what is the function of pulsation dampener on mud pump for sale

This equipment plays an important role as an accessory to Yamada air-operated double diaphragm pumps. The pulsation dampener serves to reduce pulsation produced in operation and to assure stable discharge flow and pressure.

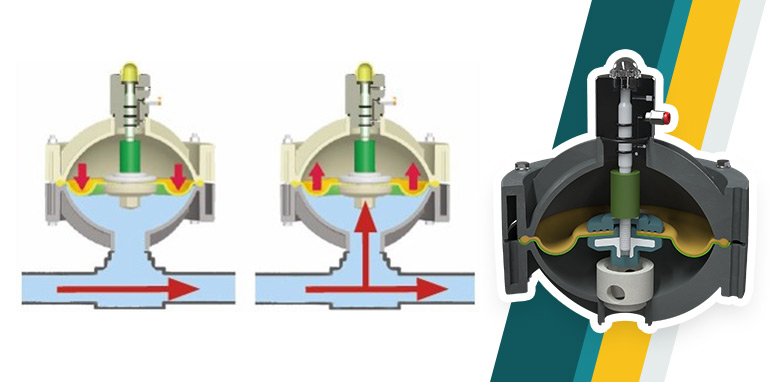

When pulsations occur with pump operation, it will result in the pressure in Chamber Bbeing greater than that in Chamber A. The diaphragm will act as an air cushion and automatically adjust to this pressure change and absorb the pulsations.

This operation will shift the center rod position upwards and allow more air in Chamber Athrough the air inlet, returning the diaphragm to a neutral position. If liquid pressure decreases, air pressure in Chamber Acauses the diaphragm to move downward, shifting shaft location and changing valve position, releasing excess air pressure in Chamber Awhich returns diaphragm to a neutral position. This action causes a reduction in surges and pulsation caused by a air operated double diaphragm pumps

All pulsation dampeners utilize one of two methods for mitigating energy produced by reciprocating pumps; compression or exchange. The traditional gas-charged dampeners use a compressible gas cushion, either by a gas over liquid or gas-filled diaphragms, bladders, or cartridge. As the reciprocating pump produces pressure spikes, the gas compresses, thus absorbing the pressure difference and smoothing the pumped media flow. For maintenance free pulsation dampeners, rely on energy exchange. There is a common misconception regarding maintenance free pulsation control devices that the pumped media is compressible enough to absorb the reciprocating pumps’ pressure spikes. This is not true. However, the maintenance free pulsation dampeners work by utilizing the kinetic energy exchange. This kinetic energy exchange can only happen if the pulsation dampener’s volume is large enough to dissipate enough energy to reduce the adverse effects caused by the reciprocating pump. This is why maintenance free pulsation devices require massive volumes to be effective. Sigma Drilling Technologies has developed a pulsation dampening system that utilizes both methods for reducing the harmful effects of positive displacement pumps, both compression and exchange.

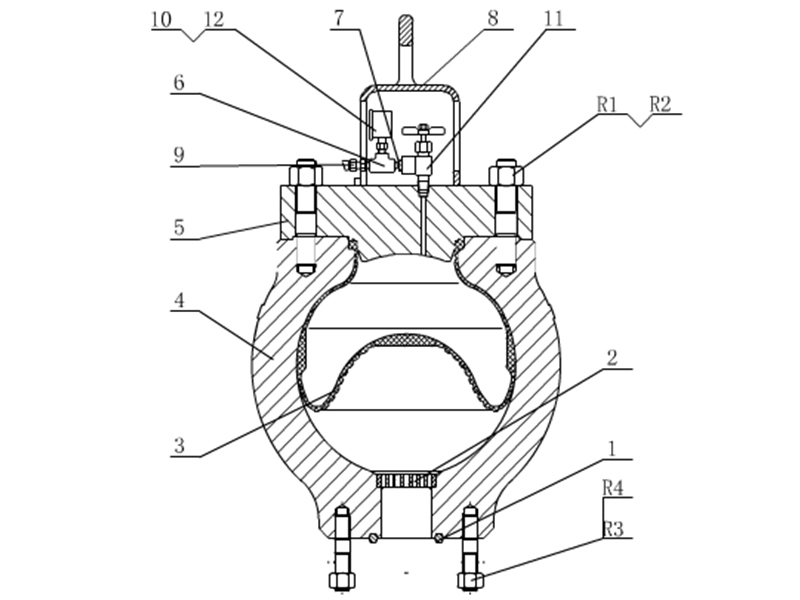

Mud Pump Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump.

