what is mud agitator in drilling quotation

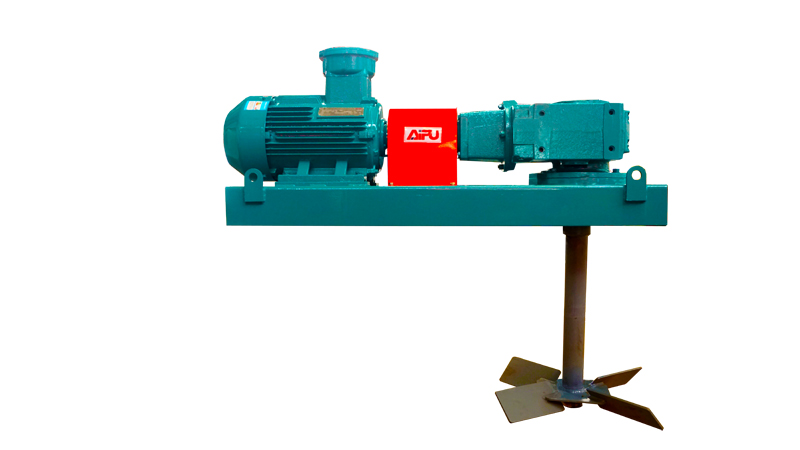

A Mud Agitator is used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation. The objective is to obtain a uniform suspension of all solids.

Mud agitator combined with motor and gear box. Mud agitators do agitation in drilling fluid make the solids suspend. Help drilling fluid property achieve better. Shaft will be connected with gear box coupled on motor. Under a certain ratio the shaft mounted with impeller rotate at uniform speed and lead an upward stream in drilling mud. This will benefit drilling mud mixture completely with sufficient viscosity, etc.

Onshore and offshore oil&gas drilling, CBM exploration, HDD,waste management, etc. process system. Mud agitators make drilling fluid property more even and stable.

3)Before running please check if impeller rotation direction is same as marked direction 4)Inspect oil height via observation window make sure the level always be at center.

6)After 5 days operation please discharge all of the oil out of gear box and clean gear box feed clean lubrication oil in it. Then do same work every 6 month

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole. The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used. Horsepower, mechanical configuration, impeller diameter, number of impeller and shaft length are customized to tank dimensions and maximum mud weights. Here is a list of our recommended configuration. Bothhorizontal / vertical drilling mud agitator available for option.

Raval Pada, Dahisar (E), Mumbai Gala No A-13 Chintypada, Bidco Road Oswal Industrial Estate Palghar Palghar Maharashtra, Raval Pada, Dahisar (E), Mumbai - 401404, Dist. Mumbai, Maharashtra

The Technostrength Mud Agitator combines compact design with high torque performance levels necessary for a uniformly suspended flow of drilled solids throughout the mud systems.

Powered by 1500RPM (4 pole) explosion proof motor and connected through heavy duty gear reducer, this agitator transfers high torque at RPM toread more...

Mud agitator, also called drilling mud agitator, used for drilling fluid agitation mix, prevent drilling fluid solid particles in the tank circulation system deposit, cycle drilling fluid performance stability, mixed evenly. Mud agitator composed by explosion-proof motor, reducer, engine base and impeller components four parts.read more...

We are providing to our clients superior quality Mud Agitators. Our offered Mud Agitators are widely appreciated by our clients which are situated all round the nation. These Mud Agitators are used for agitating mud slurry for obtaining consistency through proper blending in flow controlled applications.

Mud agitator, also called drilling mud agitator, used for drilling fluid agitation mix, prevent drilling fluid solid particles in the tank circulation system deposit, cycle drilling fluid performance stability, mixed evenly. Mud agitator composed by explosion-proof motor, reducer, engine base and impeller components four parts.read more...

Arekere Mico Layout, Banner, Bengaluru CORPORATE OFFICE #9, Naik Business House, 1st Main, Brindavan extension, Arekere Mico Layout, Banner, Bengaluru - 560076, Dist. Bengaluru, Karnataka

- Lightweight, but sturdy construction with the highest torque rating in the industry. Example: 15 hp KOE Agitator weighs 246.4 kg compared to industry averageread more...

