mud agitator parts brands

That support includes 24/7 access to our skilled service teams and vast parts inventory. We are always here for you, because we know you do not want downtime. You want quality, dependability and the support of a long-standing oilfield equipment expert backing you up.

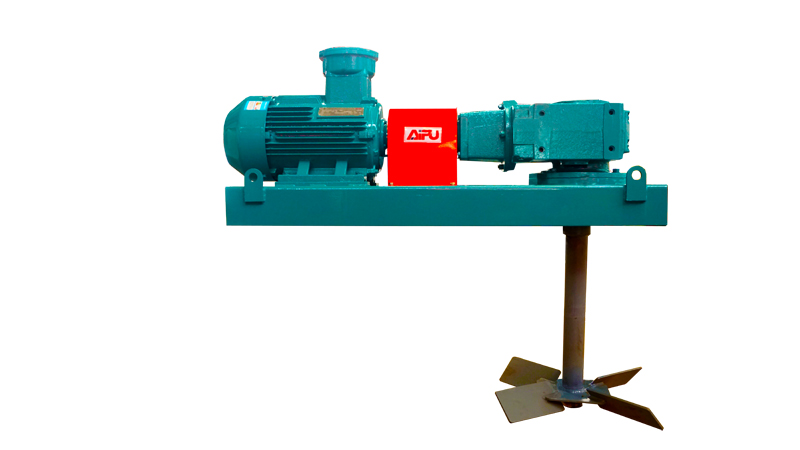

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

As Mud Agitator Manufacturer, Brightway can supply BWJBQ 5.5-22kw Mud Agitator for mud tank and mud system. including: Horizontal Mud Agitator or Vertical Mud Agitator. Brightway mud agitator can be customized once we get the detailed requirements. Buying mud agitator from Brightway will be your best choice for drilling mud circulation system.

1. Brightway mud agitator equips with a motor couple to a rugged oilfield gearbox, which can eliminates troublesome couplings, misalignment and have a longer bearing life. And it is driven by the explosion-proof motor, coupled to a gearbox which will drive the impeller shaft. Due to the simplex turbine structure of shaft,

2. Brightway mud agitator is featured by compact construction, light weight, balanced transmission, small footprint, low noise and high efficiency. And its impeller turbines can transform the mechanical power into drilling fluid agitation as well as circulation.

3. Brightway mud agitator can be designed per customer’s requirement to choose the helical-bevel design or worm design for reduction gearbox. Its motor can be horizontal or vertical. As for the shaft and impeller, compared with painting process, the galvanizing treatment is usually adopted to create a better anti-rust performance.

JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender cycloid speed reducer, and it is applied to the drug liquids mixing tank. This mud agitator has the advantage of compact structure so it occupies small area. More than 7.5 kW Mud Agitator uses the turbo and worm gear speed reducer, with the large torque transmission、 the revolution is steady、it works reliablely and has great merit. Common model of mud agitator is JBQ5.5kW 、JBQ7.5kW 、JBQ11kW and JBQ15kW.The drilling mud agitator is an important components for GN Solids Control drilling fluids processing system.

GN Solids Control as a professional manufacturer for soilds control equipments, we have designed lots of high-quality products, and JBQ series Agitator is one of them. To keep both the mud uniformity and the suspension of solids, the mud agitator is used to agitate the mud consecutively and reliably.This agitator agitates the mud to make cuttings, silt and sand pass the solids control system without being precipitated onto the tank bottom. Due to the simplex turbine decelerator, this product is featured by compact construction, light weight, balanced transmission, low noise, high efficiency of transmission and strong agitating power. Therefore, it is a reliable product in the solids control system.

China manufacturer GN Solids Control offer the world with drilling mud agitator equipments.We are an exporter of drilling fluid mud agitator for Indian, Russian,middle east.etc..Our factory and company are Quality Management System ISO 9001-2000 certified.GN Solids Control operate international oil gas drilling mud separation system sales,service,manufacturing,distribution serivce.Buy drilling fluid mud agitatorfrom China manufacturer.Your best mud agitator for drilling mud circulation system.

KOSUN mud agitator is part of the drilling fluids solids control equipment, which is mainly used to agitate and mix the drilling mud to prevent solids particles from depositing in the circulating tank and to stabilize the performance of drilling fluids. The motor and speed reducer, speed reducer and impeller shaft are connected by steel coupling.

TSC mud agitators are an important part of the mud solids control system. TSC offers a variety of motor and impeller sizes to fit specific tank configurations.

ProQuip doesn’t just make industrial tank agitators, we deliver comprehensive mixing technology and solutions that will help you meet your specific process objectives. Whether you’re in chemical processing or a wide variety of other industries, our stock and custom tank agitator designs are engineered to provide reliable, efficient, long-term performance that will help maintain product quality, maximize productivity, and reduce downtime.

Contact us today at 1-330-468-1850 or applications@proquipinc.com for help determining the right tank agitator and mixing solution for your application.