Mud Pump Pulsation Dampener is a pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

In order to reduce the fluctuation of pressure and displacement of the drilling mud pump, air bag are usually installed on the discharge line. The air bag manufactured by our company has advanced structure and reliable performance, which can make the mud pump achieve the best inhalation effect and is widely used in petroleum, high-pressure pipeline of chemical transportation. This product can also be used as a stabilizer and shock absorber for air extractors.

The pulsation dampener can be divided into discharge pulsation dampener and Suction Dampener.Discharge pulsation dampener- reduces displacement of pump and fluctuation of pressure.

In order to reduce the pressure and displacement of drilling mud pumps, air bags are usually installed on the discharge pipeline. The suction air bags produced by our company have advanced structure and reliable performance, which can make the mud pump achieve the best suction. The effect is widely used in high-pressure pipelines for petroleum and chemical transportation. It can balance the peak pressure of high-pressure fluid in mud pumps, stabilize the pressure, and reduce losses. This product can also be used as a stabilizer and shock absorber for air extractors.

The mud pump is installed on the discharge line, which can balance the peak pressure of the high pressure fluid of the mud pump, play a role in stabilizing the pressure, reducing losses and ensuring safety, so that the mud pump can achieve the best suction effect.

Drain buffer: Installed at the drain end of pumps and compressors, it can avoid fatigue damage of cylinder pistons, valves, bases and pipelines due to pressure fluctuations, thereby extending the service life of the equipment.

Absorption of oscillation: The opening of the valve in the fluid system and the sudden closing of the valve for various other reasons will cause a huge impact pressure to form a water hammer phenomenon, causing the rupture of the pipe and the pipe seat and the damage to the downstream equipment. After installing the suction air bag, it can act as a buffer to avoid this phenomenon.

Reverse Oscillation: When the head of the water pump reaches a certain height, the reverse oscillation caused by the impact of the fluid into the pump valve will cause the pump to suddenly shut down. A suction air bag is installed to absorb part of the vibration.

Energy storage: Due to the unique design of the device, energy can be stored on the hydraulic press, and a certain amount of energy can be provided in a short time according to customer requirements. This is very useful for supplying lubricant to key (sprinkler) rotary sprinklers. It can prevent the failure of the expensive (sprinkler) rotary sprinkler due to the interruption of the lubricant.

Pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

A pulsation damper is an equipment capable of playing a very important role in the use of double diaphragm pumps. As can be seen from the name, this accessory is aimed at reducing pulsations and vibrations during pump operation, thus ensuring a “continuous” and precisely non-pulsed flow rate and a reduction of vibrations on the system pipes.

A pulsation damper works thanks to the same compressed air that feeds the pump. The compressed air introduced into the counter-pressure chamber behind the membrane creates a pneumatic damping cushion that self-adjusts according to the stress exerted by the pressure pulse of the fluid generated by the pump.

EQUAFLUX dampers are used with fluids of high apparent viscosity even in the presence of solid parts in suspension. They automatically adapt to the system conditions, without manual adjustment or calibration. The high ability to minimize pulsations, vibrations and water hammers makes this component a suitable equipment for safeguarding the system, giving regularity to the outgoing flow. The wide choice of construction materials allows you to determine the best chemical compatibility with the fluid and / or the environment without neglecting the correct temperature range. The dampers are also available for use in a potentially explosive environment (ATEX certification).

Inside the hydraulic systems, the pulsations of the fluid can cause phenomena called water hammer consisting of pressure peaks caused by a sudden change in the flow rate inside the pipes or by the sudden closure of a valve. The effects of water hammer vary according to the size of the pipeline and the speed and density of the fluid but can often cause extensive damage to the elements of a system. To preserve the system from water hammer and vibrations, it is possible to use the pulsation dampers of the Equaflux series that can automatically adapt to the operating conditions of the pump.

Equaflux pulsation dampers are normally applied to pneumatic double diaphragm pumps. The latter, during the phases of use, can record pressure peaks which, if not controlled, can damage the elements of a system. The main benefits associated with the use of pulsation dampers can be summarized in the following points.

