5 mud pump liner pressure ratings in stock

Positive displacements pumps are generally used on drilling rigs to pump high pressure and high volume of drilling fluids throughout a drilling system. There are several reasons why the positive displacement mud pumps are used on the rigs.

The duplex pumps (Figure 1) have two cylinders with double acting. It means that pistons move back and take in drilling mud through open intake valve and other sides of the same pistons, the pistons push mud out through the discharge valves.

When the piston rod is moved forward, one of intake valves is lift to allow fluid to come in and one of the discharge valve is pushed up therefore the drilling mud is pumped out of the pump (Figure 2).

On the other hand, when the piston rod is moved backward drilling fluid is still pumped. The other intake and discharge valve will be opened (Figure 3).

The triplex pumps have three cylinders with single acting. The pistons are moved back and pull in drilling mud through open intake valves. When the pistons are moved forward and the drilling fluid is pushed out through open discharge valves.

When the piston rods are moved forward, the intake valves are in close position and the discharge valves are in open position allowing fluid to discharge (Figure 5).

On the contrary when the piston rods are moved backward, the intake valve are opened allowing drilling fluid coming into the pump (Figure 6). This video below shows how a triplex mud pump works.

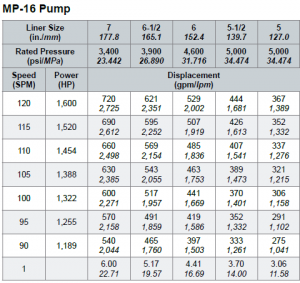

Because each pump has power rating limit as 1600 hp, this will limit capability of pump. It means that you cannot pump at high rate and high pressure over what the pump can do. Use of a small liner will increase discharge pressure however the flow rate is reduces. Conversely, if a bigger liner is used to deliver more flow rate, maximum pump pressure will decrease.

As you can see, you can have 7500 psi with 4.5” liner but the maximum flow rate is only 297 GPM. If the biggest size of liner (7.25”) is used, the pump pressure is only 3200 psi.

Finally, we hope that this article would give you more understanding about the general idea of drilling mud pumps. Please feel free to add more comments.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

Ceramic Liners are made of a ceramic inner sleeve and a forged steel outer shell. The service life of ceramic liners is about 4000 to 10000 hours, the minimum time is at least 2000 hours, which is a lot more than bi-metal liners. Because of the phase transformation toughen technology, the ceramic liners have the features of wear-resistance, erosion-resistance, high-pressure-resistance, high hardness and strength. Zirconia type and Alumina type are common type of ceramic sleeve. Compared with Alumina type, Zirconia type liners have better toughness properties and a much longer service life. Piston wear and water consumption for lubrication can be reduced as well.

Seal Rings for Liner packing are also important. Liner Seal Rings is designed and made with hard corner which is an integral part of seal rings and soft nitrile element rubber center. We could provide reliable liner Seal Rings for our customers could order them at the same time.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

Closed loop pressurized freshwater liner wash system, complete with integral water cooling tank equipped with centrifugal pump and driven by explosion proof electric motor

Belt drive transmission: two each motor sheaves and QD mounted pump sheaves; banded Kevlar Vbelts; belt guards; for use with AC drive motors c/w 20HP blower assemblies

The Hex Pump is an axial piston mud pump with six vertical pistons driven by two AC motors via a gear and a specially profiled cam. In contrast to crankshaft-driven triplex pumps, the Hex pump delivers a nearly pulsation free flow. Consequently, there is no need for pulsation dampeners on either the suction or discharge side when running this pump. Other major advantages are compactness (reduced weight and footprint) and no need for replacing liner sizes to achieve high pressure or flow. The Hex 240 version with 4 1/2" liners has a rated capacity of 2540 HP, a maximum rated pressure of 7500 PSI and a maximum flow capacity of 1034 GPM.

The Hex Pump has substantially less weight than a comparable Triplex pump, and this results in increased variable deck load capacity on drilling units. The potential cost savings related to increased variable deck load capacity both on new builds and on existing rigs will be discussed in this paper. Also, the potential steel weight reduction in the substructure on drilling units will be discussed.

The Hex Pump creates a clean standpipe pressure with much lower pressure fluctuation levels than triplex pumps. Due to this, there are no need for pulsation dampeners when running the Hex Pump. This additionally leads to much better and cleaner MWD-signals for the directional driller. As a consequence, this will contribute to faster and more accurate drilling in long and complicated directional wells.

The design and development of the Hex Pump is described in SPE paper 79831, ref /1/; "Development and Performance Testing of the Hex Mud Pump", but for the understanding of this paper it is important to understand the functionality of the Hex Pump design. Some of the main items are therefore repeated in this paper. SPE paper 92507, ref. /2/, "Operational experience with use of a Hex Pump on a land rig" focuses on the improved MWD-measurements related to use of Hex Pump compared to triplex pumps. Some of the main items discussed there will also be repeated in this paper.

8613371530291

8613371530291