electric mud pump factory

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

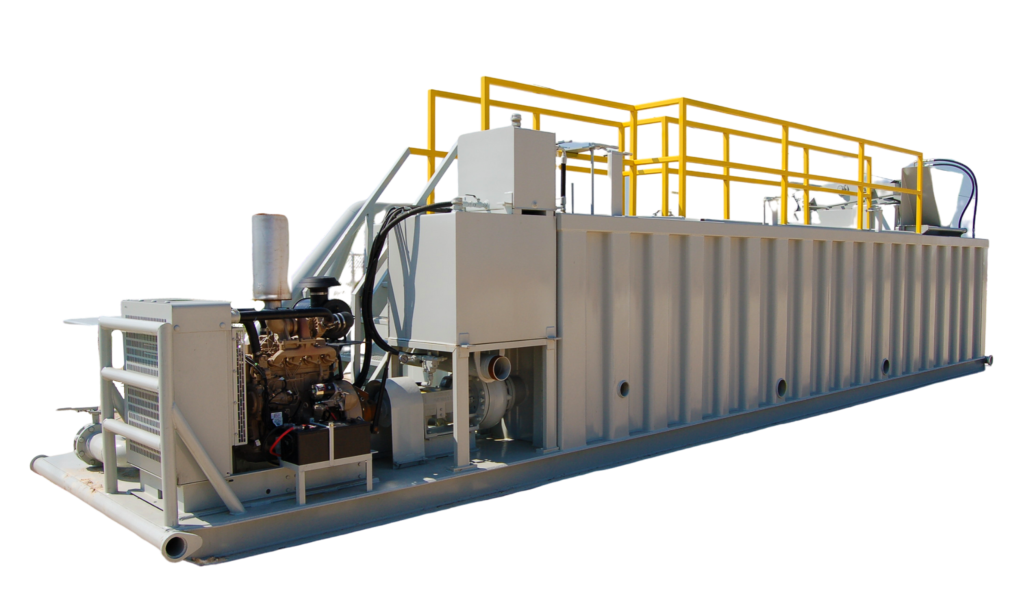

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

b) So long service life-- Wear parts of agitator pump are all constructed with abrasion resistant materials - hard chromium alloy, so pumps have better stability & longer service life. d) Mechanical seal--Unique mechanical seal device can prevent the electric motor from high pressure water and impurities, thus high suction efficiency can be ensured. b) Unique mechanical seal device can prevent the electric motor from high pressure water and impurities, thus high suction efficiency can be ensured.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

