mud agitator sizing brands

As an SPX FLOW brand, Lightnin serves the challenging waste and water treatment sector, as well as the processing of solvents, fertilizers, food/beverages, pharmaceuticals and biofuels. The mixers and agitators, that are custom designed and fabricated, are used for equalization, neutralization, flocculation, aeration, sludge mixing, flash mixing and general blending purposes. The Lightnin industrial mixer portfolio covers both portable and larger fixed-mount units. All Lightnin equipment is designed to provide prolonged trouble-free operation regardless of the specific application demands. Through the proprietary gearbox and impeller technologies developed in recent times, we can offer the market advanced mixing solutions that are far more compact and power-efficient than ever before. They also have significantly greater operational lifespans, thanks to anti-fouling mechanisms and other state-of-the-art features. Consequently, customers are able to raise their productivity levels and avoid costly downtime issues, while also keeping the energy consumption involved to an absolute minimum.

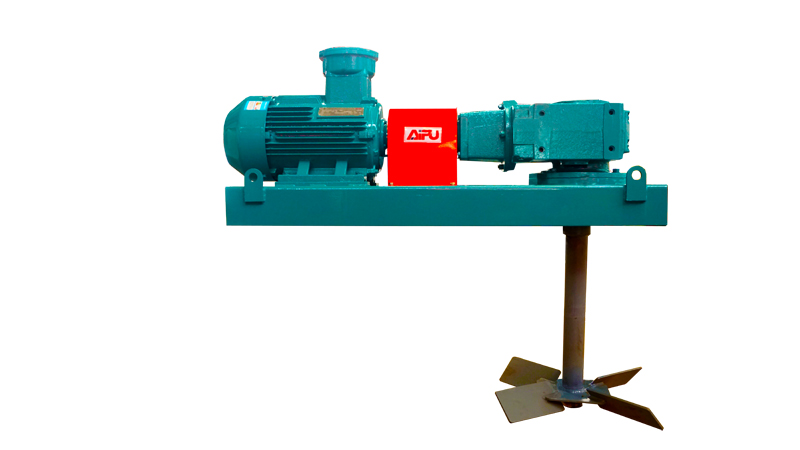

JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender cycloid speed reducer, and it is applied to the drug liquids mixing tank. This mud agitator has the advantage of compact structure so it occupies small area. More than 7.5 kW Mud Agitator uses the turbo and worm gear speed reducer, with the large torque transmission、 the revolution is steady、it works reliablely and has great merit. Common model of mud agitator is JBQ5.5kW 、JBQ7.5kW 、JBQ11kW and JBQ15kW.The drilling mud agitator is an important components for GN Solids Control drilling fluids processing system.

GN Solids Control as a professional manufacturer for soilds control equipments, we have designed lots of high-quality products, and JBQ series Agitator is one of them. To keep both the mud uniformity and the suspension of solids, the mud agitator is used to agitate the mud consecutively and reliably.This agitator agitates the mud to make cuttings, silt and sand pass the solids control system without being precipitated onto the tank bottom. Due to the simplex turbine decelerator, this product is featured by compact construction, light weight, balanced transmission, low noise, high efficiency of transmission and strong agitating power. Therefore, it is a reliable product in the solids control system.

China manufacturer GN Solids Control offer the world with drilling mud agitator equipments.We are an exporter of drilling fluid mud agitator for Indian, Russian,middle east.etc..Our factory and company are Quality Management System ISO 9001-2000 certified.GN Solids Control operate international oil gas drilling mud separation system sales,service,manufacturing,distribution serivce.Buy drilling fluid mud agitatorfrom China manufacturer.Your best mud agitator for drilling mud circulation system.