The application of diaphragm pumps equipped with pulsation dampers refer to the entire process industry: hydraulic systems, use in chemical transformation processes, use within the petrochemical, mining sectors and much more. The EQUAFLUX series is also available with ATEX certification and therefore can be used directly within sectors with the presence of explosive risks.

Pulsation dampers are very versatile tools whose use can vary according to the needs of the operating processes and application sectors. For this reason, a sales team is at your disposal to support you in choosing the most suitable configuration for your needs. Contact the Debem team now.

A Pulsation Dampener is an inline dampening device used to smooth out pulsations in a pump’s output. They are used alongside a pump as a mounted accessory to help achieve certain flow rates for an application. They can be used with a variety of Positive Displacement Pumps which typically generate a pulsed flow (Diaphragm Pumps, Peristaltic Pumps, Dosing Pumps, Piston Pumps etc)

Pulsation Dampeners are required in some process applications when the customer needs smooth flow into the next phase of the production line, for example, to get an accurate reading through a flow meter or to fill a hopper consistently. On the flip side, Dampeners can be used to reduce water hammer effects through pipework. Water hammer is where the pump causes the pipes to vibrate and potentially fail, a smooth flow from a Pulsation Dampener reduces this.

For example, Diaphragm Pumps inherently produce a very turbulent discharge flow meaning that in some instances a Pulsation Dampeners are required to give a smooth pulse-free flow.

In the Tapflo UK range, we focus on Pulsation Dampeners for Diaphragm and Peristaltic Pumps, although we can also supply them for other pump technologies.

The Active Pulsation Dampener works by supplying an equal pressure to the pulsation supplied by the pump. The Dampener supplies this pressure during the low-pressure points of the pump’s operation, as the pressure drops between pump strokes creating a pulsating flow. The pressure supplied by the dampener decreases pressure variations, therefore producing a steady flow from your Diaphragm Pump. You can see the pressure drops and Pulsation Dampener benefits in action in the diagram below.

Tapflo supplied a 2” Air Operated Diaphragm Pump to a bleach factory, the customer used the T400 PTT for a couple of days and then called us to explain that the bleach line, running along the roof of his production facility, was shaking. Due to the nature of the product being pumped health and safety on site could not allow this to continue.

To support our Peristaltic Pump customers, Tapflo offers an in-line Pulsation Dampener for our PT and PTL Series’. They can reduce the pulsation of your PT Pump by as much as 90% to reduce the vibration and water hammer effects on pipework. Another benefit of this accessory is its ability to be installed on-site horizontally or vertically for flexible installation.

For more information about pulsation dampeners, we sat down with Brandon Dalrymple and Nathan Ackeret fromBlacoh Fluid Control(manufacturer of pulsation dampeners, surge suppressors, and inlet stabilizers), and asked them to answer a few of our customers’ most common questions about pulsation dampeners.

Pulsation dampeners absorb the energy from the pulse wave created by a positive displacement pump, much like a shock absorber on a vehicle. Absorbing those pulse waves protects pipe welds and supports, and system components from damage due to pressure or excess movement.

A pulsation dampener creates an area of low pressure in the system with enough volume to absorb the pulsation. The pulsation dampener has a membrane with a "cushion" of compressible gas/air behind it that flexes to absorb the pulse, allowing a laminar flow downstream of the dampener.

Pulsation dampeners are commonly used wherever a positive displacement pump discharges flow in an unsteady manner, and where the pulse is not desired for the piping system. Air operated double diaphragm, metering and hose/peristaltic pumps typically benefit from a pulsation dampener.

The type of pulsation dampener used is typically defined by where they are placed in the system, and what they need to do. For example, "pulsation dampeners" are on the downstream side of the pump, "inlet stabilizers" are on the inlet side of the pump, and an accumulator or "surge suppressor" is used next to a valve or other device that restricts the flow in a system.

This video shows where you would place an inlet stabilizer, and how it is used to reduce the pulsation with an air operated diaphragm pump in suction lift conditions.

If you"re experiencing problems with rattling pipes, intermittent flow, water hammer, or pulsations in your system, don"t ignore it. Take the steps necessary to control these symptoms to prevent system deterioration down the road.