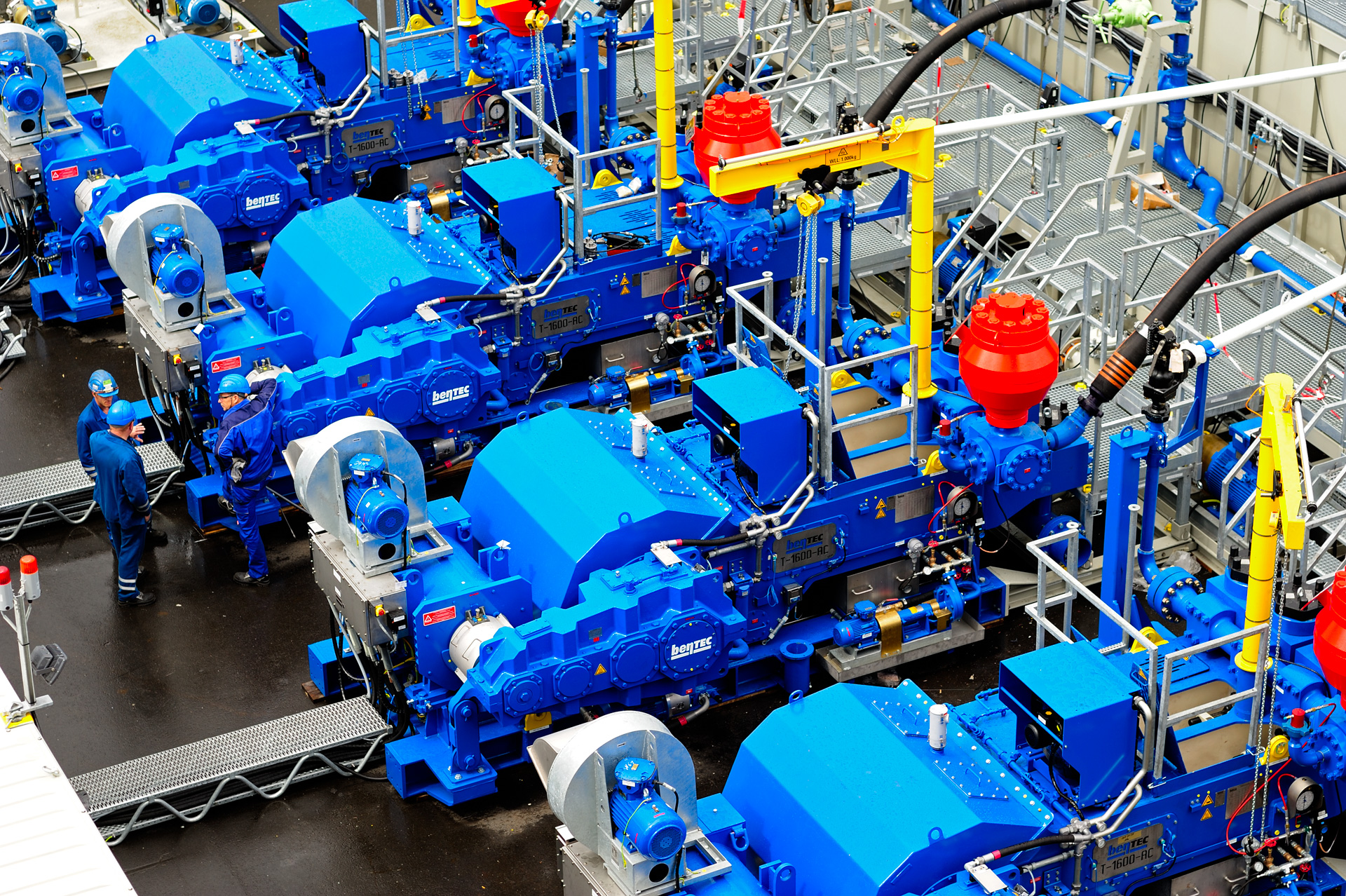

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

Mud Sucker Pro Series air driven diaphragm pumps use check ball technology in the suction and discharge valve chambers to pump slurries, abrasive fluids, solids and general wastewater. Access to both the suction and discharge areas is available within seconds.

The Mud Sucker 4B-EC includes a standard emergency pressure relief valve. Since a diaphragm pump is also a positive displacement pump, a pressure relief valve reduces the chances of damage in an over pressurization event.

The only diaphragm pump in the industry with an exclusive pump body designed to enhance the flow of slurries and debris laden liquids to prevent clogs.

Ships complete with safety guards. Pump operator does not come into contact with moving components when guards are in place (removed in illustration above for clarity).

The Electric Mud Pump Market 2022-2028’s key players National Oilwell Varco, Schlumberger, Gardner Denver, etc. are mostly focused on manufacturing innovation to boost efficiency and longevity. Electric Mud Pump Marketplace produces global business trends based on Electric Mud Pumps, with an emphasis on the most recent research, such as major drivers, obstacles, opportunities, market expansion, innovation, and business access strategy analysis.