Used for rapid and uniform incorporation of dry and liquid ingredients.Creates a deep vortex, exposing dry ingredients directly into the agitator blades. This is a standard agitator for bakery applications.Ideal for soluble, dry ingredients that want to float on the surface.

GAURAV ASSOCIATES manufacture the GAMA range of Mud Agitators. These Mud Agitators are used for agitating mud slurry for obtaining consistency through proper blending in flow controlled applications.

Sector 60, Noida, Dist. Gautam Budh Nagar B 49, Sector 60 , Noida ,Uttar Pradesh,201301 South Delhi, Sector 60, Noida - 201301, Dist. Gautam Budh Nagar, Uttar Pradesh

Dragon pump accessories are constructed to handle the harsh oilfield environment. Dragon stands ready to support our drilling and oilfield customers with the highest quality equipment in the industry. And, as always, Dragon backs every product it manufactures with the support you need.

That support includes 24/7 access to our skilled service teams and vast parts inventory. We are always here for you, because we know you do not want downtime. You want quality, dependability and the support of a long-standing oilfield equipment expert backing you up.

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Mud agitators are fluid mixing equipment that keeps solids in drilling fluid suspending, no deposit in the mud tank bottom. It uses its impeller to agitate and mix the drilling mud to prevent solid particles from depositing in the tank or mud pit.

There were many types of mud agitator, depending on purpose demand, gearbox type, and working conditions. But the basic structure of the mud agitator is all the same: Motor, gearbox [Speed reducer], shaft, and impeller.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need a vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different applications and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we’ll help you to get the ideal solution.

For oil and gas drilling, there are different configurations on tanks number, tanks size, so it’s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9 m X 2.2 m X 2.3 m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of the agitator. And the agitators are APM 7.5 driven by 7.5 kw motor.

After 5 days operation please discharge all of the oil out of the gearbox and clean gearbox feed clean lubrication oil in it. Then do the same work every 6 months.

The most important factor was the power of the mud agitator, 5.5 Kw agitator is cost far lower than 22 KW. There is apparently a different price between the explosion-proof type and Non-proof type. Higher explosion-proof grade means higher cost.

Motors are available with horizontal or vertical mounts. The motors generally have shafts that rotate much faster than the impellers need to rotate. A large gearbox, or gear reducer, used to turn the shaft, is mounted at the end of the motor. The motor size depends upon the diameter of the impeller blades and the density of the slurry.

Worm gearbox type mud agitator is a common type, durable, and easy maintenance. But its efficiency lower than the bevel gearbox. so bevel gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. Helical-worm and helical-bevel are advanced generation type of worm and bevel gearbox. They produce less vibration and noise. The planetary gearbox is mainly used in vertical agitator.

canted blade, and proprietary. Generally, Materials determine the price of shaft and impeller. Stainless steel is more expensive than common carbon steel.

Hubei Craun Technology Equipment Co., Ltd (abbreviated as Craun Tec.), with the registered capital of 10 million RMB and 25000㎡ factory ground, is located in High Tech. industrial park of Xian Ning, Hubei province, which is 100 Kilometers away from Wuhan. The HQ is divided into two parts, mechanical precision processing factory and equipment manufacturing factory. We have more than 100 sets professional precision processing center, inspection equipment, heavy manufacturing equipment and complete environmental protection treatment equipment. Craun Tec. focuses on the technology R&D on the field of solid-liquid separation, and has the independent R&D and fast & efficient system solution capabilities, it is a global professional manufacturer integrating system design, technology R&D, production and sales and after-sales service.

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

Environmental governance (river / port dredging, remediation of contaminated soil, sorting of construction waste, comprehensive disposal of municipal waste, reuse of sand washing sewage, etc.)

We adopt a complete electronic enterprise production management system, production is strictly in accordance with the API standard, we also have the traceable electronic card for single process. Adhering to the management principle of downstream management and upstream management, we pursue zero defect system delivery.

Vertical system management, continuous simplifying the production processes, improving the efficiency on production & problem solving, taking the fully responsibility for the products we produced.

A2: We will have our engineers teach you how to operate it,you can just inform us some details of the product you need then we can customize as your special order.

A3: We has been regard quality as the priority. We always attach great importance to quality controlling from the very beginning to the very end ,so our press can match all the CE and ISO standard also more strict standard .

