mud agitator sizing manufacturer

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

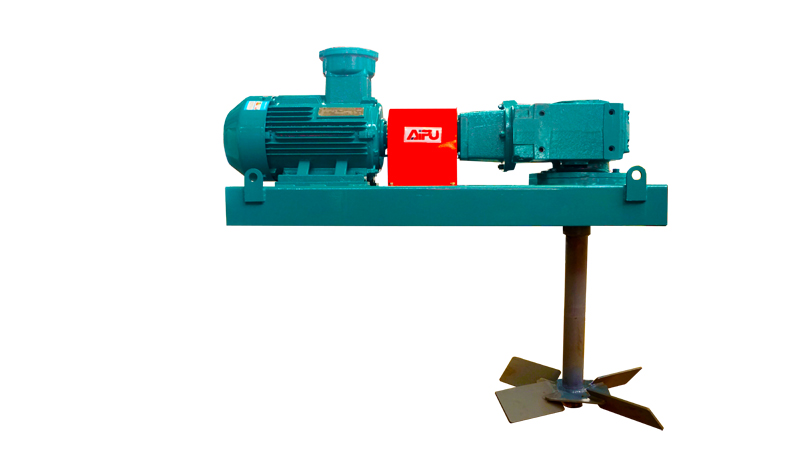

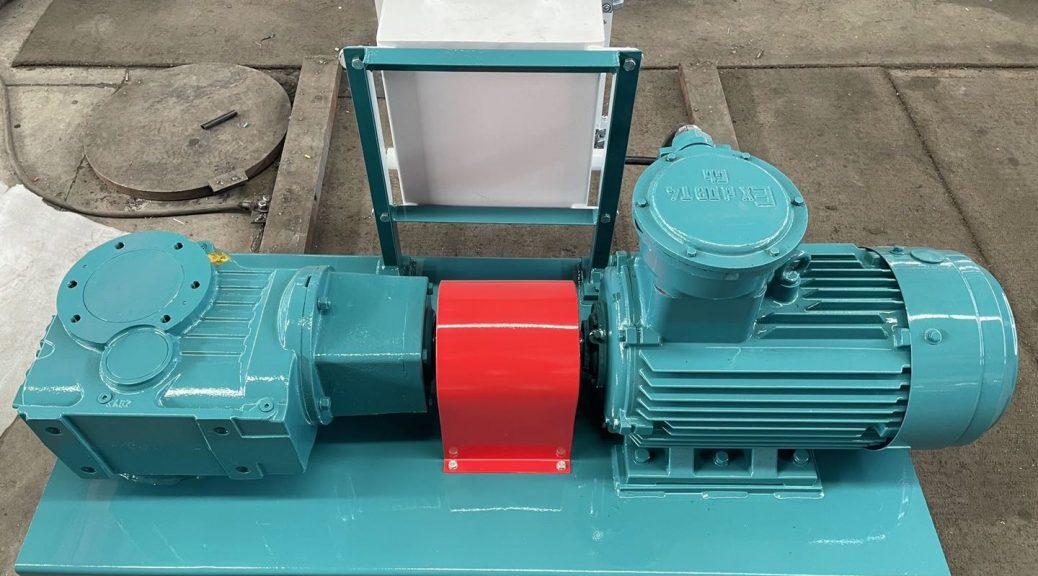

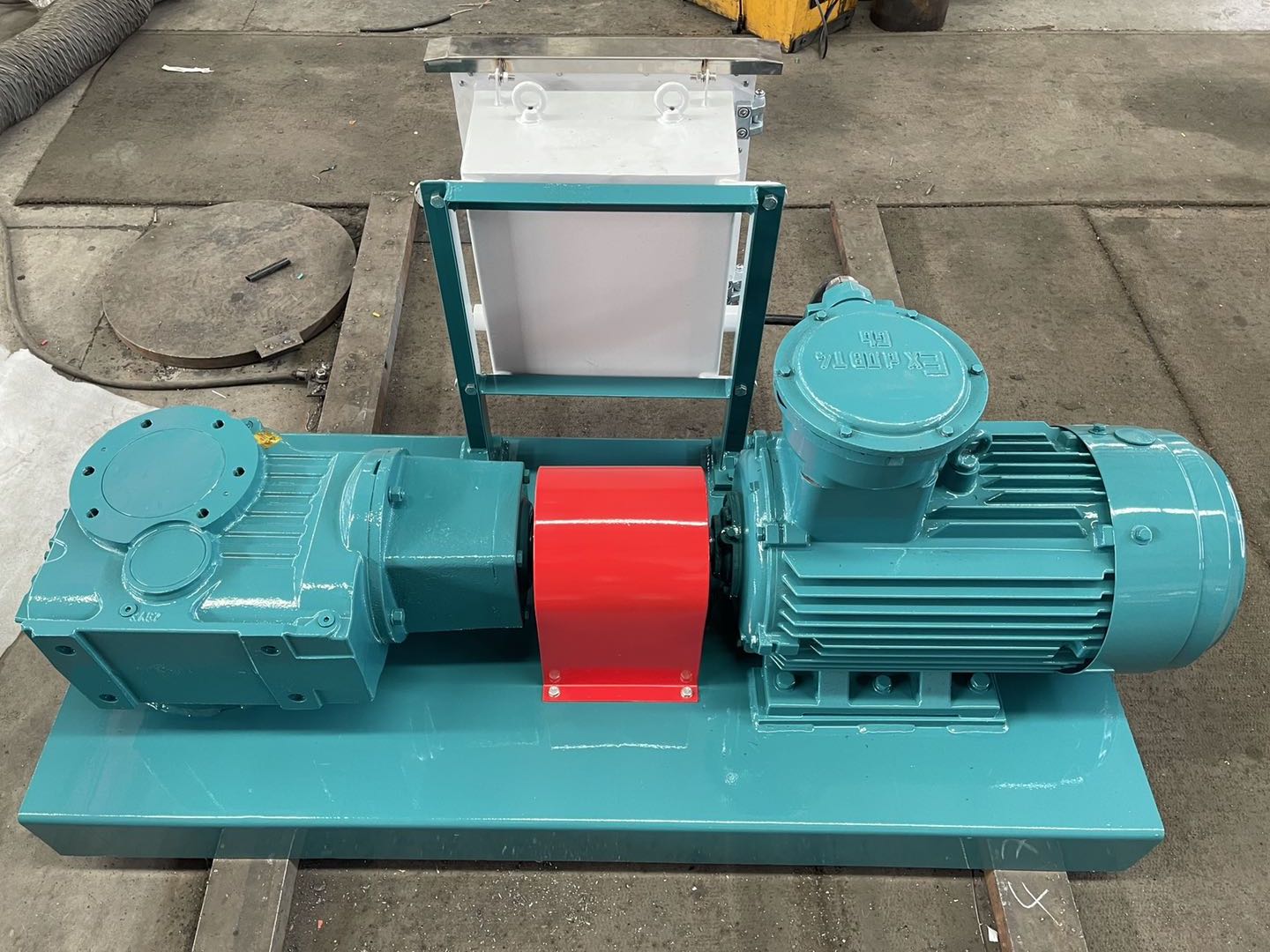

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

Mud Agitator is also called Mud Tank Agitator and widely used in the mud solids control system. It is installated in slurry storage tanks or mud tank and to prevent drilling fluid solid Particles deposited in the mud tank. Brightway is the famous and professional Mud Agitator Manufacturer and can produce the horizontal Mud Agitator and vertical Mud agitator.

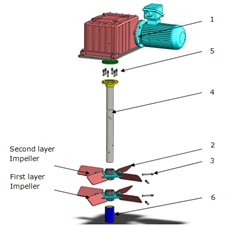

Mud Agitator is used in mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor,coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation. The objective is to obtain a uniform suspension of all solids.

Brightway mud agitator features a “C” face motor couple to a rugged oilfield gearbox, which eliminates misalignment and troublesome couplings. This configuration promotes long motor and gearbox bearing life. Please contact with Brightway representative with your tank dimension and your detail requirement. We will recommend the right model with specification about the horsepower, impeller (size, type& quality), and shaft length etc to meet your requirement.

We offer best range of Mud Agitator which works continuously at the drilling site by delivering optimum results. Our Principles has made us to supply our highly technological equipment to the power plants which are present in abroad.

Technostrength FLP Motors range from 5HP to 30HP and can be used with various power configurations. Gear reducers are worm type or helical bevel type depending on the choice of the user. For Achieving Highest Performance in various mud conditions we offer 3 to 6 blade designs, mixed and axial flow turbine types, canted, bolted and twisted profile types also. For all these equipment Mud Agitator Manufacturer in India like Technostrength is occupying the best place in the industry.

Solid Control Mud Agitators act as mud mixers on mud tank. On a usual process these agitators should rotate at 60-70 rpm. Our high performance equipment is appreciated among clients all over India. If there is a large quantity of mud present in the site then large torque mud agitator will be required.