Hubei Craun Technology Equipment Co., Ltd (abbreviated as Craun Tec.), with the registered capital of 10 million RMB and 25000㎡ factory ground, is located in High Tech. industrial park of Xian Ning, Hubei province, which is 100 Kilometers away from Wuhan. The HQ is divided into two parts, mechanical precision processing factory and equipment manufacturing factory. We have more than 100 sets professional precision processing center, inspection equipment, heavy manufacturing equipment and complete environmental protection treatment equipment. Craun Tec. focuses on the technology R&D on the field of solid-liquid separation, and has the independent R&D and fast & efficient system solution capabilities, it is a global professional manufacturer integrating system design, technology R&D, production and sales and after-sales service.

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by the impeller induces the flow and shear of the media inside the tank, which causes a single or multi-component media to homogenize. The flow of the media is kept at a uniform rate and pattern.

Agitators can handle liquid, gaseous, and solid (e.g., granules, powders) media. They can also work with slurries, suspensions, and highly viscous liquids. However, selecting the appropriate agitator type, sizing, and design for the specific nature of media is crucial. Viscosity and sensitivity to shear stress are essential considerations when selecting an agitator. Agitators are widely used in many industries, including food and beverage, pharmaceutical, agricultural, biotechnology, paint, and water treatment industries.

The terms “agitators” and “mixers” are often used interchangeably, but they technically do not mean the same thing. Mixers are equipment that rapidly blends two or more components together. These components may be of the same or different phases (e.g., solid-liquid, liquid-liquid, gas-liquid). When a component enters a mixer, it is often in a “pure” state and leaves combined with other components. On the other hand, agitators maintain homogeneity and equilibrium in an existing mixture. They prevent the formation of concentration and temperature gradients and ensure uniform consistency in a mixture.

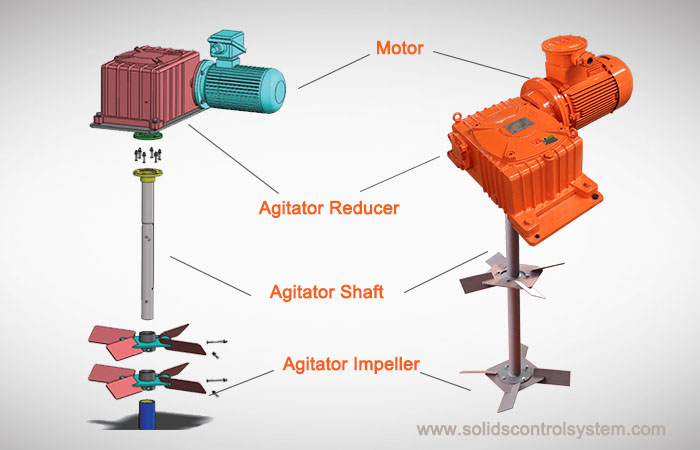

The motor drives the agitator assembly. It produces the required torque to induce flow and shear to the media at a controlled degree. The power requirement of an agitator depends on many factors such as:

The impeller is considered the most critical component of agitators that determine the flow pattern, efficiency of the homogenizing process, and mixing parameters. It is responsible for exerting energy directly to the materials being mixed. It induces fluid flow and shear patterns as it rotates. This component does the actual mixing.

Impellers mainly consist of a hub and blades. The hub is directly connected to the shaft through a shaft key and a grub screw. The agitator blades are attached to the hub by welding or screwing. A welding connection is more hygienic because it prevents material-build on the fasteners and fittings. There could be more than one impeller installed in an agitator shaft. The number of impellers depends on the type of impeller, the maximum height of the media inside the vessel, vessel diameter, and specific media gravity. This information is also necessary when determining the spacing between the impellers.

Anchor agitators have impellers that resemble the shape of an anchor. They typically have a U-shape that matches the contour of the tank. They generate a predominantly tangential flow pattern, but angled blades can be incorporated on their horizontal supports to create an axial flow.

Anchor agitators are used for blending and heat transfer of highly viscous liquids. Their impellers generate a laminar low-shear flow; hence, they are used to mix shear-sensitive media. Anchor agitators are considered the most economical laminar flow agitator. They are suitable for tanks with rounded or conical bottoms. The impeller can be designed to have a low clearance with the tank wall.

Double helical ribbon agitators are designed to have two helical blade flights running through the shaft in opposite directions. The additional flight enhances the mixing of more viscous fluids. These impellers are also used in heat transfer applications and are considered the best high viscosity laminar flow impeller. The impeller can also be designed to have a low clearance with the tank wall.

Helical ribbon agitators have a helical impeller blade fixed in the shaft by rods. These impellers are an alternative to anchor impellers which can generate laminar flow. These agitators create an axial flow pattern. They generally have a higher fluid contact area to mix fluids with higher viscosities.

Paddle agitators consist of two flat paddle-shaped impeller blades extending to reach the tank walls. They are used if no extensive axial and radial flow is required. These impellers can produce a laminar low shear flow and are used for low viscosity liquid mixing, crystallization, dissolution, and heat transfer. They are typically operated at low speeds and predominantly give a tangential flow pattern. Secondary blades can be installed on the paddle blades to enhance the mixing of more viscous materials.