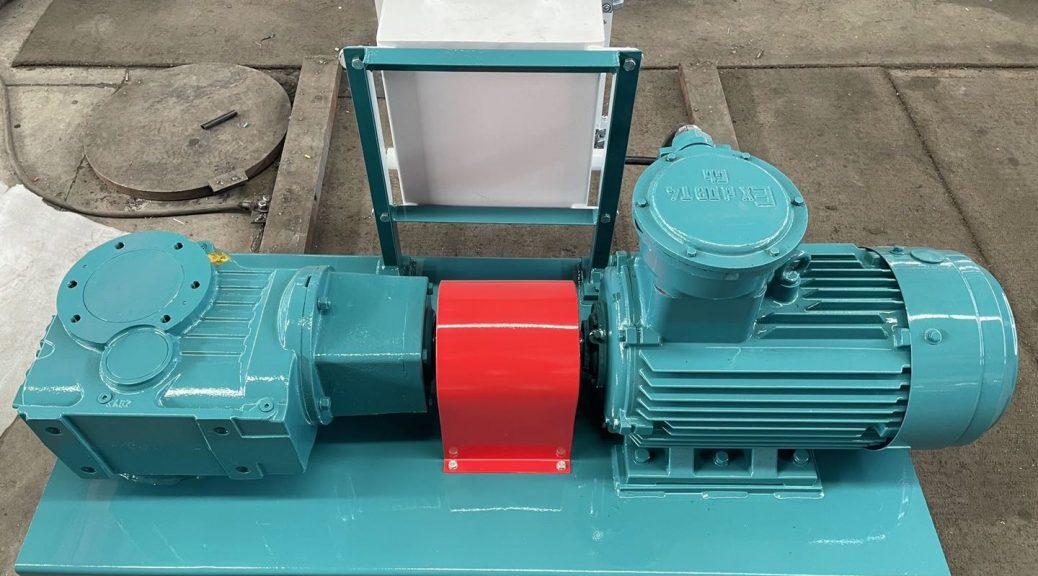

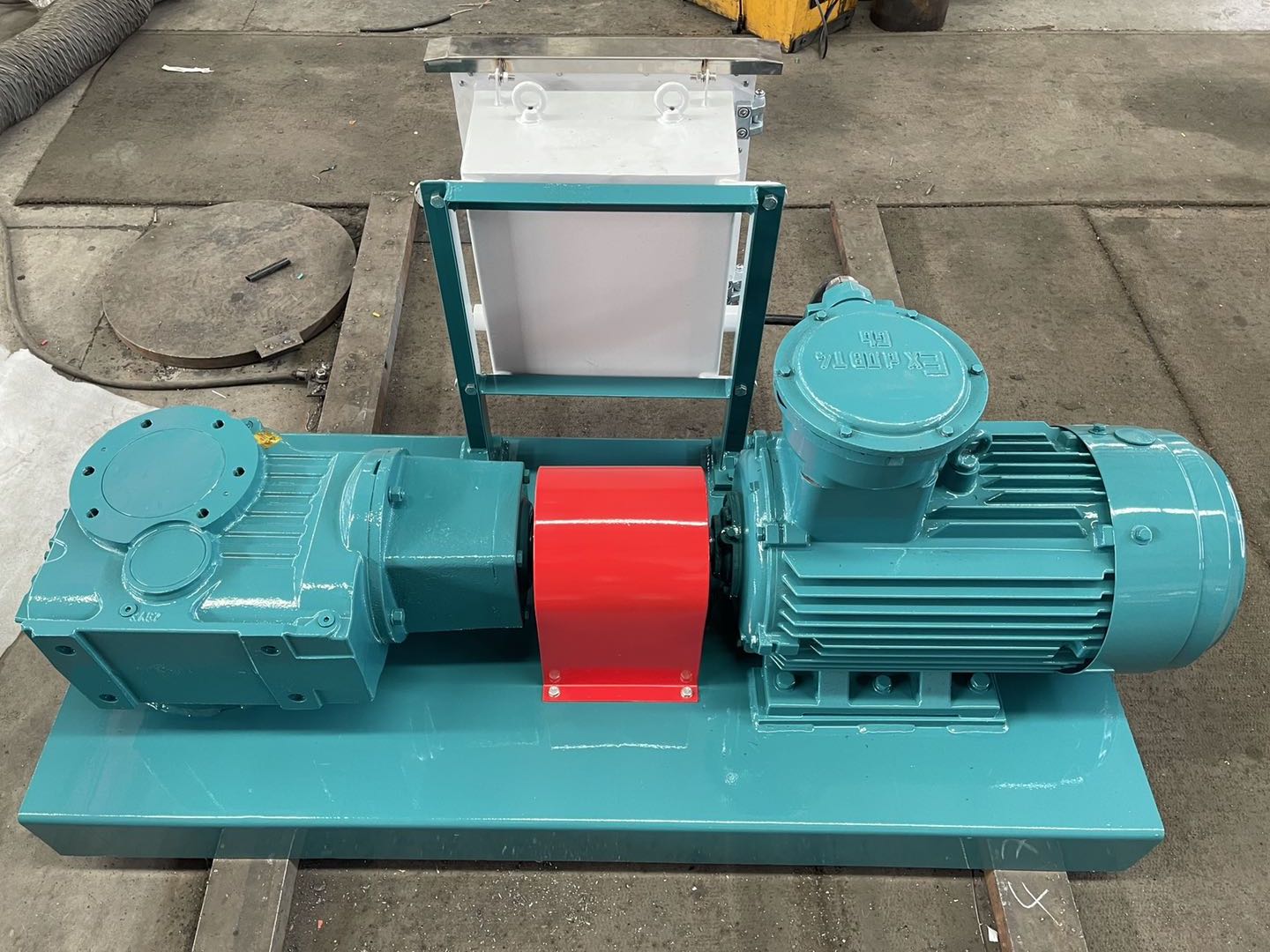

The skid mounted MA-RG agitator is compact, and its low profile reduces headroom requirements and provides more layout space on top of the tanks. The gearbox is a triple-reduction helical-bevel gear drive system that reduces the rotational speed of the motor to drive the impeller(s). Up to 95% mechanical efficiency helps reduce horsepower requirements.