Need help with pulsations or water hammer problems? Ask us about it! We gladly provide technical assistance to businesses in Wisconsin and Upper Michigan.

From the law of inertia, an object in motion will stay in motion unless acted upon by an outside force. Sometimes these forces are hard, such as an egg hitting the pavement, and sometimes they are soft, like jumping onto your bed. When the force is hard or sudden, damage is more likely to take place. Fluids have the same properties. When they are in motion, they have inertia. It takes an outside force to change the direction of the fluid.

Imagine a stretch of pipe with a liquid flowing through it. On one end, a valve is suddenly closed. When the valve closes, the moving liquid suddenly needs to come to a complete stop. Since most liquids can be considered incompressible, the force against the valve is a harsh impact. Similar to an egg hitting the pavement. This sudden change in momentum applies a force against the valve. Since there is nowhere for the liquid to flow, it creates a pressure spike.

A discharge dampener is designed and installed in the pipe to help absorb this pressure spike. The dampener consists of a vessel filled with gas or compressible material. When there are sudden changes in flow, the compressible material is able to compress and expand, similar to jumping onto your bed. The video below demonstrates the effects with and without a dampener.

The pressure spikes caused by a change in flow rate can be damaging to pipes and equipment within a system. The changes in pressure cause the walls of the pipes and materials to rapidly expand and contract. Over time, these changes can develop cracks in piping and equipment walls. If the pressure spike is large enough, the resulting spike may have enough pressure to cause the pipe to explode.

By installing a pulsation dampener, the intensity of these spikes are reduced to controlled levels.A dampener should be sized and installed in all piping that may experience a harmful level of pressure spikes.

Pulsation dampeners can be purchased in a variety of shapes, sizes, and designs. It is important to size a pulsation dampener for a specific application. Incorrect sizing or incompatible materials may cause a danger to equipment, systems, and personnel.

Membrane Pulsation Dampener: A membrane-type dampener provides a solid separation between the pumping fluid and the compressible gas. The membrane resides within the dampener and allows for the pressure to be transferred to the gas, without any mixing of the gas into the fluid.

Bladder Pulsation Dampener: A bladder type dampener fully encloses the compressible gas within a bladder. This setup ensures there is no leakage of the gas into the pumping fluid. The pressure pulsations are transferred to the gas as the bladder expands and contracts.

Bellows Pulsation Dampener: A bellows-type dampener works the same way as a bladder type dampener. However, by using a bellows-type design, it can be made with other types of materials such as PTFE or Stainless Steel. This type of dampening system is used when pumping corrosive materials that may deteriorate more common materials.

Pressure Vessel Style: A pressure vessel dampener, sometimes referred to as a “zero maintenance” style dampener does not use any moving parts. They are only effective at very high pressures. Fluids, including water, do have some degree of compressibility. Pressure Vessel Style dampeners allow for the pressure of the fluid to be dissipated within the vessel by the small amount of compressibility within the pumping fluid. In very high-pressure applications, a pressure vessel style dampener may be the only type of dampener available. It is important to note that this style of dampener does not operate as effectively as other types of dampeners.

Flexible piping: Although it is not recommended, flexible piping or hose can act as a pulsation dampener in emergency situations. As the fluid flow changes, the flexible piping is able to “move” and allow a dampening effect on the fluid. Flexible piping still requires proper sizing to reduce pressure spikes. Improper usage may result in damage to equipment and endangerment of equipment operators.

Equipment that rapidly changes flow rates is recommended to have a pulsation dampener. Plunger pumps, for example, have a highly variable flow rate. The average flow rate of a plunger pump can be accurately predicted. However, each rotation of the crankshaft produces several changes in flow velocities.

In step 2, the plunger is stopped. It is transitioning from moving backward, to moving forwards. The fluid has stopped moving through the inlet and has come to a complete stop, resulting in a pressure spike beginning at the inlet which then travels through the suction piping. The resulting change in the fluid’s momentum is a change from kinetic energy in the form of linear velocity, to potential energy in the form of pressure.

In step 3, the plunger has begun to move forward. As fluid begins moving through the outlet. The stationary fluid of the outlet is suddenly required to move as well. A pressure spike is created in the discharge, beginning at the outlet, and then carried through the discharge piping.

