diaphragm mud pump quotation

Powered by Honda GX120 Commercial Engine gas. Replaced by newer model 338G-96. AMT 2" Diaphragm pumps features 2-stage, 44 to 1 gear reduction with a large diameter output gear and heavy duty ball bearing construction. Often referred to as Mud pumps, mudhog or Sludge pumps, diaphragm pumps are designed to pump mud, slurry, sewage, and thick water liquids that have the ability to flow. AMT IPT Diaphragm pumps are available with a choice of drivers to meet your application requirements. Phelps HoneyWagon Wastecorp

Honda gasoline engines. Built-in molded polyurethane flapper/check valve assures self-priming to 20 feet after initial prime. Heavy duty gear box is designed to operate pumps at 60 strokes per minute. Each unit includes a 2" NPT steel suction strainer, two 2" NPT nipples, and wheel kit with 10" semi-pneumatic transport wheels for portability. Pumps are designed for use with non-flammable liquids which are compatible with pump component materials. Mud Trash pumps Suction and discharge port size cannot be reduced.

Suction and discharge port size cannot be reduced. Due to positive pumping action of diaphragm pumps, by all mfr"s, the discharge is recommended to only be 25FT long unless oversized. Discharge can not be restricted. There is no relief valve.

Riverside Pumps’ rugged and reliable Diaphragm Pumps are known for their ability to pump heavy mud and sludge, thicker than any centrifugal pump can handle. They also have the advantage of being able to run dry without damage, so contractors often use them to control seepage. Riverside Pumps’ Premium Series Diaphragm Pumps feature simple and durable designs proven in decades of reliable service. The DP2 Premium Series Diaphragm Pumps feature dependable, rugged designs that are easy to service. A simple and durable one-piece x-profile pump rod, and a superior fiber-core synthetic rubber diaphragm are among the reasons construction professionals choose these pumps. The DP2 is compact and light making it the choice of many utility contractors for seepage control.

Mud Sucker Pro Series engine driven diaphragm pumps use check ball technology in the suction and discharge valve chambers to pump slurries, abrasive fluids, solids and general wastewater. Access to both the suction and discharge areas is available within seconds.

The Mud Sucker 4B-M includes a standard emergency pressure relief valve. Since a diaphragm pump is also a positive displacement pump, a pressure relief valve reduces the chances of damage in an over pressurization event.

The only diaphragm pump in the industry with an exclusive pump body designed to enhance the flow of slurries and debris laden liquids to prevent clogs.

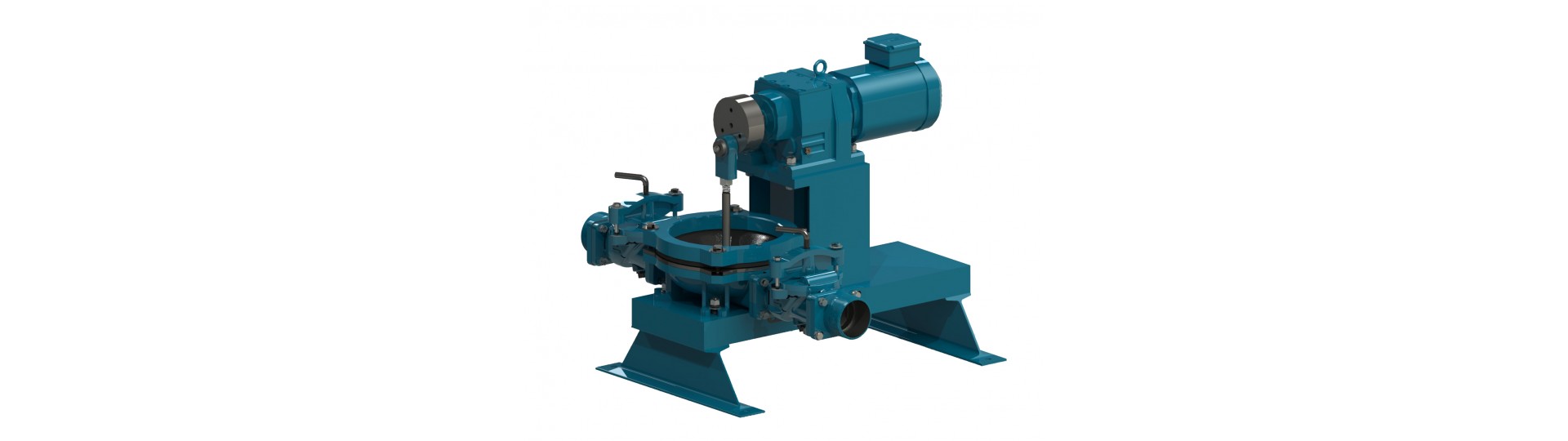

Ships complete with safety guards. Pump operator does not come into contact with moving components when guards are in place (removed in illustration above for clarity).

This Tsurumi TD5-200 is the perfect diaphragm pump for working with sand, mud, or sludge applications. With its heavy-duty Honda engine with an oil sensor, it offers high impact but with a compact and durable design.