Impellers are available with flat blades (radial flow), contour blades (axial flow), and canted blades (radial/axial flow). The impellers are sized according to tank volume and expected duty. Active mud system compartments—such as solids removal sections, mud mixing sections, and slug pits, which need a higher shear force to produce immediate mixing—are another consideration in impeller sizing.

JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender cycloid speed reducer, and it is applied to the drug liquids mixing tank. This mud agitator has the advantage of compact structure so it occupies small area. More than 7.5 kW Mud Agitator uses the turbo and worm gear speed reducer, with the large torque transmission、 the revolution is steady、it works reliablely and has great merit. Common model of mud agitator is JBQ5.5kW 、JBQ7.5kW 、JBQ11kW and JBQ15kW.The drilling mud agitator is an important components for GN Solids Control drilling fluids processing system.

Mud Agitatoras an important soilds control equipment, always used to agitate the mud consecutively and reliably to keep both the mud uniformity and the suspension of solids. Thus the drilling cuttings silt and sand in the mud will not precipitate down to the mud tank bottom when passing the solids control system. Mud agitator is typically located vertically on the mud mixing tank and mud storage tank. It can get a much better performance if worked together with the mud gun. Due to the simplex turbine decelerator, this product is featured by compact construction, light weight, balanced transmission, low noise, high efficiency of transmission and strong agitating power. Therefore, it is a reliable product in the solids control system.

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Finemade offers a variety of motor and impeller sizes to fit specific tank configurations. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole.The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used.

Landa mud agitators include an explosion-proof, “C” faced motor, reduction gearbox, impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

LIGHTNINΒs unrivaled, patented, Hydrofoil high-flow, high-efficiency style impellers are used to develop the highest flow achievable for solid suspension and blending. LIGHTNIN guarantees the performance of the mixer as well as the mixing result. Equal power is not equal mixing LIGHTNIN֒s axial flow impellers provide more mixing at the same motor power than competitive impellers. LIGHTNIN mud mixers are designed and engineered to provide complete suspension of the mud and cut- tings. This provides a uniform feed to the mud cleaning equipment regardless of the mud weight. This results in...

Exclusive helical gear construction minimizes gear wear that often plagues worm gear designs. Some mud systems require a low profile mixer to accommodate headroom requirements. LIGHTNIN right angle drives have a very low vertical profile. Oversized bearings and shafts increase life and decrease maintenance. > Splash lubrication provides constant, worry-free flow to all critical areas. Integral foot-mounted or flange-mounted configurations. Dry well construction. One piece shafts as standard. Optional couplings with rabbet/spigot fit to assure alignment. No steady bearings. Special paint and...

An Agitator is a equipment used in a tank for mixing various process media together. Media include all liquid types, gases & solids (such as salts, powders, granules etc). In summary, it works by rotating an impeller to impart energy to the media which interact and mix. The components of an agitator in general are the motor & gearbox, shaft & impellers selected for the duty.

An Agitator is used for mixing different process media – liquids, gases and solids in chemical addition or Pharmaceutical Ingredients. The agitator imparts energy through mechanical mean by rotating a shaft on which there is an impeller designed specifically for the duty. This could be axial pumping, gas induction, flocculating, high viscosity products, high & low shear mixing etc. An agitator is also used in the Water Industry for adding various chemicals to bring the source water up to drinking water standards

An Agitator is generally made up of a three main components – a shaft with impellers, a mechanical seal and motor with option of gearbox for lower RPM duties.

The agitator is mounted onto the vessel or via a supporting bridge in the water industry. The mechanical seal has a number of options depending on the duty – single/double mechanical seal, dry or wet mechanical seal, gas lift off mechanical seal that is related to the duty involved.

An agitator shaft is connected to the drive unit (motor & gearbox) and where the impellers used for the mixing are welded or bolted onto. There are options for magnetic driven units where there is a hermetic seal as opposed to mechanical.

Agitators can be simplified into Bottom Entry Agitator, Side Entry Agitator and Top entry Agitator Mud Agitator, depending on the duty & scale of the application to be mixed.

90% of Agitators are a Top Entry Agitatorin API / Chemical / Water industries. The main advantages of a Top Entry Agitator is that it can handle a larger variance in viscosities and specific gravities and also the fact that the mechanical seal is not in the liquid.

The remaining 10% include Bottom Entry Agitator, Side Entry Agitator and Bottom Entry Mag Drive Agitator. Milk silos & very large holding tanks use side entry agitators not necessarily for mixing but to keep the process media moving and keep the milk cool while bottom entry agitators are more common in the Biotechnology sector, where it is a magnetic driven unit (see below).

A slurry agitator is often used to keep the solids in suspension to prevent settling out and forming on the base of the vessel or bulk tank before being transferred to the next stage of processing.

RCI (Retreat Curve Impellers): can be used on Glass Lined Tank/Agitators, they offer lower shear than the Straight Blade Turbines with lower power requirements. They are usually used as a Bottom Impeller because they can be positioned very close to the curve of the bottom dish of the Tank, the blades curve upwards and they are also curved towards the end of the blades.

8613371530291

8613371530291