In step 4, the plunger has again come to a complete stop. Fluid is no longer flowing through either port. As it begins to move back, fluid will suddenly need to begin moving through the inlet.

When a plunger pump is running slowly, these pressure spikes can be ignored. In most cases, they will not produce enough of a spike to create damage. When the pump is running at full speed, this full cycle is taking place many times per second. The pressure spikes caused by these sudden changes will likely need a pulsation dampener.

The image above shows the visible pulsations created by a reciprocating quintuplex pump. Using flexible hoses on the inlet and outlet, the pressure fluctuations through the hose can easily be seen. Since steel piping is more rigid, it may be more difficult to visually see pressure vibrations before damage to piping and the surrounding systems takes place. It is important to correctly determine if a dampener is needed and to correctly install the required size before operating the pump system.

It is important to note that pressure pulsations are not a function of pressure. The operational pressures of a system have very little effect on the resulting pressure pulsations. Both suction and discharge sides of a reciprocating pump are susceptible to pulsations and resulting damage. Both the suction and discharge dampeners operate independently of each other. Proper sizing and installation of both suction and discharge dampeners are required for proper protection of pumping equipment and systems.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This equipment plays an important role as an accessory to Yamada air-operated double diaphragm pumps. The pulsation dampener serves to reduce pulsation produced in operation and to assure stable discharge flow and pressure.

When pulsations occur with pump operation, it will result in the pressure in Chamber Bbeing greater than that in Chamber A. The diaphragm will act as an air cushion and automatically adjust to this pressure change and absorb the pulsations.

This operation will shift the center rod position upwards and allow more air in Chamber Athrough the air inlet, returning the diaphragm to a neutral position. If liquid pressure decreases, air pressure in Chamber Acauses the diaphragm to move downward, shifting shaft location and changing valve position, releasing excess air pressure in Chamber Awhich returns diaphragm to a neutral position. This action causes a reduction in surges and pulsation caused by a air operated double diaphragm pumps

TSC offers a broad range of drilling and production spherical pulsation dampeners. Volumetric size ranges from 10 gallon to 20 gallon capacities and pressure ranges from 3000 psi to 7500 psi. The body of the TSC spherical pulsation dampeners is manufactured from a one piece steel forging, thereby eliminating the possibility of weld fatigue failure.

Xi"an KINGWELL OILFIELD MACHINERY Co., Ltd. (KINGWELL) is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provides complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, drilling tools, DST tools and Solid control products.

KINGWELL have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. kingwell can provide highly efficient services to its clients resulting in accurate and timely deliveries at the best prices. Our products have been exported to Europe, American and Middle East.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes mud pump pulsation dampener wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A mud pump pulsation dampener comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the mud pump pulsation dampener of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of mud pump pulsation dampener for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of mud Pump pulsion days, you can find the product you want from the vast collection at Alibaba.com.ther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibcom. it has easy to get the pump of your home. Thether of want a supply pump mud residential pulsity daysener is you,ll want the product that want your needs.

The EQUAFLUX 100 pulsation dampener is installed downstream of the pump to reduce pulsations and create a smooth and laminar flow. The casing can be manufactured in many materials, including; polypropylene, PVDF, PPS-V and stainless steel 316. The diaphragms come in PTFE as standard, the combinations of material options make this pulsation dampener suitable for use with a wide range of fluids.

A pulsation dampener works by creating an area of low pressure that absorbs the pulsations emitted by the pump. A diaphragm is fitted that has a cushion of compressed air, this flexes and absorbs the pulsations. The EQUAFLUX 100 is connected to the air line and fed with compressed air, the diaphragm and air work in conjunction and automatically adjust the pressure to minimise pulsations in the pipework.

The EQUAFLUX 100 pulsation dampener can be utilised for many fluids in the industrial and marine markets, including; fuels, oils, chemicals, acids, waste water, glues, resins, paints and inks. Applications for this pulsation dampener include; mechanical and metalworking industry, ceramic industry, petrochemical, waste water treatment, biofuels, marine (bilge, slop, sewage), mining, textile industry, automotive industry, paint industry, cosmetic industry, cleaning industry and ink and print industry

This pulsation dampener is Atex zone 2 as standard meaning it is suitable for operation in non safe potentially flammable environments. As an option, this can can come in an Atex zone 1 version if required.

8613371530291

8613371530291