Global Electric Mud Pump Market research report is the result of persistent work conducted by qualified forecasters, creative analysts, and brilliant researchers. With the specific and up-to-date information provided in this report, businesses can gain an understanding of the types of consumers, consumer demands and preferences, their perspectives on the product, their purchasing intentions, their response to a specific product that is already on the market, and their varying tastes about a specific product that is already on the market. As a result of the Ukraine-Russia War and COVID-19 epidemic, the Electric Mud Pump market is estimated to be worth USD million in 2022 and is forecast to be worth USD million by 2028, with a CAGR estimated to generate a lot of revenue till 2028. Electric Mud Pump Market report provides an absolute overview of the market by covering many elements of market analysis, product definition, market segmentation, significant developments, and the existing vendor landscape through 2028.

This Electric Mud Pump Market Report offers analysis and insights based on original consultations with important players such as CEOs, Managers, Department heads of suppliers, manufacturers, and distributors.

It is important to understand your competitor’s key business strategies, past performance, and portfolio of competitors’ products and services to develop better business strategies to gain a competitive advantage. This report provides an extensive analysis of the leading companies in the global Electric Mud Pump Market.

Here, Electric Mud Pump Market is segmented on the basis of type, end-use industry and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

We have been following both the direct and indirect effects of the Russia-Ukraine war and the COVID-19 epidemic on the Electric Mud Pump market. To Know How Covid-19 Pandemic and Russia-Ukraine will Impact this Electric Mud Pump Industry, this research provides an in-depth market evaluation by highlighting information on various aspects covering market dynamics like drivers, barriers, opportunities, threats, and industry news and trends. Furthermore, the report provides strategies for companies to overcome threats posed by COVID-19 period.

This research explored Electric Mud Pump volume and worth at the global, regional, and business levels. This analysis explores the complete Electric Mud Pump market size as represented by a broad perspective by isolating undeniable data from future prospects. The fragment’s perusers will see the value in how the Electric Mud Pump market scene changed across the world during the pandemic and post-pandemic. The business experts have furthermore highlighted the principal points of view that will assist players with encouraging conceivable outcomes and equilibrium out the entire region sooner rather than later. Electric Mud Pump Market investigated each region and decided the market size considering unquestionable data. This research gives arrangements and pay estimations by kind and application for the unquestionable and approaching time frames. This research integrates critical pieces of information into different districts as well as the principal associations working in each one. The perusers will procure a data on the critical players battling around here. This overview with tables and charts for analyzing trends in the global Electric Mud Pump market provides important statistics on the state of the industry and is a valuable guide for companies and individuals interested in the market.

With tables and figures to help analyze the global Electric Mud Pump market trends, this study provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Backed by our team of experts in this domain, we are instrumental in offering Mud Sewage Pumps. Our Submersible Pump is a single stage, the submersible and centrifugal pump of closed coupled construction. Our pump range is extensively used for handling of municipal and industrial waste water. We avail this pump to our client inread more...

Qualitative Mud Pumps can be obtained from us in standard designs as well as per the specifications of the customer. These pumps are extensively used in industries like construction, agriculture and waste water management, amongst many others. Mud pumps mainly function as reciprocating plunger devices. These are designed forread more... Brochure

Self Priming Non Clog Pump (Mech. Seal Fitted) manufactured using high quality raw material. The pumps are available in coupled or belt drive versions with bearings that have been greased for life, thereby, eliminating the need for external lubrication. These pumps are widely used for dewatering swamps, trenches &read more...

Owing to our in-depth knowledge and vast experience in this domain, we have been able to offer premium quality Self Priming Mud Pumps. These pumps are manufactured using excellent quality components and latest technology by our skilled professionals. In order to ensure quality, these pumps are stringently tested on various parameters by our experts. Moreover, optimum performance and functionality are some of the factors that increase the demand of our offered range in the market.

Reliable engineers are expertise in manufacturing of Mud Pumps, Design of pump is sturdy and parts are with long life, manufacturers & exporters Self Priming Mud Pumps.