The impeller blades are inclined from the plane of rotation to create an axial flow pattern. This variation of paddle agitator is typically used for homogenizing suspensions.

Propeller agitators mainly produce an axial flow pattern, though tangential flow can also be produced. The fluid is displaced and accelerated longitudinally after the impeller blades draw it. The deflection of the fluid depends on the inclination of the impeller blades. The impeller blades are tapered towards the shaft to minimize centrifugal force and maximize axial flow.

Propeller agitators are used in homogenization, dispersion, and suspension of low viscosity products. They are used in solid-liquid suspension systems and chemical reactors to prevent solids settling at the tank bottom. They may be installed in unbaffled tanks when the propeller is inclined vertically from the centerline or in an off-center position.

Turbine agitators are an intermediate between propeller and paddle agitators. They usually have larger diameters than propeller agitators. These agitators combine centrifugal and rotational motion. They are used in emulsification and dispersion processes in which the media is required to flow at high speeds. They offer a good balance between flow and shear. They are typically operated at high speeds. They can handle a wide range of material viscosities and still provide a high mixing efficiency.

Top entry agitators are installed at the overhead of the liquid level, commonly at the centerline of a baffled vessel. They are ideal for wide tanks with small aspect ratios (i.e., the ratio of liquid level to tank diameter) of about 1:1. They may be installed with an angle offset with the vertical to suspend solids in the solution effectively. They are suitable for sealed tanks and can be attached by plate mount or flange mount. Their structure and position allow easy dismantling and cleaning.

Side entry agitators are installed on the sidewall of a tank. They are used when the width of the tank is much greater than the liquid level. They are also used in tanks with low ceiling clearance, which does not permit the installation of a top-entry agitator. However, less consistent mixing is achieved because the fluid is pushed along the walls of the tank. The fluid content must be drawn during maintenance. The power requirement of side entry agitators is also higher than top entry agitators.

Bottom entry agitators are installed at the bottom of the tank. They have a short shaft that is directly connected to the motor"s driveshaft. Bottom entry agitators are used for mixing the materials which tend to settle at the tank bottom. They are commonly used in large volume tanks. They are used in homogenizing mixtures such as oils, milk, juices, and others.

The main components of an agitator are the motor, shaft, and impeller. The impeller is considered as the most critical component that primarily determines the flow pattern, efficiency of the homogenizing process, and others.

The types of agitators are paddle agitators, anchor agitators, helical ribbon agitators, propeller agitators, turbine agitators, agitators with screw impellers, retreat curve impellers, hydrofoil impellers, dispersion blade impellers, and coil impellers.

1. Use worm / worm speed reducer; Compact structure, good meshing performance, reliable operation.; 2. With the combination of the reducer and explosion-proof motor, suitable for harsh conditions in the field of work.; 3. Explosion-proof motor and reducer input shaft through the elastic coupling directly, without the use of belt transmission, so the speed of mixing impeller constant.; 4. Stirring intensity and wide range, and from the structural design avoid the motor at the start of the current overload phenomenon.; 5. Explosion-proof motor level placement, installation, adjustment or replacement is very convenient.JB/W series agitator is an important equipment of drilling fluid solid control system, which is mainly used for mixing drilling fluid to prevent the drilling fluid solid particles from settling in the circulation process, and make the drilling fluid mix evenly and stably.

Mud agitators are indispensable in drilling fluid configuration. The mud agitator adopts the circular arc cylindrical worm reducer, the shaft section is a circular arc cylindrical worm, and the worm gear tooth shape is a circle that is conjugative to the worm. Therefore, the convex-concave meshing performance is reliable, the benefit is high, and the structure is compact.

The circular arc tooth of themud agitator reducerin the mud agitator is a kind of mud agitator part that can often be seen. It has great advantages in structure and transmission, especially in special environments. It has the function of automatic locking, so it is liked by many solid control manufacturers.

1: Heat and oil leakage of the arc reducer. The arc gear worm gear reducer is designed for the purpose of improving the operation efficiency. The worm gears used are all made of non-ferrous metals, and the worms are mostly made of hard steel. Therefore, during the operation of the sliding friction drive, the worm gears are reduced. The machine will generate a large amount of heat and increase the temperature of the reducer. The temperature increase of the worm gear reducer will cause the various parts in the reducer to have differences in the fit due to the different coefficients of thermal expansion, resulting in a gap between the mating surfaces. The oil such as lubricating oil used in the reducer will also become thinner or deteriorated under the action of high temperature, resulting in leakage or lubrication failure. The way to prevent the temperature rise of the worm gear reducer is to reasonably match the material of the worm gear and worm to avoid excessive friction. At the same time, pay attention to the surface quality of the meshing friction surface and select suitable lubricants. Another direct way to cool the reducer is to install a cooling device or reduce the temperature of the operating environment.

8613371530291

8613371530291