A4: Generally, it will take 35 working days after receiving your deposit payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have standard machines in stock.

A5: We can supply 1 year warranty for our machines, We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

2. Personnel training: Our engineers will give your employees free machine training when they come to your company to assemble the machines, and welcome to our factory to learn how to operate our machineQ1. How to get an accurate quotation?.

Agitation of drilling mud pits is required for drilling mud maintenance activities such as removing drilled solids, ensuring complete mixing, and maintaining a homogeneous fluid blend throughout the entire surface mud system. To accomplish these functions, agitation equipment must be capable of generating upward velocities in mud pits that are faster than the settling velocity of the solids that are suspended in the drilling mud. It must also be capable of creating enough shearing and stirring action to completely dissolve, wet, and disperse drilling mud additives.

Most commonly, mud pit agitation has been achieved using mechanical, paddle agitators. While they are effective, mechanical agitators are expensive, large, and heavy. They often require electricity, regular maintenance, additional support structure, and create dead spots in the mud pits where settling can occur. The alternative means of agitation are commonly referred to as mud guns. A typical mud gun can be as simple as a concentric nozzle mounted inside of a mud pit, through which drilling mud is recirculated using a centrifugal pump. They are usually classified as either high pressure or low pressure and have several advantages over mechanical agitators. Two of the main advantages of mud guns are that they are considerably lower cost and have a much smaller footprint.

The Radial Eductor is a unique style of low pressure mud gun that employs a patented design to achieve up to four times the total fluid movement and upward velocity in drilling mud pits than common mud guns or nozzles. It can be used as the primary means of pit agitation, or as a complement to an existing mechanical agitator, to eliminate dead spots which commonly occur in the corners of mud pits.

The Radial Eductor consists of a uniquely designed body molded from high density, abrasion resistant polyurethane. A stainless steel female NPT connection is fused to the polyurethane body during the molding process. In a typical application, one or several eductors are mounted on a piping manifold system inside of a pit or vessel. The number and size of eductors required for a specific application is dependent on the vessel size and the necessary agitation rate, sometimes referred to as turnover rate or TOR.

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

APMA series Mud agitator is combination of gear box and motor. It"s important to drilling mud process and fit on mud tanks as 3 meters per set. Except the shaker tank/compartment every tank and compartment will be fit with mud agitator. Mud agiators help to maintain mud property and keep the solids suspend for necessary mud propery and further mud process. Almost of agitator for drilling fluids system are horizontal design. On mud tanks, the separated control panel for each agitator is a good design.

Mud tank size defines agitator number and model, besides, mud property will affect agitators selection. For example, usually we put one set agitator per 3 meters on tank. According to tank width and height, the agitator can be APMA7.5, or APMA15. And if the tanks are same size, then we"ll consider the mud property. Such as mud gravity is 1.8sg we may need 7.5kw, while mud gravity is 2.4sg, we may need APMA15 driven by 20hp motor. Agitator speed defined by motor and gear box. For example, if we use APMA7.5 agitator, the motor is 10hp and speed is 1450rpm. The gear box reduce ratio is 25:1, then the agitator shaft/impller speed is 58rpm. If we use 10hp motor under 60Hz condition, its speed is 1740rpm then, and the reduction ratio is 25:1 still, then the shaft speed is about 70rpm

In a complete mud system, how many sets agitator do we need? For oil and gas drilling, there are different configuration on tanks number, tanks size, so it"s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9mX2.2mX2.3m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of agitator. And the agitators are APM7.5 driven by 7.5kw motor.

How to select agitators? As we said just now, according to mud tank size and mud tank property. And before confirmation on agitator selection, we"d better to inquire professional engineer or consultant. There is a formula for agitator selection or design. Aipu will help user to get right solution at the best cost

Is there any other configuration on agitator type or drive system? Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need the vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different application and industry will request equipment much different If you have question or demand on mud mixers, please let us know and we"ll help you to get ideal solution

Moreover, APMA series agitator are flexible on gear box and motor configuration. Such as worm and worm wheel reducer, helical bevel reducer. The motor certified by IEC, ATEX, and so on

For any interet or demand, please feel free to contact AIPU. You will get free offer on optimal solution, you will get professional proposal very soon.

8613371530291

8613371530291