Industry for clean dirty water, acid or alkali liquids containing sand, mud or solids in suspensions, clean or dirty low viscosity petroleum products, milk , lime caustic soda etc.

waste treatment - pumping polluted, hot or corrosive waste water containing sand, mud or solids in suspensions, dosing neutralizing liquids, pumping out settled sledge

The report covers comprehensive information about market trends, volume (Units) and value (US$ Mn) projections, competition and recent developments and market dynamics in the global mud pumps market for the study period of 2013 to 2026.

The global mud pumps market is expected to reach a little over US$ 1,085 Mn over the forecast period, registering a CAGR of 4.4%. Growth in drilling activities in the oil & gas Industry to increase hydrocarbon production and ease of the mud circulation operation in drilling holes are some of the factors expected to lay a robust foundation for the growth of the global mud pumps market.

Mud pumps can be classified on the basis of the number of pistons into duplex, triplex and quintuplex, which consist of two, three and five pistons respectively. The triplex segment is expected to dominate the mud pumps market in terms of value as well as volume during the entire forecast period.

Triplex mud pumps find extensive usage in circulating drilling fluid with high pressure for deep oil well drilling application. These usage characteristics make them preferable for use, primarily in onshore and offshore oil well drilling applications.

Mud pumps are widely utilized in the oil & gas industry. On the basis of the mode of operation, mud pumps can be classified as electric and fuel engine mud pumps.

Fuel engine mud pumps use petroleum oils as the key liquefying agent. These types of mud pumps release hazardous gases into the environment. In order to contain the hazardous impact of fuel engine mud pumps on the environment, regulatory authorities are compelling manufacturers and consumers to opt for electric mud pumps, which do not emit volatile organic compounds and operate with low noise and low vibration. Electric mud pumps offer smooth operations in drilling rigs and are environment-friendly, which is why they dominate the market for mud pumps.

The electric mud pumps segment is projected to grow with a 4.5% CAGR during the forecast period in view of the tightening emission control regulations and is expected to create an absolute $ opportunity worth US$ 134 Mn between 2018 and 2026.

Among all the applications analyzed in this global mud pumps market study, the onshore application of mud pumps is expected to register about 1.43X growth in terms of value between 2018 and 2026. The offshore application of mud pumps is projected to register moderate growth during the entire forecast period, led by land oil field discoveries.

In terms of incremental $ opportunity, onshore and offshore segments are expected to compete within large margins. The onshore application of mud pumps is expected to occupy over an 86% share in terms of value by the end of 2026.

Increasing oil-well exploration activities, stable economic conditions and consistent growth in oil well drilling rig sales in the region are expected to drive the demand for mud pumps in the region.

The comparatively well-established production sector in the region and increasing oil and gas industry and hydrocarbon consumption will create a healthy platform for the growth of the mud pumps market. Some regions including China and Europe are expected to gain traction in the latter half of the forecast period, owing to the anticipated growth of the oil & gas industry in these regions. North America is expected to register above-average 1.1X growth in the market. All the other regions are anticipated to exhibit moderate growth during the same period.

The global mud pumps market is consolidated with limited market players holding considerable double-digit market shares as of 2017. Globally, the top 12 players in the mud pumps market collectively hold between 53% and 58% of the market share.

Over the past few years, the mud pumps market has witnessed significant technological advancement from the competition perspective. Acquisitions, collaborations and new product launches are some of the key strategies adopted by prominent players to expand and sustain in the global mud pumps market.

In 2015, Flowserve opened a new pump manufacturing plant in Coimbatore, India. Through this new facility, the company aims to provide pump products for the oil and gas industry in Asia Pacific

Some of the key players involved in this market study on the global mud pumps market include National Oil Varco Inc., Schlumberger Limited, Gardner Denver Inc., Weatherford International Plc., China National Petroleum Corporation, Trevi-Finanziaria Industriale S.p.A., MhWirth, BenTech GmbH Drilling Oilfield systems, American Block Inc., Honghua Group Limited, White Star Pump Company LLC, Flowserve corporation, Ohara Corporation, Mud King Products, Inc. and Herrenknecht Vertical GmbH.

