; , C21B 1SV 3K ,. TANK DEPTH IS DEFINED AS THE DIISTANCE FROM C1021 930 THE TANK BDTTOMTO THE TOP OF THE AGITATOR h:=- SUPPORTBEAMS. 2. REOUIRED, IF THE TANK DEPTH IS EOUAL TO OR GREATERTHAN8 FT. 3. SECURE MUD AGITATOR BASE BY Y(ELDING TO TANK. I--- & 4. SEE P198"1 FOR IMPELLER MOUNTING LOCATIONS

1 10835 09.16.98 KA A TUBOSCOPf COM PA,NY REV. ECN NO. DATE -- HAFT AND IMPELLER~ASSEMBLY .s~~~ TITLES I BUSINESS PROPRIETARY THIS INroRMATX>N IS THE PROPERTYOf TUBOSCOPE VETCOINTER~roNAl MA-10 MUD AGITATOR INto AND IS NOTro BE COPIED,DISCLOSED OR USED ft)R .ANYPURPOSE OTHERTHAN n£ PURPOSEroR WHICHIT HAS BEEN SUBMITTEDWITHOUT OWN. DC IMTE 1"."0.92

-- NOTES: ,. TANK DEPTHIS DEFINEDAS THE DISTANCEFROM THE TANK BOnOM TO THE TOP OF THE AGITATOR SUPPORTBEAMS. 2. REQUIRED,IF THE TANK DEPTH I~i EQUAL TO OR GREATERTHAN8 FT. 3. SECUREMUD AGITATORBASE BY WELDING TO TANK. & 4. SEE P19S"1 FOR IMPELLERMOUNrrlNGLOCATIONS

REV. ECN NO. DATE OWN. CHK"D. ~I PC;IN~~ PROPRlnARVTHISINFUR~OON IS T~~_o~";;E~;-~;"oscoPE VETCOINTERNATIONAl MA-15 MUD AGITATOR1Nc. AND IS NOT ro BE COPIED. DISCLOSED OR USED FUR ANY PURPOSEOTHERTHANTHE PURPOSEFUR WHCH IT HAS BEEN SUB\4ITTEDWITHOUT I OWN. DC 04TE 1 1.10.92 DRAWINGNO.PRIORWRITTEN PER~ISSK)N BY TUBOSCOPE VLTCOINTERNATION4L INC. I CHI<"O. IAPP"o. TCA DATE DATE 11.12.92 PI 5 500 88 7 7 I ioEV. 1 -m "" t IQ l"-

, 21l 3N NOTES: 1. TANK DEPTHIS DEFINEDAS THE DISTANCEFROM C218 15H -4 3N THE TANK BOTTOMTO THE TOP OF THE AGITATOR rs I ~1Q21 930 SUPPORTBEAMS. I 1 2. REQUIRED.IF THE TANK DEPTH IS EQUALTO OR C~"57 17AX GREATERTHAN 8 FT. C~"57 17U 3. SECUREMUD AGITATORBASE BY WELDING C~"57 17V TO TANK. ~J]57 17G ~ 4. SEE PI9812 FOR IMPELLERMOUNTINGLOCATIONS

T;;e...,~CE~ NOTES: 1. TANK DEPTH IS DEFINEDAS THE DISTANCEFROM THE TANK BDnOM TO THE TOP OF THE AGITATOR SUPPORTBEAMS. 2. REQUIRED.IF THE TANK DEPTH IS EQUALTO OR GREATERTHAN 8 FT. 3. SECURE MUD AGITATORBASE BY WELDING TO TANK. & 4. SEE PI9813 FOR IMPELLERMOUNTINGLOCATIONS

- Lightweight, but sturdy construction with the highest torque rating in the industry. Example: 15 hp KOE Agitator weighs 246.4 kg compared to industry averageread more...

We are providing to our clients superior quality Mud Agitators. Our offered Mud Agitators are widely appreciated by our clients which are situated all round the nation. These Mud Agitators are used for agitating mud slurry for obtaining consistency through proper blending in flow controlled applications.

The Technostrength Mud Agitator combines compact design with high torque performance levels necessary for a uniformly suspended flow of drilled solids throughout the mud systems.

Powered by 1500RPM (4 pole) explosion proof motor and connected through heavy duty gear reducer, this agitator transfers high torque at RPM toread more...

Mud agitator, also called drilling mud agitator, used for drilling fluid agitation mix, prevent drilling fluid solid particles in the tank circulation system deposit, cycle drilling fluid performance stability, mixed evenly. Mud agitator composed by explosion-proof motor, reducer, engine base and impeller components four parts.read more...

Used for rapid and uniform incorporation of dry and liquid ingredients.Creates a deep vortex, exposing dry ingredients directly into the agitator blades. This is a standard agitator for bakery applications.Ideal for soluble, dry ingredients that want to float on the surface.

GAMA Mud Agitators have compact design and their low profile reduces headroom requirements providing more layout space on top of the tanks for other equipment. The low center of gravity ensures stability and safety should sudden shock loads be encountered by the Impeller

Mud agitator, also called drilling mud agitator, used for drilling fluid agitation mix, prevent drilling fluid solid particles in the tank circulation system deposit, cycle drilling fluid performance stability, mixed evenly. Mud agitator composed by explosion-proof motor, reducer, engine base and impeller components four parts.read more...

Mud Agitator Price is composed of two parts, one is the Mud Agitator Power you will use, and the other is the material of the impeller and length of the impeller. So if you want the details of Mud Agitator Price, you need to provide your use and requirements. How much power is needed and your deepth of mud tanks.

Brightway is the famous mud agitator manufacturer and mud agitator supplier in China. and have more types mud agitators used in the mud tank of drilling mud system or other industry. such as 5.5KW 7.5kw 11kw 15kw mud agitators, or Horizontal Mud Agitator and Vertical Mud Agitator for Mud tank. Gear driven, Advanced impeller designs, Good Packed and delivered quickly. At present, Brightway BWJBQ series mud agitator had been exported to 40+ countries and service for many coustomers. Competitive Prices of Mud Agitator and good sevice is the importent factor.

If you want kown the Mud Agitator Price, please send your request to Brightway Email ( brightway@bwwell.com ) and our sales engineer will give you an Competitive Prices offer as soon as possible.

8613371530291

8613371530291