The AMT 335E-96 diaphragm trash pump is designed to move thick liquids like sewage and sludge. Features a heavy duty 2 stage forged gear driven transmission that operates at 40 strokes per minute. Modular component design permits easy maintenance and cleanout. Wheel kit and handle are included.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm mud pump systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes diaphragm mud pump wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A diaphragm mud pump comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the diaphragm mud pump of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of diaphragm mud pump for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of diiphrag m mud pump, you can find the product you want from the vast collection at Alibaba.com.therther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

The AMT line of Diaphragm pumps features a 2-stage, heavy duty forged gear driven transmission. Often referred to as Mud or Sludge Pumps, diaphragm pumps are designed to pump mud, slurry, sewage and thick liquids that have the ability to flow. AMT Diaphragm pumps are available with a choice of drivers to meet your application requirements: gasoline, diesel or single or three phase electric motor. Built-in check valve assures self-priming to 20 feet after initial prime. Heavy duty forged gear driven transmission is designed to operate pump at 40 strokes per minute for electric motor models and 60 strokes per minute for engine driven models. Each unit includes a 2” or 3” NPT steel suction strainer, two NPT nipples and a wheel kit for portability. Models 338E K6, 338G-K6, 337H-K6 and 337E-K6 are kits provided less motor or engine. Suction and discharge port sizes cannot be reduced.

Condor Pumps have been appointed exclusive NZ distributors for TTi Trans Tank International - Australia"s safest tanks and trailers - down load your TTi New Zealand catalogue by clicking on the image below

The Tsurumi Pump diaphragm pumps features a 2-stage, heavy duty forged gear driven transmission. Often referred to as Mud or Sludge Pumps, diaphragm pumps are designed to pump mud, slurry, sewage and thick liquids that have the ability to flow. Built-in check valve assures self-priming to 20 feet after initial prime. Heavy duty forged gear driven transmission is designed to operate pump at 60 strokes per minute.

Honda’s WDP30 diaphragm pump is a positive displacement pumps that can pump thick sludge or water containing large solids. Instead of an impeller and a volute, diaphragm pumps use a neoprene diaphragm. The WDP30 offers an exceptional value for construction, industrial, and agricultural applications.

A Diaphragm is often referred to as Mud or Sludge pump. These heavy duty pumps are designed to pump mud, slurry, sewage, and thick liquids that have the ability to flow. Most models are designed for use with non-flammable liquids which are compatible with pump component materials.

Built to handle the pumping of dirty waters from sumps, pits, basements and building sites, these diaphragm style pumps feature some unique features not seen on centrifugal style pumps making them ideal for sluge and slurry service. Coupled to quality Honda GX series commercial engines, these pump sets are exceptional quality and built to last.

PADDOCK delivers a diaphragm style pump which is different to the commonly seen centrifugal style pump. This unique design is suited to a wide range of applications and performs exceptionally well in services other pumps struggle.

Diaphram pumps are completely different to centrifugal style pumps. Rather then having a impeller which rotates at high speed to generate flow, the diaphragm style of pump uses one-way valves on the suction and discharge, in combination with a diaphram which rises and falls to draw in and discharge fluid. The diaphragm pump operates a little like the human heart only much less complicated. In fact, diaphragm pumps are sort after for their low complexity and simple servicability by unskilled labour.

The diaphragm pump is not damaged if left to run dry. The diapgrahm continues to rise and fall just without fluid being pumped. This makes them ideal for pumping slow filling sumps over the course of a day. Where a centrifugal pump might pump the pit dry and then burn out the seals, the diaphraghm pump simply unloads and continues cycling without harm. As fluid reaches the suction line it will be drawn into the pump and discharged.

The moving parts of the diaphragm pump run slow in comparison to a rotating impeller, meaning there is less wear and errosion when pumping dirty fluids and slurries. This makes this style of pump ideal for building and construction sites where conditions can vary day to day. These pumps are ideal for flood recovery and clean up and are difficult to destroy.

The pump flowrate is proportional to the engine RPM meaning you can turn the pump right down to a slow speed and still get effective fluid transfer. This can result in quieter operation in sensative areas and allows the user to match the pumps speed to the conditions and increase overall efficiency.

Diaphragm pumps won"t achieve the same high flowrates as a centrifugal style of pump nor will they achieve exceptionally high discharge heads. These pumps will discahrge to respectable elevations which suit most transfer operations but care does need to be taken when making the selection. This pump is not the most efficient solution for large, bulk water transfers between dams, although it will perform this task at a lower speed. These pumps are ideal for moving low quality water from pits as they fill.

Scintex can supply a range of hose and fittings options to suit these pumps. Our range of suction, discharge and lay flat hoses are available here. For inlet strainers and check valves see here. For camlock fittings in aluminium and stainless steel see here. Scintex is happy to help advise with the set up of these pumps and supply any fittings, hose or clamps you may require.

These pumps can be shipped Australia wide and are also available for pick up from our Brisbane warehouse. Due to the high weight for these products we advise contacting us for a accurate freight quote to your location as the shipping estimator can sometimes over or under estimate.

8613371530291

8613371530291