CharacteristicThe deplex piston pump is design for deliverying slurry with the pressure, normally, before come out of factory, the pump pressure is often set to be 1.5map.

The piston slurry mud pump is formed by two cylinders with porcelain piston, by suction and delivery valves, by an air tank and by a manometer which is installed on the air tank to check the mud pressure.

How Ceramic Plunger Pump Work:The electric motor drive the oil gear pump, which is inside the oil tank of duplex piston pump, to develop an oil delivery which feeds the upper and lower oil cylinder, by means of the distributor with mechanical pilots, to let the pistons work in turns, the porcelain piston, in turn, which is connected to the hydraulic piston , is alternately driven. And thanks of the suction and delivery valves, begins the fluid pumping.

Mud pumps are the pumps deployed in the oil and gas industry, mainly to circulate drilling fluids and other kinds of fluids in and out of the drilled wells for exploration. The mud pumps transfer the fluids at a very high pressure inside the well using the piston arrangement. The number of pistons decides the displacement and efficiency of working of the mud pumps, originally only dual piston pumps and three-piston pumps were used, but the technological advancements have seen pumps with five and six pistons to come up. Currently the triplex pumps which have three pistons are used, but the duplex pumps having two pumps are still deployed in the developing countries.

Based on its types, global mud pump market can be segmented into duplex, triplex, and others. The triplex mud pumps will dominate the mud pump marking in the given forecast period owing to its advantages and ongoing replacement of duplex pumps with triplex pumps. Based on operation, the global mud pumps market can be segmented into electric and fuel engine.

The electric mud pumps will dominate the market during the given forecast period due to the advantage of eliminating the harmful carbon emission which is done in the case of fuel engine pumps. Based on its application, the global mud pumps market can be segmented into oil & gas, mining, construction, and others.

The major market driver for the global mud pumps market is the increasing exploration activities taking place in various regions of the world to satisfy the increased energy demand. The number of drilled wells has increased in recent years, which has certainly impacted the growth of the mud pumps market in both oil & gas and mining sectors.

Key market restraint for the global mud pumps market is the drift towards the cleaner sources of energy to reduce the carbon emissions, which will certainly decrease the demand for oil & gas and therefore will have a negative impact on the growth of the global mud pumps market.

Some of the notable companies in the global mud pump market are Mud King Products, Inc. Gardner Denver Pumps, Weatherford, Schlumberger, National Oilwell Varco, China National Petroleum Corporation, Flowserve Corporation, MHWirth, American Block, Herrenknecht Vertical Gmbh, Bentec GmbH Drilling & Oilfield Systems, Drillmec Inc, Sun Machinery Company, Shale Pumps, and Dhiraj Rigs.

The global mud pump market has been segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Owing to the well-established production sector and stable exploration industry North America holds the largest market for the mud pumps. The onshore exploration activities of oil & gas have increased at a good rate in the North America region, which has certainly boosted the growth of the mud pumps market in the region.

The demand from Europe and Asia Pacific has also increased due to exploration activities in both the regions owing to the increased energy demand. The energy demand specifically in the Asia Pacific has increased due to the increased population and urbanization. The Middle East and Africa also hold significant opportunities for the mud pumps market with increased exploration activities in the given forecast period.

In August 2018, Henderson which is a leading company in sales and service of drilling rigs, and capital drilling equipment in Texas signed a contract with Energy Drilling Company for the purchase and upgrade of oil field equipment’s which included three 1600hp × 7500psi mud pumps. This will be the first refurbishment completed at Henderson’s new service center and rig yard.

In January 2018, Koltek Energy Services launched the 99-acre facility for the testing of the oil field equipment in Oklahoma. This will allow the oil field equipment manufacturers to test their equipment at any given time. The company has deployed the MZ-9 pump which has a power rating of 1000Hp.

8613371530291

8613371530291