We suggest the customers to choose the mud agitator according to the size of tank along with torque level. Mud Agitator Manufacturer in Hyderabad is the name suggested to our services by all our previous customers.

We present to you a line of very efficient and highly productive Agitators that are used in various industries. We make use of a variety of the choicest materials like steel, stainless steel, hastelloy and titanium in the manufacture of these agitators. We offer this type in technical specifications as per your requirements.

Adinath designs and manufactures assorted types of Anchor Type Agitators and also customized turbines in accordance with the requirements of the process. The height and the sweep diameter of the turbine are carefully ascertained for competent dispersion of the reactants and homogenous mass. The Agitators are dynamically balanced to guarantee weight balance at high rpm, thereby increasing the agitator and motor life. These types of Agitators are used if dispersion is required at high rpm.

Along with the ability for Design and Fabrication of Agitator For Process Vessels, we offer complete mixing agitators, chemical agitators, mixers, blenders, reactors with shortest deliveries for trouble free lifelong operations

An Agitator is a equipment used in a tank for mixing various process media together. Media include all liquid types, gases & solids (such as salts, powders, granules etc). In summary, it works by rotating an impeller to impart energy to the media which interact and mix. The components of an agitator in general are the motor & gearbox, shaft & impellers selected for the duty.

An Agitator is used for mixing different process media – liquids, gases and solids in chemical addition or Pharmaceutical Ingredients. The agitator imparts energy through mechanical mean by rotating a shaft on which there is an impeller designed specifically for the duty. This could be axial pumping, gas induction, flocculating, high viscosity products, high & low shear mixing etc. An agitator is also used in the Water Industry for adding various chemicals to bring the source water up to drinking water standards

An Agitator is generally made up of a three main components – a shaft with impellers, a mechanical seal and motor with option of gearbox for lower RPM duties.

The agitator is mounted onto the vessel or via a supporting bridge in the water industry. The mechanical seal has a number of options depending on the duty – single/double mechanical seal, dry or wet mechanical seal, gas lift off mechanical seal that is related to the duty involved.

An agitator shaft is connected to the drive unit (motor & gearbox) and where the impellers used for the mixing are welded or bolted onto. There are options for magnetic driven units where there is a hermetic seal as opposed to mechanical.

Agitators can be simplified into Bottom Entry Agitator, Side Entry Agitator and Top entry Agitator Mud Agitator, depending on the duty & scale of the application to be mixed.

90% of Agitators are a Top Entry Agitatorin API / Chemical / Water industries. The main advantages of a Top Entry Agitator is that it can handle a larger variance in viscosities and specific gravities and also the fact that the mechanical seal is not in the liquid.

The remaining 10% include Bottom Entry Agitator, Side Entry Agitator and Bottom Entry Mag Drive Agitator. Milk silos & very large holding tanks use side entry agitators not necessarily for mixing but to keep the process media moving and keep the milk cool while bottom entry agitators are more common in the Biotechnology sector, where it is a magnetic driven unit (see below).

A slurry agitator is often used to keep the solids in suspension to prevent settling out and forming on the base of the vessel or bulk tank before being transferred to the next stage of processing.

RCI (Retreat Curve Impellers): can be used on Glass Lined Tank/Agitators, they offer lower shear than the Straight Blade Turbines with lower power requirements. They are usually used as a Bottom Impeller because they can be positioned very close to the curve of the bottom dish of the Tank, the blades curve upwards and they are also curved towards the end of the blades.

JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender cycloid speed reducer, and it is applied to the drug liquids mixing tank. This mud agitator has the advantage of compact structure so it occupies small area. More than 7.5 kW Mud Agitator uses the turbo and worm gear speed reducer, with the large torque transmission, the revolution is steady,it works reliablely and has great merit. Common model of mud agitator is JBQ5.5kW ,JBQ7.5kW ,JBQ11kW and JBQ15kW.The drilling mud agitator is an important components for ZS Solids Control drilling fluids processing system

China manufacturer ZS Solids Control offer the world with drilling mud agitator equipments.We are an exporter of drilling fluid mud agitator for Indian, Russian,middle east.etc..Our factory and company are Quality Management System ISO 9001-2000 certified.ZS Solids Control operate international oil gas drilling mud separation system sales,service,manufacturing,distribution serivce.Buy drilling fluid mud agitatorfrom China manufacturer.Your best mud agitator for drilling mud circulation system.

When the process is not verified by previous installations PG will do a CFD analysis of the tank and agitator to verify the rheology and the required installed power.

8613371530291

8613371530291