forum mud pump parts in stock

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

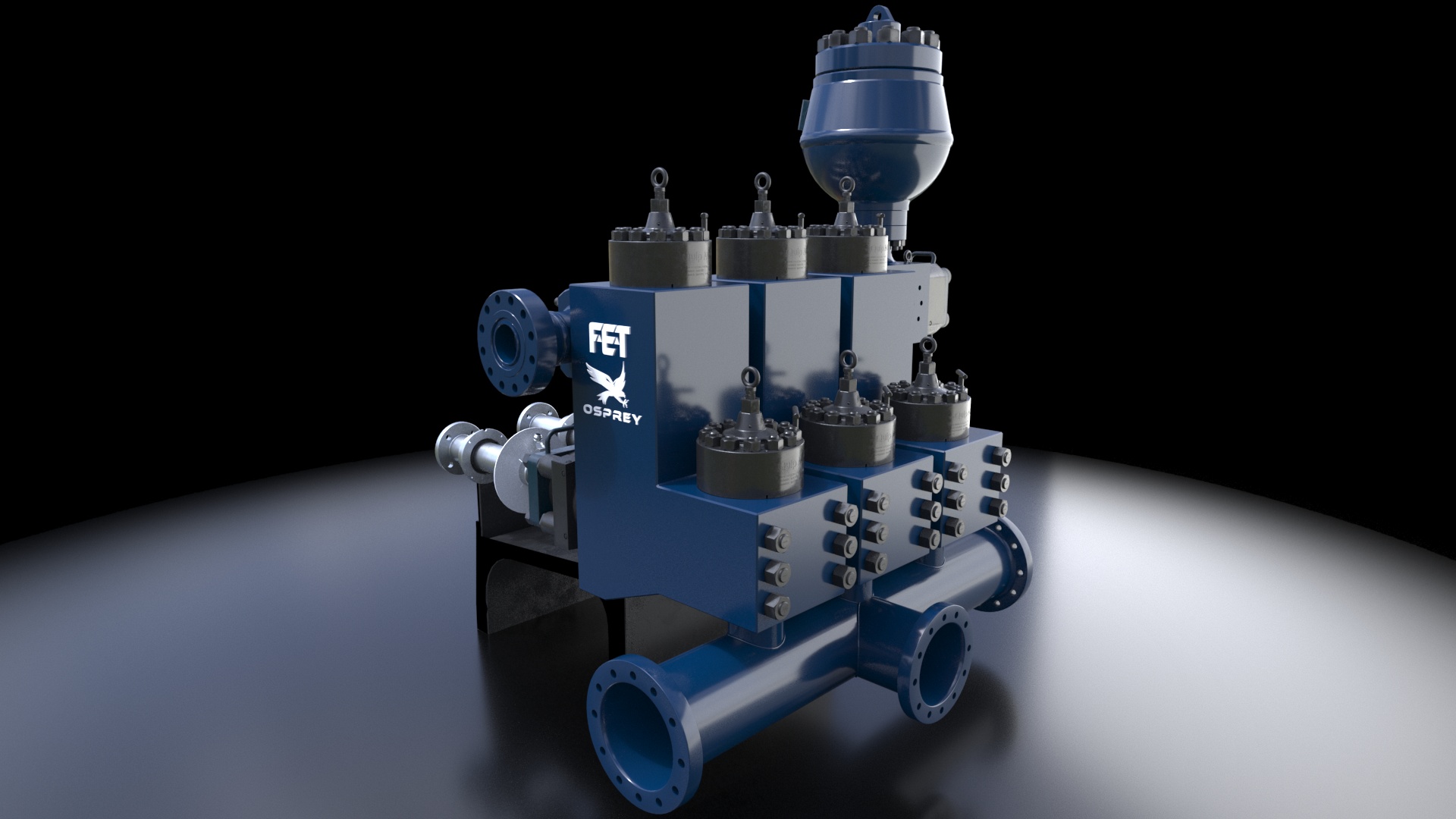

Mud systems are essential to every oil and gas rig. To successfully transfer fluid throughout your circulating system at pressures up to 7,500 pounds per square inch you need proven and reliable products. FET’s products have 30 years of innovation and field experience in providing industry-leading technology for your mud system operations.

Our industry-recognized centrifugal pumps, gate valves, drill pipe float valves, and wash pipes provide you with robust systems that meet the high-pressure demands of today’s drilling landscape.

JL Offshore AS keep inventory and provide a full range of Fluid End Expendable Pump Parts for every drilling condition and different Mud Pumps from well known manufacturers.

Smart solutions. Powerful products. All Forum Energy Technologies products are reliable and easy to use; every piece designed with you in mind ─ ensuring that servicing your products is quick and stress-free.

Forum has a comprehensive offering in addition to their own high-quality product lines, by bringing together some of the most trusted brands in the industry. Their legacy includes recognizable brands like Baker SPD, Blohm + Voss, CraneSafe, Merrimac, OBI, P-quip and Pipe Wranglers.

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

If you spot a washout on any of the fluid end parts, you need to replace the part immediately. A washout can get much worse very quickly, leading to costly repairs.

Forum Energy Technologies Inc is a global products company, serving the drilling, downhole, subsea, completions, and production sectors of the energy industry. The company designs, manufactures, and distributes products and engages in aftermarket parts supply and services that complement its product offering. Its products include highly engineered capital equipment, as well as products that are consumed in the drilling, well construction, production, and transportation of oil and natural gas. It operates in three reporting segments, namely drilling and downhole, completions, and production. Revenue largely comes from consumable products and activity-based equipment. Consumable products include valves, centrifugal pumps, mud pump fluid end components, rig sensors, inserts, and dies.

8613371530291

8613371530291